A method for improving fracture toughness and strength of aluminosilicate glass

An aluminosilicate glass and fracture toughness technology, applied in the field of glass strengthening, can solve problems such as low glass strength and inability to meet glass strength requirements, and achieve the effect of small strength dispersion, high fracture toughness and strength, and improved fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

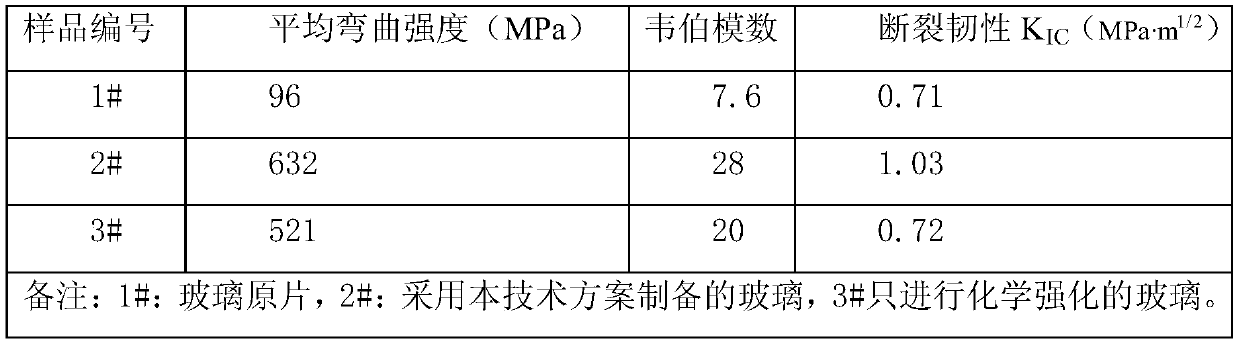

Embodiment 1

[0015] A method for improving the fracture toughness and strength of aluminosilicate glass, the steps of the method are:

[0016] (1) Cutting, edging, cleaning and drying the aluminosilicate glass.

[0017] (2) Put the washed and dried aluminosilicate glass into a high-temperature furnace for annealing treatment, the annealing temperature is 500°C, and the annealing time is 6h.

[0018] (3) Put the annealed aluminosilicate glass into a nitriding furnace for nitriding treatment. The specific nitriding parameters are: increase the temperature at 2°C / min to 520°C, hold for 3 hours, and the ammonia decomposition rate is 15%, then increase the temperature at 5°C / min to 550°C, hold for 5 hours, and the ammonia decomposition rate is 40%. , and then cool the furnace to room temperature.

[0019] (4) Put the nitrided aluminosilicate glass into a chemical strengthening furnace for chemical strengthening, the chemical strengthening temperature is 430° C., and the chemical strengthening...

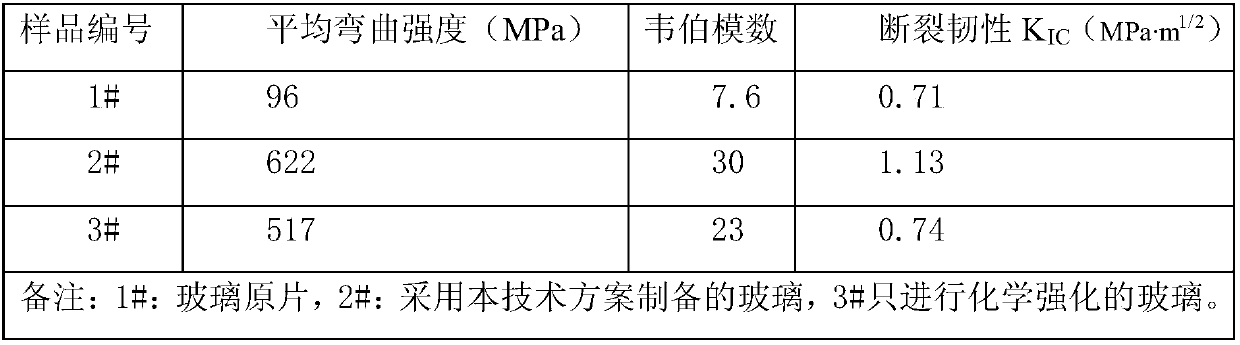

Embodiment 2

[0024] A method for improving the fracture toughness and strength of aluminosilicate glass, the steps of the method are:

[0025] (1) Cutting, edging, cleaning and drying the aluminosilicate glass.

[0026] (2) Put the cleaned and dried aluminosilicate glass into a high-temperature furnace for annealing treatment, the annealing temperature is 550° C., and the annealing time is 8 hours.

[0027] (3) Put the annealed aluminosilicate glass into a nitriding furnace for nitriding treatment. The specific nitriding parameters are: increase the temperature at 4°C / min to 540°C, hold for 4 hours, and the ammonia decomposition rate is 25%, then increase the temperature at 7°C / min to 570°C, hold for 6 hours, and the ammonia decomposition rate is 60%. , and then cool the furnace to room temperature.

[0028] (4) Put the nitrided aluminosilicate glass into a chemical strengthening furnace for chemical strengthening, the chemical strengthening temperature is 435° C., and the chemical stren...

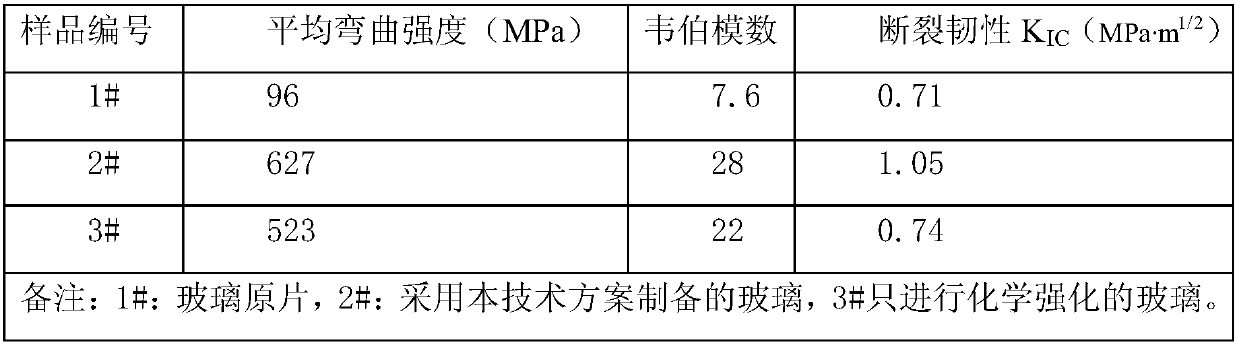

Embodiment 3

[0033] A method for improving the fracture toughness and strength of aluminosilicate glass, the steps of the method are:

[0034] (1) Cutting, edging, cleaning and drying the aluminosilicate glass.

[0035] (2) Put the cleaned and dried aluminosilicate glass into a high-temperature furnace for annealing treatment, the annealing temperature is 530°C, and the annealing time is 7h.

[0036] (3) Put the annealed aluminosilicate glass into a nitriding furnace for nitriding treatment. The specific nitriding parameters are: increase the temperature at 3°C / min to 530°C, hold for 4 hours, and the ammonia decomposition rate is 20%, then increase the temperature at 6°C / min to 560°C, hold for 5 hours, and the ammonia decomposition rate is 50%. , and then cool the furnace to room temperature.

[0037] (4) Put the nitrided aluminosilicate glass into a chemical strengthening furnace for chemical strengthening, the chemical strengthening temperature is 430° C., and the chemical strengthenin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com