Method for integrating three-dimensional conductive metal micro-nano structure inside transparent material

A transparent material and micro-nano structure technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of limited precision, inflexible geometric configuration of metal structure space, etc., and achieve high device stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

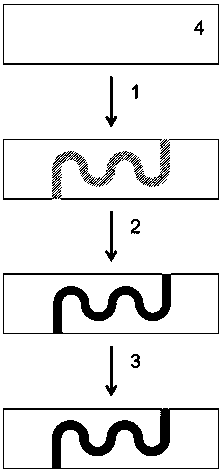

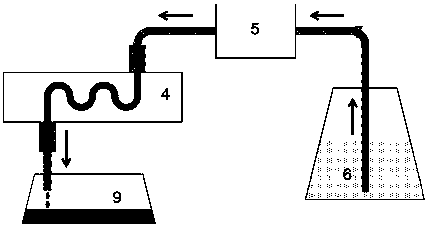

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby. figure 1 It is a schematic flow chart of integrating a three-dimensional metal micro-nano structure inside a transparent material in the present invention. Now take quartz glass as an example to illustrate the present invention. It can be seen from the figure that the present invention uses a femtosecond laser to integrate a three-dimensional conductive metal micro-nano structure in glass. The method includes the following steps:

[0026] (1) Femtosecond laser irradiation: take a clean quartz glass sample 4 with a size of 10 mm×10 mm×2 mm and polish the upper and lower surfaces, and fix it on a three-dimensional translation stage; the femtosecond laser directly writes microchannels inside the quartz glass sample When patterning, the central wavelength is 515 nm, the repetitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com