Process for preparing zinc oxide nanometer wire array by femtosecond laser and device thereof

A technology for zinc oxide nanowires and nanowire arrays, which is applied in the field of femtosecond laser preparation of zinc oxide nanowire arrays, can solve the problems of complex process, low output and high cost, and achieves simple preparation process, high preparation efficiency, raw material consumption and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

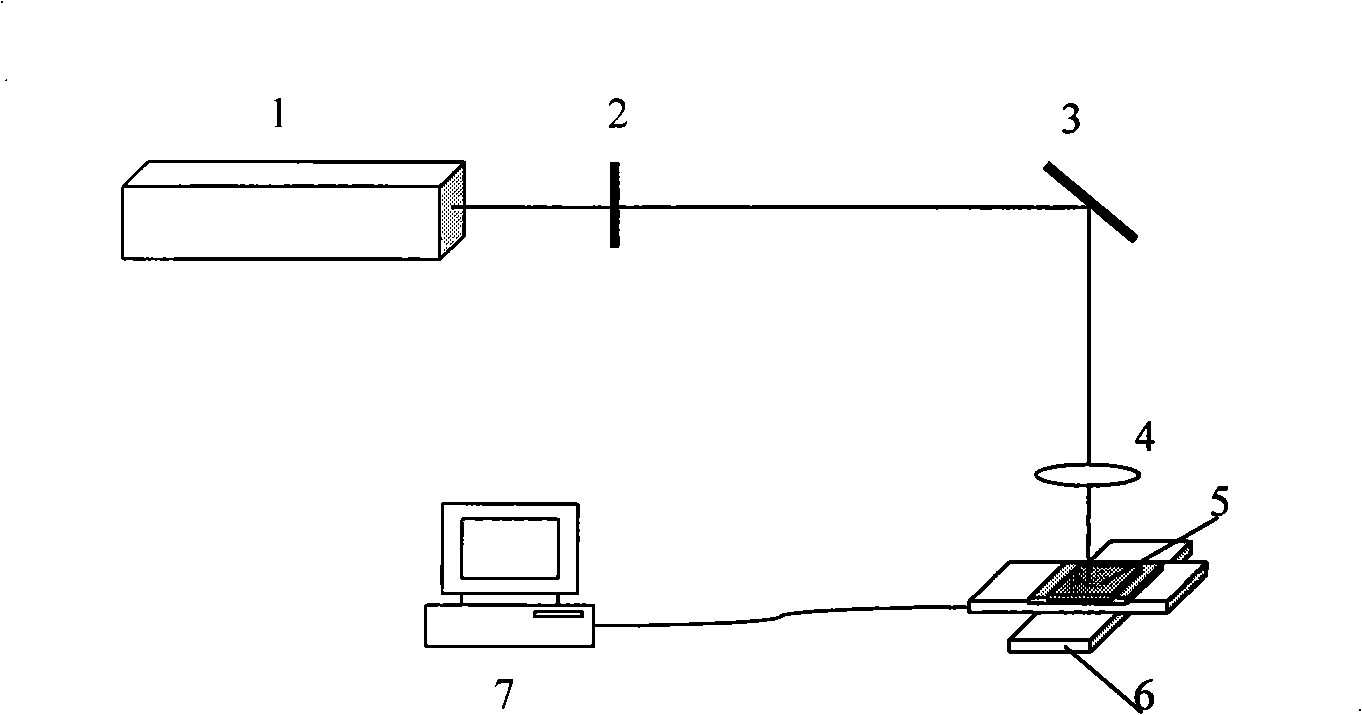

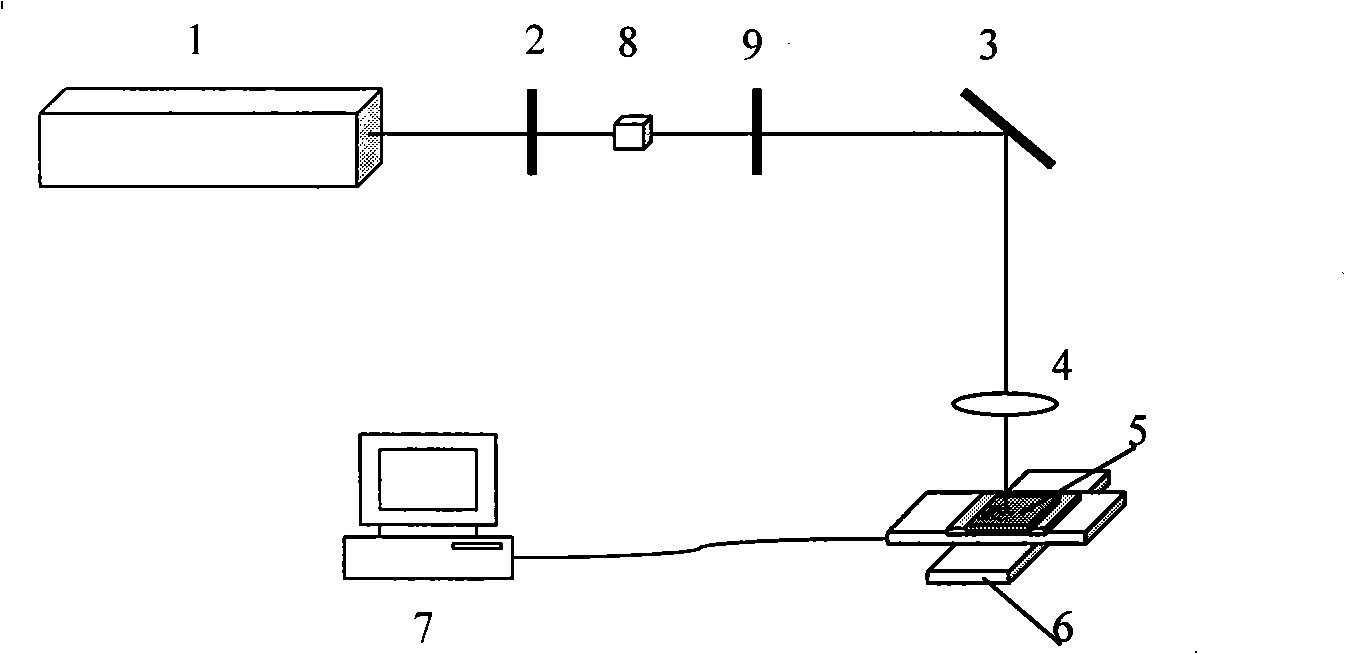

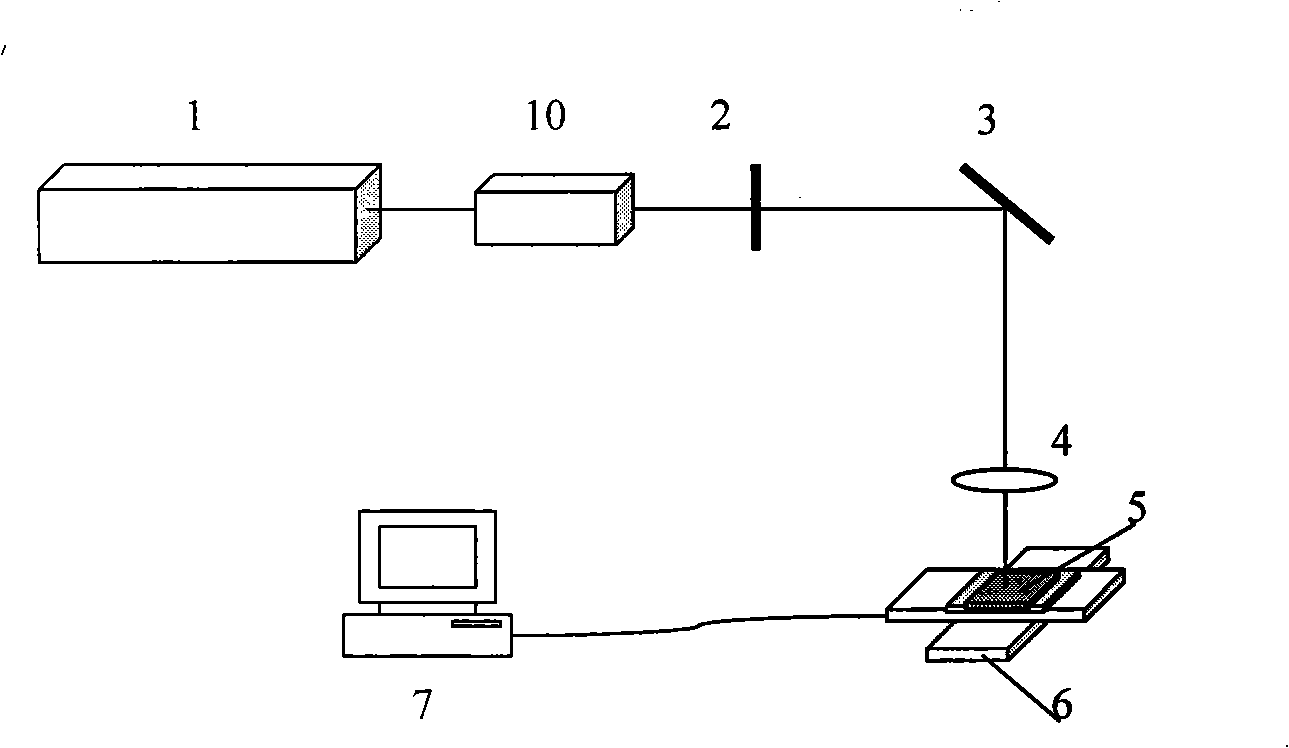

Method used

Image

Examples

Embodiment 1

[0030] The femtosecond laser emitted by the Ti:Sapphire femtosecond laser has a pulse width of 30fs, a wavelength of 800nm, a pulse frequency of 1kHz, and a laser beam of pulse energy of 1mJ. The beam is focused on a quartz glass substrate through a focusing lens with a focal length of 100mm. On the zinc oxide target, the sample is controlled by a computer-operated two-dimensional mobile platform, and the diameter of the focused spot is about 100um. In this way, periodic nanostructures are gradually formed in the laser irradiation area. Using a scanning electron microscope (5000x / 20kV) to focus on the laser-induced region in the glass sample, ZnO nanowires were observed such as image 3 As shown, a zinc oxide nanowire array with a diameter of 150nm and a length of 2um. The substrate is zinc oxide target made of quartz glass, ordinary glass or silicon material.

Embodiment 2

[0032] Choose a laser with a pulse width of 50fs, a wavelength of 400nm, a pulse frequency of 1kHz, and an energy of 200uJ. The beam is focused on a zinc oxide target made of ordinary glass through a focusing lens with a focal length of 100mm. The sample is moved two-dimensionally by a computer. Platform control, focusing spot diameter is about 100um. In this way, periodic nanostructures are formed in the laser-induced region.

Embodiment 3

[0034] A laser with a pulse width of 40fs, a wavelength of 325nm, a pulse frequency of 1kHz, and an energy of 100uJ is selected. The beam is focused on a zinc oxide target made of silicon through a focusing lens with a focal length of 100mm. The sample is moved two-dimensionally by a computer. Platform control, focusing spot diameter is about 100um. In this way, periodic nanostructures are formed in the laser-induced region.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com