Method for preparing spinel type Li4Ti5O12 ultrathin nano-sheets

A spinel-type, nano-sheet technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low gram capacity, unfavorable high-rate cycle, etc., and achieve simple and easy process, good cycle performance, Inexpensive to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

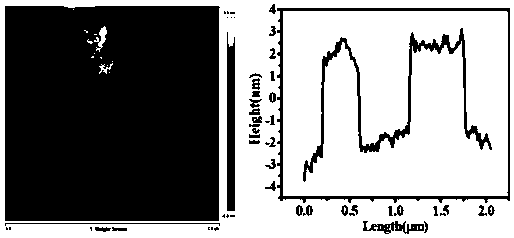

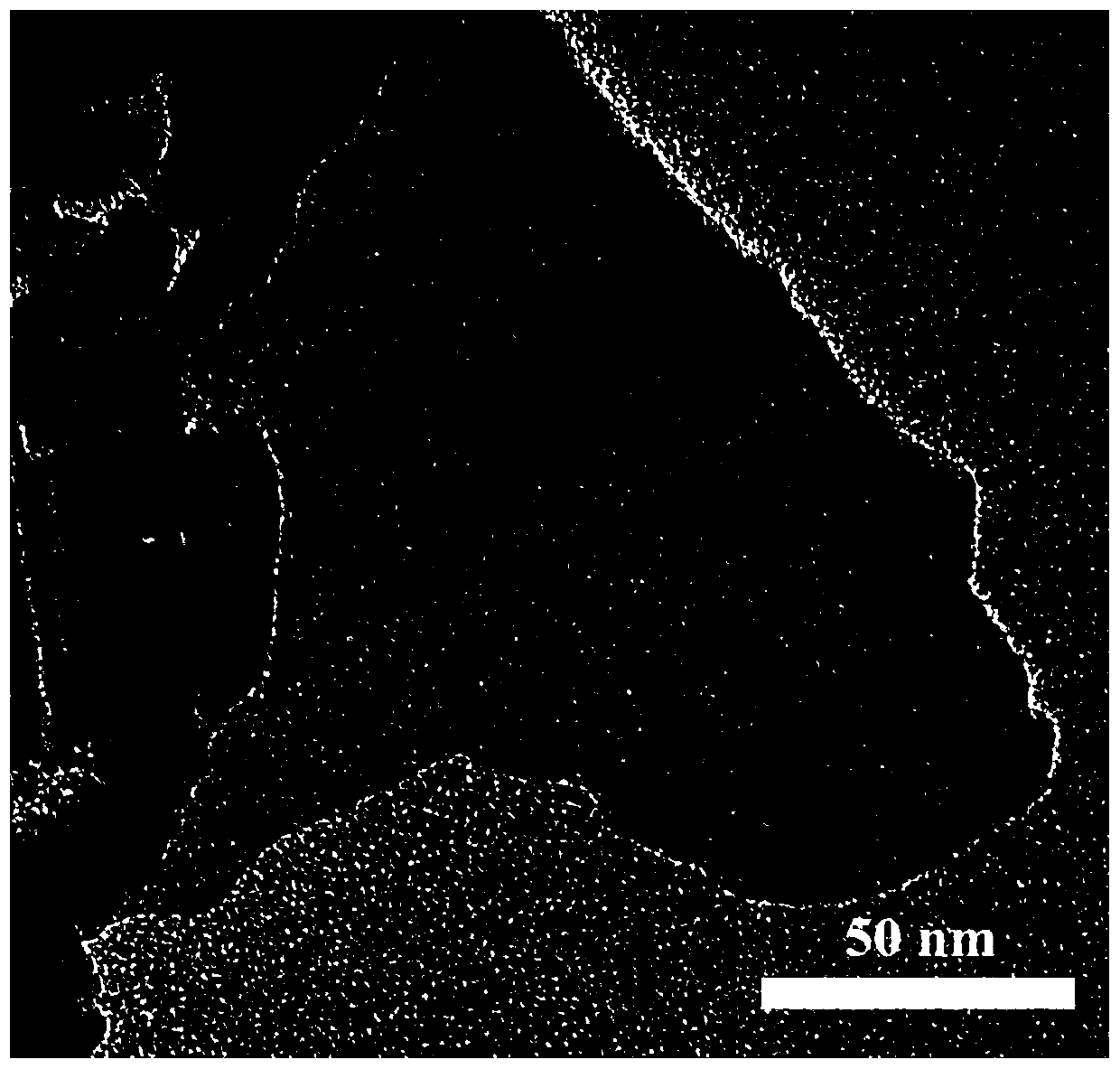

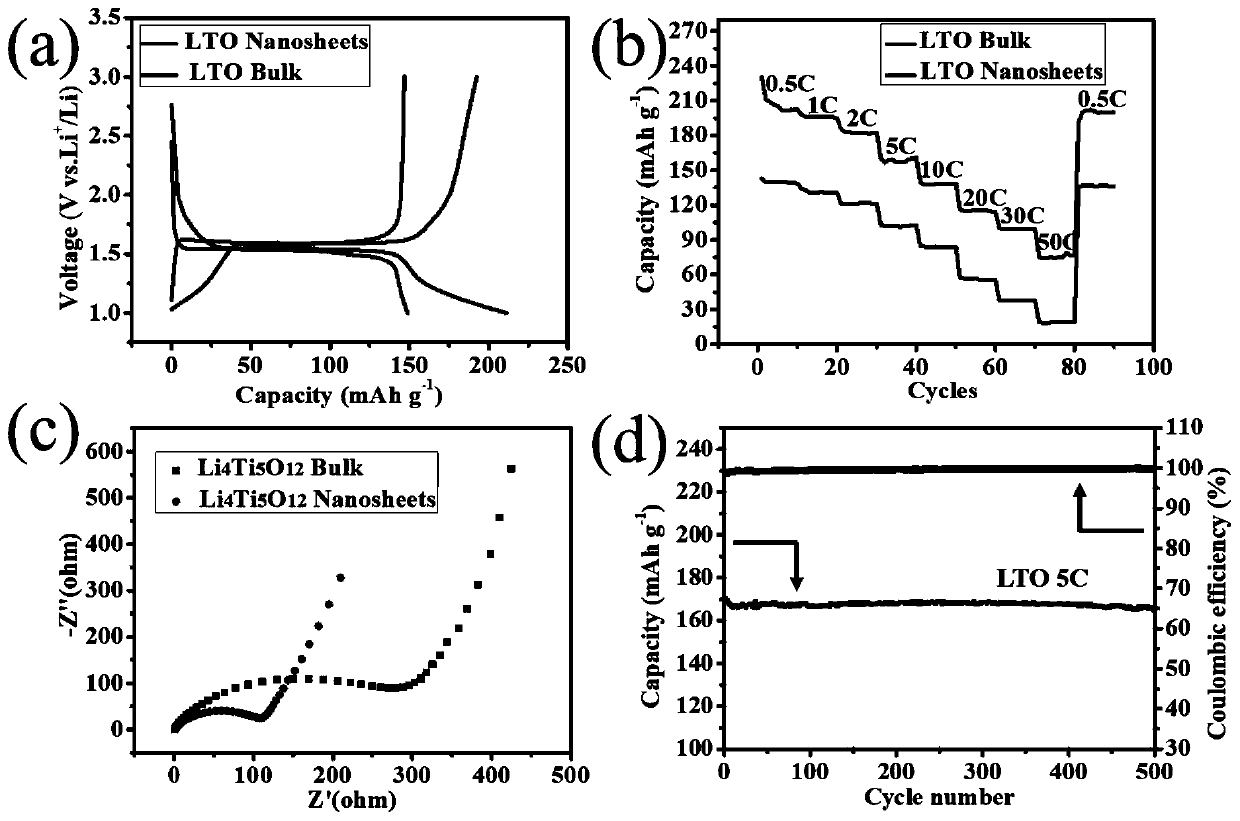

[0022] A preparation of spinel-type Li 4 Ti 5 o 12 The method for ultrathin nanosheets, comprising the following steps:

[0023] Step 1. Preparing original layered Na by sol-gel method 2 Ti3 o 7 Materials, including solution A and solution B, wherein the solution A is mixed successively with 10ml tetrabutyl titanate (TBOT) (Aladdin, ≥99.99%), 40ml ethanol (AR, ≥99.7%), 3ml acetic acid (AR , ≥99.8%), solution B is 1.038g Na 2 CO 3 (AR, ≥99.8%) was dissolved in 4ml of deionized water, under continuous magnetic stirring, solution B was added dropwise to solution A until a uniform semi-solid gel was formed, and the freeze-dried gel powder was heated at 780°C Heat treatment in air atmosphere to get Na 2 Ti 3 o 7 ;

[0024] Step 2, take by weighing the Na synthesized in 1g step 1 2 Ti 3 o 7 And dispersed in 300ml 0.5M (mol / L) HCl solution, stirred for 24 hours to make Na + H2Ti3O7 is obtained after being completely exchanged by H+, and then washed with deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com