CVD diamond film continuous preparation system

A preparation system and diamond film technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of large filament loss, long auxiliary time, high preparation cost, etc., to achieve industrialized production and reduce manufacturing costs. The effect of small cost and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

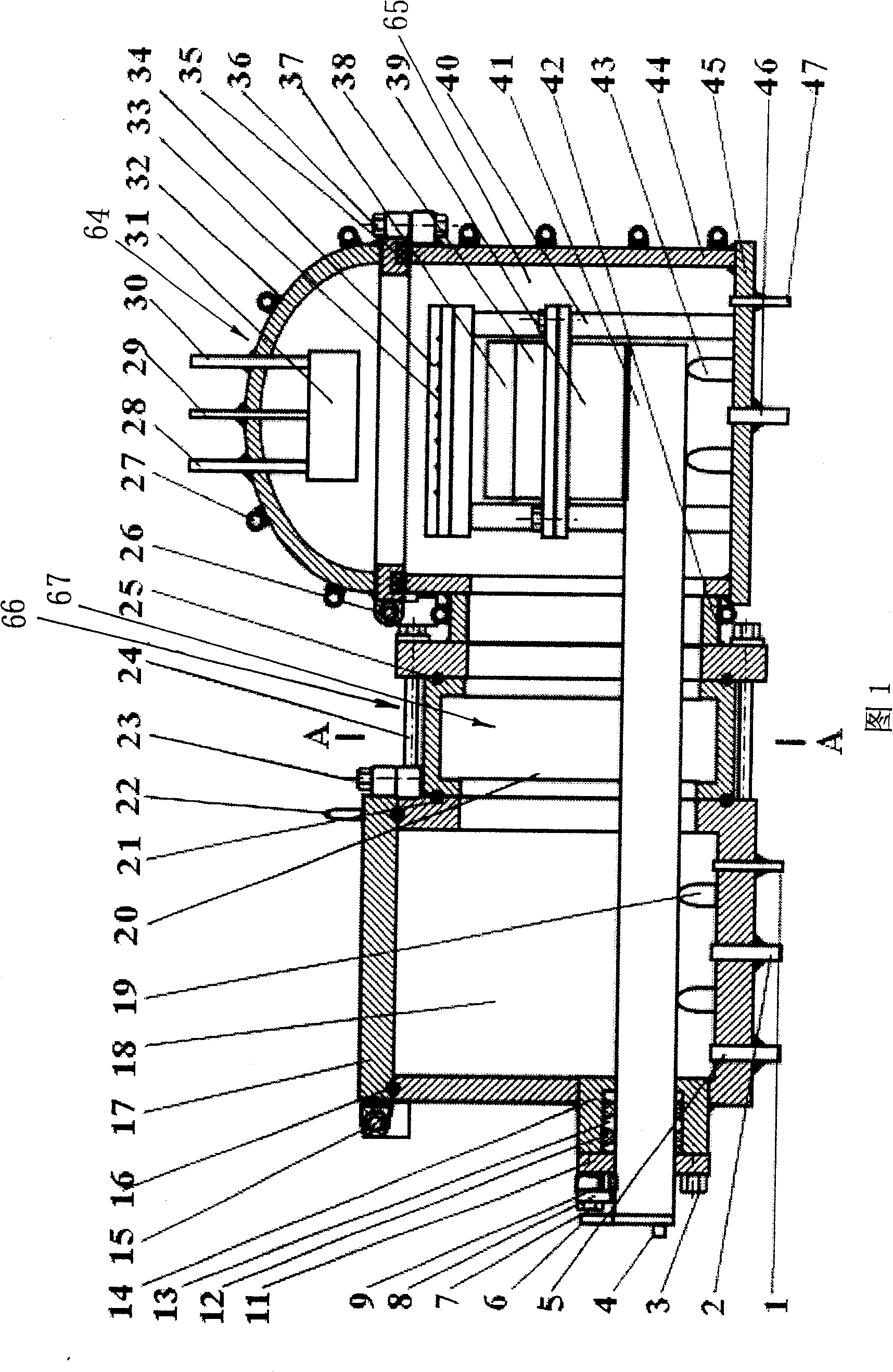

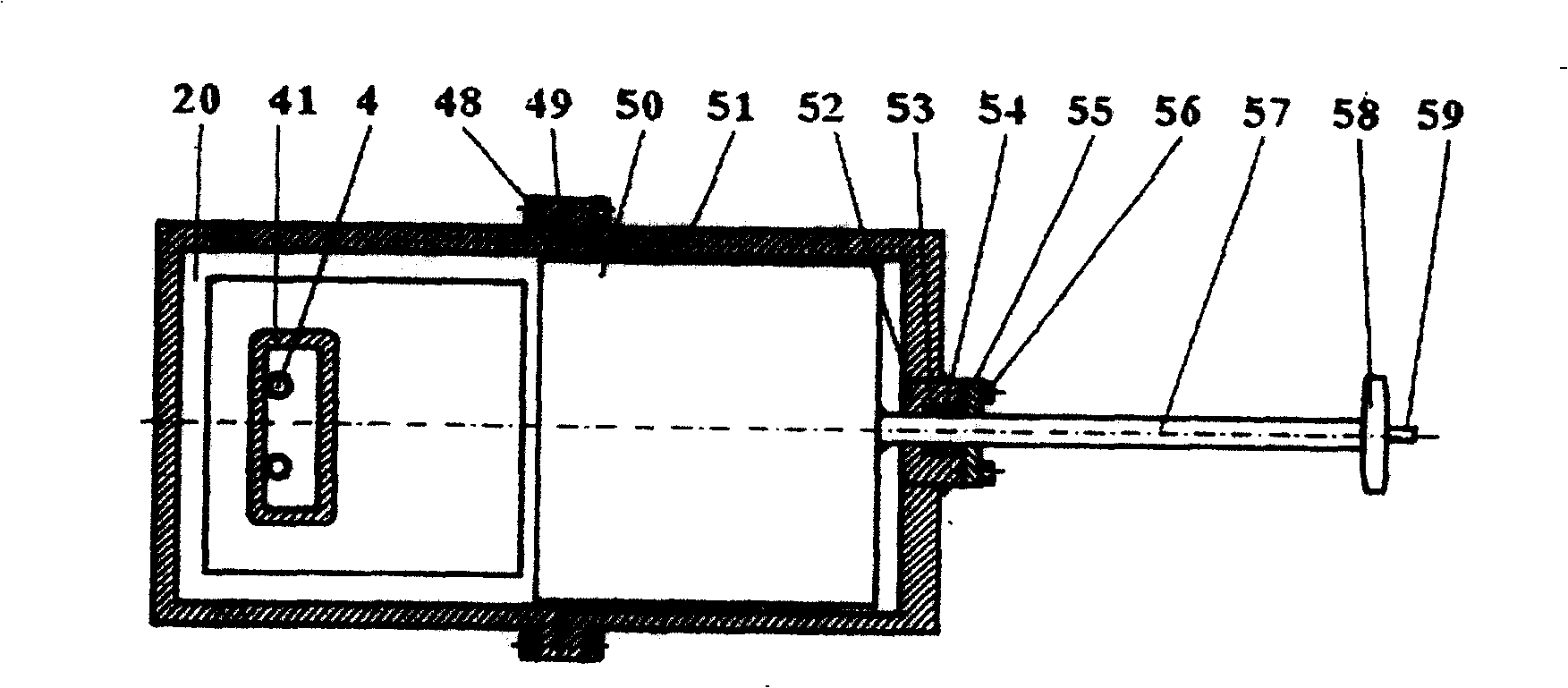

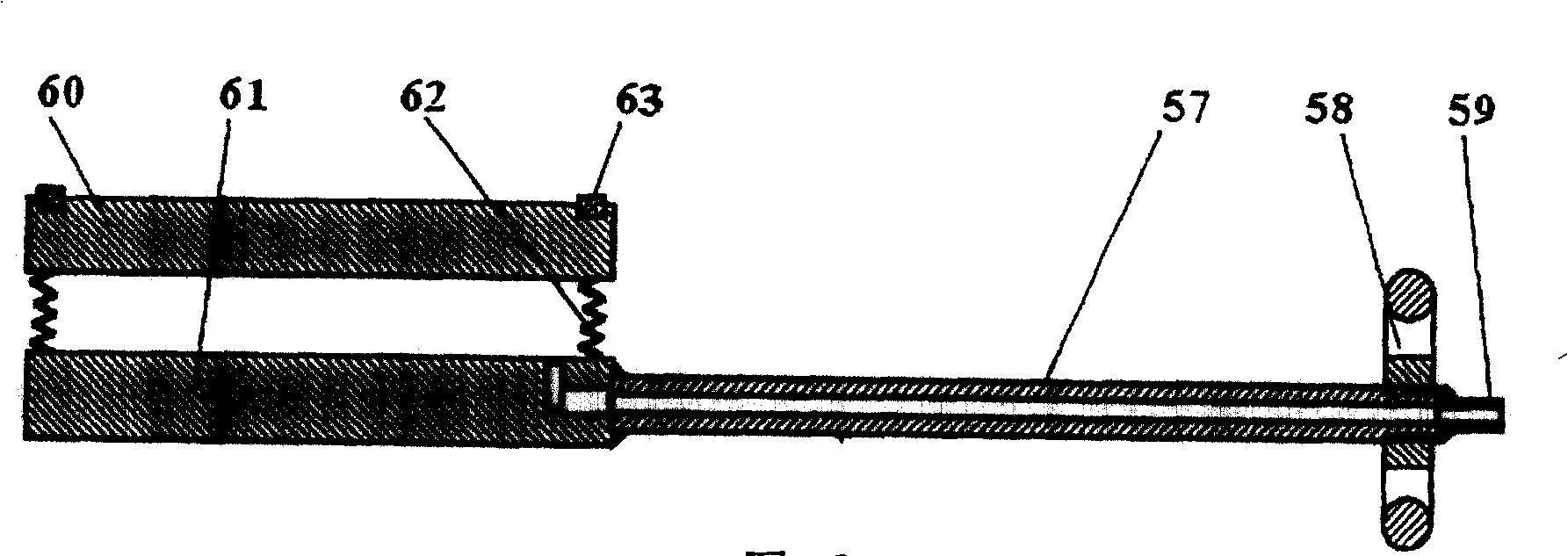

Method used

Image

Examples

example 1

[0046] After adopting the present invention, in H 2 -CH 4 Prepare a batch of CVD diamond-coated tools under the system, the batch size is 500 pieces, a square substrate table with a diameter of 80×80 is used, the heating wire is a tantalum wire of φ0.3, and the substrate table can be placed with a size of 12.7 25 blades of ×12.7×4.76, auxiliary time for filament installation, filament carbonization, vacuuming, etc. is about 9 hours, it takes 15 minutes to vacuumize the loading and unloading chamber and place the substrate each time, and the deposition time is about 5 hours each time, 500 pieces of tools The deposition time of the CVD diamond coating is about 114 hours. And do not adopt the present invention to prepare diamond-coated cutter, filament installs once and can deposit 25 cutters, and the cost of tantalum wire is about 1500 yuan when depositing 500 cutters, and the time of filament installation, filament carbonization, vacuumizing, vacuum chamber venting etc. is abo...

example 2

[0048] After adopting the present invention, in H 2 -CH 4 Prepare a batch of CVD diamond-coated wire-drawn films under the system, the batch size is 800, a circular substrate table with a diameter of φ80 is used, and a tantalum wire with a diameter of φ0.3 is used for the hot wire. The substrate table can be placed with a size of φ5 at a time. 100 drawing film blanks of ×3, about 9 hours for filament installation, filament carbonization, vacuuming, etc., 20 minutes for vacuuming the loading and unloading cavity and placing the substrate each time, about 6 hours for each deposition, 800 pieces of drawing film The deposition time of the CVD diamond coating is about 48 hours. Without adopting the present invention to prepare diamond-coated cutters, 100 wire-drawn films can be deposited once the filament is installed. When depositing 800 wire-drawn films, the cost of tantalum wire is about 600 yuan. Filament installation, filament carbonization, vacuuming, vacuum chamber degassin...

example 3

[0050] After adopting the present invention, in H 2 -CH 4The mechanism research experiment of nano-diamond film was carried out under the Ar system. Three factors were considered, each factor was taken at three levels, and five test pieces were used for each pilot point. In order to ensure the accuracy of the test, each pilot point uses 3 repeated tests, the total number of tests is 27, and the total number of test pieces needs to be 135. The test uses a substrate table with a diameter of φ30mm, and 5 specimens are placed on the substrate table for each test, and the heating wire uses a φ0.3 tantalum wire. Compared with not using the present invention, it can reduce the installation of hot wire by 26 times, save the cost of filament by about 1000 yuan, reduce the auxiliary time by about 250 hours, and save about 2500 yuan in deposition costs such as water, electricity and gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com