A Method for Reducing Strength Dispersion of Chemically Strengthened Glass by Temperature Modulation

A technology of strength dispersion and strengthening glass, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of low strength dispersion, and achieve the effect of reducing strength dispersion, improving strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 100×100×4mm float glass sample, the composition is as follows:

[0018] SiO 2

al 2 o 3

CaO

MgO

Na 2 o

K 2 o

67

5

2.6

9.5

16.4

0.5

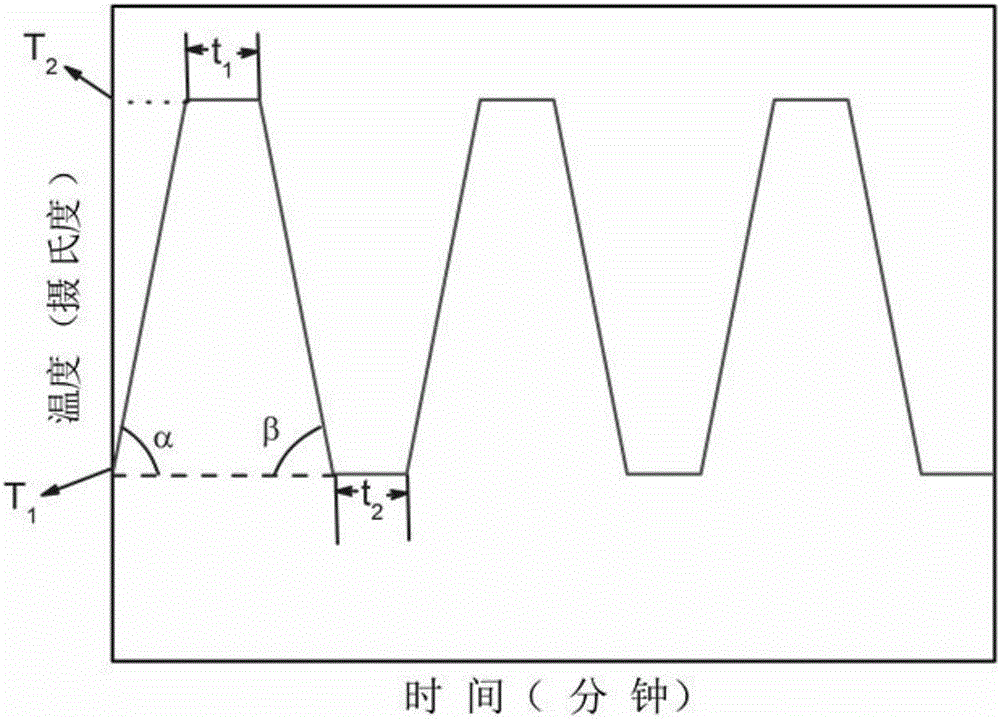

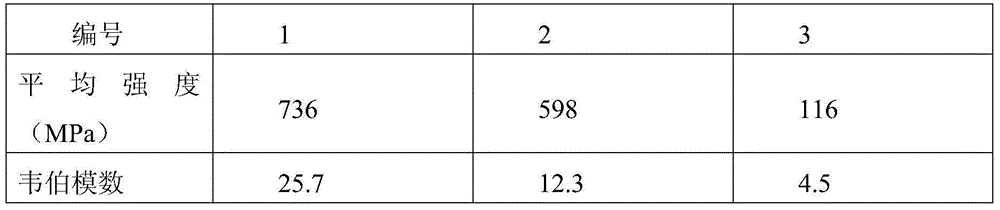

[0019] First wash the glass with deionized water, then dry it naturally. Heat the mixture of potassium nitrate, cesium nitrate and sodium nitrate (mass ratio 94%:4%:2%) used for chemical strengthening to T 1 =420°C and keep warm for 24 hours. Then put the dried glass into a chemical strengthening furnace for preheating at 380°C for 2 hours. After the glass is kept warm, it is placed in molten salt for chemical strengthening. Periodic temperature modulation method is adopted during chemical strengthening, T 2 =450°C. In the heating stage, tanα=2, the holding time t1=10h, in the cooling stage, tanβ=15, and the holding time t 2 =8h, after one modulation cycle is completed, take out the glass, cool it with the furnace, wash the glass with deionized water and dry it. ...

Embodiment 2

[0023] 100×100×6mm float glass sample, the composition is as follows:

[0024] SiO 2

al 2 o 3

CaO

MgO

Na 2 o

K 2 o

72

0.5

9.2

3.3

14.5

0.5

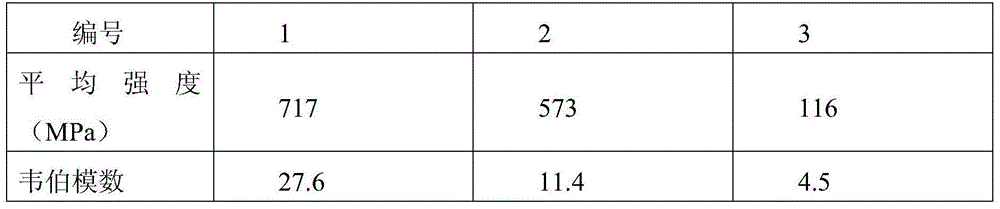

[0025] First wash the glass with deionized water, then dry it naturally. The pure potassium nitrate molten salt used for chemical strengthening is heated to T1=410°C and kept for 24 hours. Then put the dried glass into a chemical strengthening furnace for preheating at 380°C for 3 hours. After the glass is kept warm, it is placed in molten salt for chemical strengthening. Periodic temperature modulation method is adopted during chemical strengthening, T2=450℃. In the heating stage, tanα=5, holding time t1=15h, in the cooling stage, tanβ=10, holding time t2=10h, after 3 modulation cycles, take out the glass, cool it with the furnace, wash the glass with deionized water and dry it. The chemically strengthened glass is then tested for flexural strength using the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com