Patents

Literature

56results about How to "Reduced creep deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

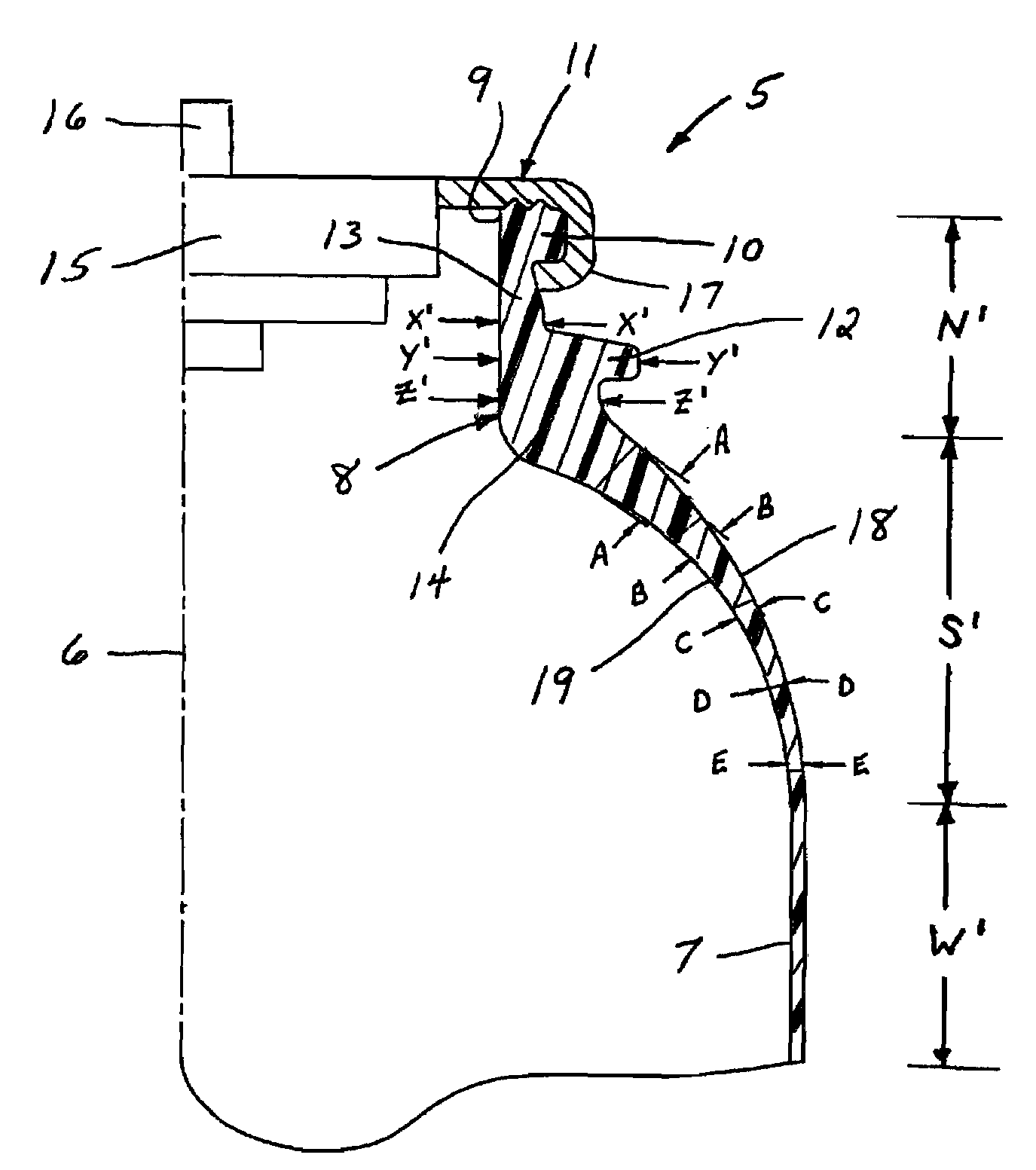

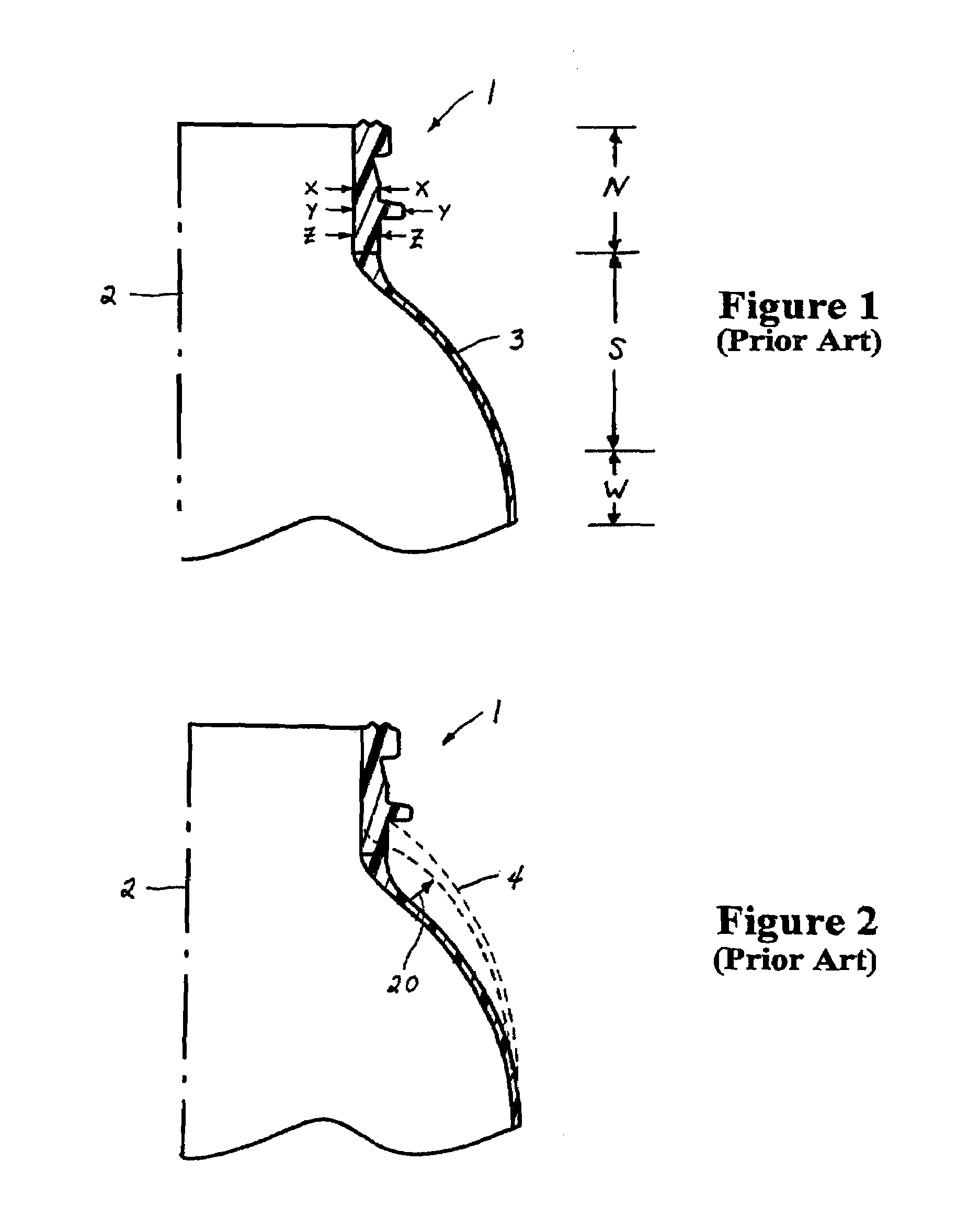

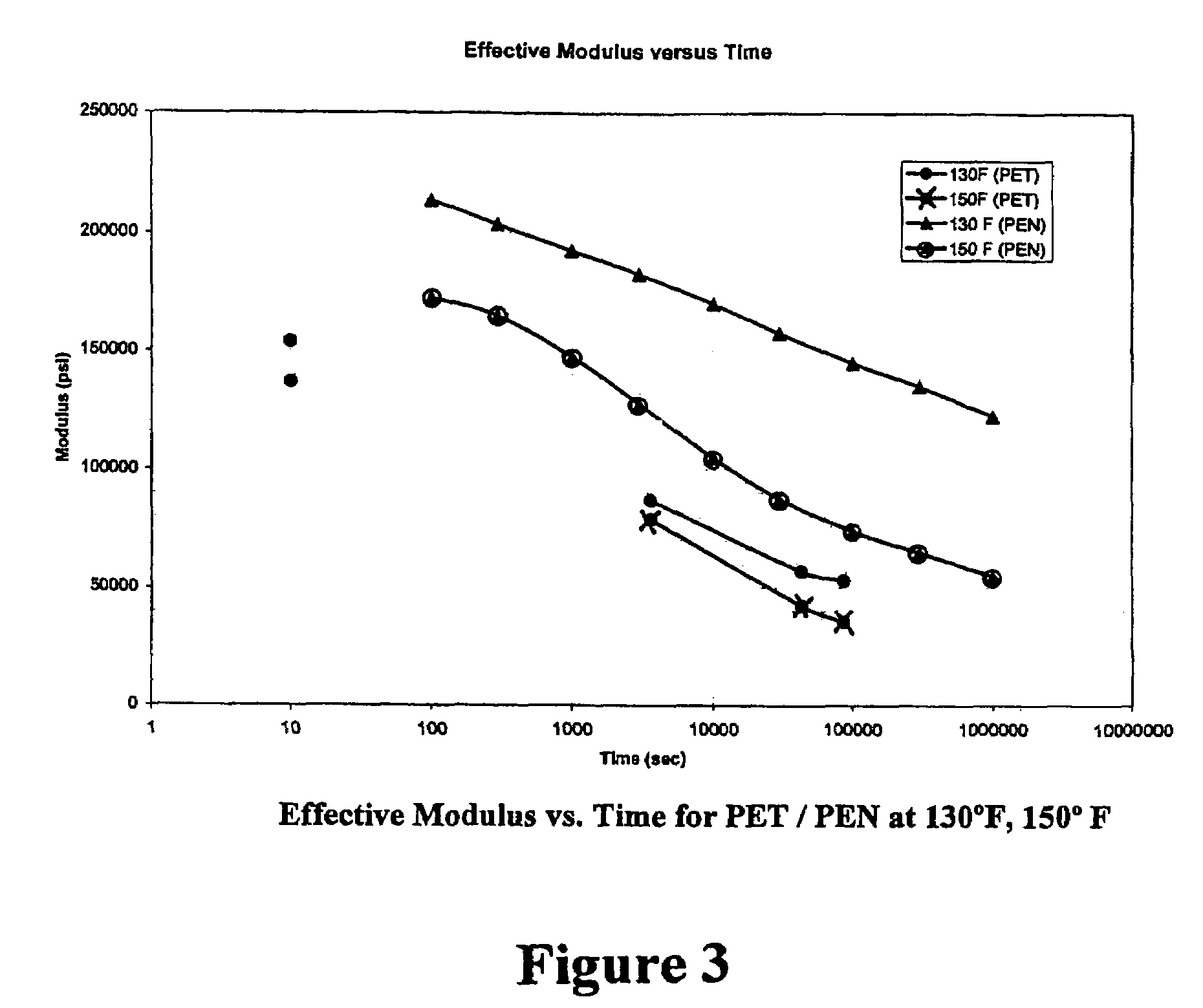

Pressurized plastic bottle with reinforced neck and shoulder for dispensing an aerosol

ActiveUS7303087B2Eliminate previously inherent instabilityAvoid instabilityCapsClosure capsShoulder regionEngineering

A pressure resistant plastic bottle for containing and dispensing an aerosol composition. The plastic bottle is designed to reduce deformation by a local reinforcement to the neck and shoulder regions. The reinforcement preferably comprises the provision of a wall thickness for a lower portion of the neck as compared to the wall thickness of the upper portion of the neck to be increased by a ratio of from about 1.25:1 to about 2.5:1.

Owner:SC JOHNSON & SON INC

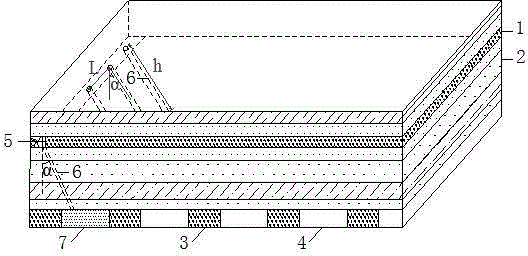

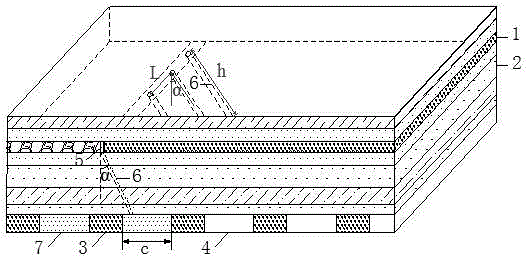

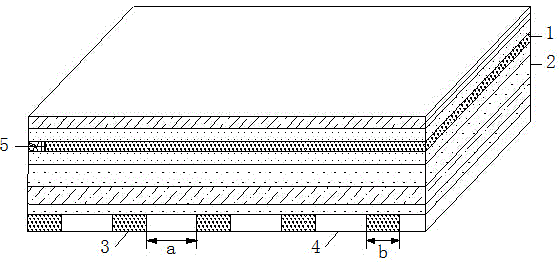

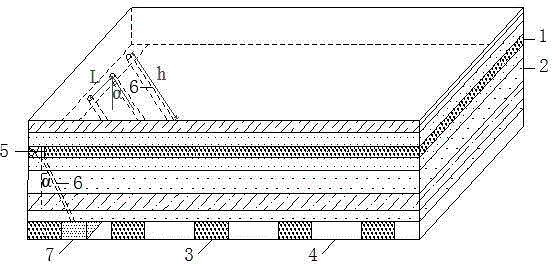

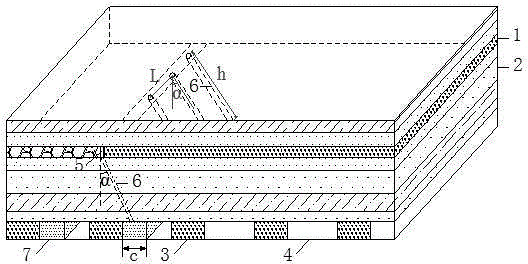

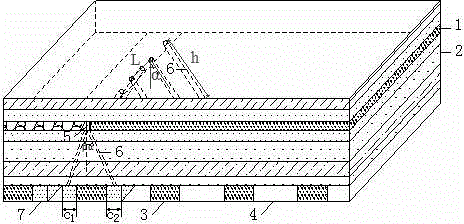

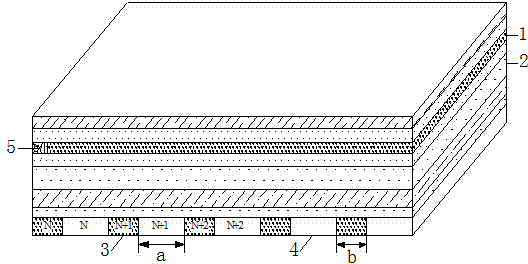

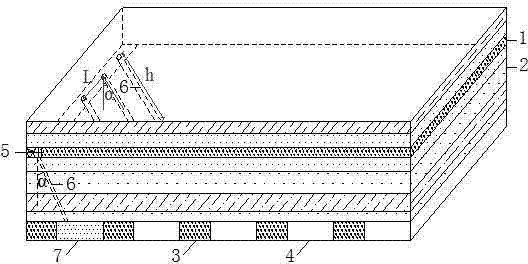

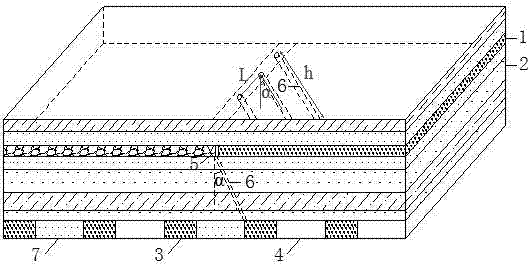

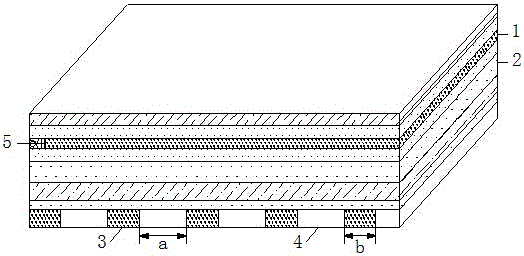

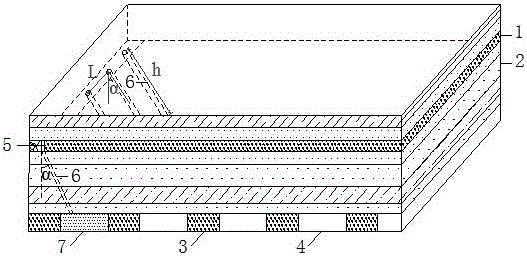

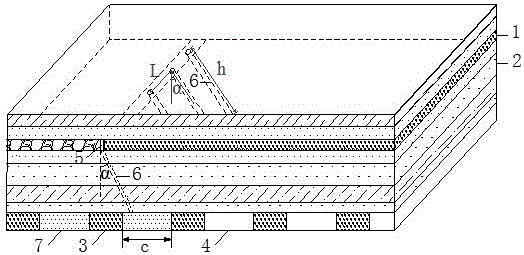

Method of beside-pillar double-side total-filling ascending re-mining overhead coal seam

ActiveCN104832174APlay a role of side protectionDegree of reductionUnderground miningSurface miningReamerCoal pillar

The invention discloses a method of a beside-pillar double-side total-filling ascending re-mining overhead coal seam. In the invention, on the basis of determining overhead coal seam mining feasibility and detecting distribution situations of a coal pillar group and a mined area group of a reamer-pillar remnant mining area, a beside-pillar double-side total-filling method is employed for successively side-protecting the coal pillar group in the underlie reamer-pillar remnant mining area of the overhead coal seam and gradually mining the overhead coal resources. By means of the method, a beside-pillar double-side filling body formed in the mined area group can not only achieve a side-protecting effect on the reamer-pillar coal pillar group but also form a common bearing body therewith, thereby further reducing degree of stress concentration and creep deformation of the coal pillar group. The method can enhance long-term stability, can avoid local instantaneous unstability or domino-like unstable damage and finally can ensure safe mining of the overhead coal seam of the reamer-pillar remnant mining area.

Owner:TAIYUAN UNIV OF TECH

Method for pillar adjacency single side partial filling of ascending re-mining hollow coal seam

ActiveCN104790952APlay a role of side protectionDegree of reductionUnderground miningSurface miningCoal pillarInstability

The invention discloses a method for pillar adjacency single side partial filling of an ascending re-mining hollow coal seam. Based on discrimination of hollow coal seam ascending mining feasibility and ascertaining of distribution statuses of a knife-pillar type residual mining area coal pillar group and a knife-pillar type residual mining area empty area group, the method for pillar adjacency single side partial filling comprises that the hollow coal seam underlying knife-pillar type residual mining area coal pillar group is successively laterally protected, and hollow coal resources are gradually mined. A pillar adjacency single side partial filling body formed in the empty area group not only can play a role in laterally protecting the knife-pillar type coal pillar group, but also can form a common supporting body with the coal pillar group, so as to reduce the stress concentration degree and creep deformation of the coal pillar group, enhance the long-term stability, avoid occurrence of local instantaneous instability or 'domino' type instability damage, and ultimately ensure safe mining of a knife-pillar type residual mining area overlying hollow coal seam.

Owner:TAIYUAN UNIV OF TECH

Lead free solder alloy and its preparation method

InactiveCN1990161AReduced creep deformationWelding/cutting media/materialsSoldering mediaRare earthCopper

The invention discloses a lead-free welding materials alloy which consists of silver, copper, tin and mixed rare earth Re, and the weight percentage of the composition is: Ag 3 ~ 8%, Cu 0.1 ~ 1.0%, mixed rare earth Re 0.01 ~ 0. 5% and cushion is Sn. The invention also discloses the preparation method of said lead-free welding materials alloy. The lead-free welding materials alloy in the invention can be widely used in welding materials of various circuit boards, components and assembly production line. The lead-free welding materials alloy in the invention has excellent rollout performance, low melting point but high environmental protection, and does not generate low melting point eutectic composition; it is conducive to forming reliable welding joints in welding process.

Owner:上海飞轮有色冶炼厂

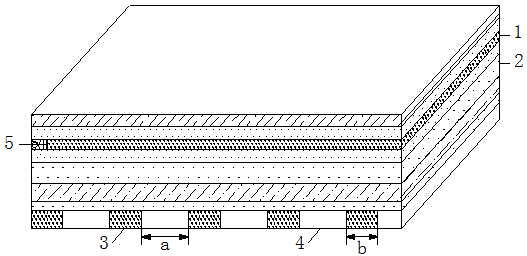

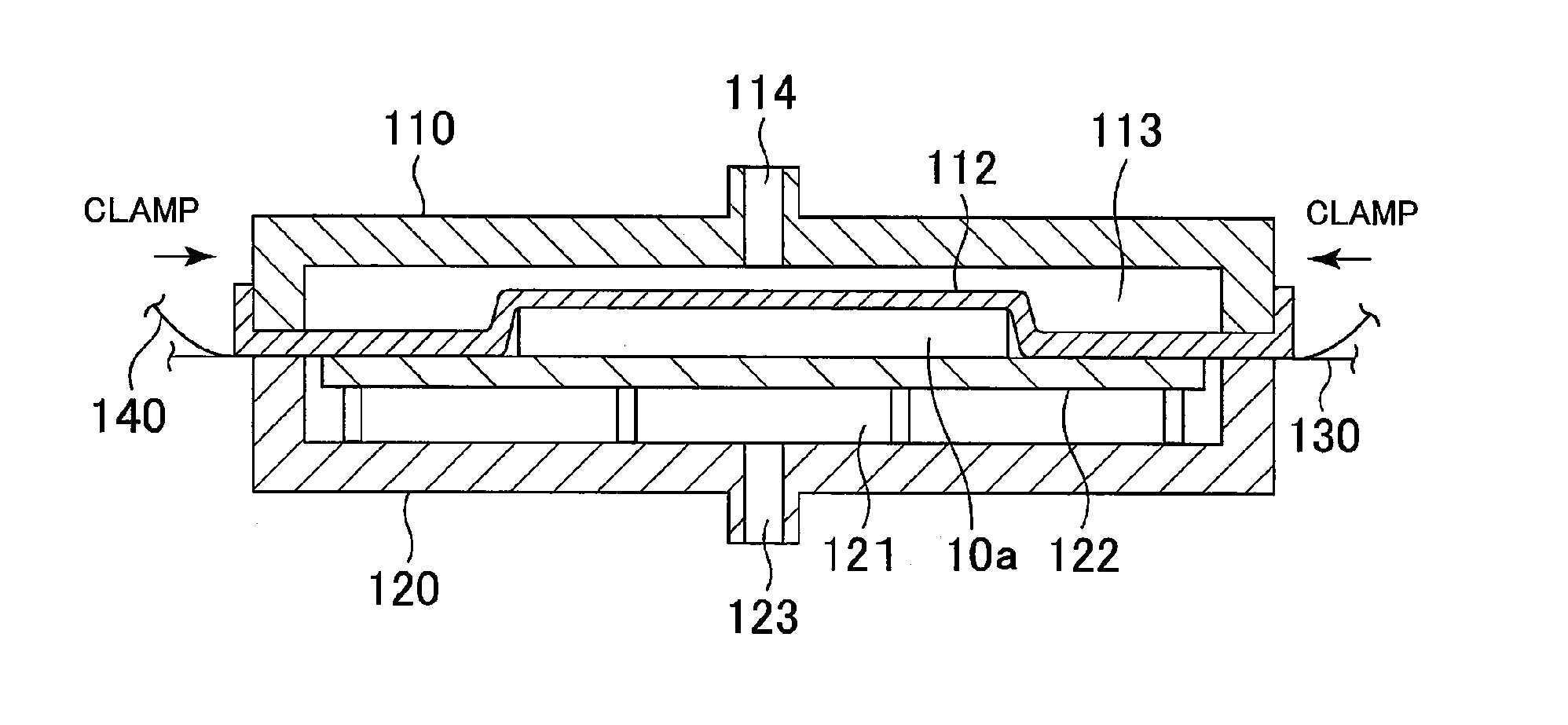

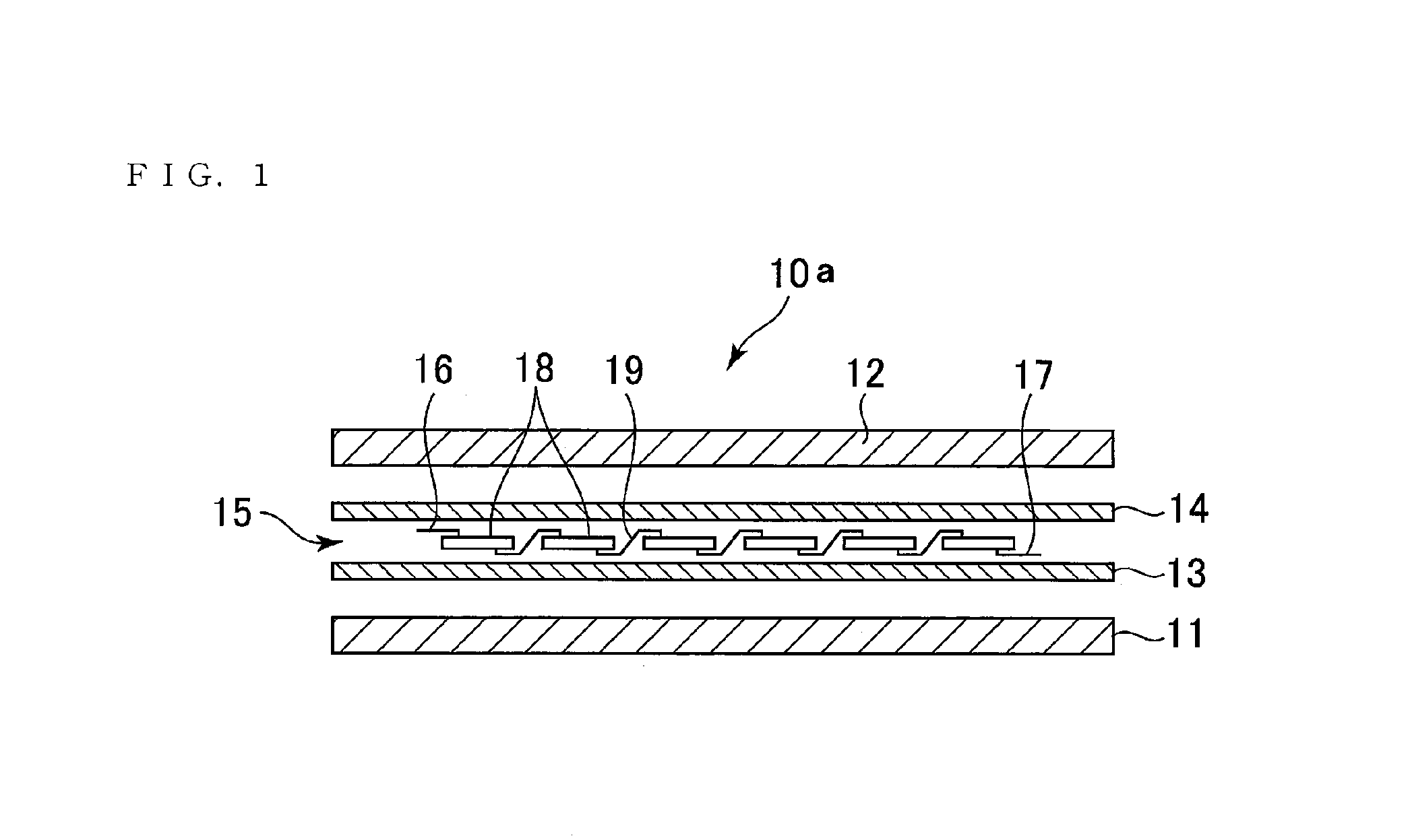

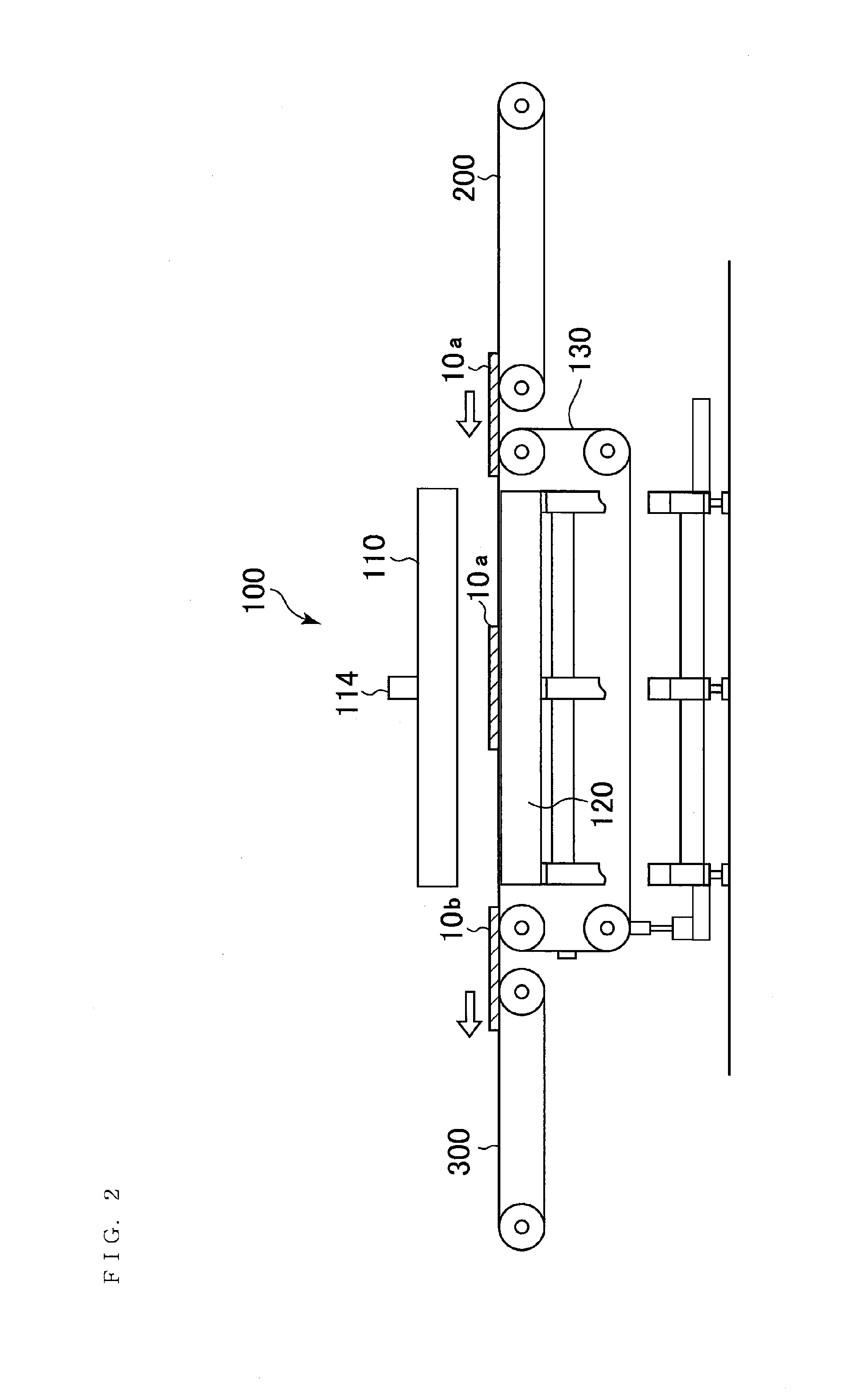

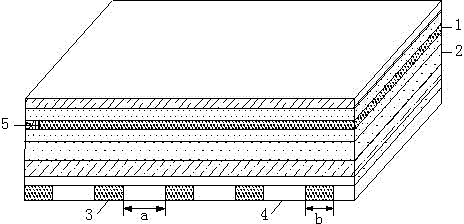

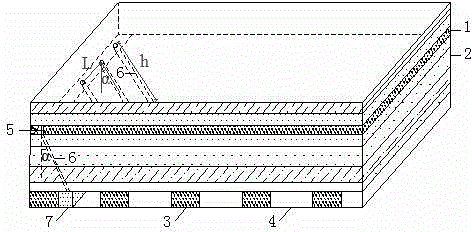

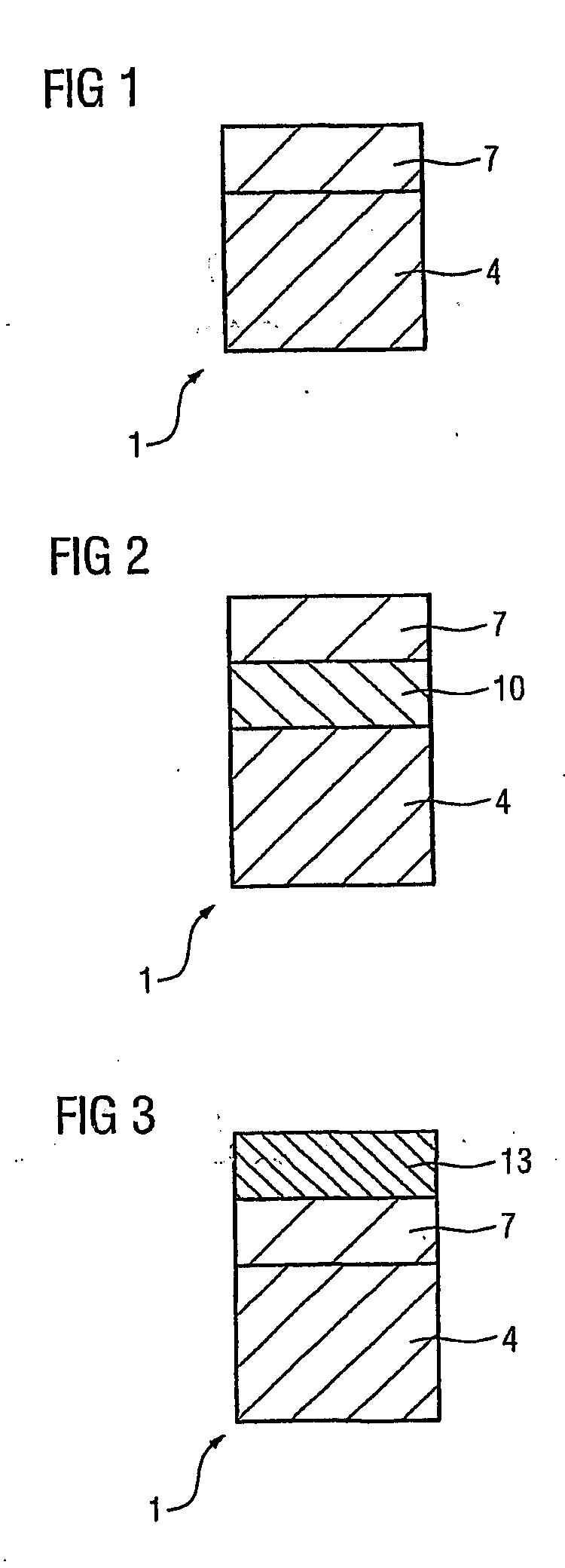

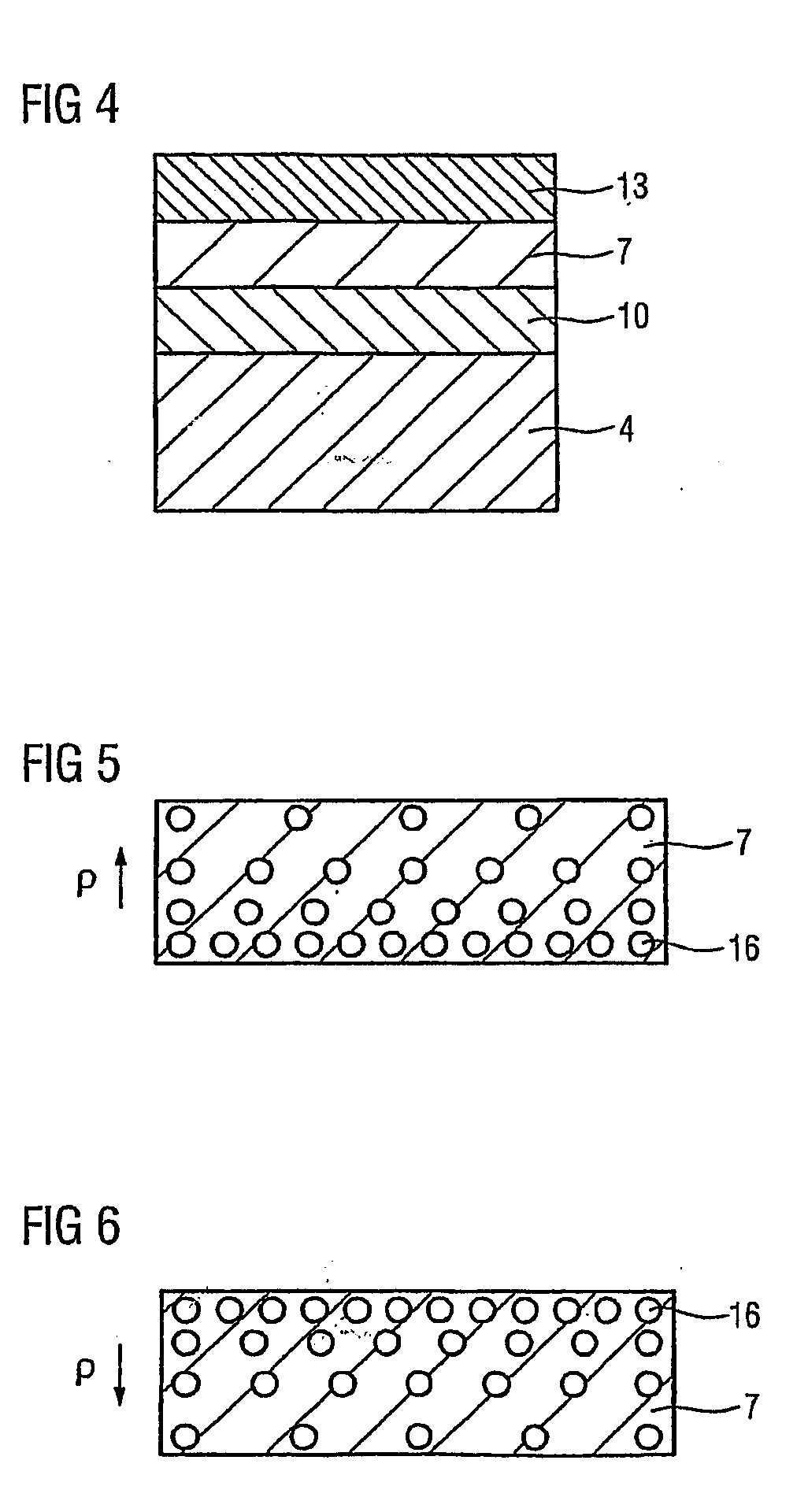

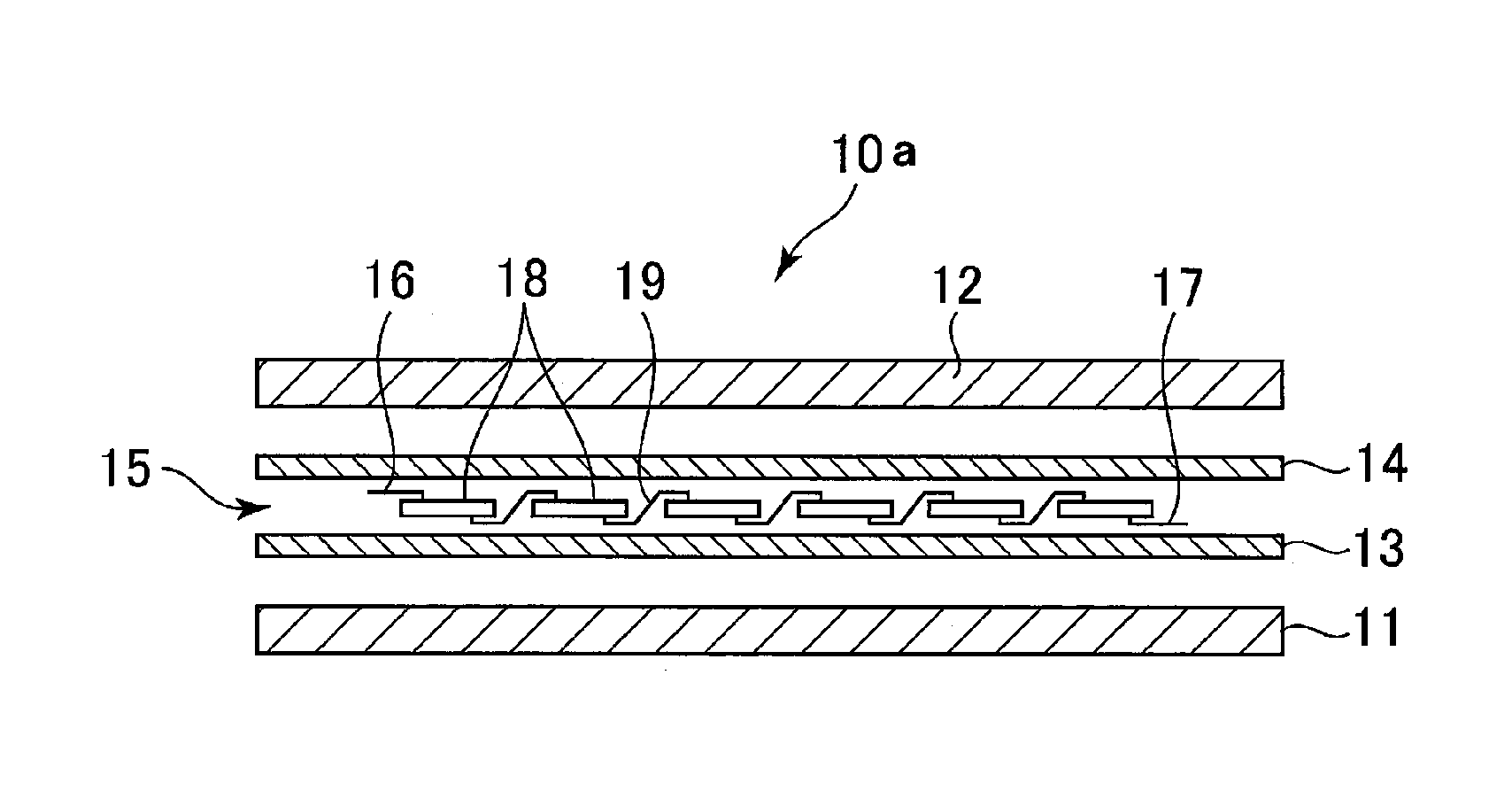

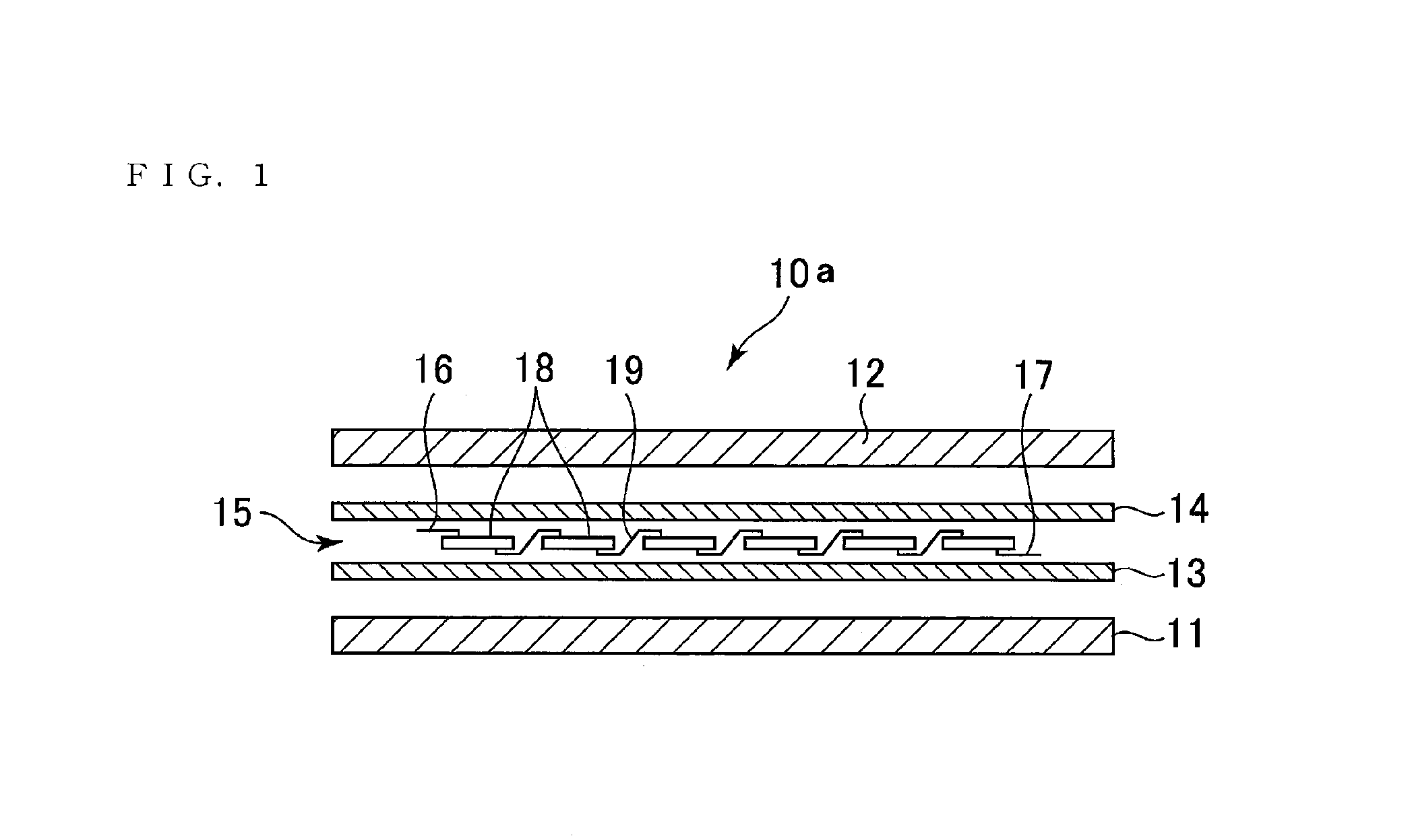

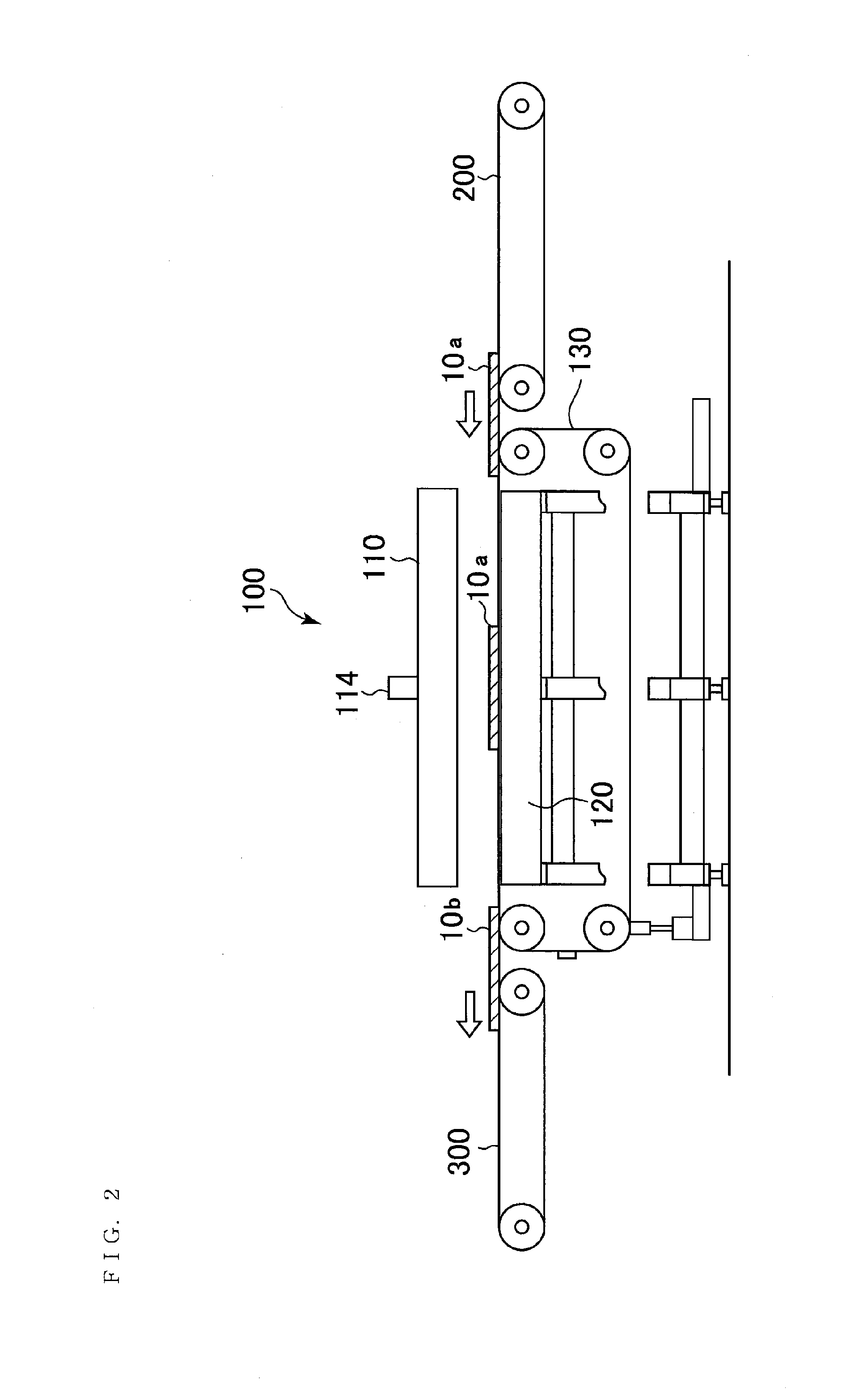

Diaphragm sheet, method for manufacturing solar cell module using diaphragm sheet, and lamination method using laminator for solar cell module manufacture

InactiveUS8865505B2Increase productionIncrease productivityLaminationSemiconductor/solid-state device manufacturingElectrical batteryComputer module

The performances and durability of a diaphragm sheet of a solar cell laminator are enhanced, and a favorable lamination work is stably performed over a long period of time. In addition, by stably performing sufficient and uniform lamination over a long period of time, a high-quality module is stably manufactured over a long period of time.A solar cell module is manufactured by using a diaphragm sheet formed of a composition containing an ethylene-propylene-diene rubber (EPDM), which is low in creep deformation and high in durability against an organic peroxide and a silane coupling agent.

Owner:NISSHINBO MECHATRONICS

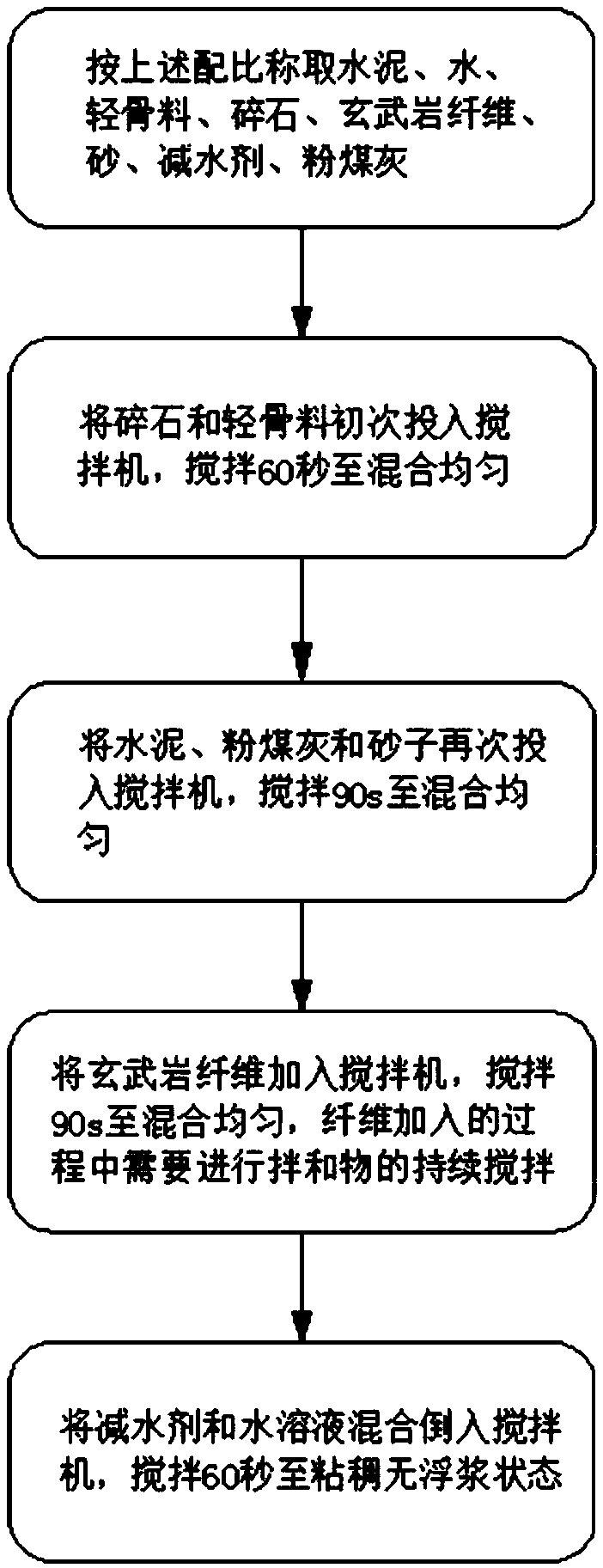

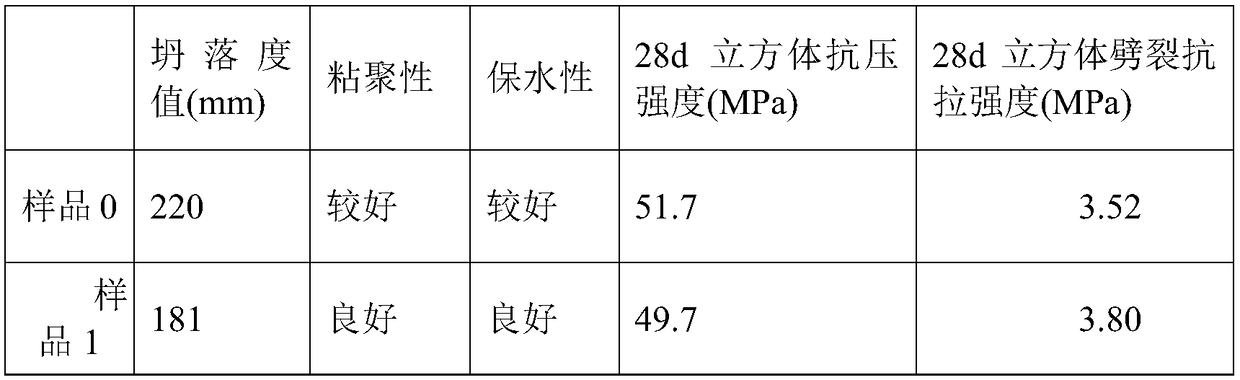

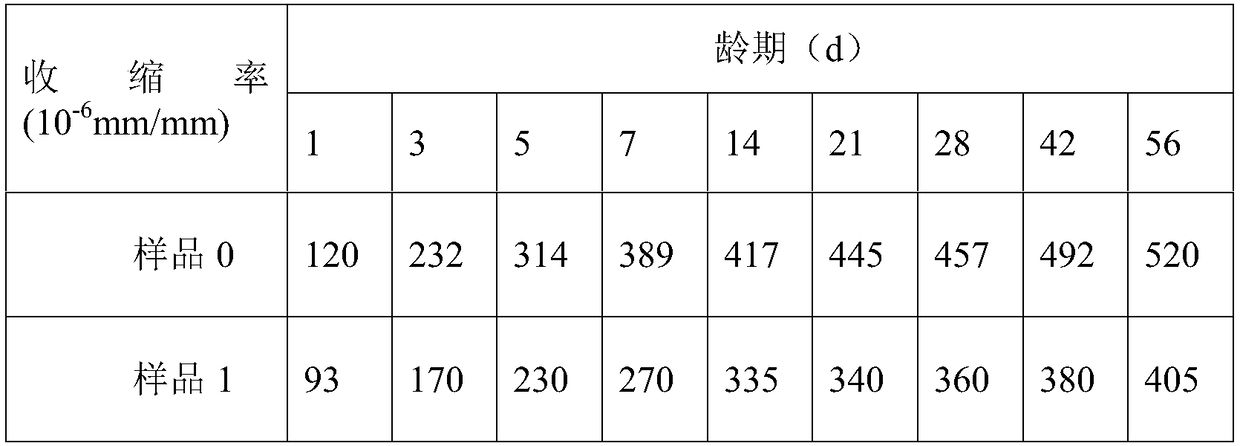

Shrinkage-reducing anti-cracking pavement cement concrete and preparing method thereof

Shrinkage-reducing anti-cracking pavement cement concrete and a preparing method thereof are disclosed. The cement concrete is prepared from water, cement, fly ash, basalt fibers, light aggregate, broken stone, sand and a water reducing agent in a mass ratio of (180-200):(400-410):(40-50):(2.65-5.3):(229-286):(465-559):(830-850):(4.1-4.5). The light aggregate is uniformly dispersed in the concrete, the concrete is not liable to crack, adhesive force between the fibers and cement slurry is high, microcrack development is slow, and the concrete has high fatigue resistance and tension resistance.

Owner:CHANGAN UNIV

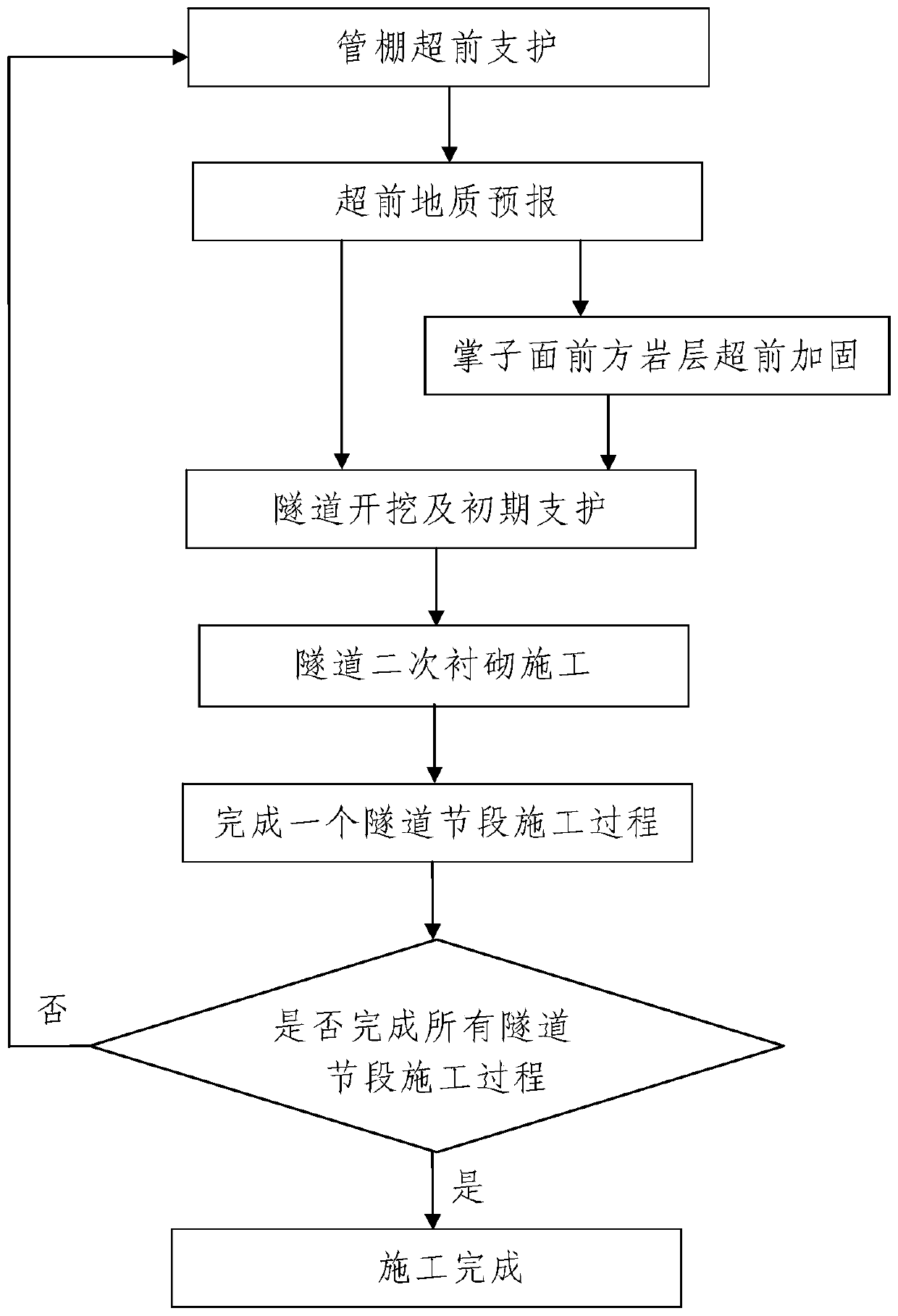

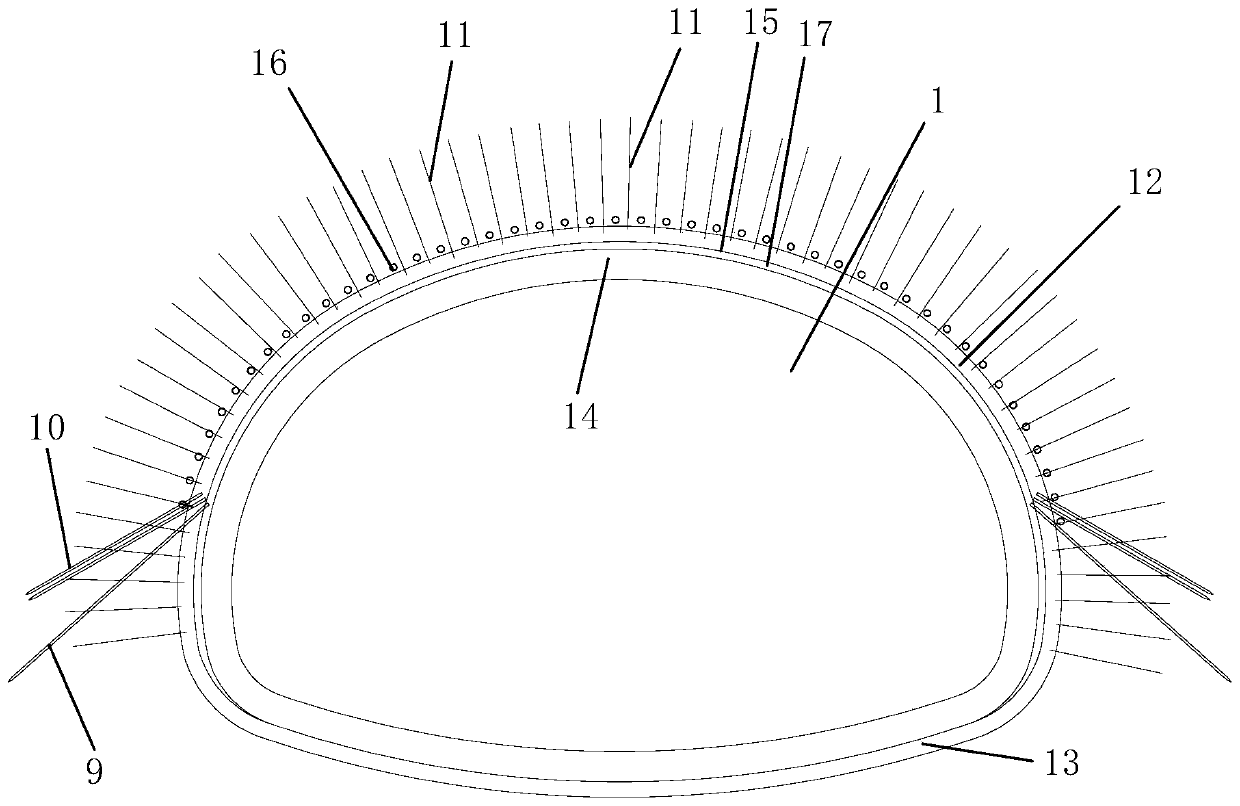

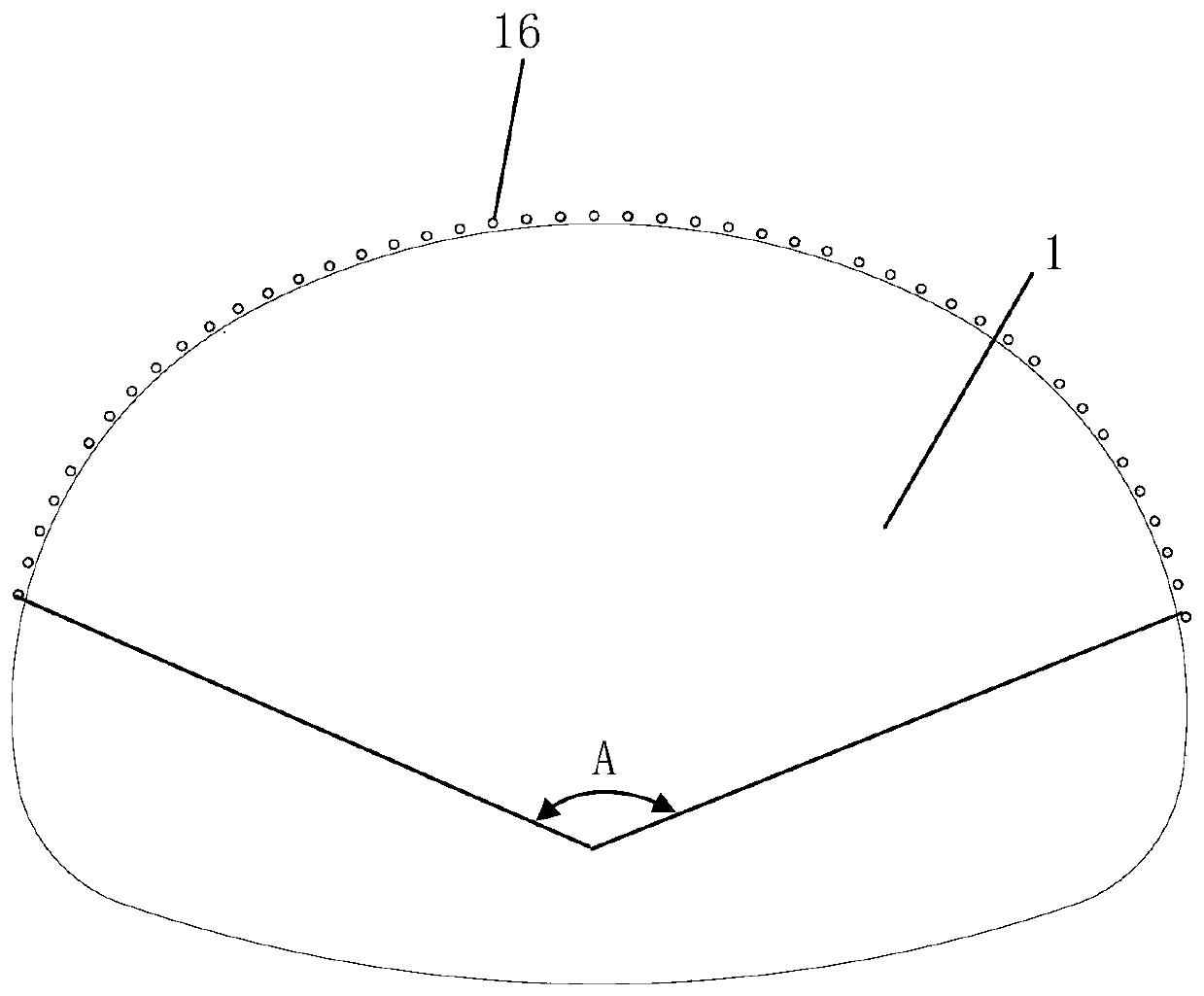

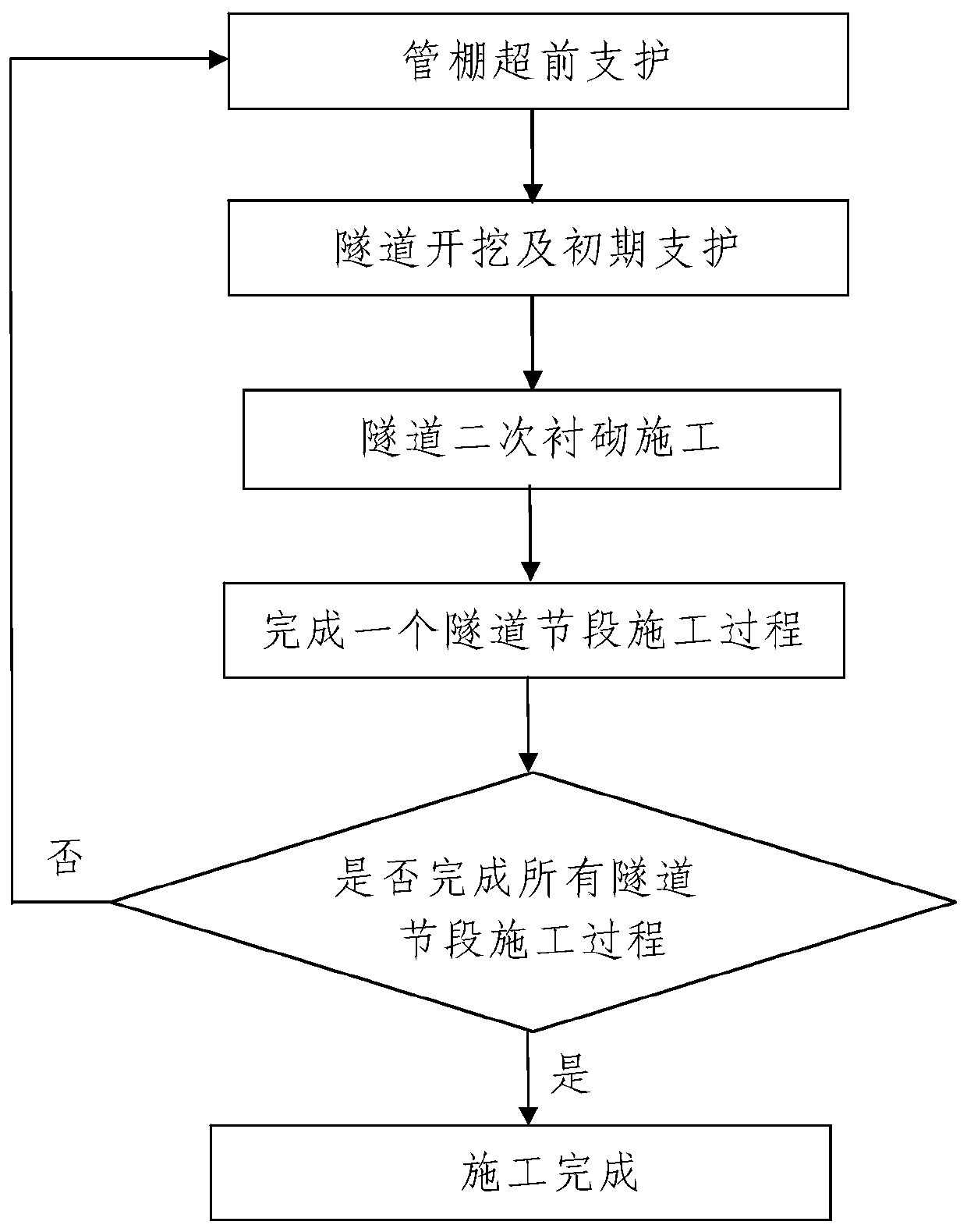

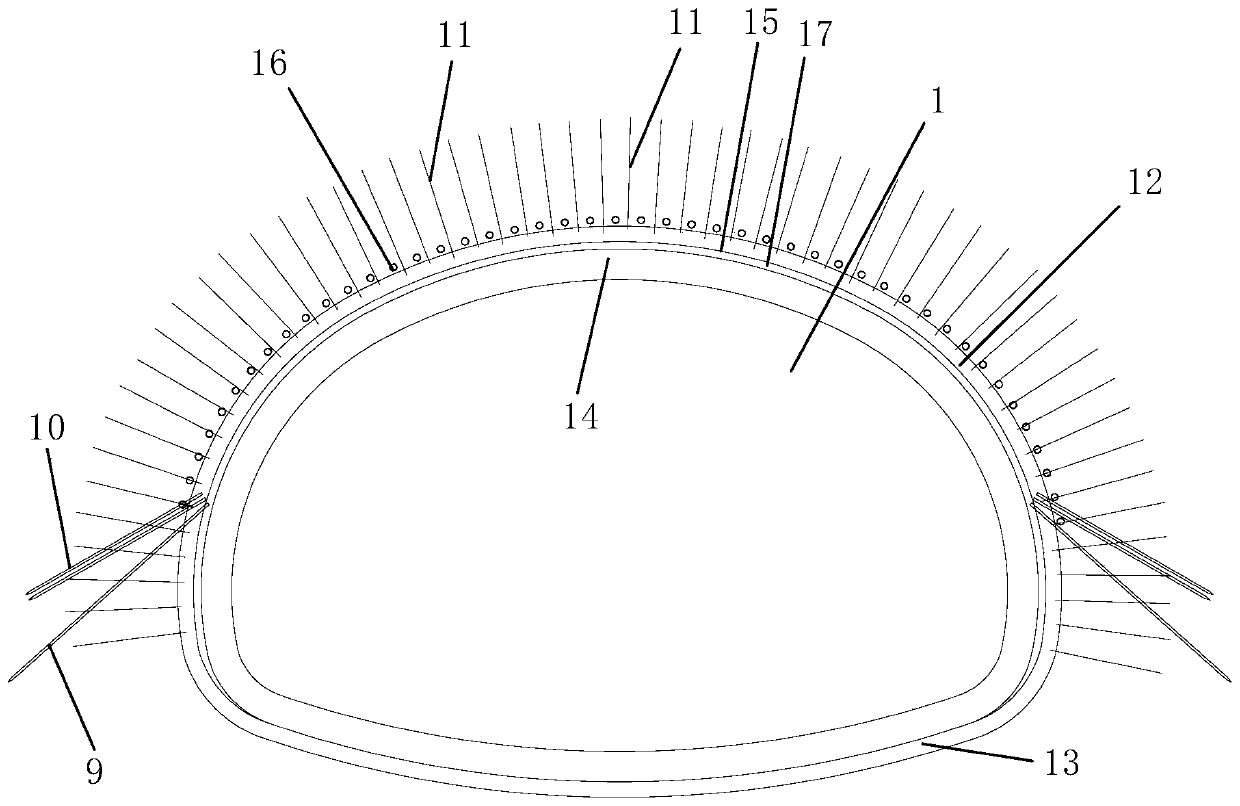

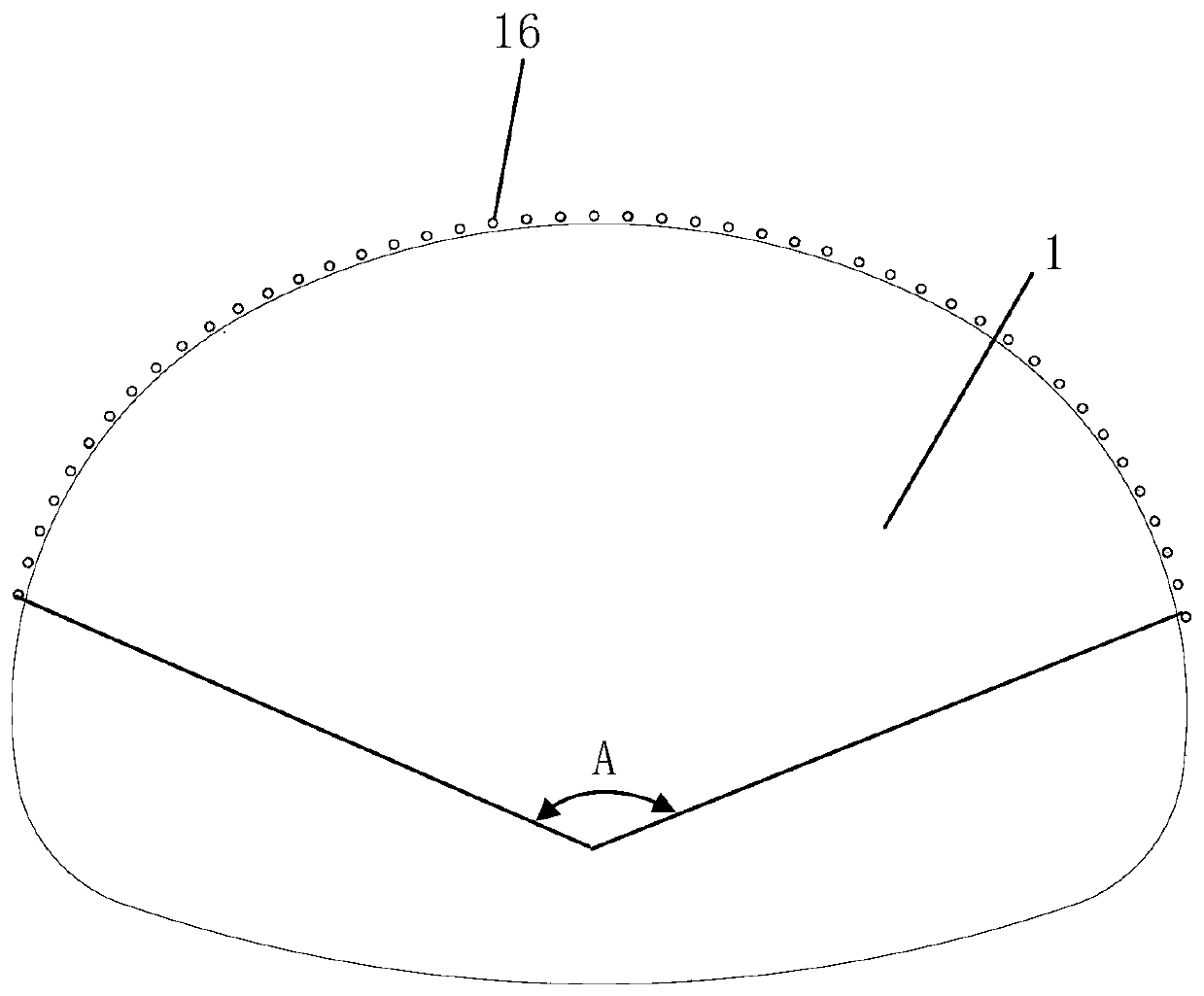

Stability control construction method of water-enriched soft rock tunnel passing through fault crushed zone

ActiveCN110905530AThe method steps are simpleReasonable designUnderground chambersDrainageSupporting systemArchitectural engineering

The invention discloses a stability control construction method of a water-enriched soft rock tunnel passing through a fault crushed zone. A plurality of tunnel segments in a construction tunnel are constructed respectively from back to front. During construction of any one of the tunnel segments, the method comprises the following steps: 1, performing pipe shed forepoling; 2, performing tunnel excavation and preliminary bracing: performing upper peripheral side cavity excavation and preliminary bracing, performing a reserved core soil area cavity excavation and preliminary bracing, excavatingthe cavity which is excavated firstly and performing preliminary bracing as well as excavating the cavity which is excavated secondly and performing preliminary bracing; and 3, performing tunnel secondary lining construction. The method is reasonable in design, simple and convenient in construction and good in use effect; before excavation, the upper cavity is subjected to forepoling by a self-drilling pipe shed and is excavated by a two-step method, so that the excavation efficiency is effectively improved; and meanwhile, an integral supporting system with a stable structure, which is formedby connecting a surrounding rock integral reinforced structure outside the cavity and a tunnel preliminary bracing structure and tunnel secondary lining, can effectively improve the stability of thetunnel structure and guarantee the later safety of the tunnel structure.

Owner:中铁二十局集团第二工程有限公司

High-energy consumption viscoelastic silicone oil cabin vibration damper

InactiveCN102494078AImprove energy consumptionIncreased creep deformationSpringsShock absorbersViscoelastic dampingHigh energy

The invention discloses a high-energy consumption viscoelastic silicone oil cabin vibration damper, which comprises an oil cylinder, silicone oil, a central shaft, a damping cup, a damping element, a support sheet for supporting the damping element and a spring for supporting the damping cup, wherein the support sheet is clamped at the reducing position of the oil cylinder; the spring is arranged between the damping cup and the bottom of the oil cylinder; the damping cup is fixedly connected with central shaft by a bolt; a damping cup oil opening is formed on the damping cup; a damping material in the damping element is a high-energy consumption viscoelastic damping material; and a tubular stiffener is inlaid in the high-energy consumption viscoelastic damping material to play a role in supporting and protecting the high-energy consumption viscoelastic damping material. According to the high-energy consumption viscoelastic silicone oil cabin vibration damper, the viscoelastic material with high energy consumption is used as the damping material, so that a vibration isolating and damping effect is improved greatly; the central shaft is separated from the damping element, so that the service life of the vibration damper is prolonged greatly; and the high-energy consumption viscoelastic silicone oil cabin vibration damper is very convenient to maintain in the later period.

Owner:常州市东海橡胶厂有限公司

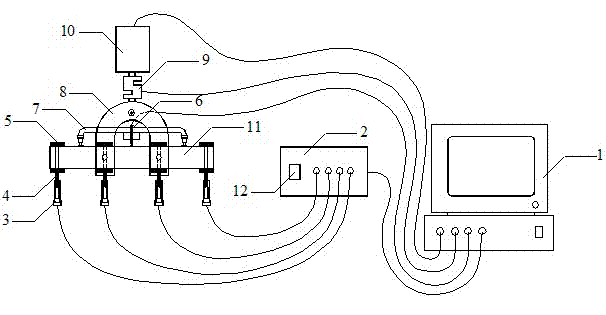

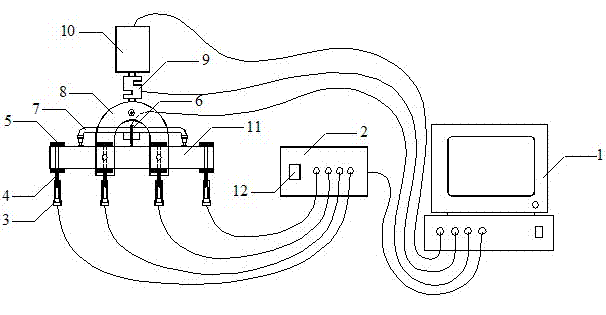

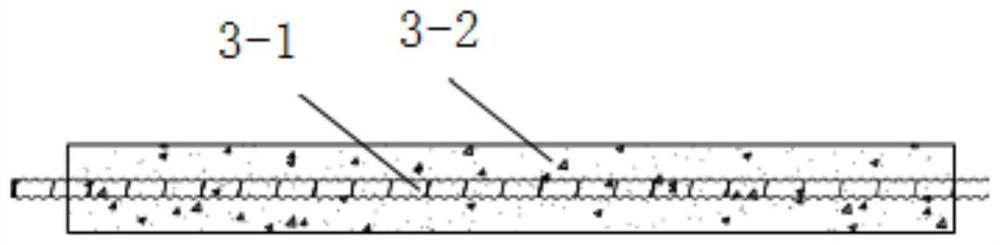

Test control system and method used for viscous-elastic material bending fatigue test

ActiveCN102359908ARealize real-time dynamic adjustmentReduced creep deformationMaterial strength using steady bending forcesComputer control systemClassical mechanics

The invention relates to a test control system and method used for a viscous-elastic material bending fatigue test. The test control system comprises a testing member (11), a computer control system (1), a clamping control device and an adjusting device, wherein the clamping control device is connected between the testing member (11) and the computer control system (1); and the adjusting device is used for adjusting the clamping force magnitude of the clamping control device on the testing member and connected between the clamping control device and the computer control system. In the invention, a bending stiffness modulus value of a viscous-elastic material measured in real time is obtained through the data collection function of a computer system, converted into an electric signal according to proportions, the adjusting device is controlled by the electric signal to adjust the current magnitude of the clamping control device and further adjust the clamping force of the clamping control device. The test result is true and reliable.

Owner:GUANGDONG GT TECH ROAD MATERIAL TECH CO LTD

Method for constructing water-rich weak surrounding rock tunnel crossing fault broken belt

ActiveCN110924959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringRock tunnel

The invention discloses a method for constructing a water-rich weak surrounding rock tunnel crossing a fault broken belt. The method comprises the following steps that firstly, construction is carriedout on a plurality of tunnel sections in a construction tunnel from front to rear, and when any tunnel section is constructed, the construction method comprises the following steps that 1, advanced support is carried out on a pipe shed; 2, tunnel excavation and initial support are carried out, wherein upper peripheral side hole excavation and initial support are carried out, reserved core soil area hole excavation and initial support are carried out, first hole excavation and initial support are carried out firstly and thereafter second hole excavation and initial support is carried out; and3, tunnel secondary lining construction is carried out. The method has the beneficial effects that the design is reasonable, construction is easy and convenient, and the use effect is good; the self-drilling pipe shed is adopted to carry out advanced support on the upper hole body before excavation, and two-step method excavation is adopted, so that the construction efficiency can be effectively improved; meanwhile, the whole reinforcing structure of the hole peripheral rock, the tunnel primary support structure in holes and the tunnel secondary lining are connected to form an integral supportsystem with a stable structure, the stability of the tunnel structure can be effectively improved, and the safety of the later tunnel structure is ensured.

Owner:中铁二十局集团第二工程有限公司

Method of beside-pillar double-side partial-filling ascending re-mining overhead coal seam

ActiveCN104832175APlay a role of side protectionDegree of reductionUnderground miningSurface miningStress concentrationCoal pillar

The invention discloses a method of a beside-pillar double-side partial-filling ascending re-mining overhead coal seam. In the invention, on the basis of determining overhead coal seam mining feasibility and detecting distribution situations of a coal pillar group and a mined area group of a reamer-pillar remnant mining area, a beside-pillar double-side partial-filling method is employed for successively side-protecting the coal pillar group in the underlie reamer-pillar remnant mining area of the overhead coal seam and gradually mining the overhead coal resources. By means of the method, a beside-pillar double-side filling body formed in the mined area group can not only achieve a side-protecting effect on the reamer-pillar coal pillar group but also form a common bearing body therewith, thereby further reducing degree of stress concentration and creep deformation of the coal pillar group. The method can enhance long-term stability, can avoid local instantaneous unstability or domino-like unstable damage and finally can ensure safe mining of the overhead coal seam of the reamer-pillar remnant mining area.

Owner:TAIYUAN UNIV OF TECH

Use of a Thermal Barrier Coating for a Housing of a Steam Turbine, and a Steam Turbine

InactiveUS20090232646A1Good effectSmall operationSpecific fluid pumpsPump componentsEngineeringThermal barrier coating

The invention relates to the use of a thermal insulating layer for a housing of a steam turbine in order to even out the deformation behaviour of different components based on different heatings of the components.

Owner:SIEMENS AG

Preparation method of cylindrical box body with antifouling property for deep and open sea net cage

ActiveCN111657197AGood antifouling effectAntifouling effectiveElectroconductive/antistatic filament manufactureClimate change adaptationOpen seaHigh density

The invention provides a preparation method of a cylindrical box body with the antifouling property for a deep and open sea net cage. The method comprises the following steps of A, preparing an antifouling netting, which comprises three aspects of preparing a modified high-density polyethylene composite material, preparing an antifouling monofilament bundle and processing the antifouling netting;B, preparing an anti-abrasion netting from a polyamide netting coated with a polyurea coating; and C, preparing the cylindrical box body, which comprises three aspects of side net processing, bottom net processing and cylindrical box body processing. According to the cylindrical box body with the antifouling property for the deep and open sea net cage obtained by the preparation method, the antifouling property of the cylindrical box body can be greatly improved and the water resistance of the cylindrical box body and the attachment area of fouling organisms can be reduced on the premise of keeping the netting strength of a side net unchanged, fouling organism attachment of the cylindrical box body and net breaking fish escape accidents under severe sea conditions can be greatly reduced, and green development and modern construction of the deep and open sea net cage culture industry are realized.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for performing ascending re-mining on hollow coal bed by column with one completely-filled side

ActiveCN104775818APlay a role of side protectionDegree of reductionUnderground miningSurface miningCoalCoal pillar

The invention discloses a method for performing ascending re-mining on a hollow coal bed by a column with one completely-filled side. On the basis that the feasibility of ascending mining on a hollow coal bed is evaluated and the distribution of coal pillars and mined area in a pillar type mined area has been explored, a method by completely filling the single side of a column is carried out to protect the coal pillars in the pillar type mined area under the hollow coal bed, and thus the coal can be exploited gradually. The fillers, which are formed in the mined area and are near the columns, can protect the coal pillars and bear force together with the coal pillars, thus the stress concentration and creep deformation of the coal pillars are reduced, the stability of the coal pillars in the long term is enhanced, the local and instant disability is avoided or the domino-type destruction caused by disability is avoided, and thus the safe exploitation is guaranteed.

Owner:TAIYUAN UNIV OF TECH

Diaphragm sheet, method for manufacturing solar cell module using diaphragm sheet, and lamination method using laminator for solar cell module manufacture

InactiveUS20140120649A1Increase productionIncrease productivitySemiconductor/solid-state device manufacturingLaminationEngineeringSolar cell

The performances and durability of a diaphragm sheet of a solar cell laminator are enhanced, and a favorable lamination work is stably performed over a long period of time. In addition, by stably performing sufficient and uniform lamination over a long period of time, a high-quality module is stably manufactured over a long period of time.A solar cell module is manufactured by using a diaphragm sheet formed of a composition containing an ethylene-propylene-diene rubber (EPDM), which is low in creep deformation and high in durability against an organic peroxide and a silane coupling agent.

Owner:NISSHINBO MECHATRONICS

Production of concrete beam

A technology for preparing concrete beam includes such steps as providing shuttering boards, binding reinforcing bars, arranging prestressing corrugated pipe and twisted steel wires, pouring concrete, stretching, grouting, sealing anchor, ageing, stretching for external prestressing, grouting, sealing anchor, precise locating, and installing track or other functional parts.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

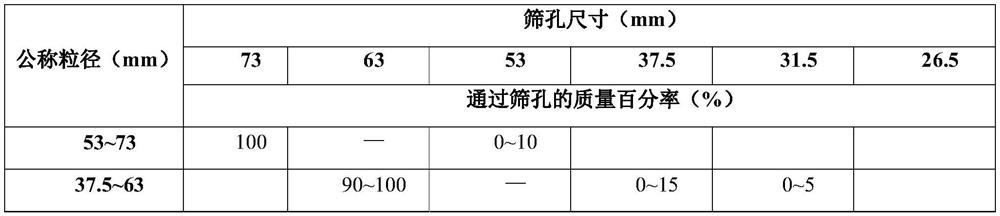

Construction method of large-particle-size cement regenerated base pavement structure

InactiveCN114032727AImprove carrying capacityPreserve local semi-rigidityIn situ pavingsCrushed stoneRoad surface

The invention relates to a construction method of a large-particle-size cement regenerated base pavement structure. The problems that an existing pavement has the defect of reflection cracks and is low in heavy load resistance, and a flexible base layer is prone to net cracks and sinking are solved. According to the technical scheme, the building material comprises a main aggregate, a filling material and a caulking material. The method comprises the following steps: paving a main aggregate, rolling the main aggregate, paving a filling material, uniformly mixing the filling material and the main aggregate, conducting rolling, spreading a caulking material, and conducting rolling and preserving for 7 days. The rebound modulus is about 1200 MPa, the main aggregate is large-particle-size broken stone, the nominal particle size of the main aggregate is 53-73 mm or 37.5-63 mm, the filling material and the caulking material adopt an on-site cement cold recycled asphalt surface layer milling material, the cement cold recycled asphalt surface layer milling material is formed by mixing an old road asphalt pavement structure layer milling material, cement and water in regeneration equipment, the maximum particle size of the cement cold recycled asphalt surface layer milling material is smaller than 16 mm, the continuous grading curve requirement is met, the cement dosage range is 5-12%, and the 7d unconfined compressive strength representative value is not lower than 3 Mpa.

Owner:西安长大公路养护技术有限公司

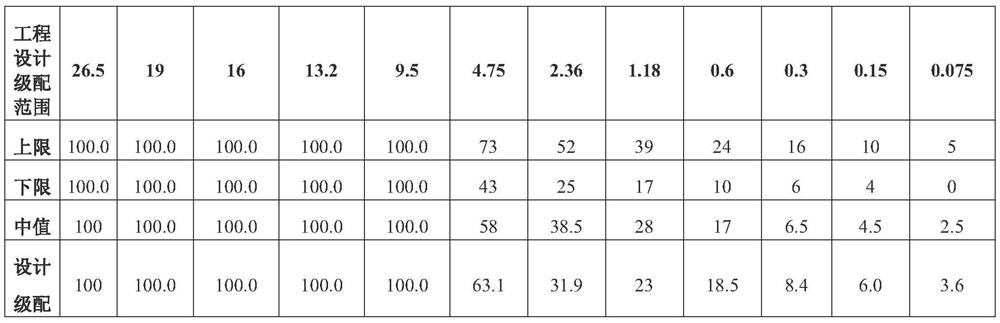

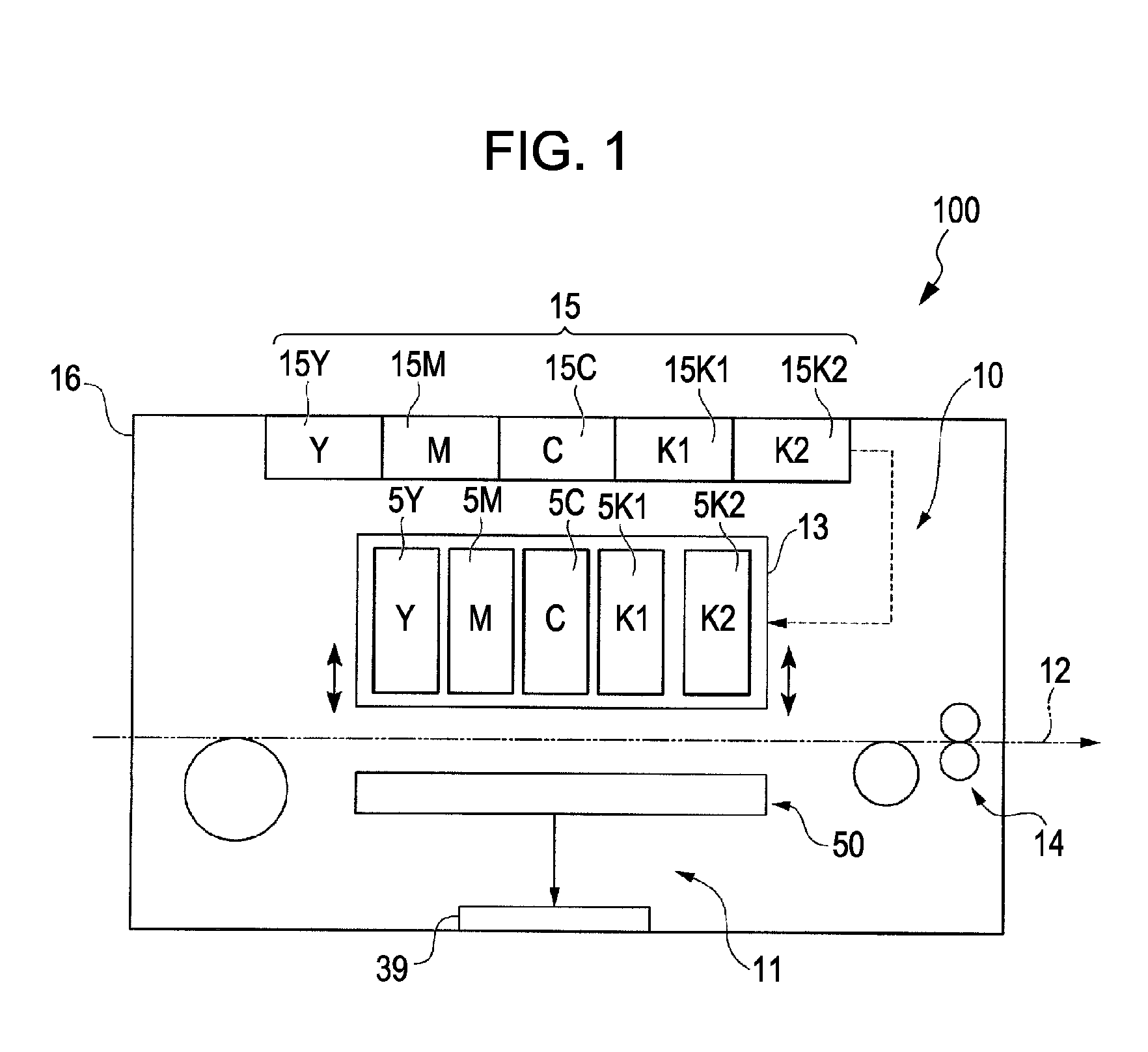

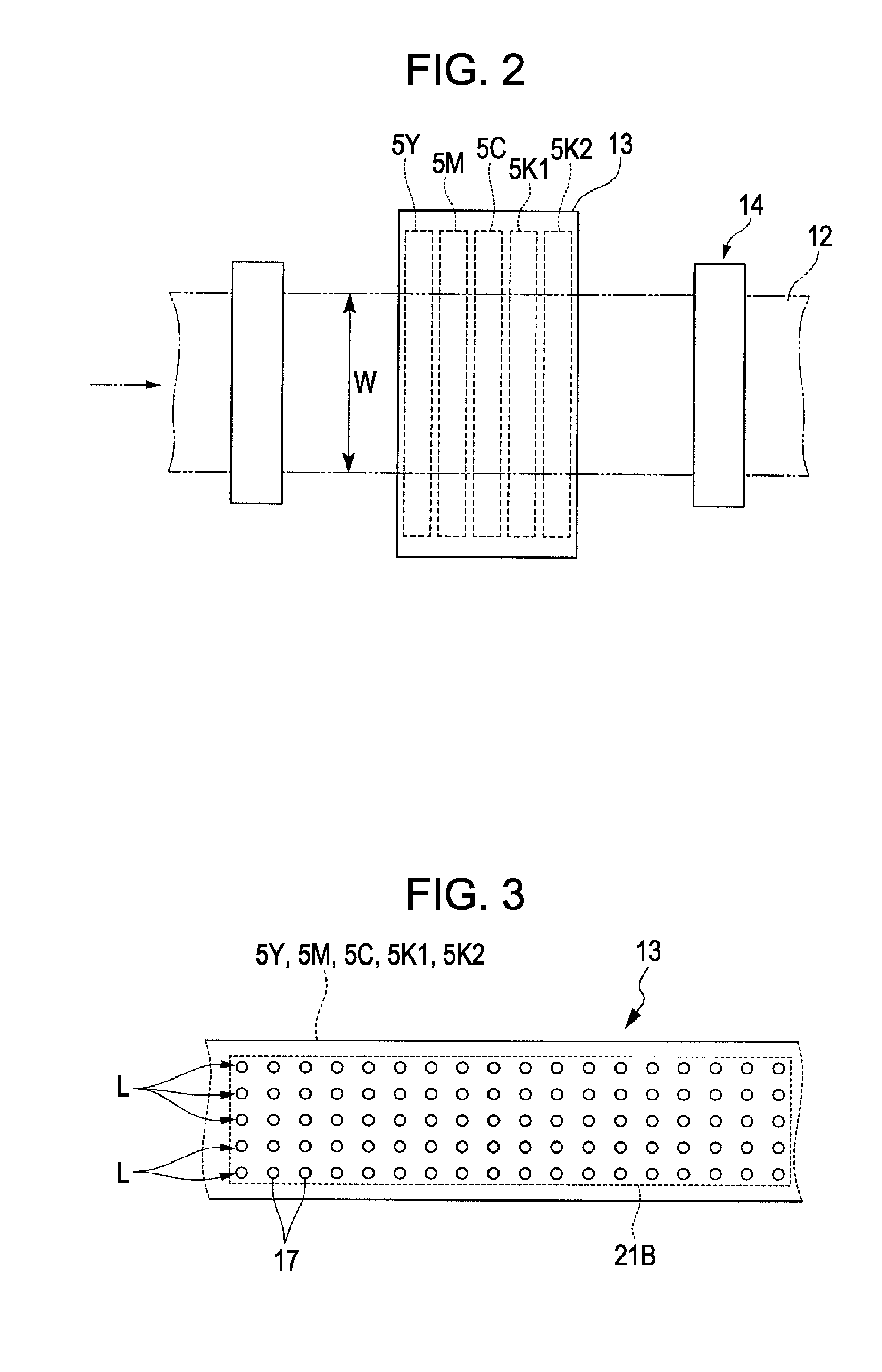

Fluid ejecting apparatus

A fluid ejecting apparatus includes an ejection head having an ejection surface with a nozzle region and a capping device that contacts the ejection surface. The capping device includes first and second contact members held by a cap body. When the first contact member contacts the ejection surface, a surface of the first contact member surrounds the nozzle region. The second contact member is formed in a closed frame-shape to be disposed outside a surface of the first contact member opposite the surface of the first contact member. The cap body includes first and second suction ports. The first suction port decompresses a first space formed between the first contact member and the ejection surface when the capping device contacts the ejection head. The second suction port decompresses a second space formed between the second contact member and the ejection surface when the capping device contacts the ejection head.

Owner:SEIKO EPSON CORP

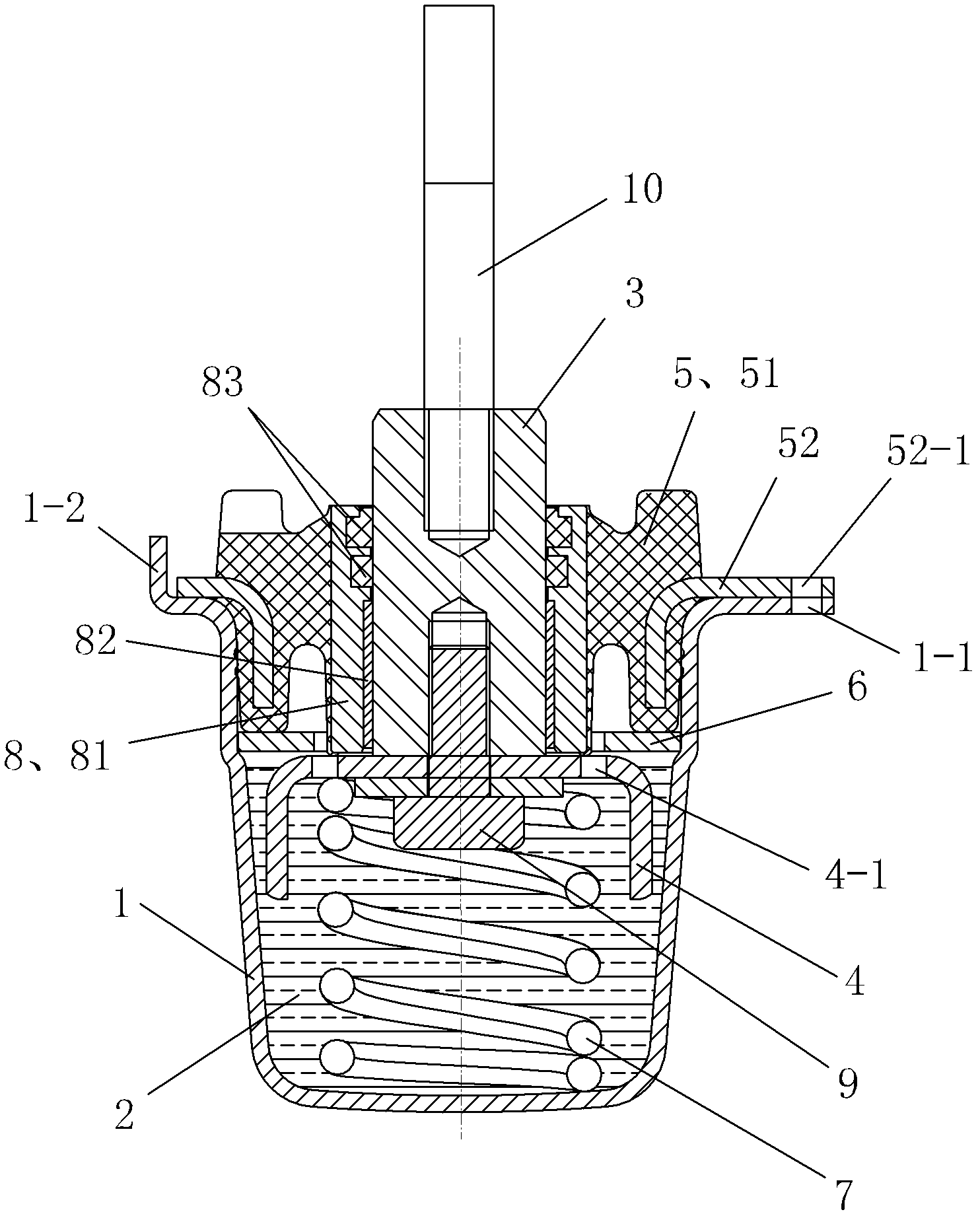

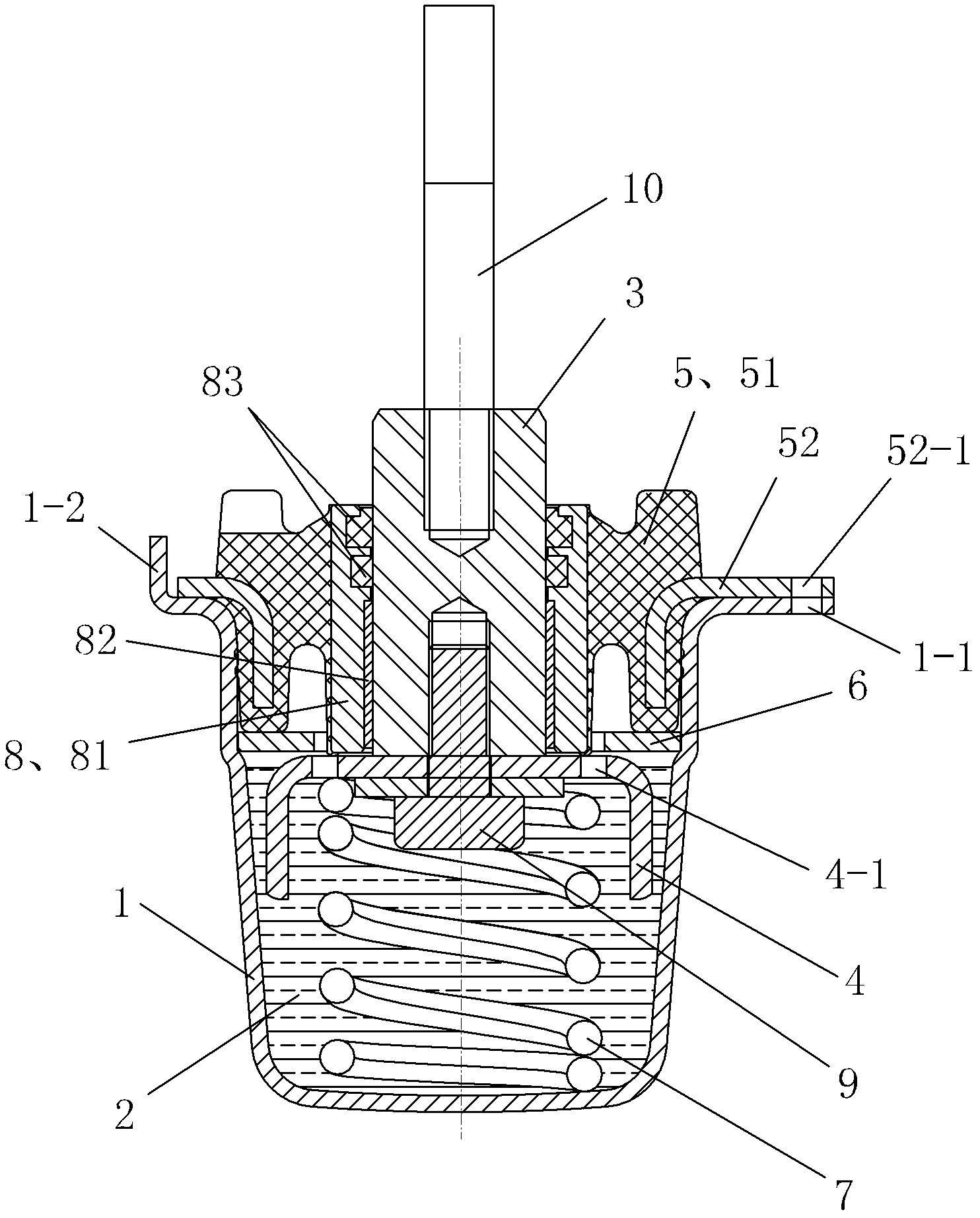

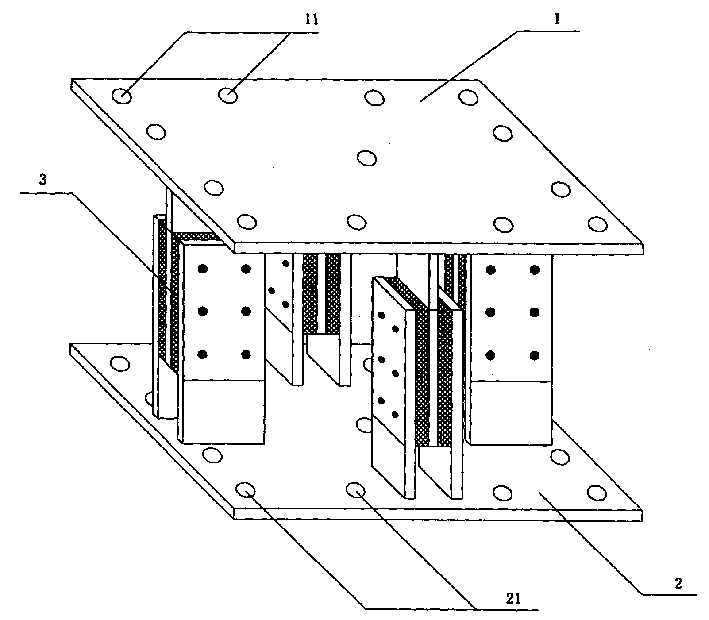

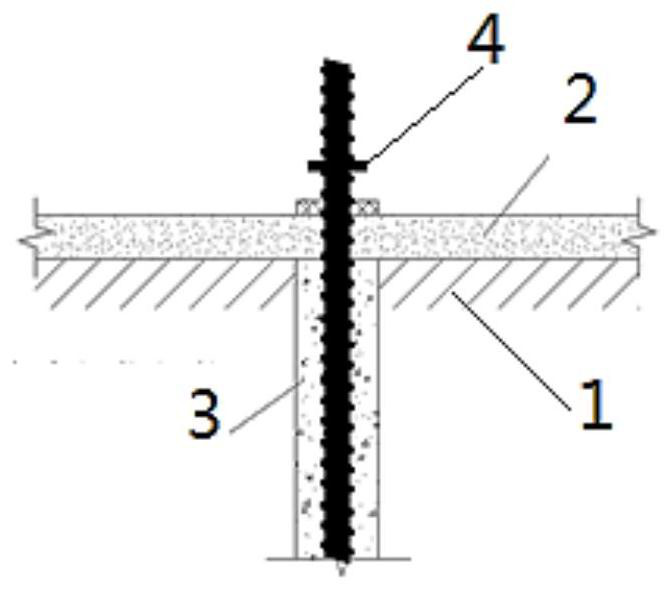

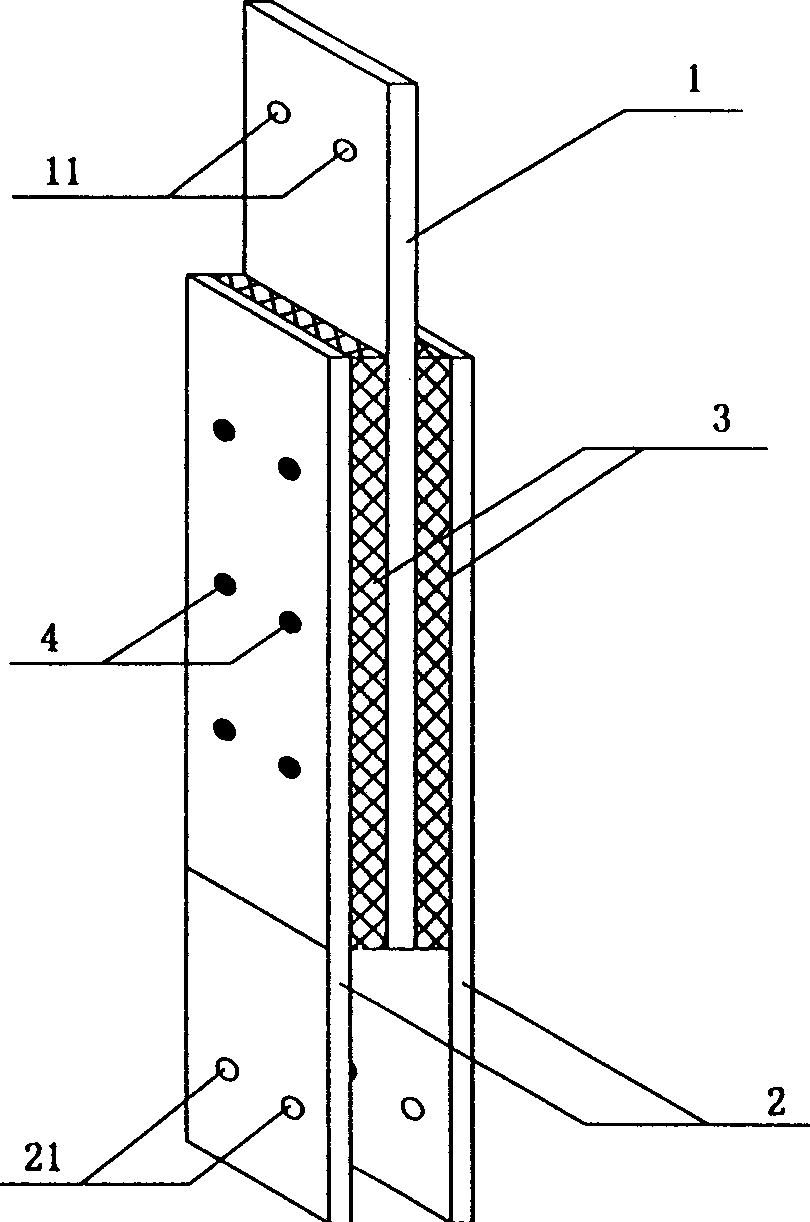

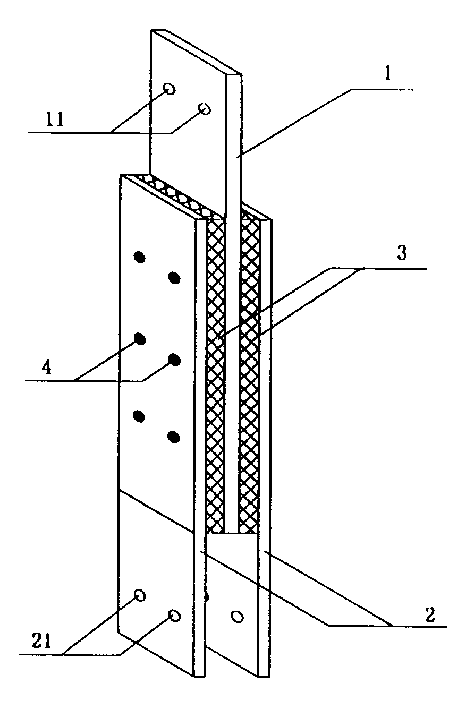

Vertical earthquake isolating equipment for engineering structure

InactiveCN1096534CImprove the resistance to vertical earthquake forceSufficient vertical stiffnessShock proofingEngineeringEngineering structures

The vertical seismic isolation device for engineering structures is a device used for anti-seismic, seismic isolation and shock absorption in civil engineering. The device is composed of a vertical damper, an upper horizontal steel plate and a lower horizontal steel plate. The upper part of the vertical damper and the The upper horizontal steel plate is connected, the lower part of the vertical damper is connected with the lower horizontal steel plate, and the upper horizontal steel plate and the lower horizontal steel plate are respectively provided with bolt holes.

Owner:SOUTHEAST UNIV

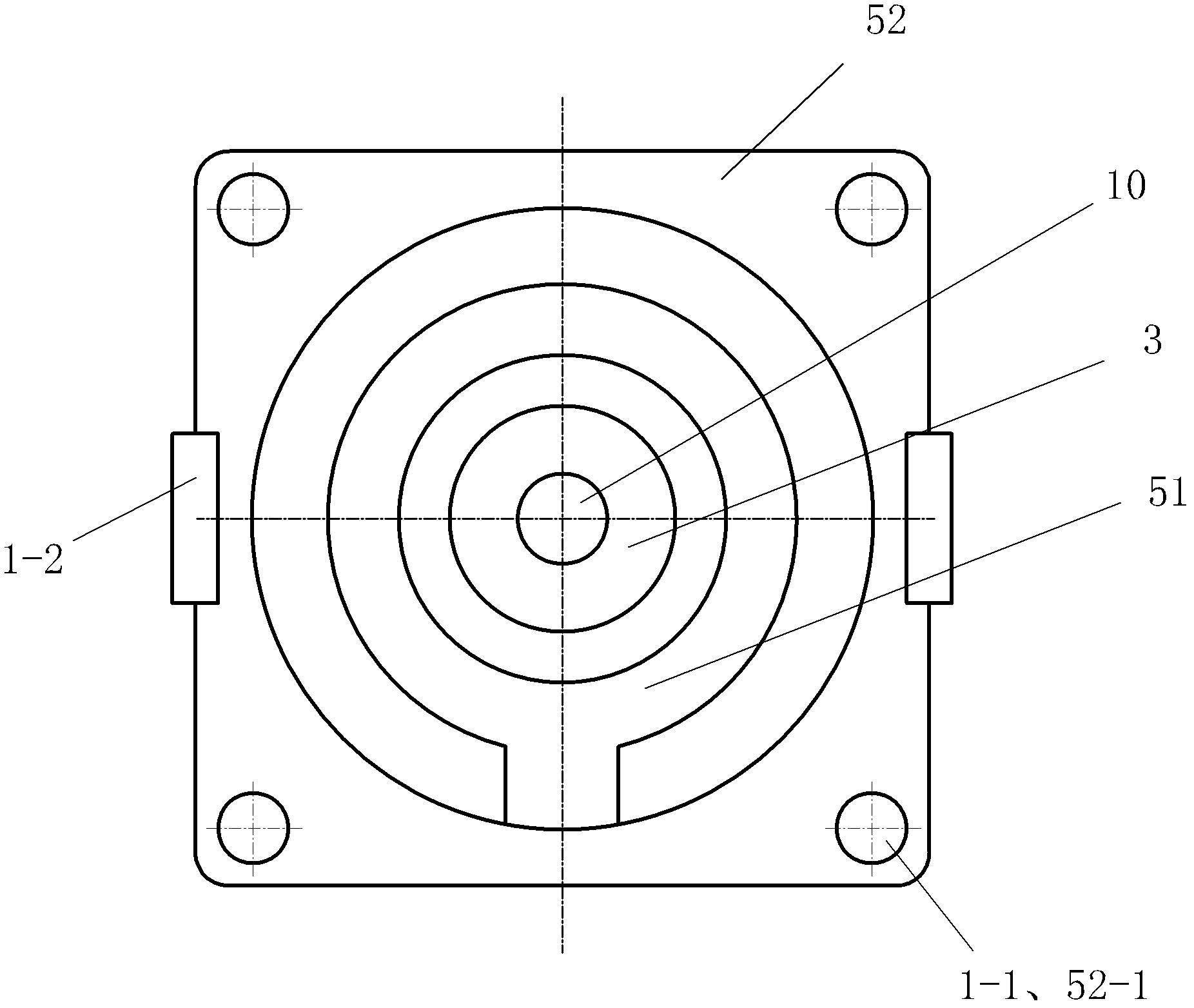

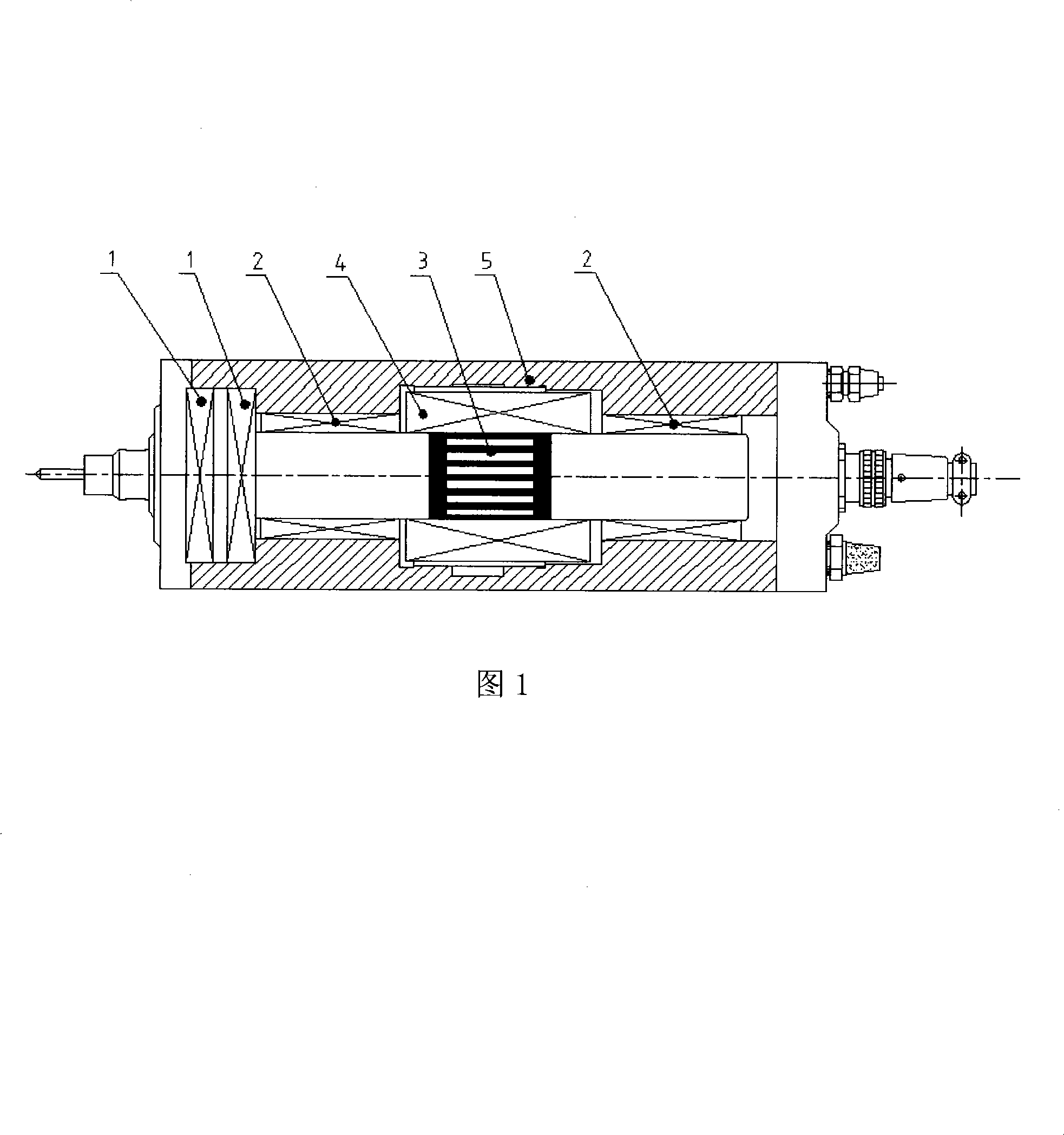

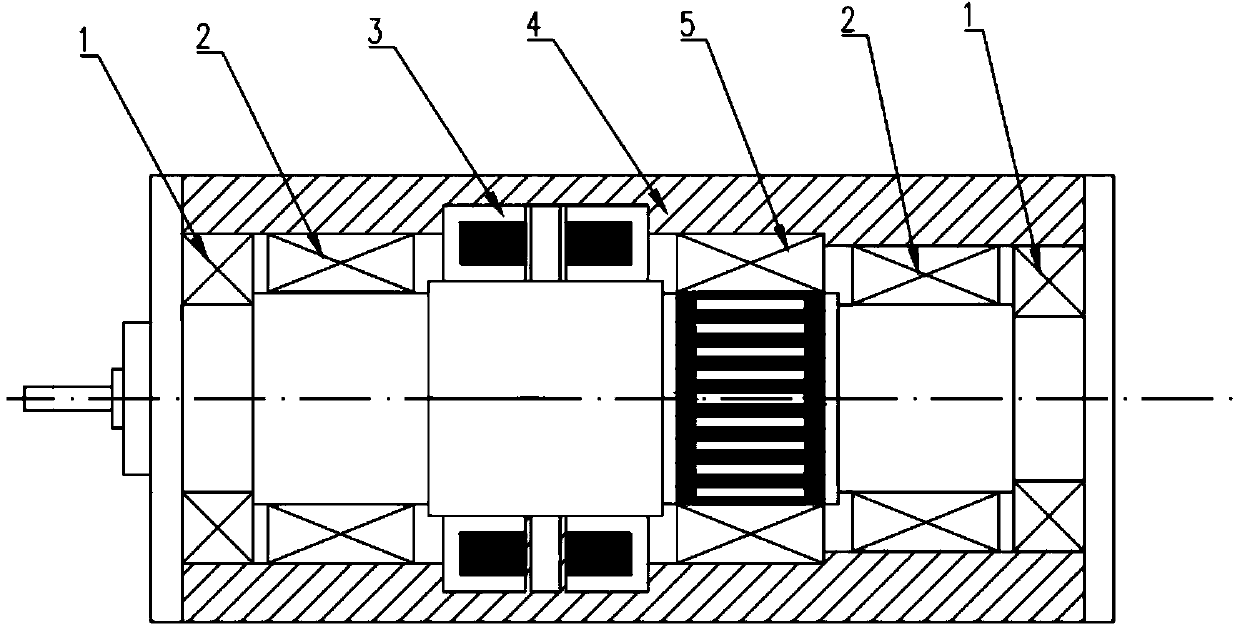

An electric spindle design adopting air static pressure anti-thrusting and air static pressure radial bearing support

InactiveCN101217241ACompact structureEasy to installAsynchronous induction motorsMechanical energy handlingThrust bearingEngineering

The invention relates to an electric spindle design adopting an aerostatic pressure anti-thrust and an aerostatic pressure radial bearing support. According to the outline dimension limit and the stiffness requirement of the electric spindle, the front end inside a shell (5) of the electric spindle is centrally provided with two aerostatic pressure anti-thrust bearings (1), thus leading the space utilization to be optimized and the structure to be compact, and at the same time the two aerostatic pressure anti-thrust bearings lead a supply air line convenient to centralize and install and provides the needed radial stiffness for a rotor-rotating shaft integrated shaft system (3). The two sides of a stator (4) are symmetrically provided with an aerostatic pressure radial bearing (2) so as to support the rotor-rotating shaft integrated shaft system, reduce the vibration of the shaft system (3) and ensure the radial stiffness. The rotor-rotating shaft integrated shaft system makes the squirrel-cage bar of the rotor of the electric motor and the rotating shaft into the integrated structure and the corresponding position of the stator arranged in the middle section and the shell of the electric spindle, that is the position of the squirrel-cage bar, adopts copper alloys directly welded in a groove of the integrated shaft system so as to reduce the creep deformation of the squirrel-cage bar, reduce the vibration value of the integrated shaft system and improve the power rate and the structural strength.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Prestressed unbonded anchor rod steel bar, anchor rod and construction method

PendingCN111691417AImprove safety and reliabilityIncreased durabilityProtective foundationExcavationsPre stressPlastic film

The invention provides a prestressed unbonded anchor rod steel bar. The prestressed unbonded anchor rod steel bar comprises a main steel bar body serving as a basic force bearing structure, the main steel bar body is a finish rolling steel bar or a common steel bar, an anti-corrosion grease layer is arranged on the surface of the main steel bar body, and a plastic film sleeve is arranged outside the anti-corrosion grease layer. The number of the main steel bar bodies is one or one to five, and the main steel bar body is of a main steel bar structure formed by connecting segmented reinforcing steel bars through connecting nuts. According to the prestressed anchor rod prepared from the unbonded anchor rod steel bars, the unbonded main steel bars are directly cast into the prestressed anchorrod through concrete, or the lower end of the prestressed anchor rod is connected with grouting bodies or concrete of expanded heads; the grouting body or concrete of the expanded head is internally wrapped with a steel reinforcement framework or a bag, wherein the steel reinforcement framework comprises one or more steel reinforcements, a steel reinforcement cage with a common structure and a variable-diameter steel reinforcement cage; an anti-floating tensile anchor rod of a concrete prefabricated pipe column is prepared when a steel reinforcement cage and a variable-diameter steel reinforcement cage of a common structure are adopted; one or more reinforcing steel bars are connected by using one or more reinforcing steel bar anchor rod reinforcing steel bars; and one or more reinforcingsteel bars or reinforcement cages are still arranged in the center of the bag.

Owner:安徽俊力建设有限公司

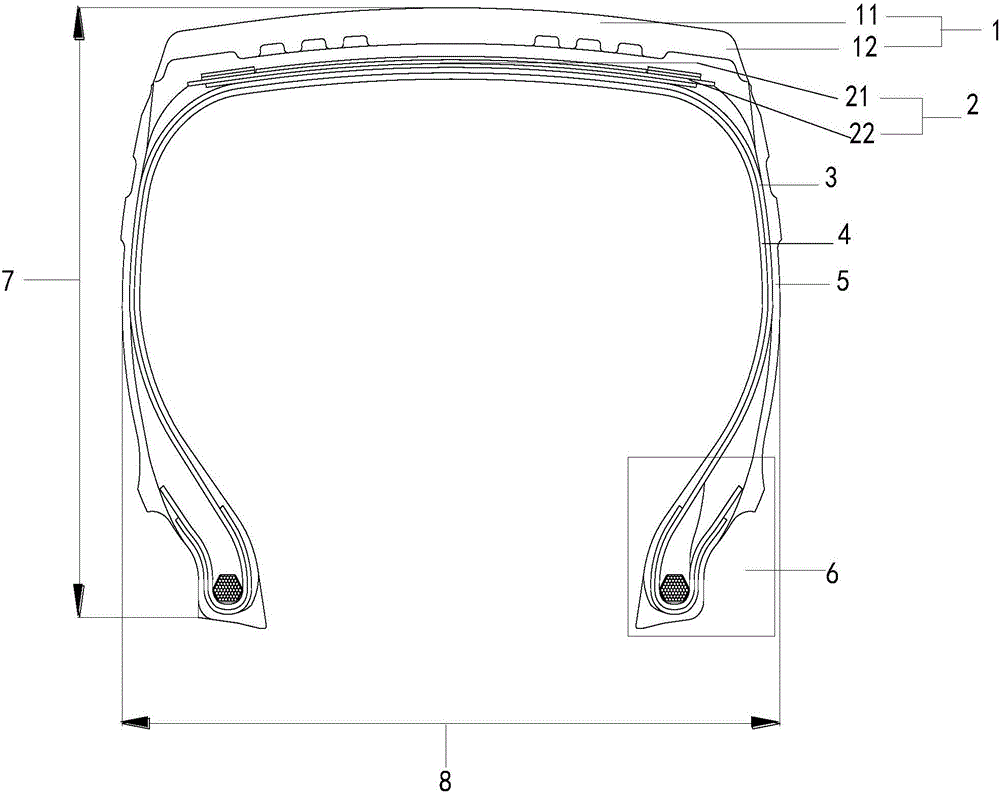

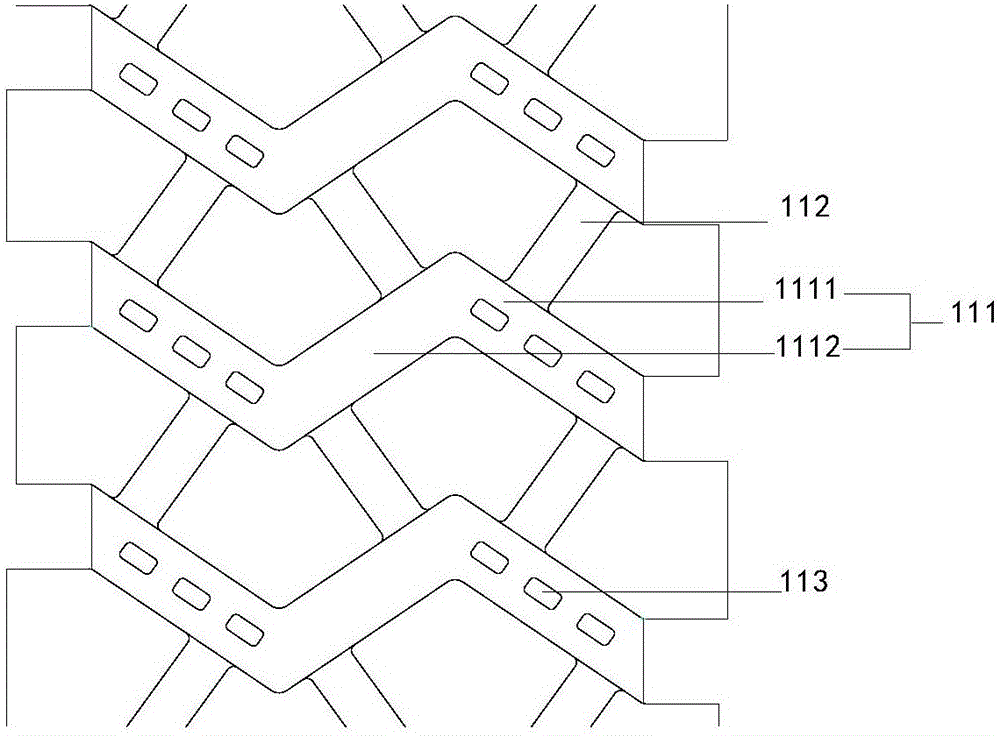

Military full steel tubeless radial tire

InactiveCN106739838AReduce rolling noiseReduced creep deformationPneumatic tyre reinforcementsTyre beadsWear resistantNoise reduction

The invention provides a military full steel tubeless radial tire, and belongs to the field of a tire. Through matching noise reduction patterns with the ultrahigh-intensity framework, the sub opening support performance is improved. By aiming at the condition that the military tire can effectively reduce the tire rolling noise, the bearing performance, the tire crown rigidity, the sub opening support performance, the wear-resistant performance and the safety performance of the tire can be improved. A tire surface (1) of the military full steel tubeless radial tire comprises a tire crown (11) with noise reduction patterns and a tire shoulder (12) connected with the tire crown (11); the noise reduction patterns comprise peripheral distribution variable-pitch transverse pattern grooves (111); a plurality of bulges (113) are formed in the bottom of the transverse pattern grooves (111); support bulges (51) are arranged in the peripheral direction of the position, near a sub opening (6), of the tire side (5).

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Explosive modified by grafting in-situ hyperbranched polyurethane as well as preparation method and application of explosive

ActiveCN109761729ALow solvencySolve incomplete coverageNon-explosive/non-thermic compositionsFiltrationSolvent

The invention discloses explosive modified by grafting in-situ hyperbranched polyurethane as well as a preparation method and application of the explosive. The preparation method comprises the following steps: (1) adding explosive into a Tris deionized water buffering solution, stirring and dispersing; (2) adding dopamine, uniformly stirring, carrying out a self-polymerization reaction of dopamineon the surface of the explosive, washing by using deionized water after the reaction is completed, carrying out suction filtration and vacuum drying to obtain the pre-modified explosive with dopaminepolymerized on the surface; and (3) adding the pre-modified explosive into butyl acetate, dispersing, increasing temperature, adding A2 type monomers and dibutyltin dilaurate, reacting, then washingby using butyl acetate, carrying out suction filtration, then transferring the explosive to a second solvent, dropwise adding dibutyltin dilaurate, gradually adding a monomer mixture and reacting, washing for four times after the reaction is completed, carrying out suction filtration, and drying to obtain the explosive modified by grafting in-situ hyperbranched polyurethane. The method improves the property of the surface of the explosive and enhances bonding strength between a bonding agent and an explosive interface.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

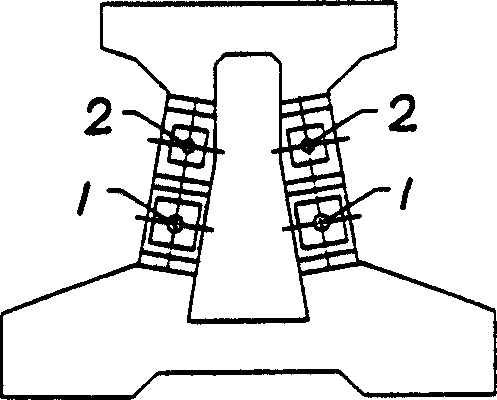

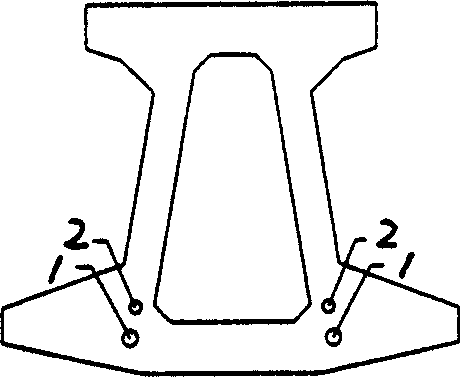

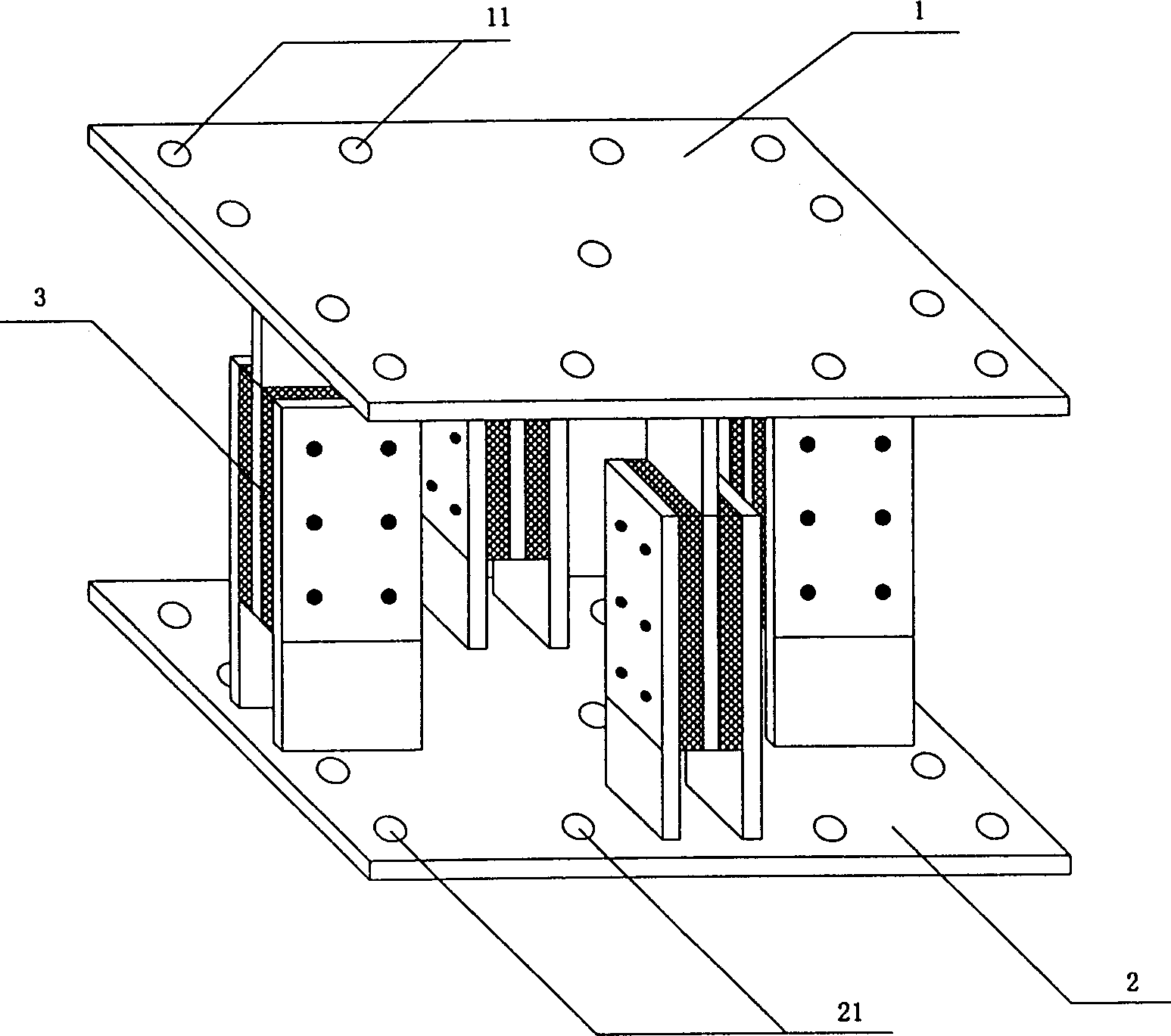

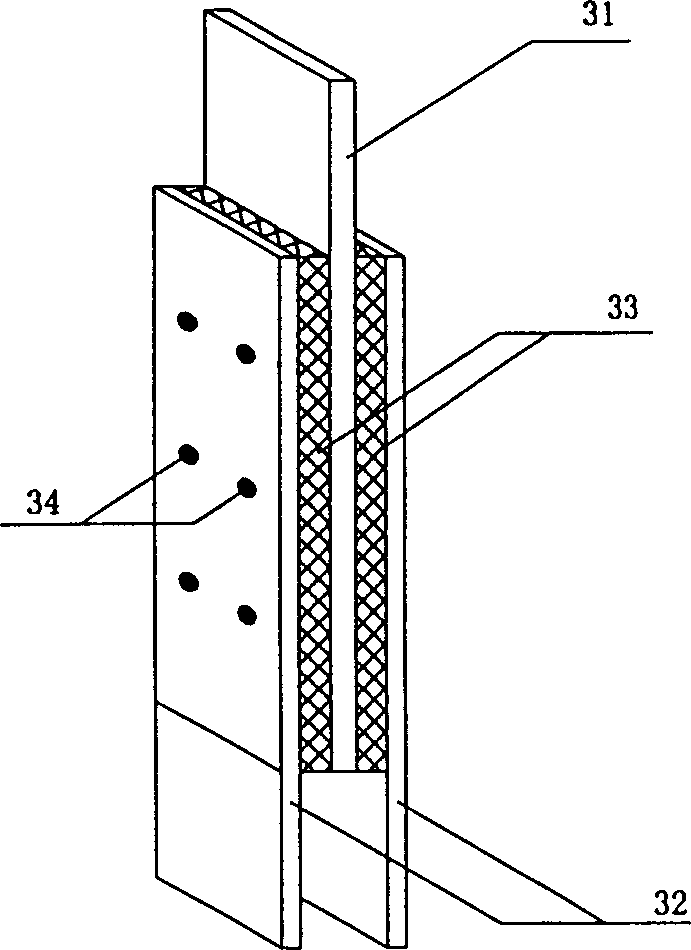

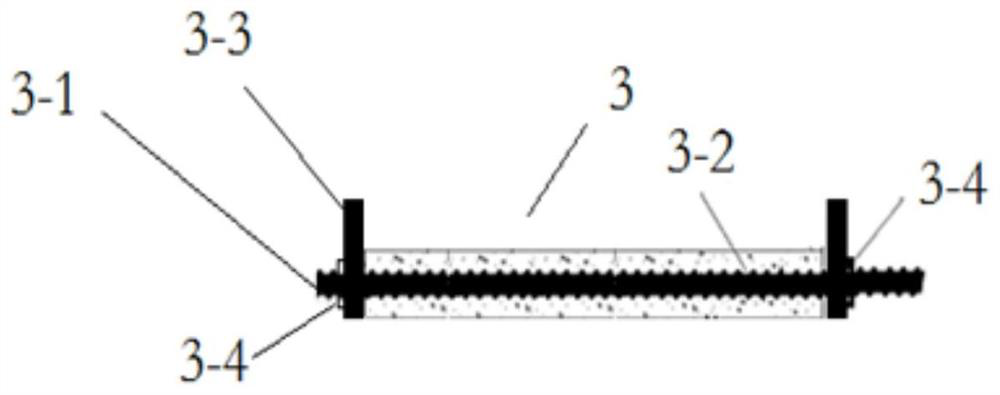

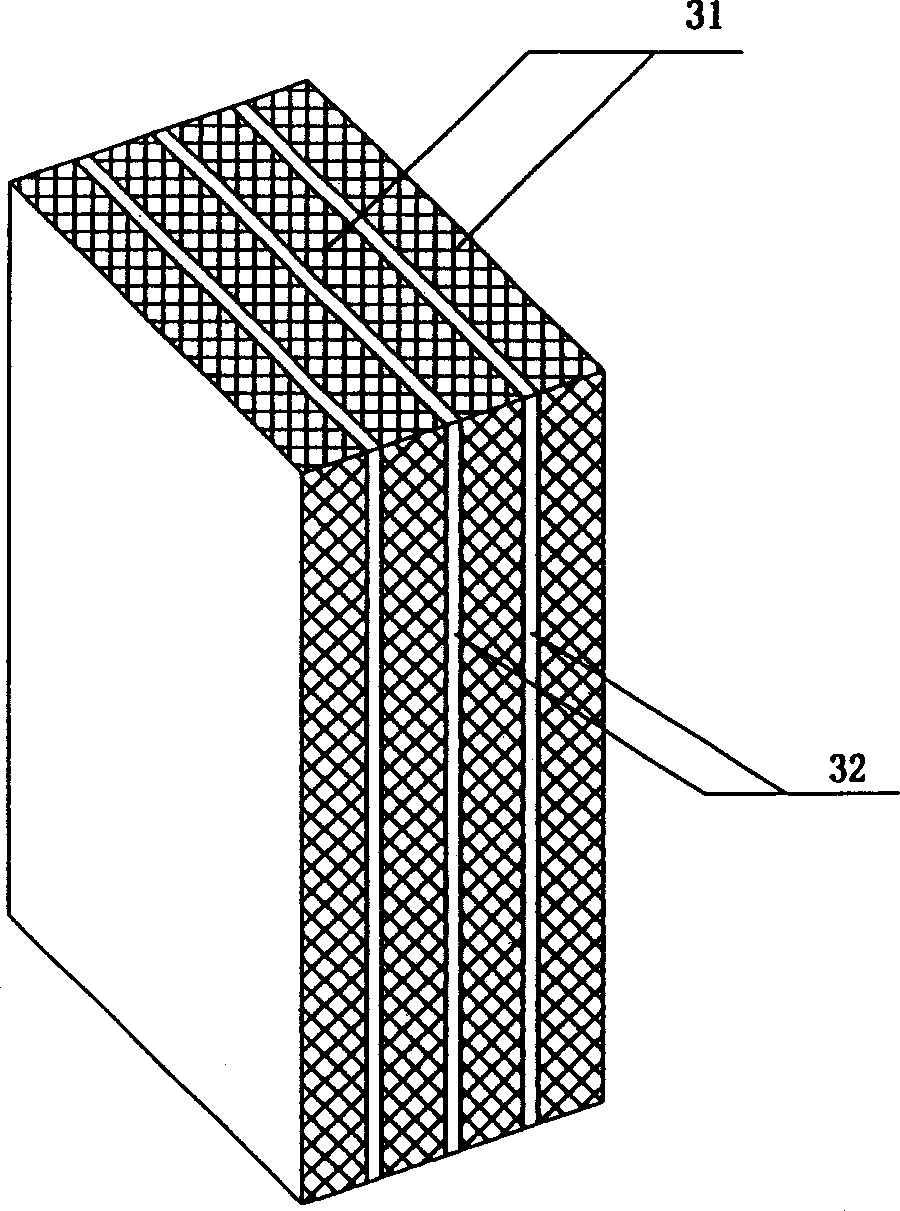

Engineering structure lead pin viscoelastic damper

InactiveCN1126847CLow costImprove seismic reliabilitySolid based dampersShock proofingViscoelastic dampingAdhesive

The engineering structure lead pin viscoelastic damper is a kind of anti-seismic and shock-absorbing device used in civil engineering, especially a device suitable for indoor and outdoor, and suitable for protecting engineering structures during large and small earthquakes. The damper is a secondary stress type damper, which is composed of a middle steel plate 1, two side steel plates 2, a damping layer 3 that is stressed in the second stage, and a lead pin 4 that is stressed in the first stage. The damping layers are respectively bonded on the sides of the damping layer, and the steel plates on both sides are respectively bonded on the outer sides of the damping layer. Lead pin holes are respectively set on the middle steel plate, the steel plates on both sides and the damping layer, and the lead pins are passed through the lead pin holes. The steel plate, the steel plates on both sides, and the damping layer are connected as a whole; the shear force on the lead pin is divided into two stages. When the shear force is not too large, it is the first stage. When reaching the lead pin layer section, it enters the second stress stage, at this time, the shear force borne by the lead pin no longer increases and is a constant value, and the remaining shear force is all borne by the damping layer.

Owner:SOUTHEAST UNIV

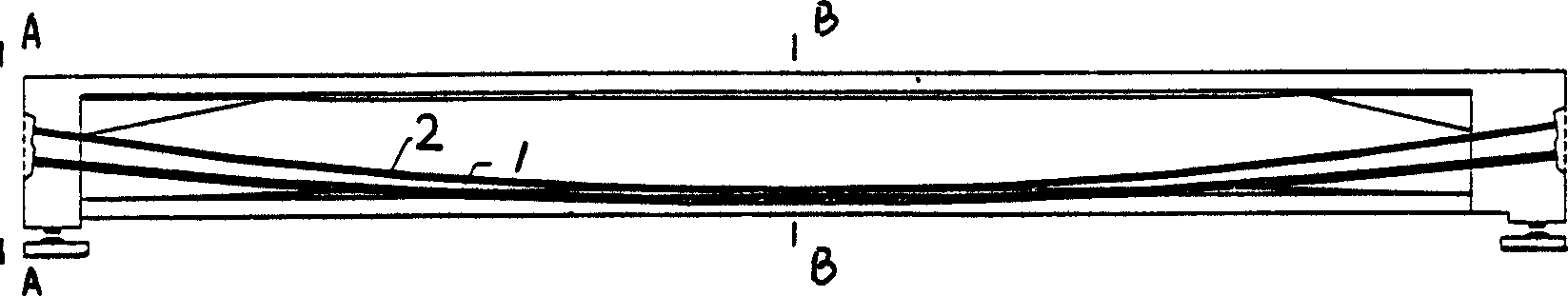

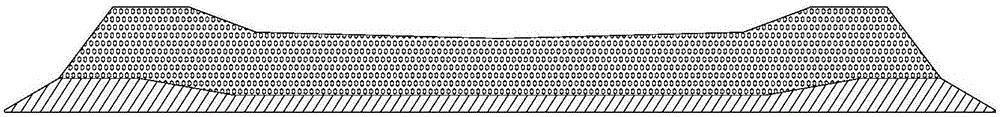

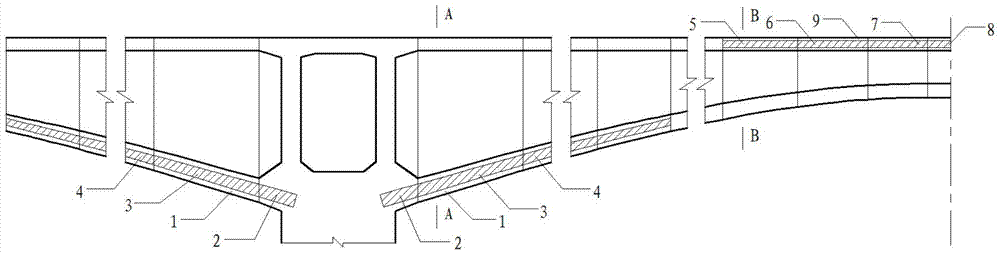

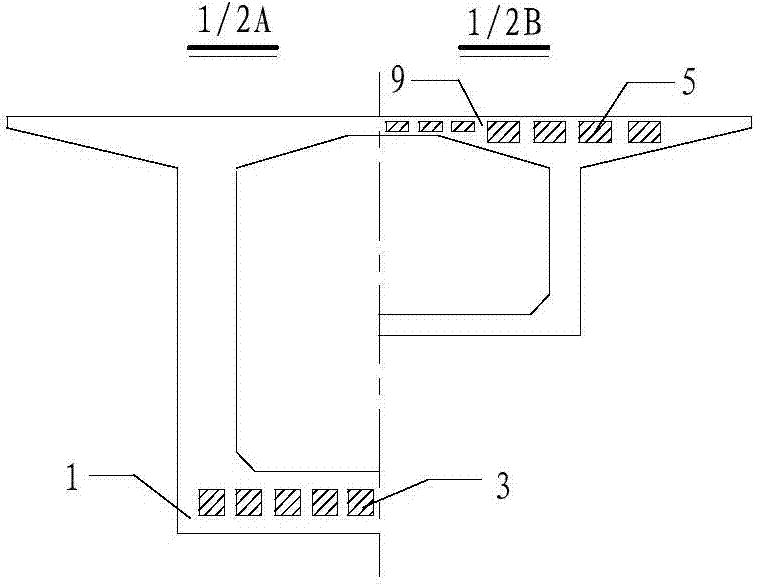

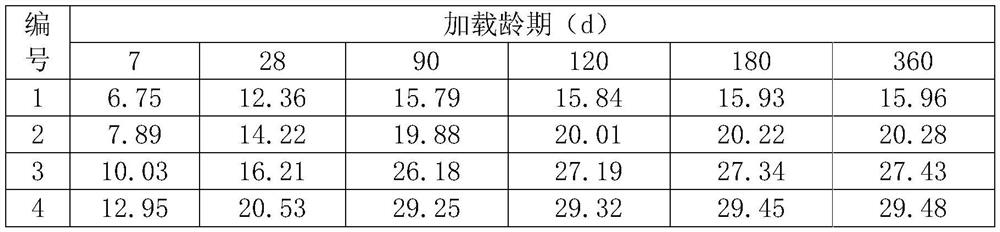

Technology for solving long-term downwarping of large-span PC box girder bridge through prefabricated reactive powder concrete (RPC) columns

ActiveCN104746416ACreep coefficient reductionSmall creep deformationBridge materialsAgricultural engineeringRigid frame

The invention relates to a technology for lowering long-term downwarping of a large-span PC rigid frame bridge by adding prefabricated Reactive Powder concrete (RPC) Columns. The technology includes the steps of longitudinal arrangement of the first prefabricated RPC column (2), the second prefabricated RPC column (3), the third prefabricated RPC column (4), the fourth prefabricated RPC column (5), the fifth prefabricated RPC column (6), the sixth prefabricated RPC column (7) and the seventh prefabricated RPC column (8), connection between the first prefabricated RPC column (2), the second prefabricated RPC column (3), the third prefabricated RPC column (4), the fourth prefabricated RPC column (5), the fifth prefabricated RPC column (6), the sixth prefabricated RPC column (7) and the seventh prefabricated RPC column (8) and common concrete (9) of the same section and connection of the sections of the first prefabricated RPC column (2), the second prefabricated RPC column (3), the third prefabricated RPC column (4), the fourth prefabricated RPC column (5), the fifth prefabricated RPC column (6), the sixth prefabricated RPC column (7) and the seventh prefabricated RPC column (8). By means of the technology, long-time creeping downwarping of the large-span rigid frame bridge can be lowered effectively, construction is convenient to conduct and easy to implement, the cost is lower, and the technology can be widely applied to the actual design of rigid frame bridges.

Owner:HUNAN UNIV

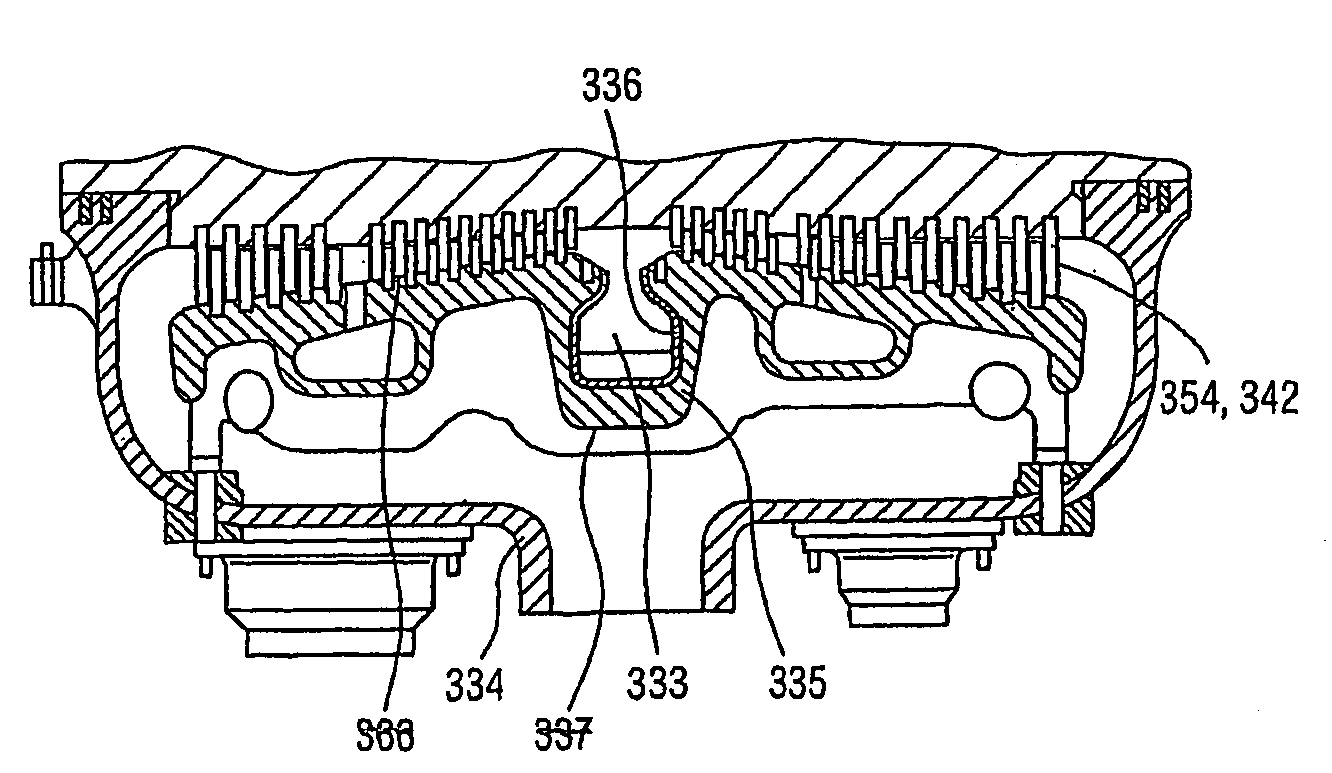

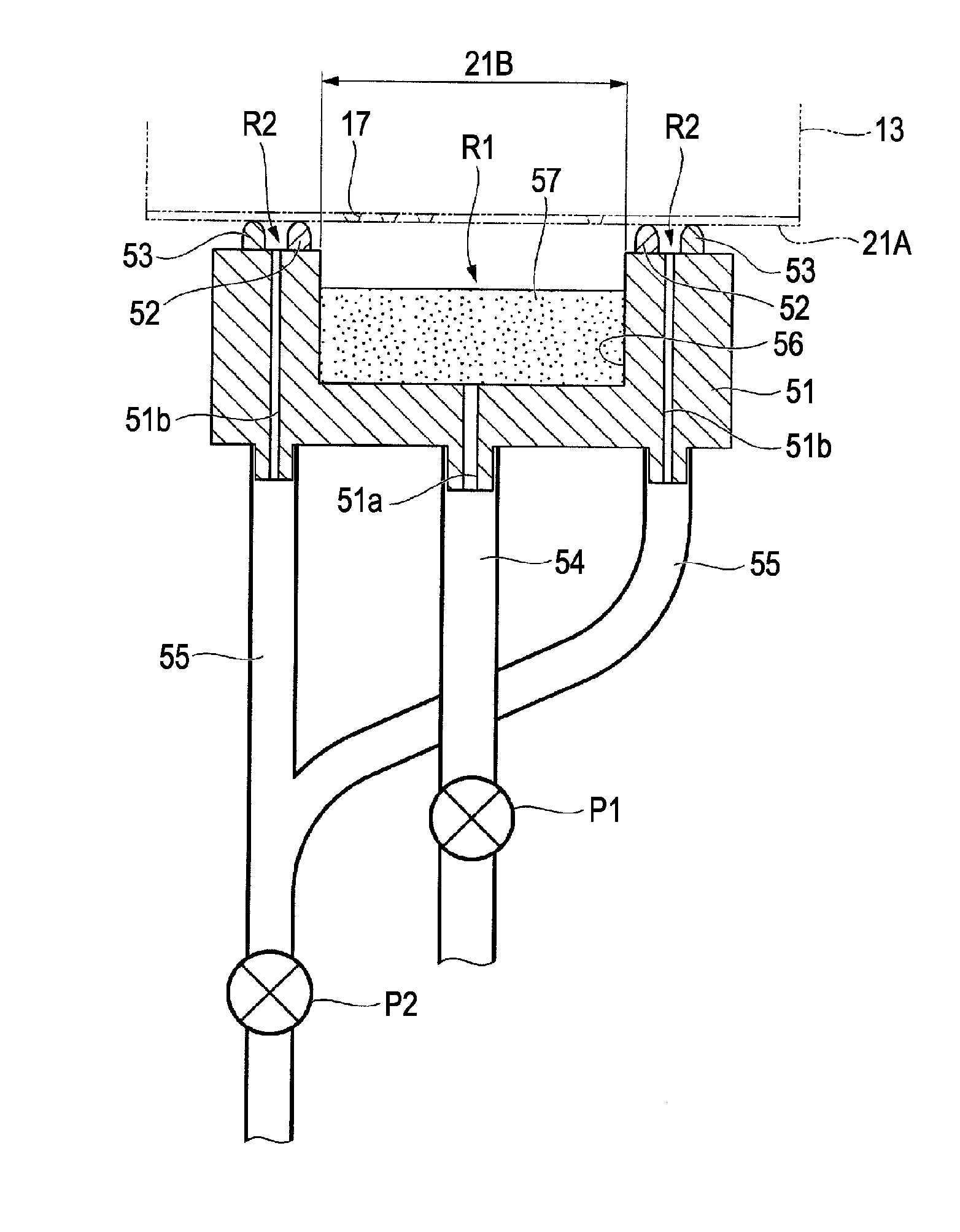

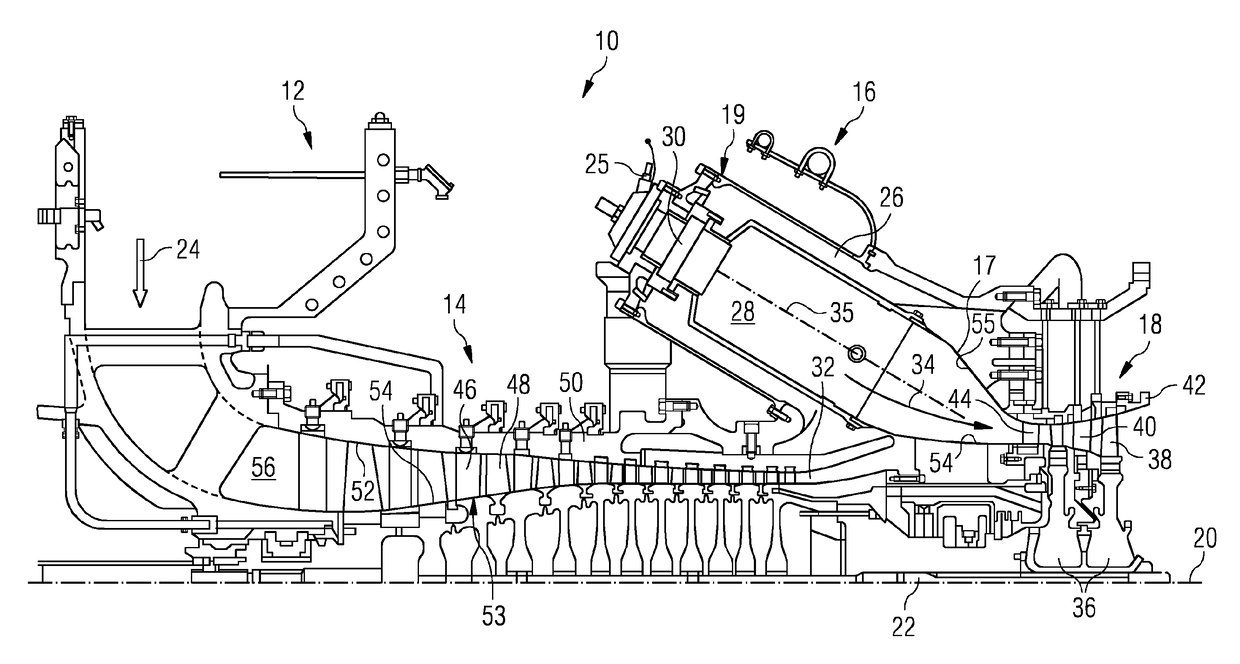

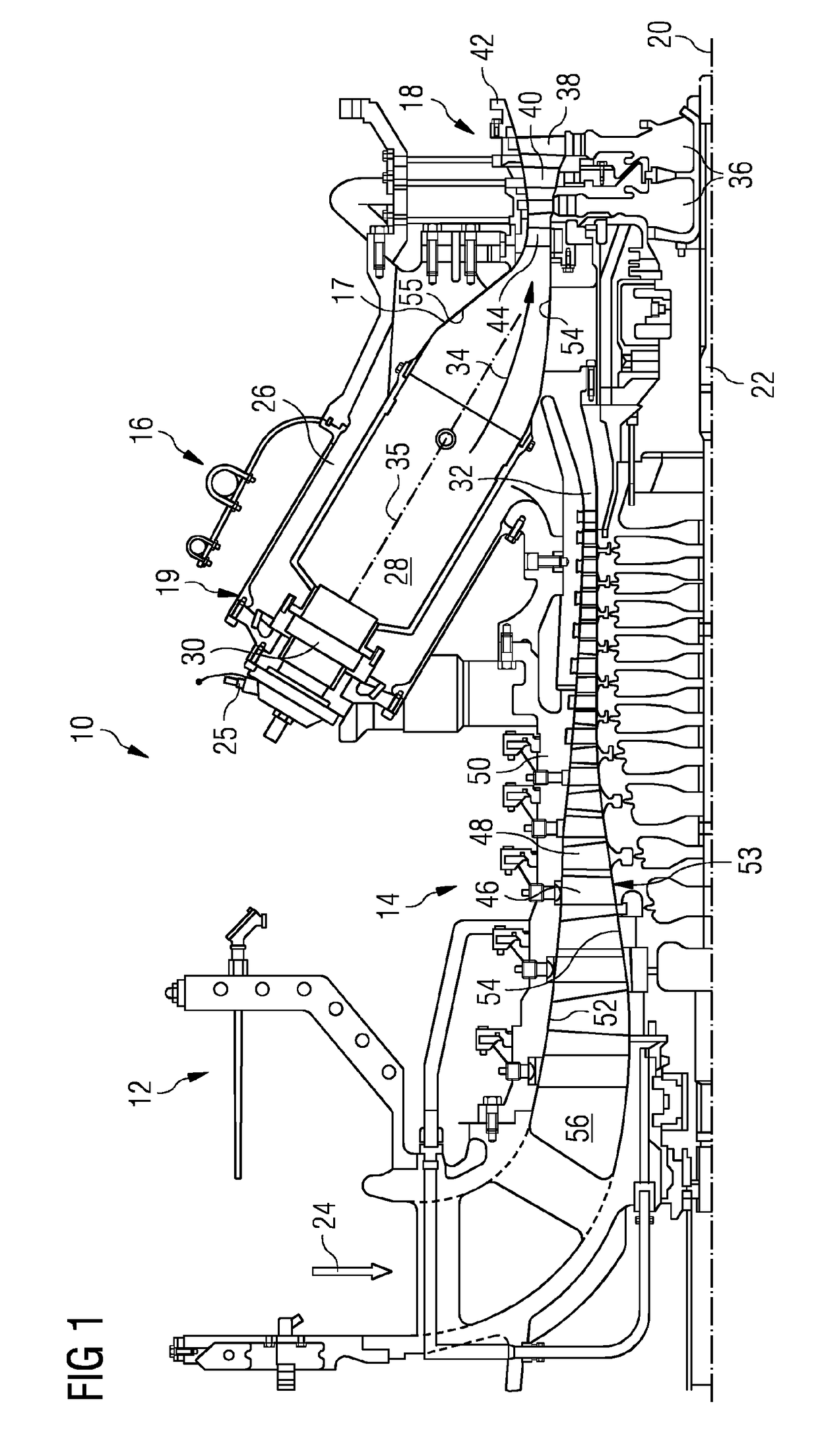

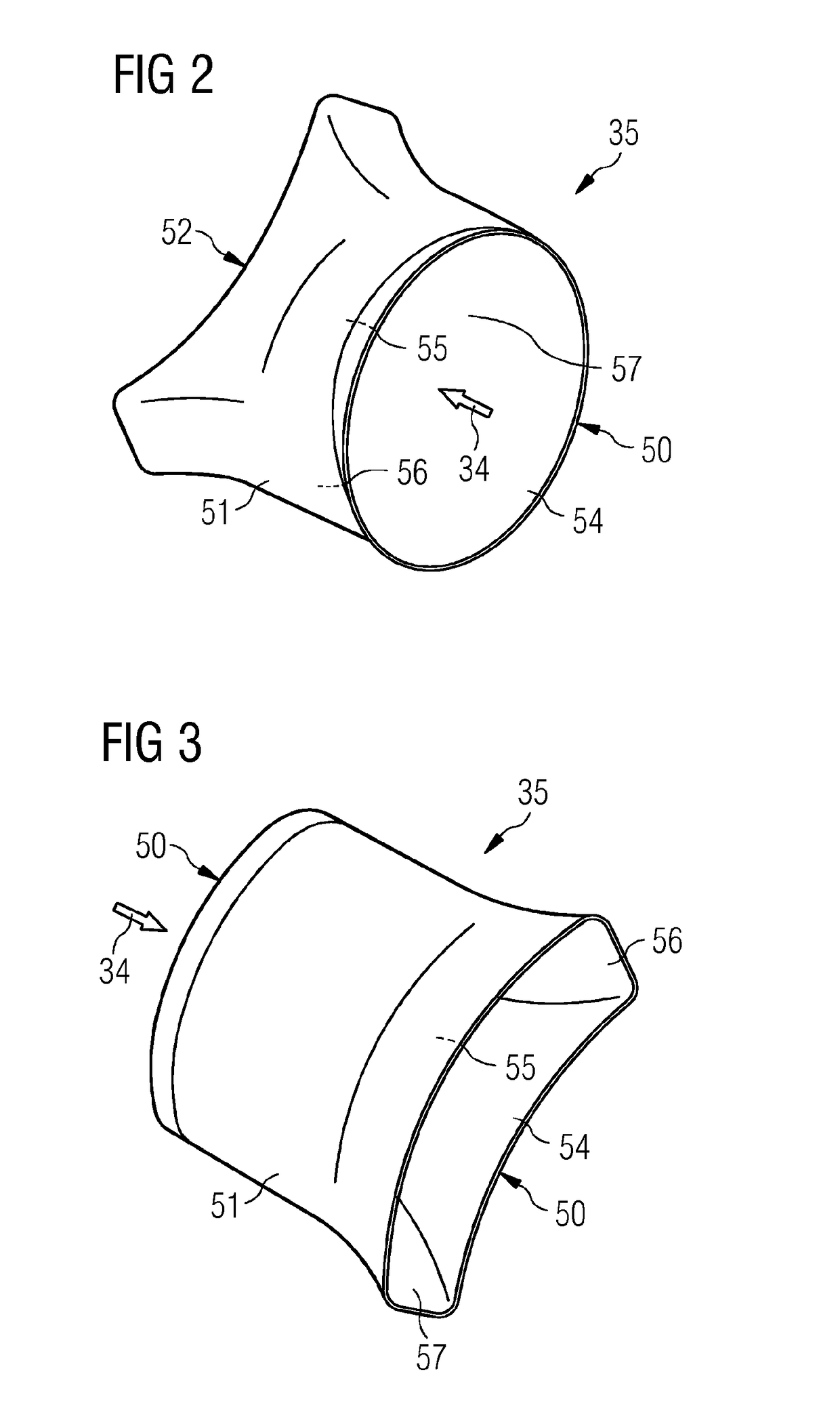

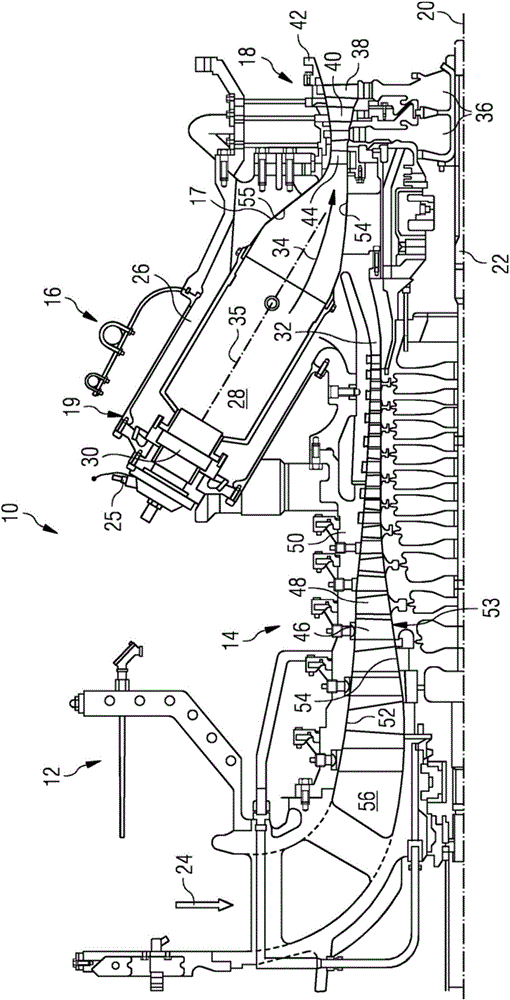

Gas turbine engine with a transition duct and corresponding method of manufacturing a transition duct

ActiveUS20170107833A1High gradientReduced creep deformationEngine fuctionsStatorsCombustorEngineering

A gas turbine engine having a combustor, turbine and transition duct to channel hot gas from combustor to turbine. The transition duct has an internal surface on which the hot gas impinges causing a varying temperature profile. A thermal barrier coating is located on the internal surface having a first and second thermal barrier coating patch. The first patch having a first thickness located on the internal surface and within a first area subject to a higher temperature than an uncoated part and bounded by a first isotherm of a first temperature. The second patch having a second thickness located on the internal surface and within a second area subject to a higher temperature than the uncoated part and bounded by a second isotherm of a second temperature. The second temperature is higher than the first temperature and the second thickness is thicker than the first thickness.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

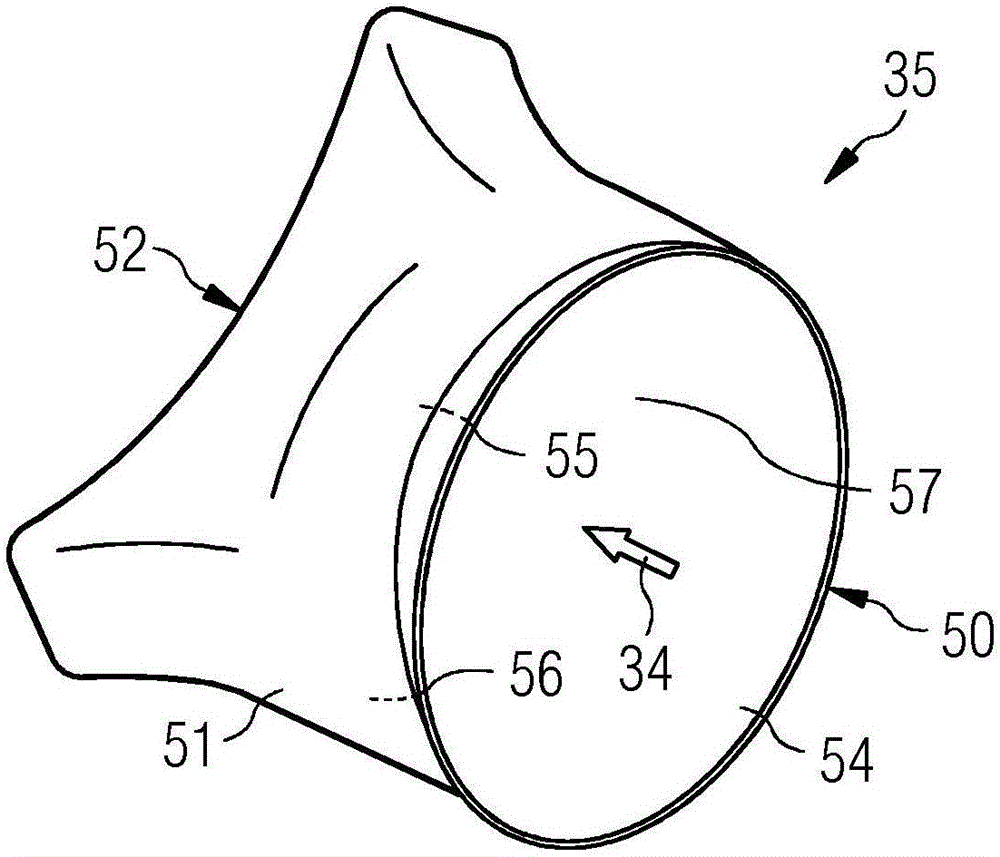

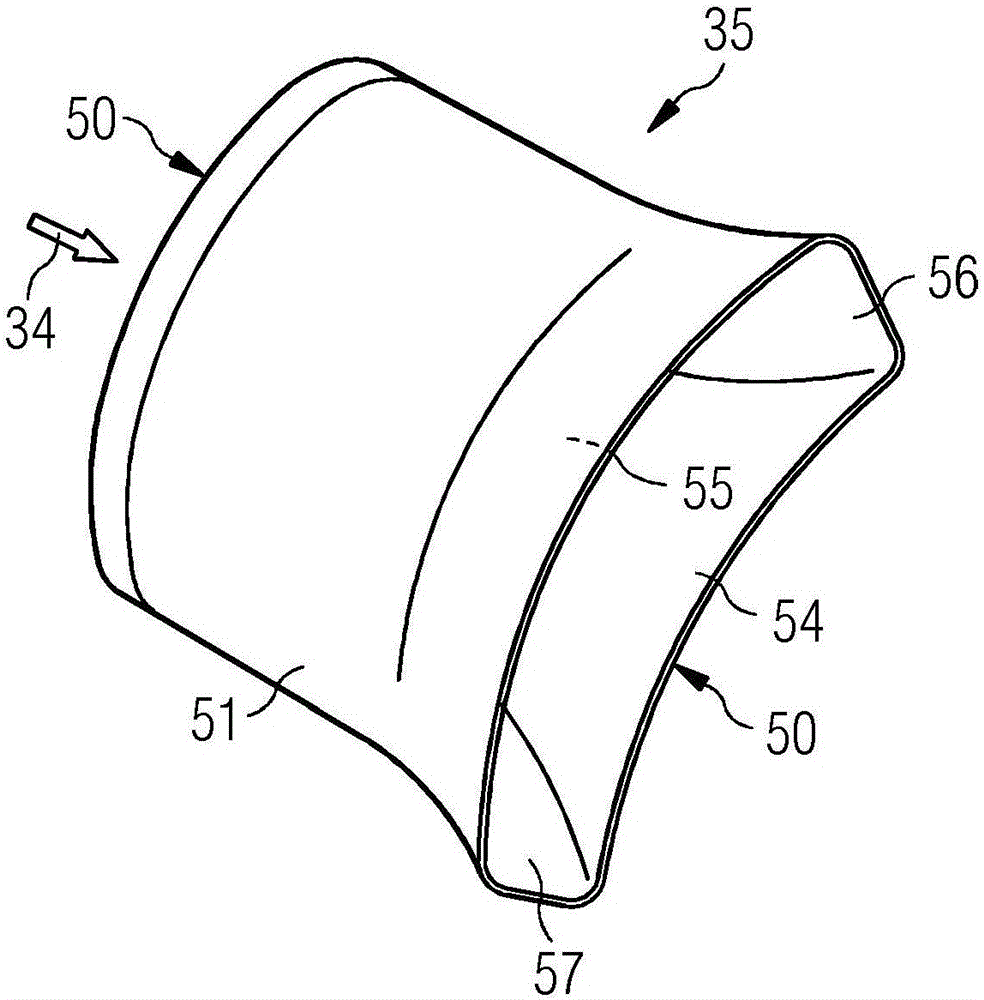

Gas turbine engine with a transition duct and corresponding method of manufacturing a transition duct

ActiveCN106661950ARaise the temperature gradientReduced creep deformationEngine fuctionsStatorsCombustorEngineering

The invention discloses a gas turbine engine with a transition duct and a corresponding method of manufacturing a transition duct. The gas turbine engine (10) having a combustor (16), a turbine (18) and a transition duct (17), the transition duct (17) is located between the combustor (16) and the turbine (18) to channel hot gas (34) from the combustor (16) to the turbine (18). The transition duct (17) has an internal surface (54, 55, 56, 57) on which the hot gas (34) impinges to cause a varying temperature profile over the internal surface (54, 55, 56, 57). A thermal barrier coating (100) is located on the internal surface (54, 55, 56, 57) and comprises at least a first thermal barrier coating patch (72P) and a second thermal barrier coating patch (74P). The first thermal barrier coating patch (72P) having a first predetermined thickness (72T) located on the internal surface (54, 55, 56, 57) and within a first area (72A) subject to a higher temperature than an uncoated part of the internal surface (54, 55, 56, 57) and bounded by a first isotherm (73) of a first predetermined temperature. The second thermal barrier coating patch (74P) having a second predetermined thickness (74T) located on the internal surface (54, 55, 56, 57) and within a second area (74A) subject to a higher temperature than the uncoated part of the internal surface (54, 55, 56, 57) and bounded by a second isotherm (75) of a second predetermined temperature. The second predetermined temperature is higher than the first predetermined temperature and the second predetermined thickness (74T) is thicker than the first predetermined thickness (72T). A corresponding method of manufacturing a transition duct is also provided.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Electric spindle adopting double supports of electromagnetic bearing and angular contact ball bearing

InactiveCN111431337AIncrease limit speedExtended service lifeMechanical energy handlingSupports/enclosures/casingsMagnetic bearingBall bearing

The invention relates to an electric spindle adopting double supports of an electromagnetic bearing and an angular contact ball bearing. An axial magnetic bearing (3) is arranged on the spindle in anelectric spindle shell (4), and radial magnetic bearings (2) are symmetrically arranged on the two sides of the axial magnetic bearing (3). The rigidity of the magnetic suspension bearing at a balanceposition is improved by using the electric spindle structure supported by the electromagnetic bearing and the angular contact ceramic ball bearing so that the magnetic suspension bearing is no longerlimited by the current rigidity.

Owner:SHENYANG POLYTECHNIC UNIV

A method of double-sided full filling of pillars and upward re-mining of the empty coal seam

ActiveCN104832174BPlay a role of side protectionDegree of reductionUnderground miningSurface miningStress concentrationRetrofitting

The invention discloses a method of a beside-pillar double-side total-filling ascending re-mining overhead coal seam. In the invention, on the basis of determining overhead coal seam mining feasibility and detecting distribution situations of a coal pillar group and a mined area group of a reamer-pillar remnant mining area, a beside-pillar double-side total-filling method is employed for successively side-protecting the coal pillar group in the underlie reamer-pillar remnant mining area of the overhead coal seam and gradually mining the overhead coal resources. By means of the method, a beside-pillar double-side filling body formed in the mined area group can not only achieve a side-protecting effect on the reamer-pillar coal pillar group but also form a common bearing body therewith, thereby further reducing degree of stress concentration and creep deformation of the coal pillar group. The method can enhance long-term stability, can avoid local instantaneous unstability or domino-like unstable damage and finally can ensure safe mining of the overhead coal seam of the reamer-pillar remnant mining area.

Owner:TAIYUAN UNIV OF TECH

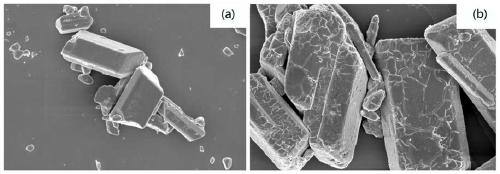

Green low-creep concrete

The invention provides green low-creep concrete, which is prepared from the following components in parts by weight: 340 to 385 parts of cement, 45 to 56 parts of waterworks sludge powder, 45 to 48 parts of white corundum powder, 622 to 652 parts of river sand, 69 to 72 parts of fine ceramic microbead aggregate, 1036 to 1087 parts of gravel, 136 to 192 parts of water and 4.5 to 4.8 parts of a water reducing agent. The green low-creep concrete provided by the invention is beneficial to harmless treatment of sludge, and also can reduce the consumption of resources such as cement and natural river sand.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com