Gas turbine engine with a transition duct and corresponding method of manufacturing a transition duct

一种燃气涡轮、发动机的技术,应用在发动机功能、发动机元件、机器/发动机等方向,能够解决热梯度脱粘、龟裂等问题,达到延长寿命、减少停机时间、增加可用性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

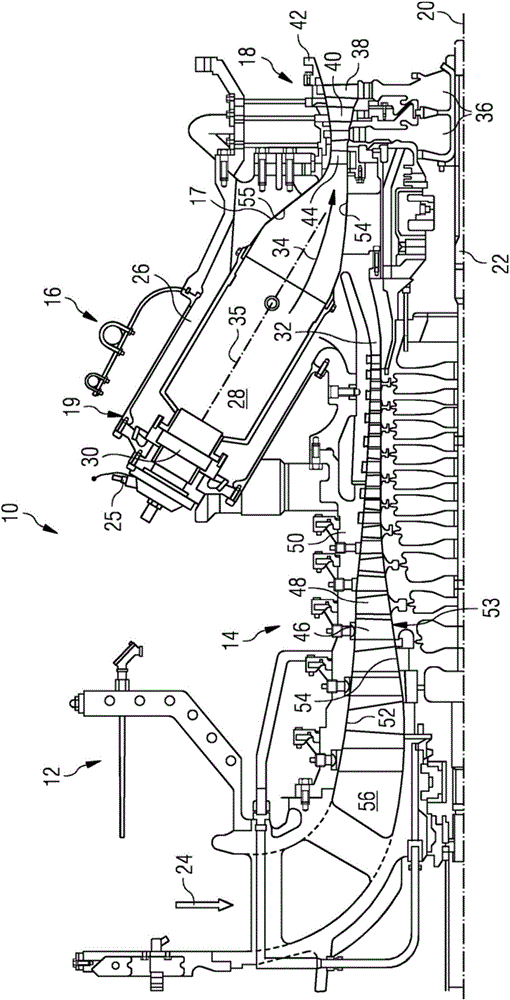

[0046] figure 1 An example of gas turbine engine 10 is shown in cross-section. Gas turbine engine 10 includes, in a flow sequence, an inlet 12 , a compressor section 14 , a combustor section 16 , and a turbine section 18 generally arranged in flow sequence and generally about and in the direction of a longitudinal or rotational axis 20 . Gas turbine engine 10 further includes a shaft 22 rotatable about an axis of rotation 20 and extending longitudinally through gas turbine engine 10 . Shaft 22 drivingly connects turbine section 18 to compressor section 14 .

[0047] In operation of gas turbine engine 10 , air 24 drawn through air inlet 12 is compressed by compressor section 14 and delivered to combustion or burner section 16 . The burner section 16 includes a burner plenum 26 , one or more combustion chambers 28 and at least one burner 30 secured to each combustion chamber 28 . Combustion chamber 28 and burner 30 are located inboard of burner plenum 26 . Compressed air pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com