A closed tobacco leaf front and back feeding equipment

A technology of closed tobacco leaves and feeding equipment, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of unsuitable for large-scale automatic production, low uniformity of tobacco surface, and poor stability of application accuracy, etc., and achieves simple structure, The effect of improving the effect and stabilizing the feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

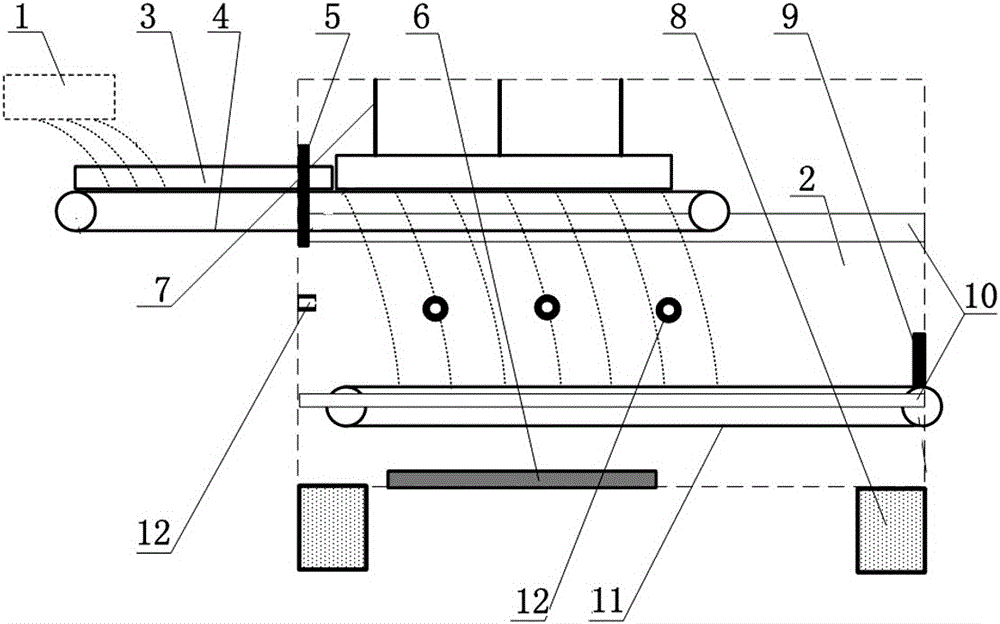

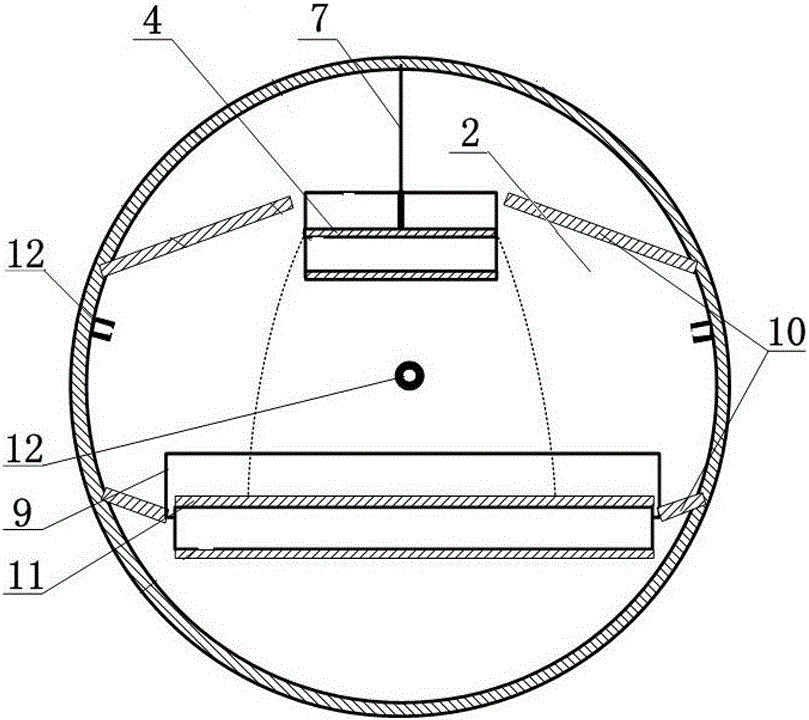

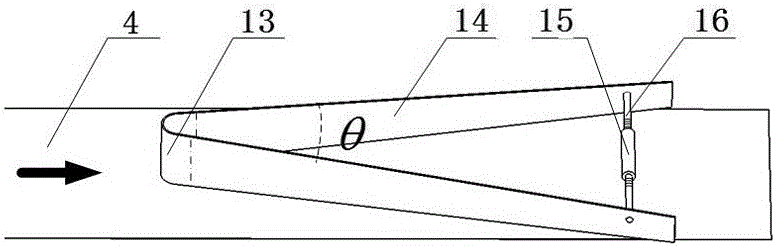

[0018] Such as figure 1 As shown, a closed tobacco leaf front and back feeding equipment includes a leaf inlet system, a distribution system, a tobacco leaf inlet 5, an atomization chamber sewage outlet 6, an atomization chamber 2, an atomization chamber fixing bracket 8, a tobacco leaf outlet 9, and an atomization chamber. A chamber sealing plate 10, a liquid spray nozzle 12, and a leaf-out conveyor belt 11. The leaf-feeding system includes a tobacco leaf feeder 1, a leaf-feeding conveyor trough 3, and a leaf-feeding conveyor belt 4. A leaf-feeding conveyor trough 3 is arranged below the tobacco leaf feeder 1. A part of the leaf-feeding delivery tank 3 is set through the tobacco leaf inlet 5, the atomization chamber fixing bracket 8 is fixedly arranged under the atomization chamber 2, and a shunt system is arranged at the end of the leaf-feeding delivery tank 3, such as image 3 As shown, the distribution system is arranged inside the atomization chamber 2. The distribution s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com