Preparation method and application of a new type of silicon-based composite porous negative electrode material for lithium ion battery

一种锂离子电池、负极材料的技术

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

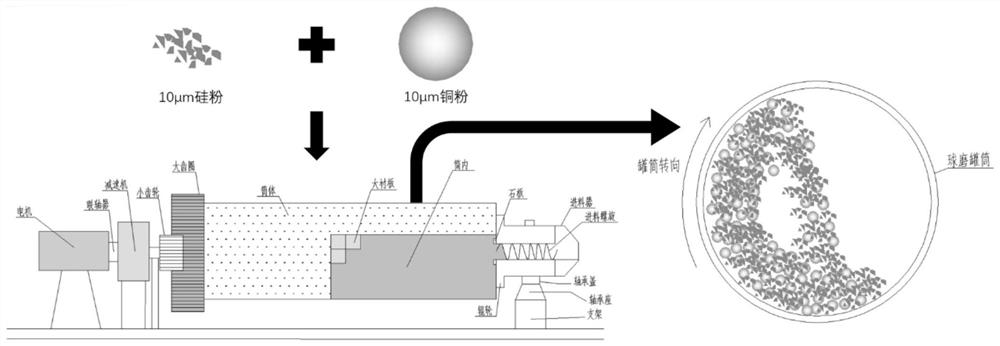

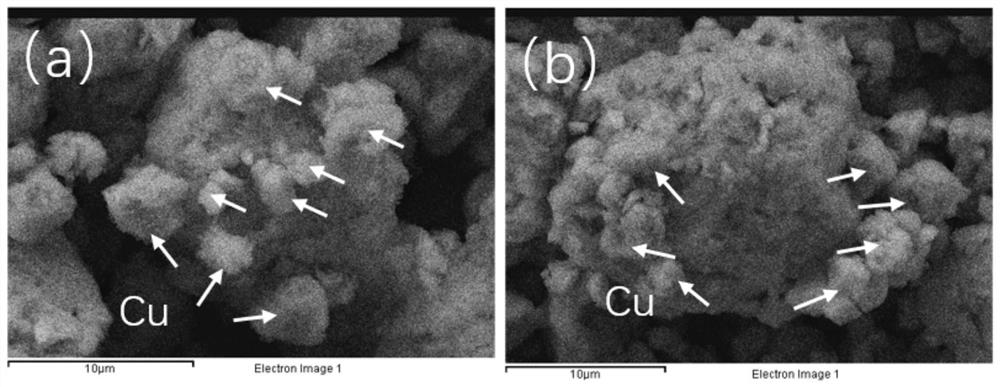

[0046] The metal lithium sheet is used as the positive electrode sheet of the lithium ion battery to prepare a silicon copper composite powder as a negative electrode active substance of a lithium ion battery. The specific implementation steps are as follows: 10 μm silicon powder, 10 μm copper powder is mixed by volume ratio 1: 1, such as figure 1 In the ball mill, the rotation speed is 600 rpm, the spherium is 10: 1 (W), 12H, 24H ball mill, to obtain a negative electrode active substance and submissive SEM microscopic test ( figure 2 . By adjusting the heater and air compressor, the holding pressure and temperature is 2 MPa and 300 ° C, the spray distance is controlled at 30 mm, the nozzle scan speed is controlled at 0.1 m / s, and the stepper motor is set to 500 Hz, the thickness of the copper foil is 0.05mm, such as Figure 4 , Sprayed 1 second, prepared for composite coating, resulting in a composite negative electrode and subtracted by SEM ( Figure 5 .

[0047] Will 1mol·L -1 ...

Embodiment 2

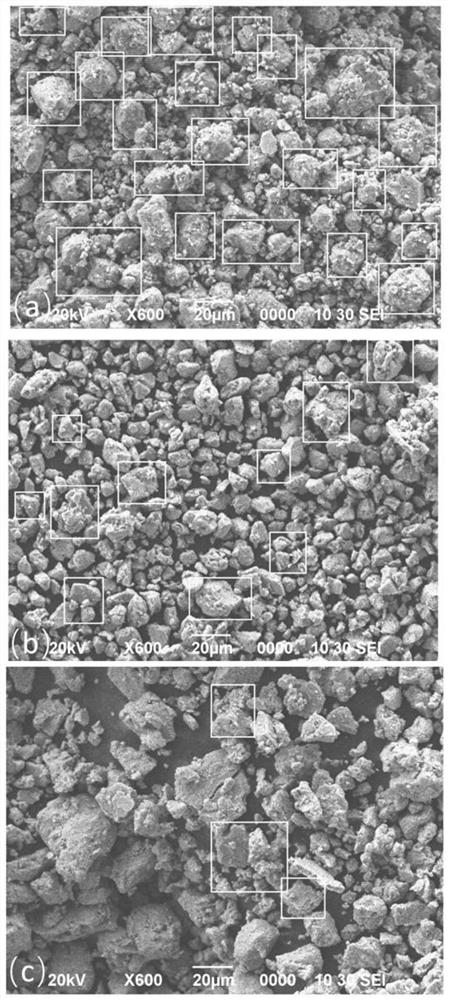

[0052] The metal lithium sheet is used as the positive electrode sheet of the lithium ion battery to prepare a silicon copper composite powder as a negative electrode active substance of a lithium ion battery. The specific implementation steps are as follows: 10 μm silica powder, 10 μm copper powder is mixed in volume ratio 1: 1, 1: 2, 1: 3, such as figure 1 The ball mill is 600 rpm in the ball mill, the ball ratio is 10: 1 (W), and the ball milling of 24h is performed, and the negative electrode active material is obtained and the SEM microscopic test is performed. figure 2 , image 3 ), XRD comparison analysis ( Figure 8 . By adjusting the heater and air compressor, the holding pressure and temperature is 2 MPa and 300 ° C, the spray distance is controlled at 30 mm, the nozzle scan speed is controlled at 0.1 m / s, and the stepper motor is set to 500 Hz, the thickness of the copper foil is 0.05mm, such as Figure 4 , Sprayed 1 second, prepared for composite coating, resulting in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com