Self-generation pressurization system suitable for pressurization of multi-working-condition storage tank of nuclear vehicle

A technology for a pressurization system and a carrier, which is applied to the propulsion system of space navigation vehicles and other directions, can solve the problems of difficulty in meeting the pressurization requirements of nuclear carriers, slow startup and shutdown of the reactor, and long engine startup and shutdown time. Refinement control of supercharging, quality reduction, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

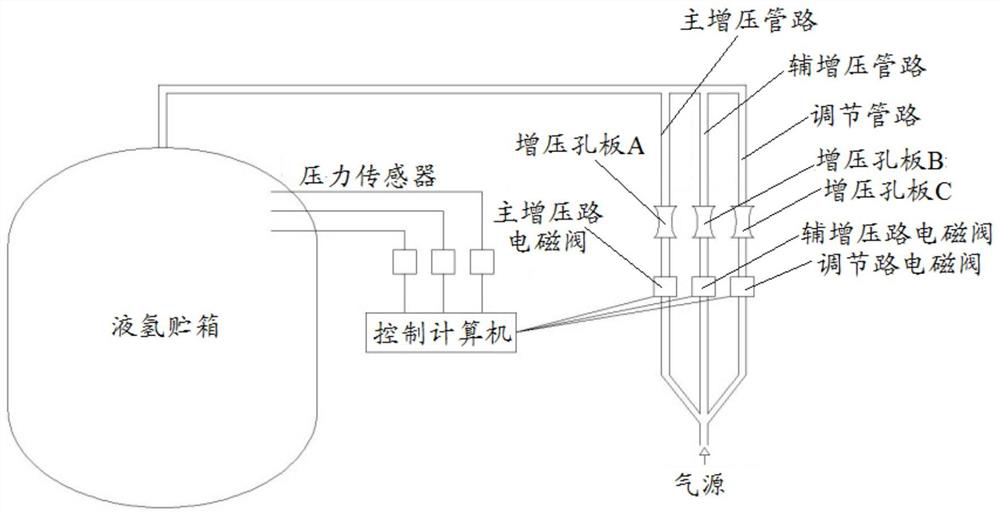

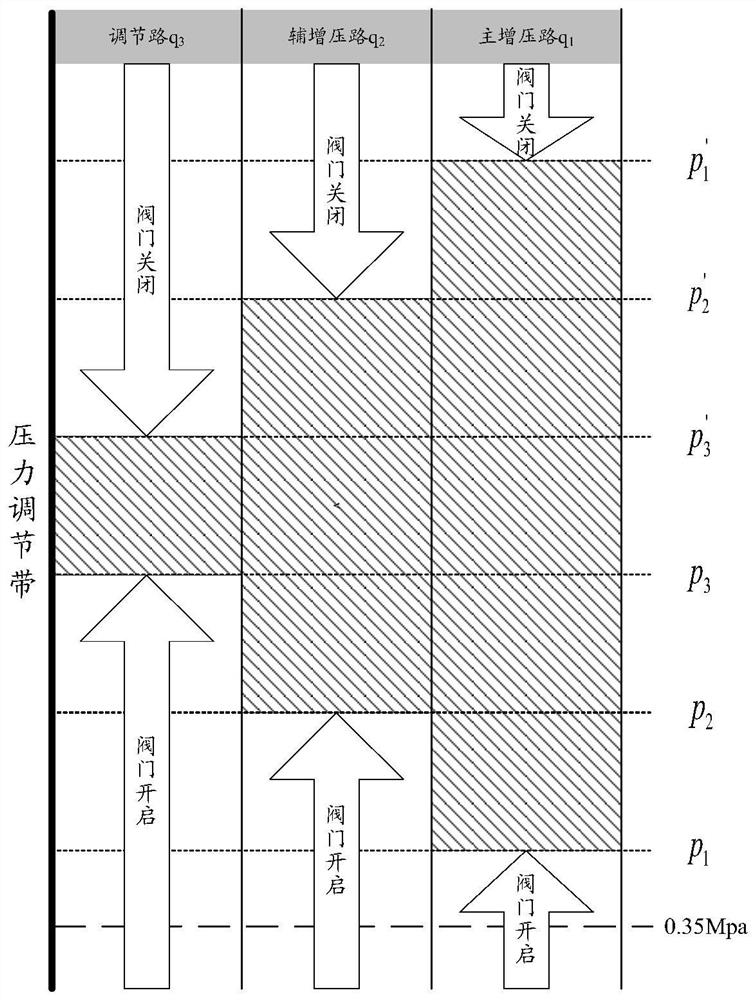

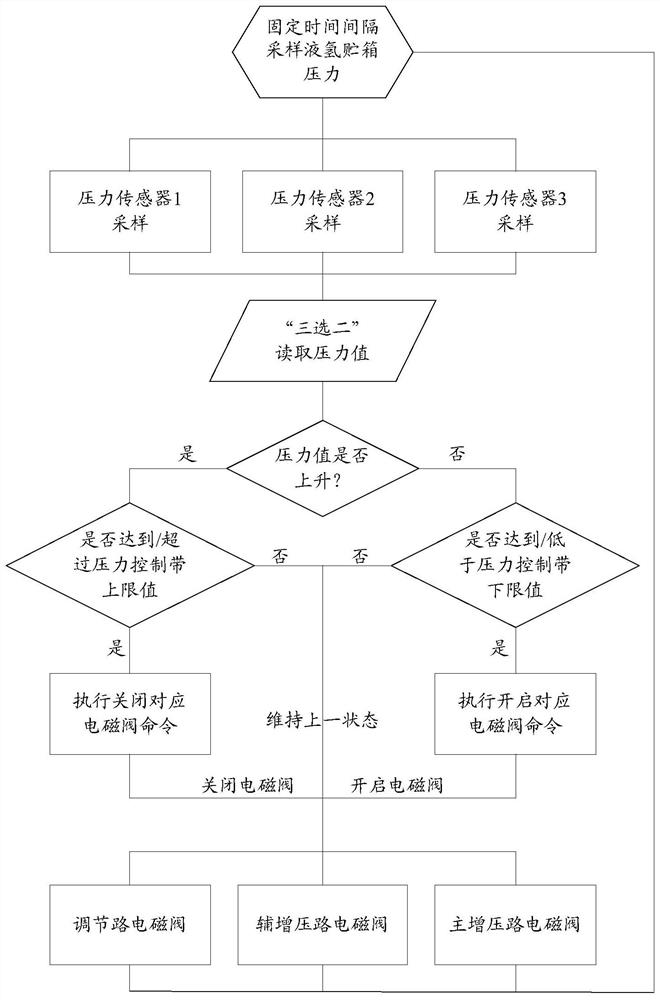

[0046] like figure 1 , in this embodiment, the self-generated pressurization system suitable for multi-working condition storage tank pressurization of nuclear carrier includes: gas source, main pressurization pipeline, auxiliary pressurization pipeline, regulating pipeline, main pressurization solenoid valve, auxiliary booster solenoid valve, regulating solenoid valve, pressure sensor, liquid hydrogen storage tank and control computer. Among them, the gas source is connected to the liquid hydrogen storage tank through the main booster pipeline, the auxiliary booster pipeline and the regulating pipeline respectively; Solenoid valve, auxiliary booster solenoid valve and regulation solenoid valve. The pressure sensor is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com