Preparation method of large-scale array graphene nanoelectronic resonator based on femtosecond laser

A femtosecond laser and nano-electromechanical technology, applied in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc., can solve the secondary pollution of graphene, reduce the resonance frequency and quality factor of nano-electromechanical resonators and other issues, to achieve the effect of improving resonance frequency and quality factor, reducing secondary pollution, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

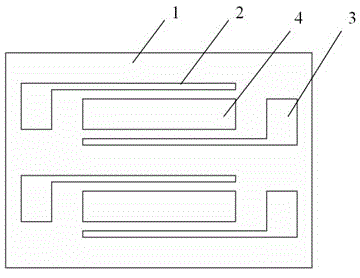

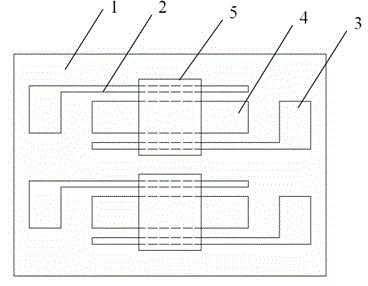

[0017] see figure 1 and figure 2 , the present invention first SiO 2 The surface of / Si substrate 1 is patterned by conventional reactive ion etching (RIE) to form a patterned substrate, and then large-area graphene 5 is transferred to the surface of the patterned substrate, and finally processed by femtosecond laser micromachining technology Etching large-scale arrays of graphene nanoelectromechanical resonators. The specific implementation steps are as follows:

[0018] 1. Thermally grow 300 nm thick SiO on the surface of n-type Si substrate 2 insulating layer, forming SiO 2 / Si substrate 1 . Wherein, the resistivity of the n-type Si substrate is 1~10 Ωcm.

[0019] 2. In SiO 2 The surface of Si substrate 1 is sputtered with 5 nm thick TiW alloy and 100 nm thick Au; photolithography is carried out with No. 1 mask plate, after development, TiW / Au is etched in a metal corrosion solution to form an array of TiW / Au The wiring 2 and the Au electrode sheet 3 of the array. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com