Anti-reflective film and preparation method thereof

An anti-reflection film and light reflection technology, applied in the field of plasma, can solve the problems of affecting the photoelectric conversion efficiency of solar cells, large differences in chemical composition and optical properties, uneven changes in refractive index, etc. Optical characteristics, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

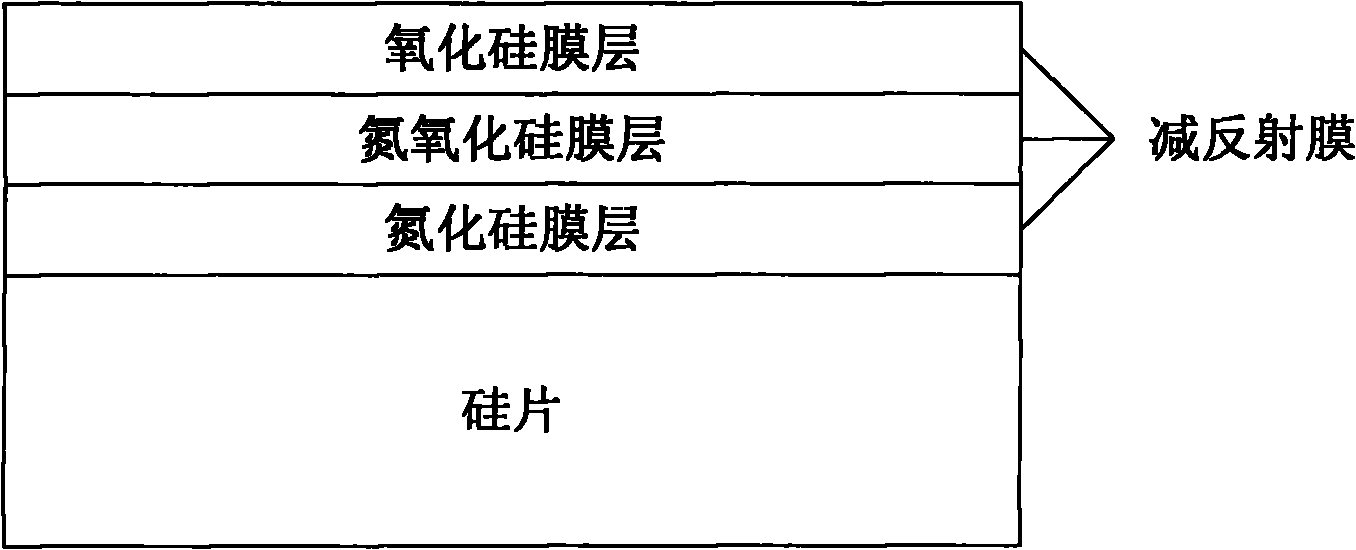

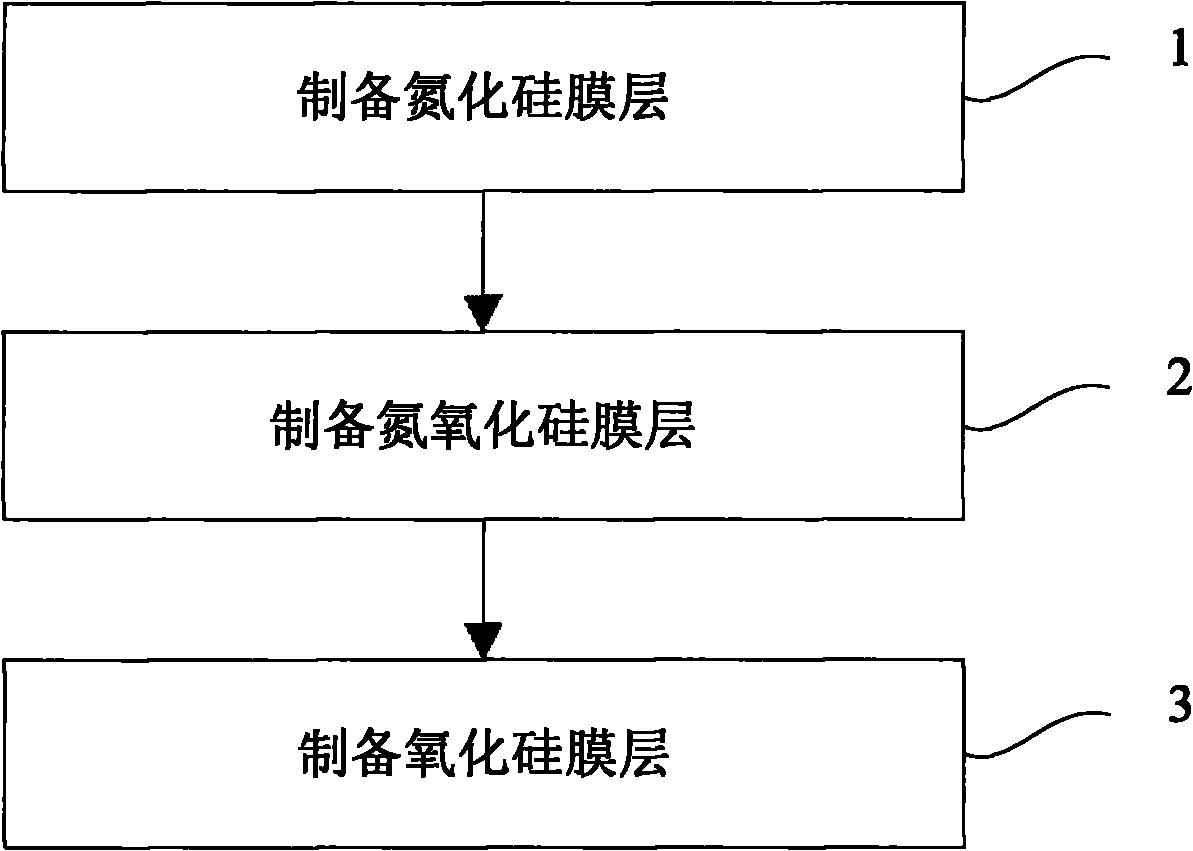

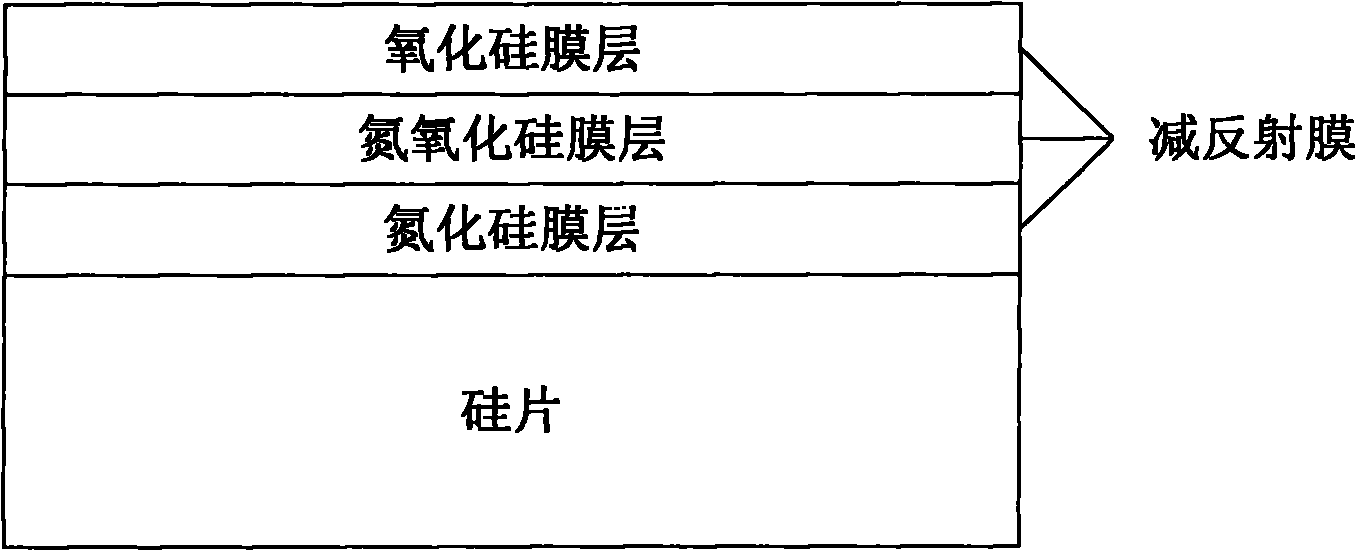

[0026] see figure 1 The first embodiment of the anti-reflection film provided by the present invention includes a silicon nitride film layer, a silicon oxynitride film layer and a silicon oxide film layer sequentially deposited on the surface of a silicon wafer. Wherein, the refractive index of each film layer gradually decreases from inside to outside, and here, from inside to outside refers to the direction from the silicon nitride film layer to the silicon oxide film layer.

[0027] Specifically, the thickness of the silicon nitride film layer is about 9-12 nm, and the refractive index is about 2.1-2.4. For example, the thickness of the film layer can be approximately 10 nm, and of course the thickness can be appropriately increased or decreased as required, as long as it can satisfy the passivation effect on the silicon wafer without causing light absorption loss.

[0028] On the silicon nitride film layer are silicon nitride oxide film layer and silicon oxide film layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com