Method for acquiring refractive index variation of transparent film in femtosecond laser micromachining

A technology of femtosecond laser processing and transparent thin film, which is applied in the direction of phase influence characteristic measurement, etc., can solve the problems of difficult precise positioning, large measurement area, and difficult precise positioning of the measured area, and achieve an easy-to-achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

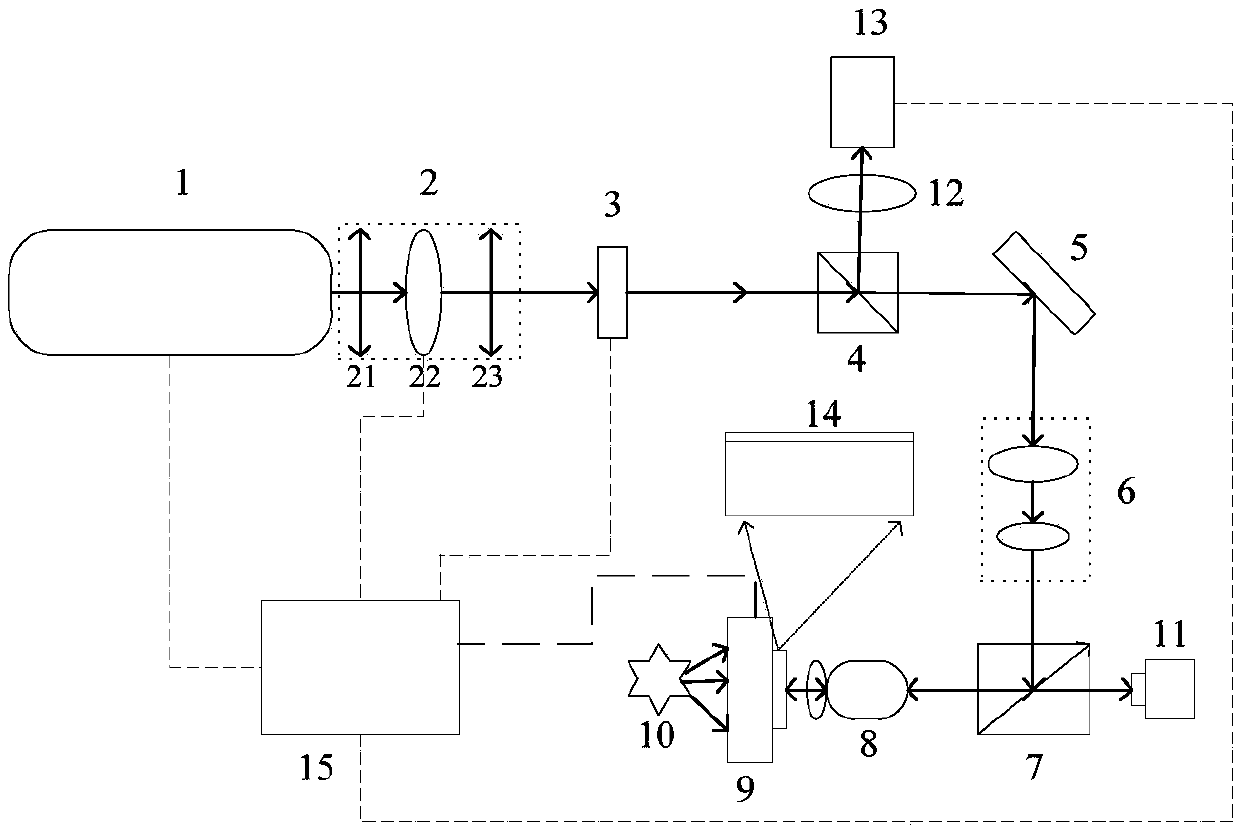

[0014] Embodiment one: if figure 1 As shown, the femtosecond laser processing equipment includes a laser 1 for emitting a processing beam, a laser power tuning mechanism 2, a shutter 3, a first polarization beam splitter prism 4, a total reflection mirror 5, and a laser beam diameter adjustment system arranged in sequence along the main optical path 6. The second polarizing beamsplitter prism 7, objective lens 8, and a three-dimensional mobile platform 9 for placing samples, and the laser power tuning mechanism 2 are composed of a first polarizer 21, a wave plate 22 and a second polarizer 23, and the power tuning accuracy is 1μW, the laser beam diameter adjustment system 6 is composed of a group of lenses, the diameter of the laser beam emitted from the laser beam diameter adjustment system 6 is 5 mm, the numerical aperture of the objective lens 8 is 1.4, and the back of the three-dimensional mobile platform 9 is placed for background illumination of the sample An LED light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com