Process method for preparing thermal barrier coating containing diffusion-resistant layer by EB-PVD (electron beam-physical vapor deposition) one-step method

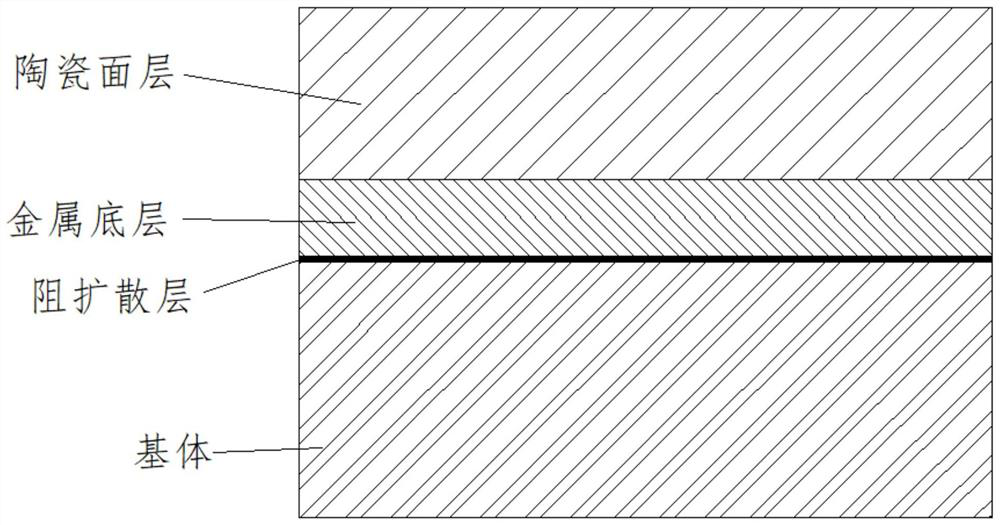

A technology of barrier diffusion layer and thermal barrier coating is applied in the field of preparation of thermal barrier coating containing barrier diffusion layer by EB-PVD one-step method, which can solve the problems of sand contamination of interface quality, processing length, and reduction of high temperature mechanical properties of substrates. , to achieve the effect of simplifying the coating preparation process, low manufacturing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

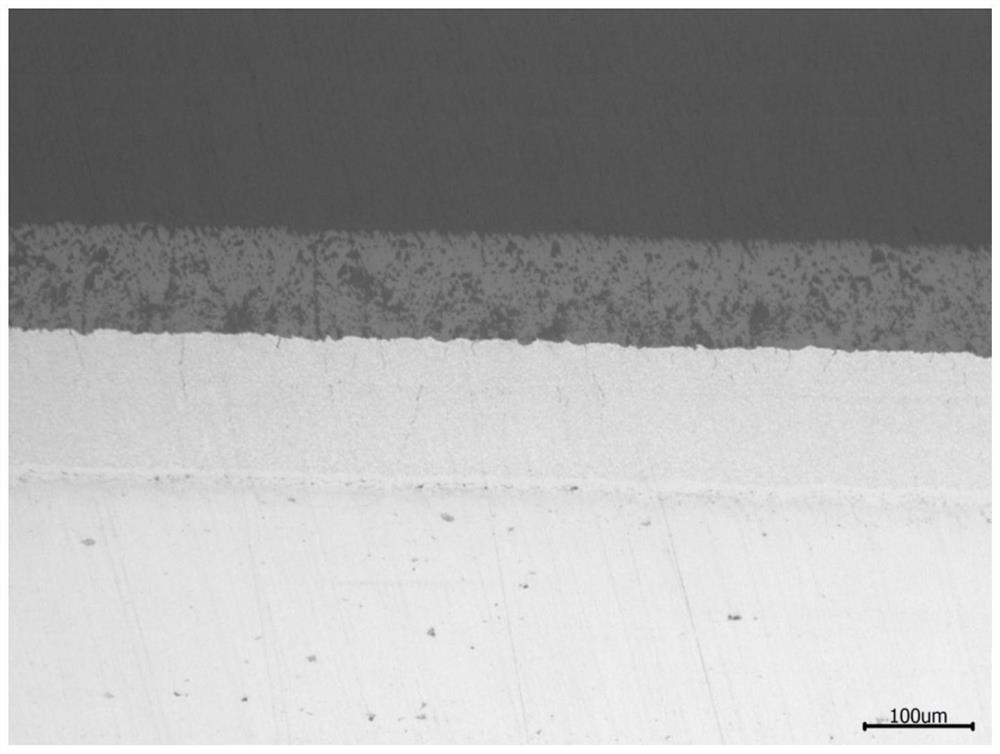

[0043] The composite ingot includes 50g of NiAl metal ingot, 3g of C 14 H 10 Bulk material and 500g of ZrO 2 ~8Y 2 O 3 The ceramic ingot, wherein the Ni content in the NiAl metal ingot is 60wt.%, and the Al content is 40%.

[0044] Before loading, wet sand blasting and ultrasonic cleaning are performed on the surface of the parts to ensure that the surface of the parts is free from oil stains, oxides, etc. The cleaned parts are loaded into the loading chamber, and the loading chamber is evacuated so that the parts are at 5×10 ~3 Torr under vacuum conditions.

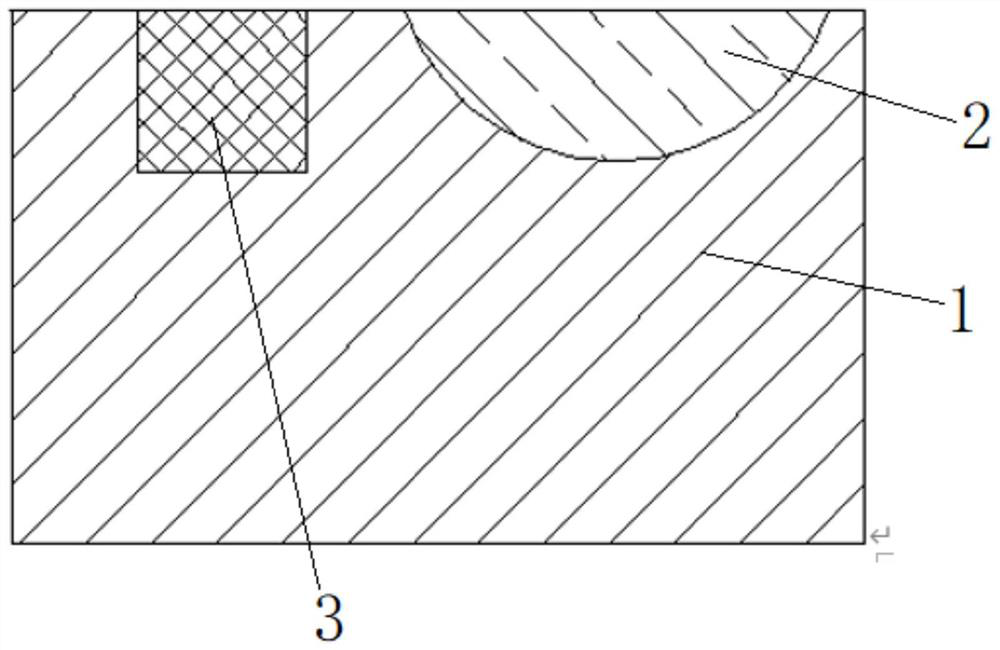

[0045] Subsequently, the shaft that started the EB-PVD equipment was rotated at 20 rpms to move the part directly above the composite ingot for deposition.

[0046] During the deposition of the diffusion barrier, a heat gun was used to bring the temperature of the part to 900°C. At the same time, increase the current of the evaporation gun to 0.5A so that C 14 H 10 The bulk material is evaporated within 1 min to...

Embodiment 2

[0052] The composite ingot includes 70g of NiAl metal ingot, 4g of C 14 H 10 Bulk material and 600g of ZrO 2 ~8Y 2 O 3 The ceramic ingot, wherein the Ni content in the NiAl metal ingot is 65wt.%, and the Al content is 35%.

[0053] Before loading, wet sand blasting and ultrasonic cleaning are performed on the surface of the parts to ensure that the surface of the parts is free from oil stains, oxides, etc. The cleaned parts are loaded into the loading chamber, and the loading chamber is evacuated so that the parts are at 5×10 ~3 Torr under vacuum conditions.

[0054] Subsequently, the shaft that started the EB-PVD equipment was rotated at 23 rpms to move the part directly above the composite ingot for deposition.

[0055] During the deposition of the diffusion barrier, a heat gun was used to bring the temperature of the part to 930°C. At the same time, increase the current of the evaporation gun to 0.55A, so that C 14 H 10 The bulk material was evaporated within 1.5 m...

Embodiment 3

[0061] The composite ingot includes 90g of NiAl metal ingot, 5g of C 14 H 10 Bulk material and 700g of ZrO 2 ~8Y 2 O 3 A ceramic ingot, wherein the Ni content in the NiAl metal ingot is 70wt.%, and the Al content is 30%.

[0062] Before loading, wet sand blasting and ultrasonic cleaning are carried out on the surface of the parts to ensure that the surface of the parts is free from oil stains, oxides, etc. The cleaned parts are loaded into the loading chamber, and the loading chamber is evacuated so that the parts are at 5×10 ~3 Torr under vacuum conditions.

[0063] Subsequently, the shaft that started the EB-PVD equipment was rotated at 25 rpms to move the part directly above the composite ingot for deposition.

[0064] During the deposition of the diffusion barrier, a heat gun was used to bring the temperature of the part to 950°C. At the same time, increase the current of the evaporation gun to 0.6A, so that C 14 H 10 The bulk material was evaporated within 2 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com