Method for manufacturing high-performance medical metal by mixing selective laser melting and laser surface texture

A technology of laser selective melting and surface texture, which is applied in the direction of additive manufacturing, energy efficiency improvement, process efficiency improvement, etc., to achieve excellent antibacterial performance, corrosion performance, and excellent osseointegration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

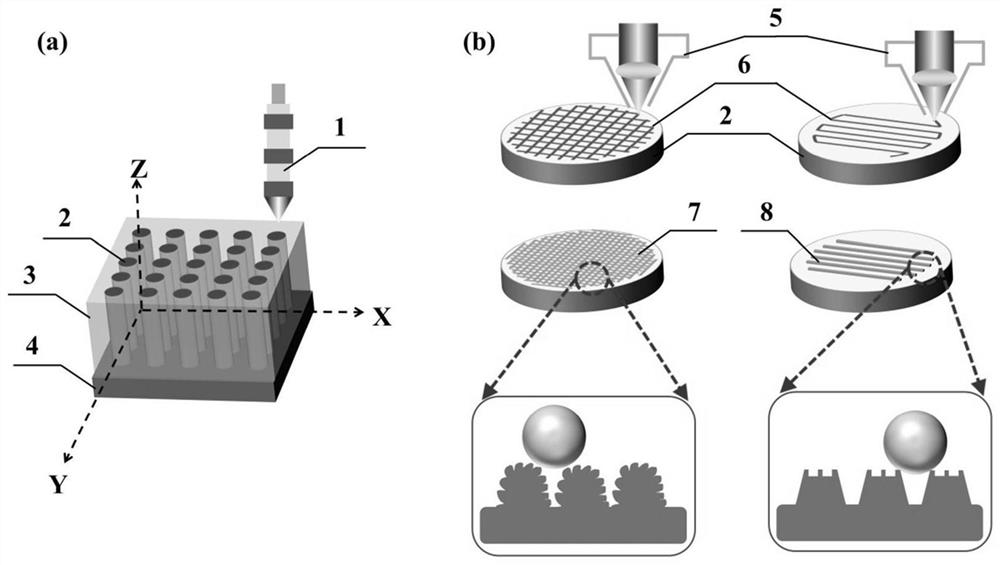

Method used

Image

Examples

Embodiment 1

[0039] The rust-removed and sand-blasted stainless steel is used as the base material, and the copper-containing antibacterial stainless steel is prepared by laser selective melting forming combined with laser surface texture. The microstructural characteristics of the obtained copper-containing antibacterial stainless steel are: And cylindrical face-centered cubic austenite grain size is between 500 and 800nm, and the edge of the molten pool is composed of well-oriented and interconnected cellular and columnar subgrains; The nanometer ε-Cu particles with cubic structure are uniformly distributed in γ-Fe; after femtosecond laser treatment, the surface wettability behavior of copper-containing antibacterial stainless steel is hydrophilic, and the contact angle increases to 90-100°, which is beneficial to Bacterial cells dissociate and desorb on the surface of copper-containing antibacterial stainless steel; when tested in human serum bioelectrolyte, the charge transfer resistanc...

Embodiment 2

[0048] The rust-removed and sand-blasted stainless steel is used as the base material, and the copper-containing antibacterial stainless steel is prepared by laser selective melting forming combined with femtosecond laser treatment. The microstructural characteristics of the obtained copper-containing antibacterial stainless steel are: And cylindrical face-centered cubic austenite grain size is between 500 and 800nm, and the edge of the molten pool is composed of well-oriented and interconnected cellular and columnar subgrains; The nanometer ε-Cu particles with cubic structure are evenly distributed inside the γ-Fe lattice; after femtosecond laser treatment, the surface wettability behavior of copper-containing antibacterial stainless steel is hydrophilic, and the contact angle increases to 90-100°, It is conducive to the dissociation and desorption of bacterial cells on the surface of copper-containing antibacterial stainless steel; when tested in the biological electrolyte of...

Embodiment 3

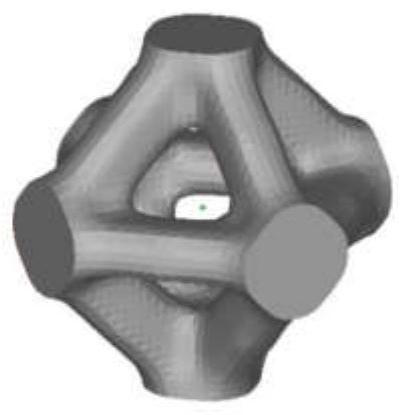

[0057] The titanium alloy that has been derusted and sandblasted is used as the substrate, and the copper-containing antibacterial titanium alloy is prepared by laser selective melting forming combined with femtosecond laser treatment. The microstructural characteristics of the obtained copper-containing antibacterial titanium alloy are as follows: as a matrix, small The grain size of acicular martensite can reach hundreds of nanometers to several micrometers in width and tens of micrometers in length, and the edge of the molten pool is composed of well-oriented and interconnected subgrain structures; it is formed by self-assembly due to liquid phase separation Nano-sized ε-Cu particles with a face-centered cubic structure are uniformly distributed inside the martensitic lattice; after femtosecond laser treatment, the surface wettability behavior of the copper-containing antibacterial titanium alloy is hydrophilic, and the contact angle increases to 90 ~100°, which is conducive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com