A kind of manufacturing method of high-strength glass

A manufacturing method and high-strength technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., to achieve the effects of increased strength, low strength dispersion, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

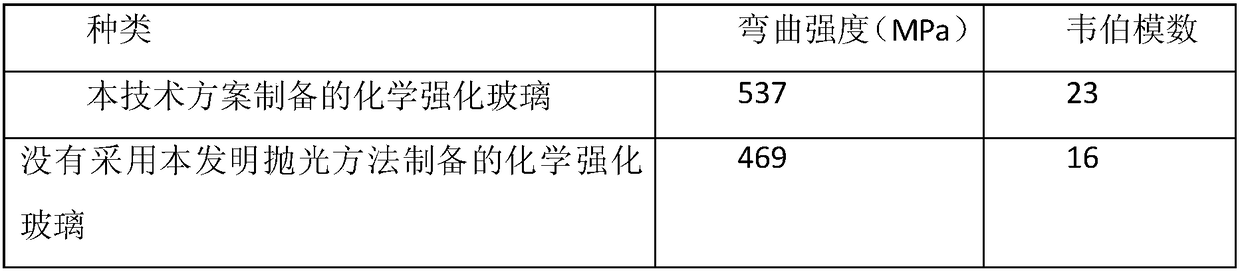

Embodiment 1

[0013] 100×100×2mm float glass sample, the glass composition (wt.%) is as follows:

[0014] SiO 2

al 2 o 3

CaO

MgO

Na 2 o

K 2 o

72

0.5

6.9

3.7

16.4

0.5

[0015] The steps of preparing high-strength glass by adopting the technical solution of the present invention are as follows:

[0016] (1) Prepare polishing fluid. The polishing liquid contains abrasives, sodium bicarbonate, sodium hydroxide, sodium fluoride and deionized water. Wherein, the abrasive refers to a mixture of cerium oxide with a particle size of 300-350 nm and silicon carbide with a particle size of 250-300 nm. The content of cerium oxide in the polishing liquid is 25%, the content of silicon carbide is 8%, the content of sodium bicarbonate is 10%, the content of sodium hydroxide is 5%, the content of sodium fluoride is 1%, and the content of deionized water is 51 %. The pH value of the polishing solution is 8.1.

[0017] (2) Using the prepare...

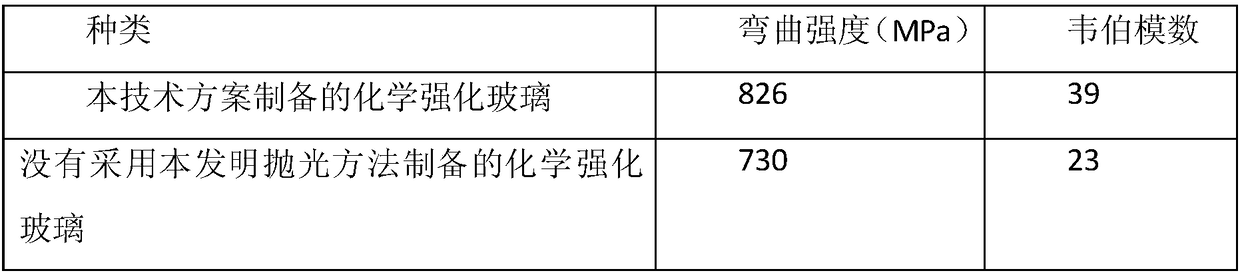

Embodiment 2

[0024] 100×100×2mm float glass sample, the glass composition (wt.%) is as follows:

[0025] SiO 2

Al 2 o 3

CaO

MgO

Na 2 o

K 2 o

64

16

3

1

15.5

0.5

[0026] The steps of preparing high-strength glass by adopting the technical solution of the present invention are as follows:

[0027] (1) Prepare polishing fluid. The polishing liquid contains abrasives, sodium bicarbonate, sodium hydroxide, sodium fluoride and deionized water. Wherein, the abrasive refers to a mixture of cerium oxide with a particle size of 300-350 nm and silicon carbide with a particle size of 250-300 nm. The content of cerium oxide in the polishing liquid is 20%, the content of silicon carbide is 6%, the content of sodium bicarbonate is 12%, the content of sodium hydroxide is 10%, the content of sodium fluoride is 2%, and the content of deionized water is 50% %. The pH value of the polishing solution is 8.8.

[0028] (2) Using the prepared p...

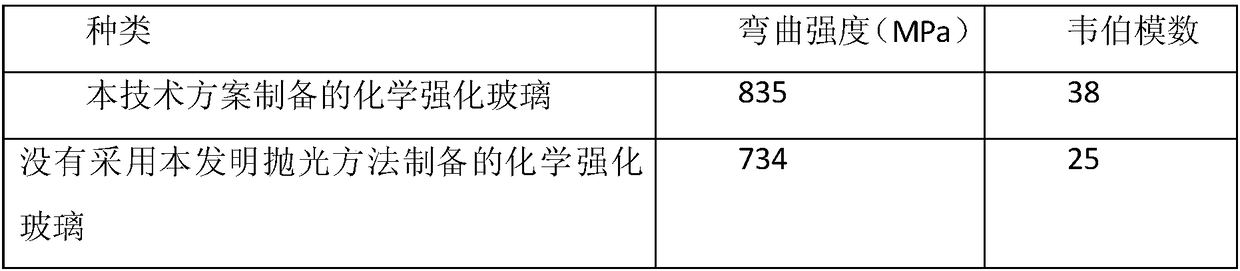

Embodiment 3

[0035] 100×100×2mm float glass sample, the glass composition (wt.%) is as follows:

[0036] SiO 2

al 2 o 3

CaO

MgO

Na 2 o

K 2 o

64

16

3

1

15.5

0.5

[0037] The steps of preparing high-strength glass by adopting the technical solution of the present invention are as follows:

[0038] (1) Prepare polishing fluid. The polishing liquid contains abrasives, sodium bicarbonate, sodium hydroxide, sodium fluoride and deionized water. Wherein, the abrasive refers to a mixture of cerium oxide with a particle size of 300-350 nm and silicon carbide with a particle size of 250-300 nm. The content of cerium oxide in the polishing liquid is 20%, the content of silicon carbide is 10%, the content of sodium bicarbonate is 11%, the content of sodium hydroxide is 8%, the content of sodium fluoride is 5%, and the content of deionized water is 46%. %. The pH value of the polishing solution is 8.6.

[0039] (2) Using the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com