Round sand for porcelain insulator and preparation method and application thereof

A technology of porcelain insulators and round sand, applied in applications, household appliances, clay products, etc., can solve the problems of small dispersion, less sand, easy to break or fall off, etc., to achieve small strength dispersion, uniform particle size, The effect of easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Table 1 prepares the formula of round sand

[0037]

[0038] The preparation process of described round sand is as follows:

[0039] (1) Prepare raw materials according to the formula in Table 1. Weigh bauxite powder, Datong soil, feldspar, Zhangcun soil, elutriation soil, cooked talc, production blank, BaCO 3 And 9300, and added to the ball mill in order, set the ball milling time to 11h, continuous ball milling;

[0040] (2) After the particle size is qualified, it is sieved and ground;

[0041] (3) After the fresh slurry is deironed, it is spray-dried to make powder through pressure spray tower equipment;

[0042] (4) The powder is rolled into particles with a size of 2.0mm through the wet core-agglomerate method, and the speed is controlled at 9r / min when rolling;

[0043] (5) Bake the prepared granules in a drying room for 72 hours at a temperature of 100°C;

[0044] (6) Put the dried particles into a sagger, and burn them together with the insulator under ...

Embodiment 2

[0048] Table 2 prepares the formula of round sand

[0049]

[0050] The preparation process of described round sand is as follows:

[0051] (1) Prepare raw materials according to the formula in Table 2. Weigh bauxite powder, Chengcheng soil, feldspar, Jingyang soil, elutriation soil, cooked talc, production blank, BaCO 3 And pc-64, and added to the ball mill in order, set the ball milling time to 10.5h, continuous ball milling;

[0052] (2) After the particle size is qualified, it is sieved and ground;

[0053] (3) After the fresh slurry is deironed, it is spray-dried to make powder through pressure spray tower equipment;

[0054] (4) The powder is rolled into particles with a size of 2.2mm through the wet core-agglomerate method, and the speed is controlled at 10r / min during rolling;

[0055] (5) Bake the prepared granules in a drying room for 84 hours at a temperature of 90°C;

[0056] (6) Put the dried particles into a sagger, and burn them together with the alumina...

Embodiment 3

[0060] Table 3 Formula for preparing round sand

[0061]

[0062] The preparation process of described round sand is as follows:

[0063](1) Prepare raw materials according to the formula in Table 3. Weigh bauxite powder, bauxite, feldspar, panning soil, cooked talc, production blank, BaCO 3 And CMC, and added to the ball mill in order, set the ball milling time to 11.5h, continuous ball milling;

[0064] (2) After the particle size is qualified, it is sieved and ground;

[0065] (3) After the fresh slurry is deironed, it is spray-dried to make powder through pressure spray tower equipment;

[0066] (4) The powder is rolled into particles with a size of 1.9mm through the wet core-agglomerate method, and the speed is controlled at 8r / min when rolling;

[0067] (5) Bake the prepared granules in a drying room for 96 hours at a temperature of 95°C;

[0068] (6) Put the dried granules into the glaze drying room for use.

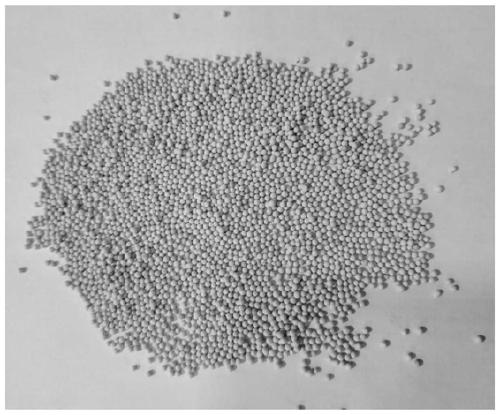

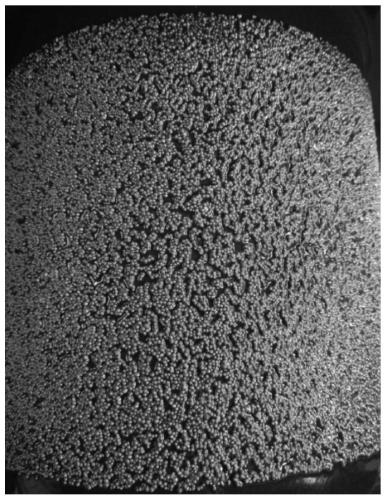

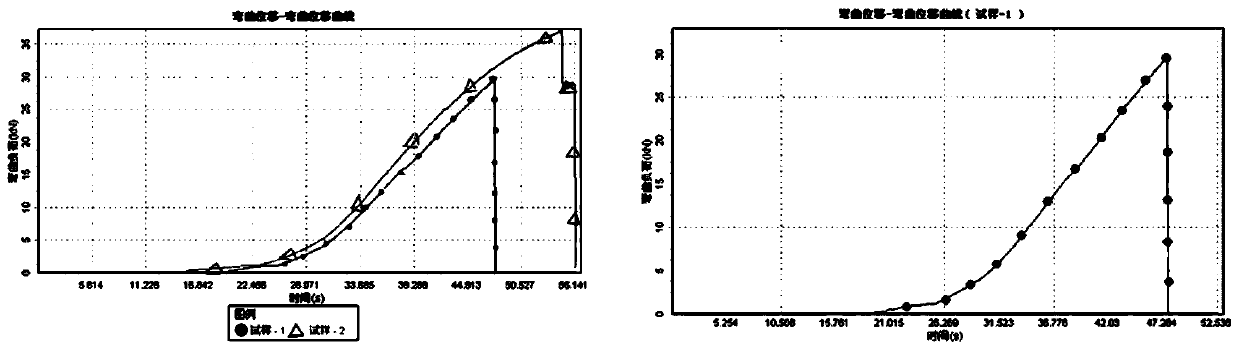

[0069] Apply the test effect of the sample prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com