Test control system and method used for viscous-elastic material bending fatigue test

A control system and bending fatigue technology, applied in the direction of using a stable bending force to test the strength of materials, analyze materials, strength characteristics, etc., can solve the problems affecting the authenticity and reliability of the test results, excessive creep deformation, etc. The effect of expanding the test material range and test temperature range, reducing creep deformation, improving the success rate and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

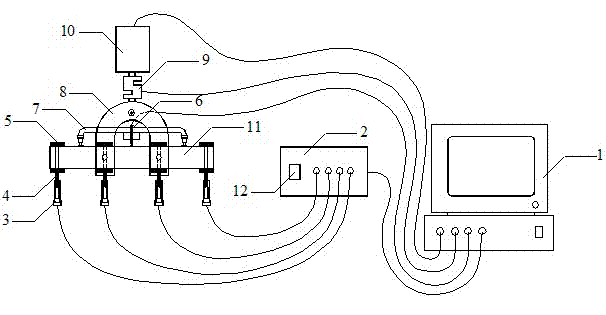

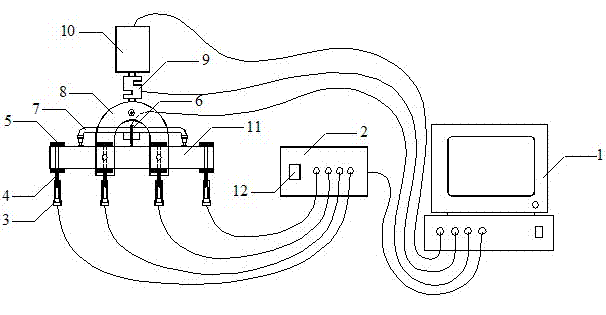

[0025] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0026] like figure 1 As shown, the present invention discloses a test control system for bending fatigue tests of viscoelastic materials, including a test piece 11, a computer control system 1 and a clamping control device connected between the test piece 11 and the computer control system 1 and An adjusting device for adjusting the clamping force of the clamping control device on the test piece, the adjusting device is connected between the clamping control device and the computer control system 1 .

[0027] In this embodiment, the clamping control device includes a stepper motor 3, a lifting screw 4, a test piece chuck 5, a displacement sensor 6, a displacement sensor bracket 7, a force transmission frame 8, a force sensor 9, and a power system 10; The device is a stepper motor adjustment module 2 provided with an adjustment switch 12; the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com