Method for continuously forming organosilicon heat-conducting patch

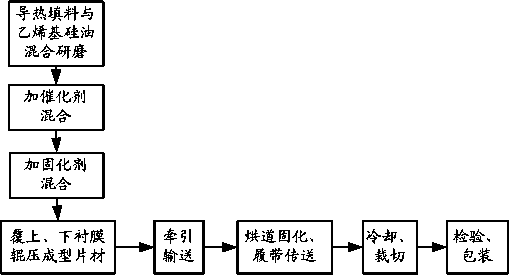

A molding method and silicone technology, applied in the field of continuous molding of silicone thermal conductive patches, can solve the problems of waste of scraps, intermittent operation, molding process, complicated equipment, etc., and achieve the effect of uniform sheet thickness and continuous large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] ①. Add 30 parts by weight of vinyl silicone oil and 70 parts by weight of thermally conductive filler into a planetary mixer and mix for 1 hour. After cooling to room temperature, carry out three-roll grinding, and use a scraper fineness meter to measure the fineness to 20-30 microns, and obtain Primary pulp;

[0050] 2. Add 100 parts by weight of primary slurry to the planetary mixer, and add 0.9 parts by weight of an isopropanol catalyst containing 0.1% (mass) of Pt content of chloroplatinic acid. The parameters of the planetary mixer are set to: revolution 40~45rpm, disperse 60~65rpm, vacuumize (keep the vacuum at 0.095MPa) and stop after stirring for 10 minutes;

[0051] ③. Add 0.6 parts by weight of hydrogen-containing silicone oil, the parameter setting and vacuum degree of the planetary mixer are the same as step ②, and vacuumize and stir for 10 minutes to obtain the silicone thermally conductive composition slurry;

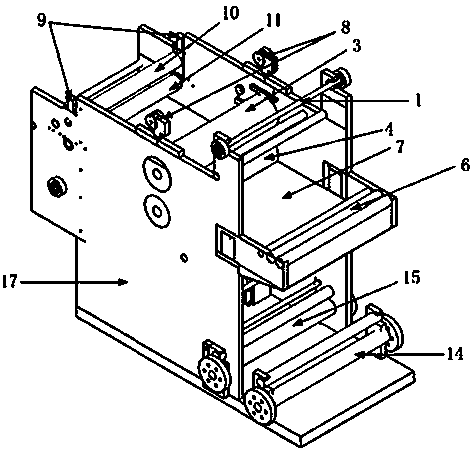

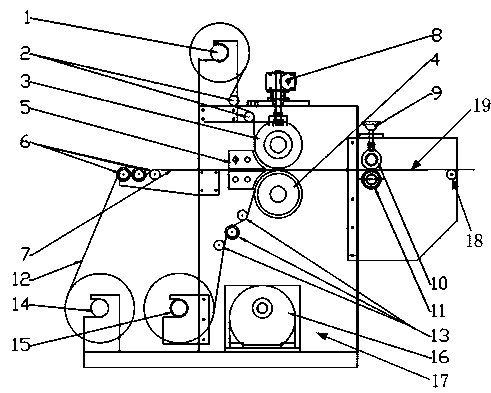

[0052] ④. Turn on the sheet forming machine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com