M-Z type hydrogen sensing head based on femto-second laser micro-machined hollow PBGF with written-in LPGs

A femtosecond laser and micromachining technology, which is applied in the direction of phase influence characteristic measurement, etc., can solve the problems of hydrogen-sensitive film preparation, process sensor structure, optimal life and detection accuracy, and achieve high sensitivity, simple structure, and high precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

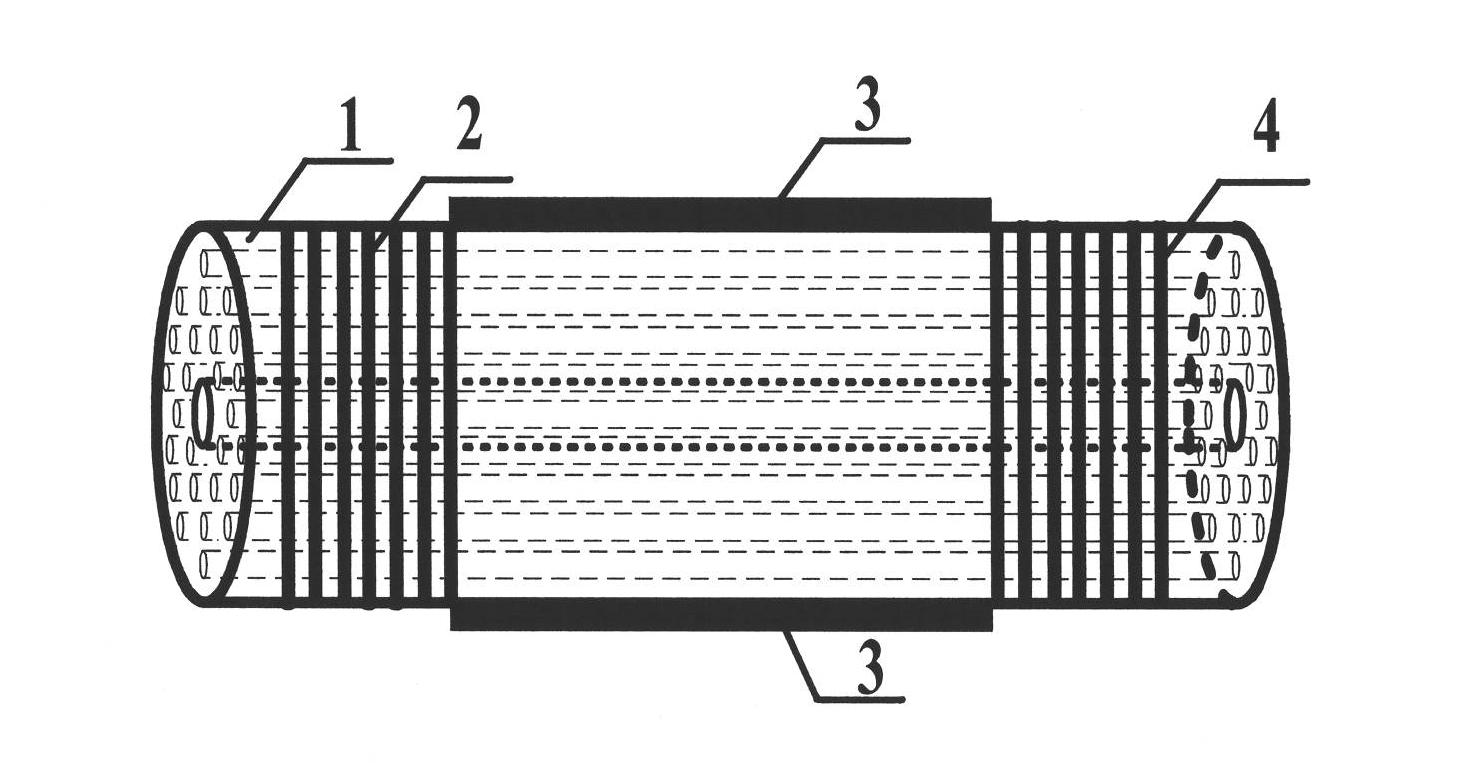

[0025] Implementation example 1: such as figure 1 As shown, the MZ type hydrogen sensor head based on femtosecond laser micromachining of hollow core PBGF to write LPG is characterized in that it is composed of hollow core PBGF (1) and a second LPG (4); in a section of hollow core PBGF The first LPG (2) and the second LPG (4) are respectively engraved with a femtosecond laser at both ends, and the surface of the hollow PBGF (1) between the first LPG (2) and the second LPG (4) is spin-plated with palladium alloy Membrane (3).

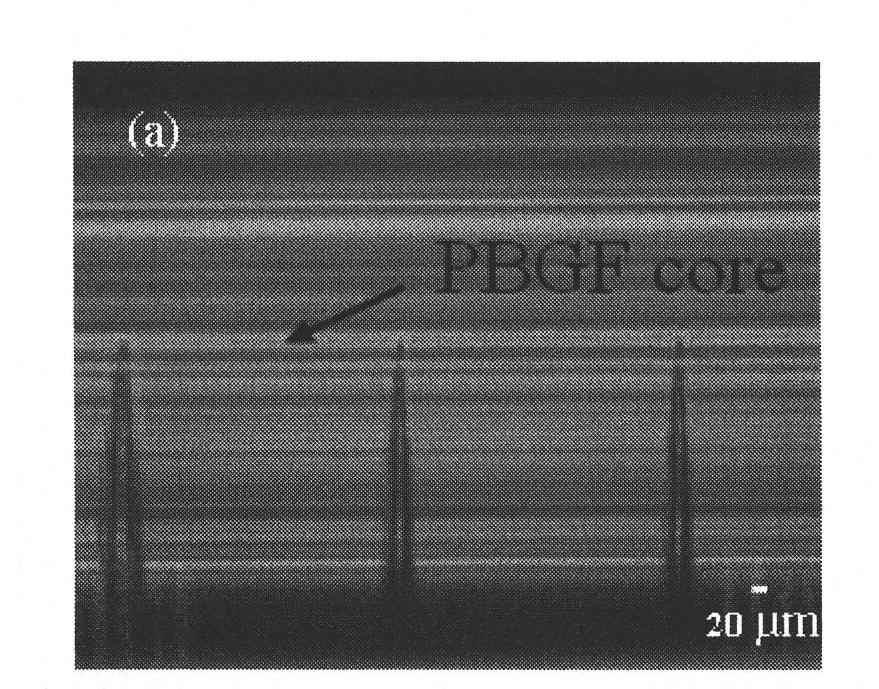

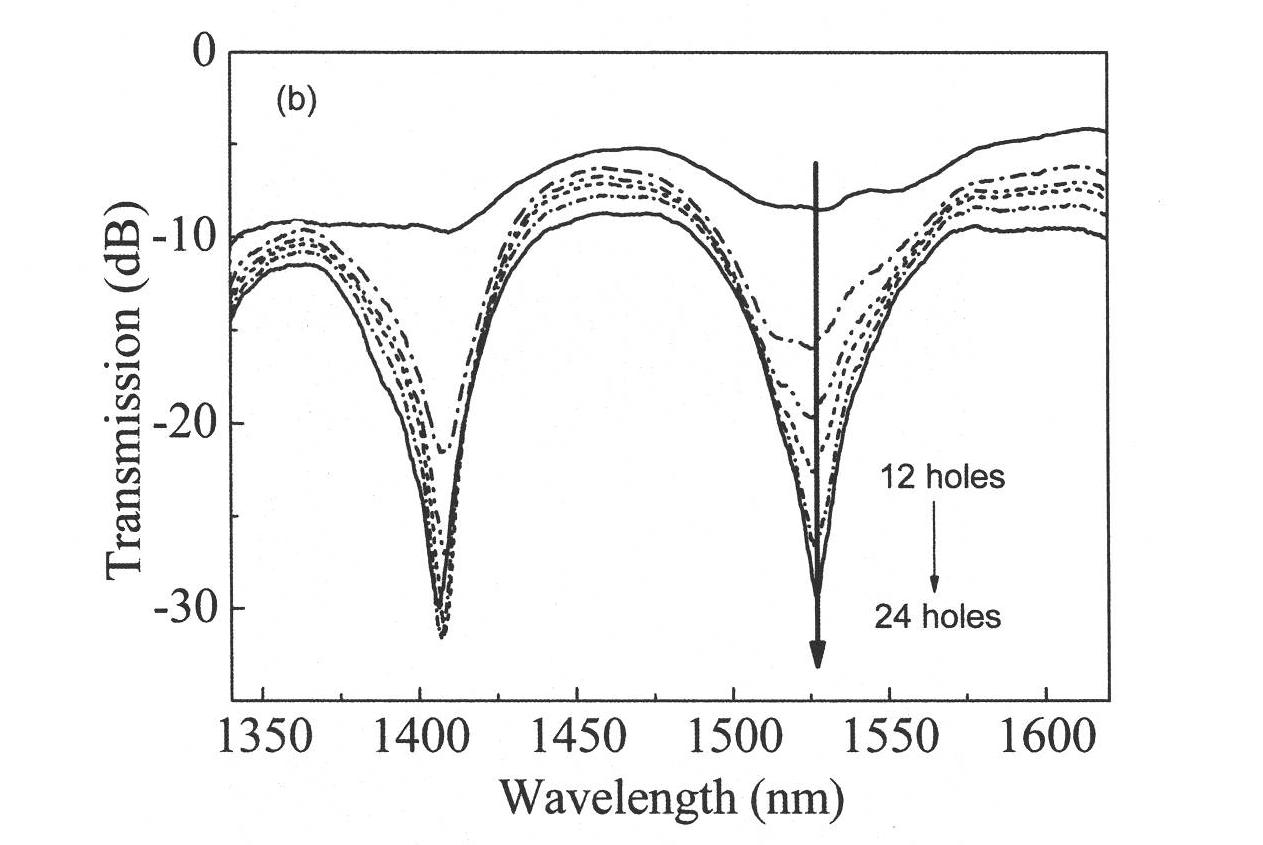

[0026] The hollow core PBGF is written by a femtosecond laser, and the writing method is directly opposite to the core. The writing depth is 1 / 2 of the diameter of the hollow core PBGF, such as figure 2 Shown. The period of the first LPG (2) and the second LPG (4) is 400 microns, and the length of the hollow core PBGF between the first LPG (2) and the second LPG (4) is 3 cm. The length of the film coated on the hollow core PBGF between the first LPG (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com