Production of concrete beam

A technology of concrete beams and manufacturing methods, which is applied in the direction of joists, girders, trusses, etc., and can solve problems such as increasing project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

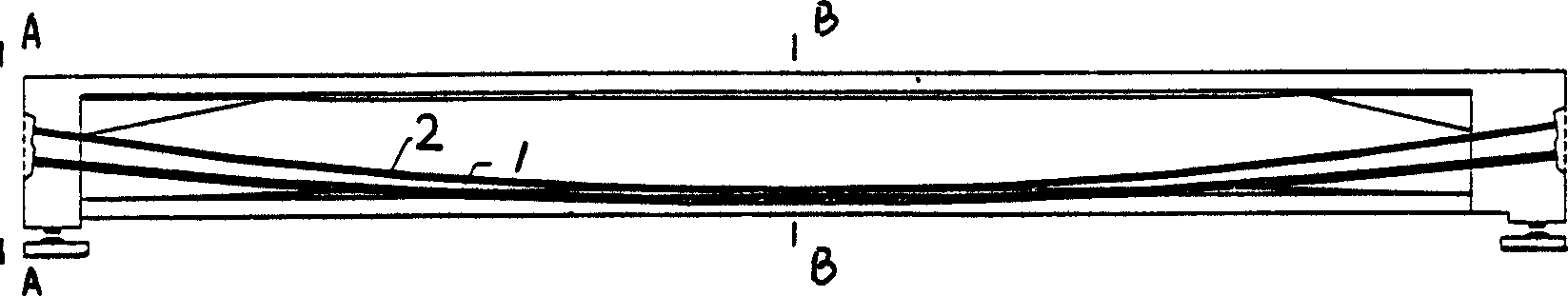

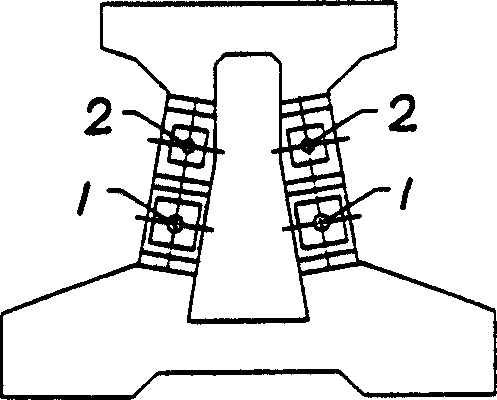

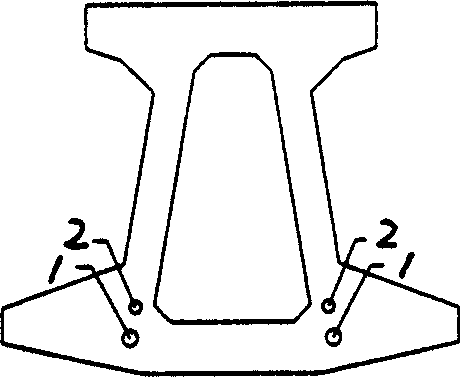

[0014] The present invention is a manufacturing method of concrete beams, characterized in that: the method for setting the prestressed concrete beams includes the following steps: a. erecting formwork and binding steel bars; b. laying prestressed corrugated pipes and prestressed steel strands; c. Pouring concrete; d. After the concrete reaches a certain strength, pre-tensioning and post-tensioning; e. Grouting and anchoring; f. When the tunnel mortar and anchoring concrete reach the strength required by the design, hoist it to the beam storage area. Storage; g. Tensioning of external prestress; h. Grouting and anchoring; I. Accurate positioning after the tunnel mortar and anchoring concrete reach the strength required by the design; j. Installing rails or other functional parts. The design requirement strength of concrete mentioned in this production m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com