Explosive modified by grafting in-situ hyperbranched polyurethane as well as preparation method and application of explosive

A technology of hyperbranched polyurethane and graft modification, which is applied in the direction of explosives, non-explosive/non-thermal agent components, offensive equipment, etc. It can solve the problem that the weak interface between coupling agent and explosives cannot be solved, which is unfavorable for the development of water suspension granulation preparation process , the coating strength of the coupling agent is not high, etc., to achieve the effect of reducing creep deformation, easy to realize, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

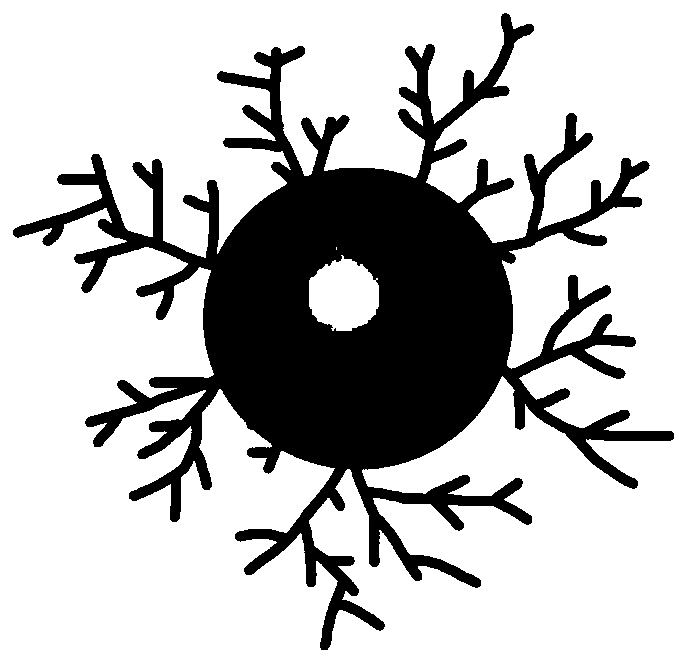

Image

Examples

Embodiment 1

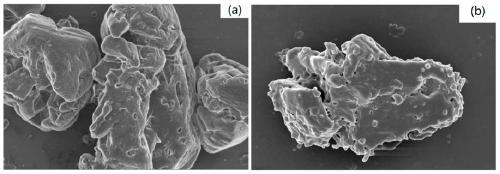

[0023] Step 1: Weigh 0.96g of Tris and dissolve it in 800ml of deionized water, add hydrochloric acid dropwise to prepare a buffer solution with a pH value of 8.5, then add 50g of TATB to the buffer solution, stir and disperse, add 1.92g of dopamine, and start The self-polymerization reaction is completed after 4 hours, washed with deionized water, suction filtered, and vacuum-dried in an oven at 60°C to obtain a polydopamine-premodified explosive;

[0024] Step 2: Add the pre-modified explosive obtained in Step 1 to 600g of butyl acetate, ultrasonically disperse, add 0.5g of catalyst dibutyltin dilaurate, 3g of toluene diisocyanate, stir at 300rpm, and react at 80°C for 1.5h Finished, washed with butyl acetate, and suction filtered. Then transfer to 600g of tetrahydrofuran solvent, heat in a water bath at 60°C, add dropwise 0.5g of catalyst dibutyltin dilaurate, and gradually add 3g of toluene diisocyanate, 1g of diethanolamine monomer, then continue to react for 2h, tetrahyd...

Embodiment 2

[0028] Step 1: Weigh 0.96g of Tris and dissolve it in 800ml of deionized water, add hydrochloric acid dropwise to prepare a buffer solution with a pH value of 8.5, then add 50g of TATB to the buffer solution, stir and disperse, add 1.92g of dopamine, and start The self-polymerization reaction is completed after 6 hours, washed with deionized water, suction filtered, and vacuum-dried in an oven at 60°C to obtain a polydopamine-premodified explosive;

[0029] Step 2: Add the pre-modified explosive obtained in step 1 into 600g of butyl acetate, ultrasonically disperse, add 0.5g of catalyst dibutyltin dilaurate, 3g of 4,4'-diphenylmethane diisocyanate, and stir at 350rpm, The reaction was completed after 1.5 h at 80° C., washed with butyl acetate, and suction filtered. Then transferred to 600g tetrahydrofuran solvent, heated in a water bath at 60°C, added dropwise 0.5g catalyst dibutyltin dilaurate, and gradually added 3.3g 4,4′-diphenylmethane diisocyanate, 0.8g diethanolamine mono...

Embodiment 3

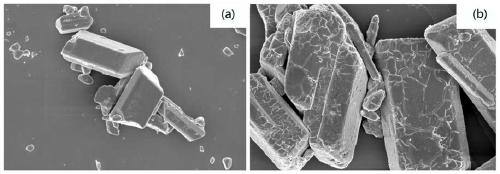

[0033] Step 1: Weigh 0.96g of Tris and dissolve it in 800ml of deionized water, add hydrochloric acid dropwise to prepare a buffer solution with a pH value of 8.5, then add 50g of LLM-105 to the buffer solution, stir and disperse, then add 1.92g of dopamine , start the self-polymerization reaction, end after 6h, wash with deionized water, filter with suction, and dry in a 60°C oven in vacuum to obtain a polydopamine-premodified explosive;

[0034] Step 2: Add the pre-modified explosive obtained in Step 1 to 600g of butyl acetate, ultrasonically disperse, add 0.5g of catalyst dibutyltin dilaurate, 3g of toluene diisocyanate, stir at 300rpm, and react at 80°C for 1.5h Finished, washed with butyl acetate, and suction filtered. Then transfer to 600g tetrahydrofuran solvent, heat in a water bath at 60°C, add dropwise 0.5g catalyst dibutyltin dilaurate, and gradually add 1.5g toluene diisocyanate, 0.5g diethanolamine monomer, 3.0g polybutylene adipate Diol (PBA, M n 600), then co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com