Method for improving photoelectric properties of aluminum-doped zinc oxide film through femtosecond lasers

An aluminum-doped zinc oxide, femtosecond laser technology, applied in photovoltaic power generation, laser welding equipment, circuits, etc., can solve problems such as large surface reflection of aluminum-doped zinc oxide sheet resistance, improve photoelectric conversion efficiency, increase optical path difference , enhance the effect of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

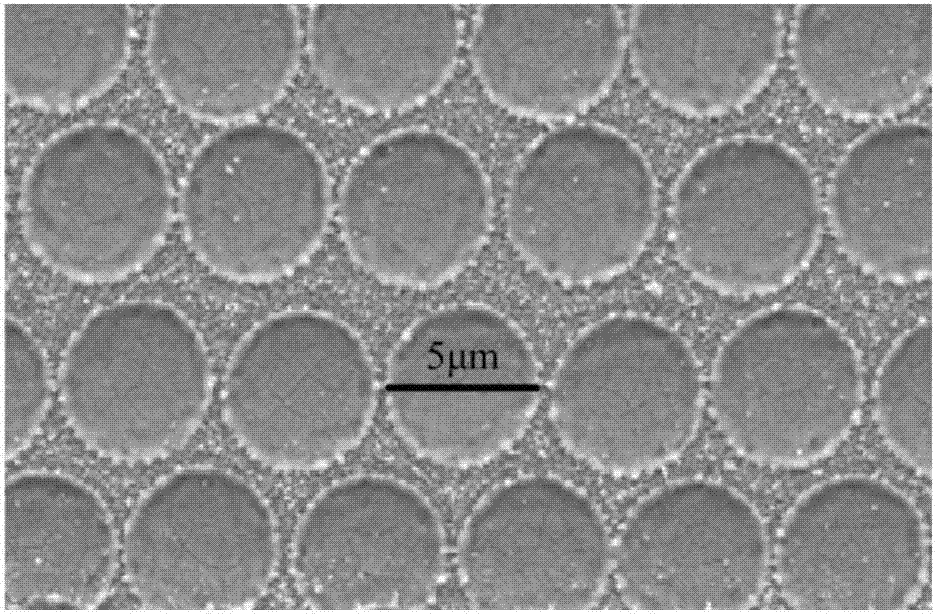

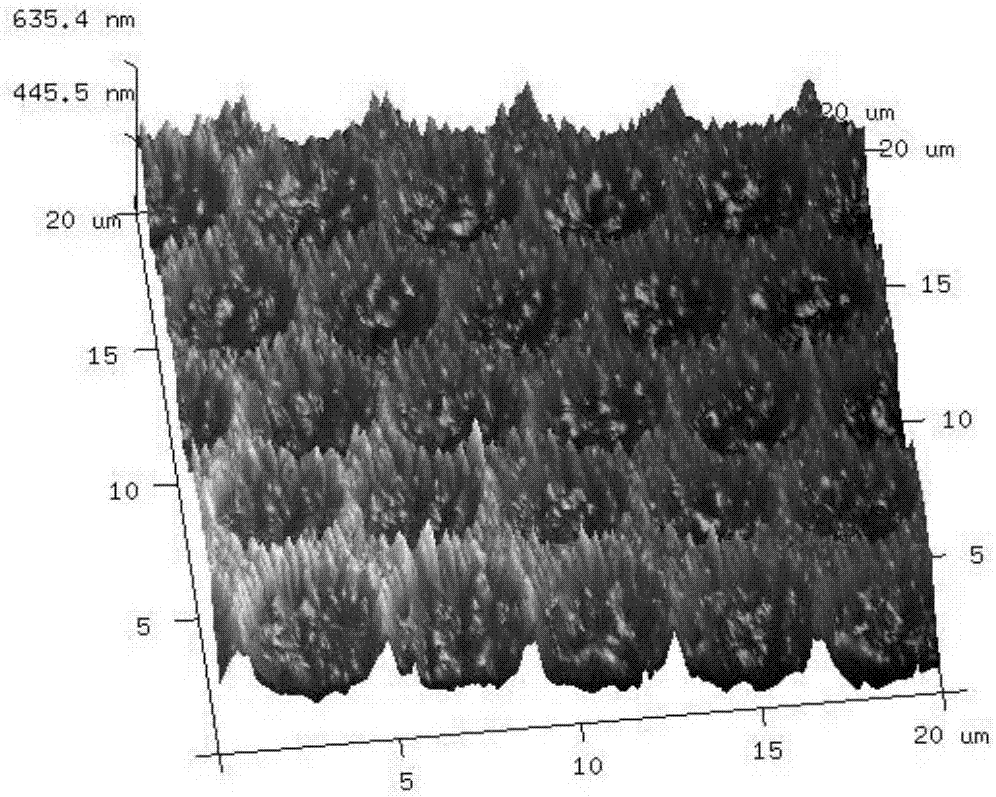

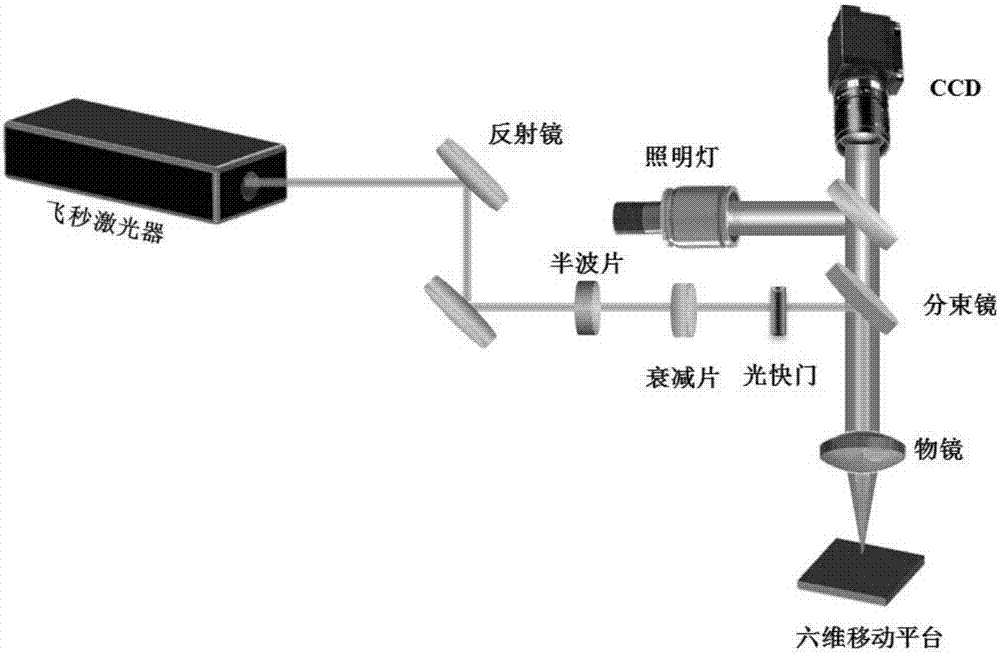

[0025] Embodiment: Utilize femtosecond laser to improve the method for the optoelectronic performance of aluminum-doped zinc oxide film on the glass that is coated with 600nm thick Al-doped zinc oxide film, based on such as image 3 The femtosecond laser processing system shown includes a femtosecond laser, a mirror, a half-wave plate, an attenuation plate, an optical shutter, an objective lens, a six-dimensional moving platform, a beam splitter, an imaging device, and an illumination lamp. The processing optical path: The laser light emitted by the second laser is reflected by two mirrors, then passes through the half-wave plate, attenuation plate, optical shutter, and then is reflected by the beam splitter and then focused to the surface of the material through the objective lens. The illumination light from the illuminating lamp passes through the beam splitter and the objective lens It irradiates the surface of the material, and after being reflected by the surface of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com