Flow control structure of nitrogen-oxygen separation device

A flow control and nitrogen-oxygen separation technology, applied in the field of oxygen generators, can solve the problems of large gas fluctuation, automatic and precise control of nitrogen-oxygen mixed gas, and inability to output flow gas, so as to avoid being too sensitive and easy to monitor and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

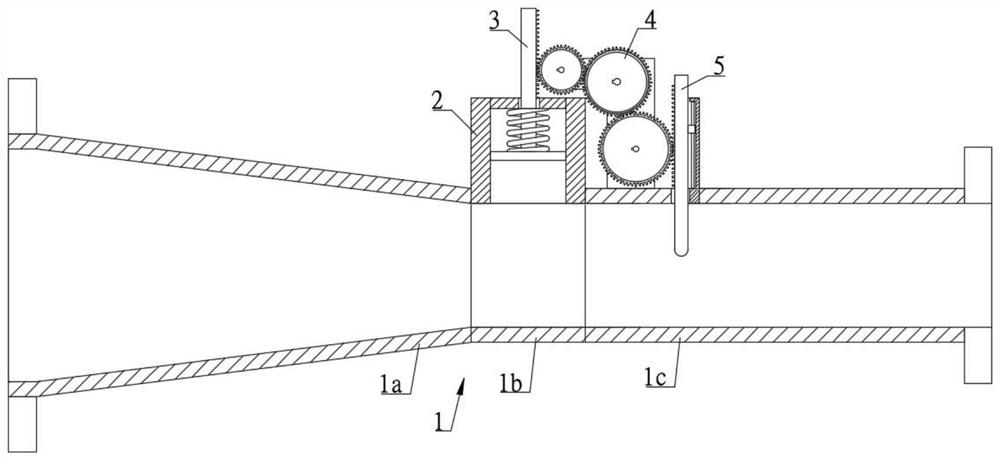

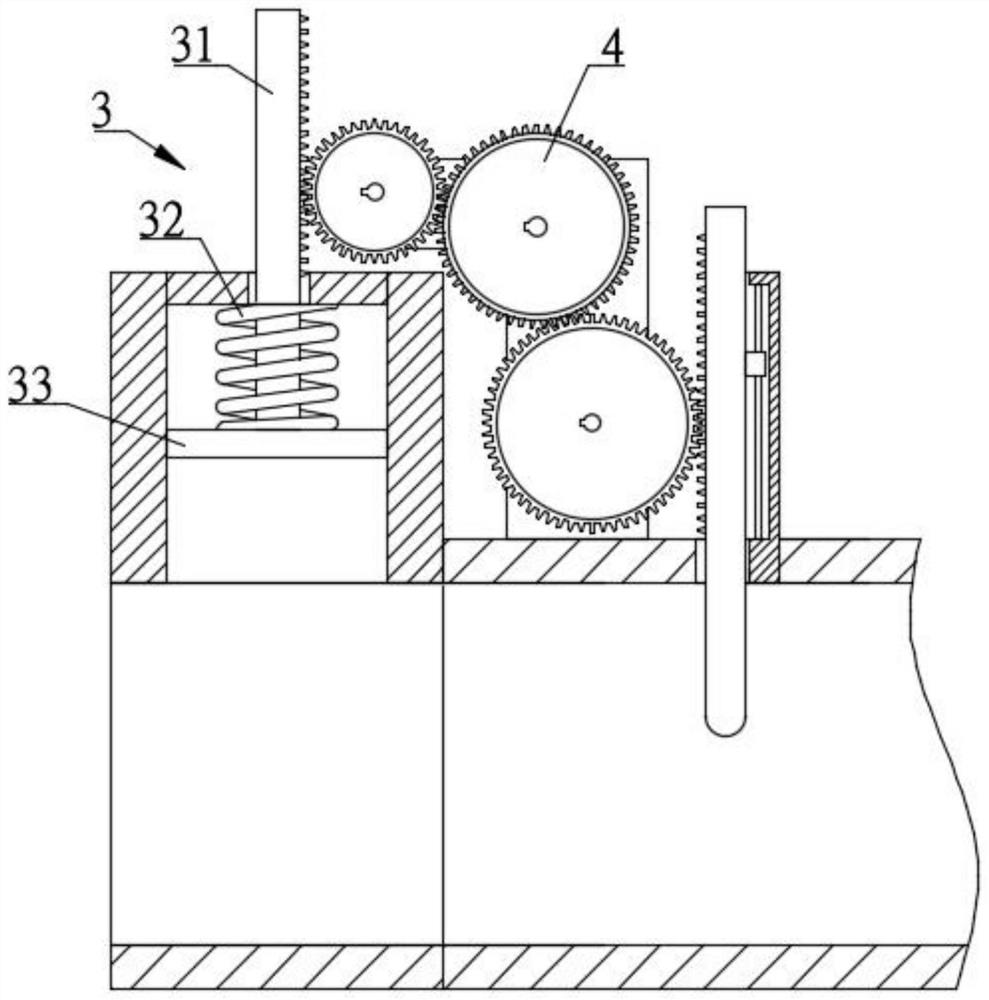

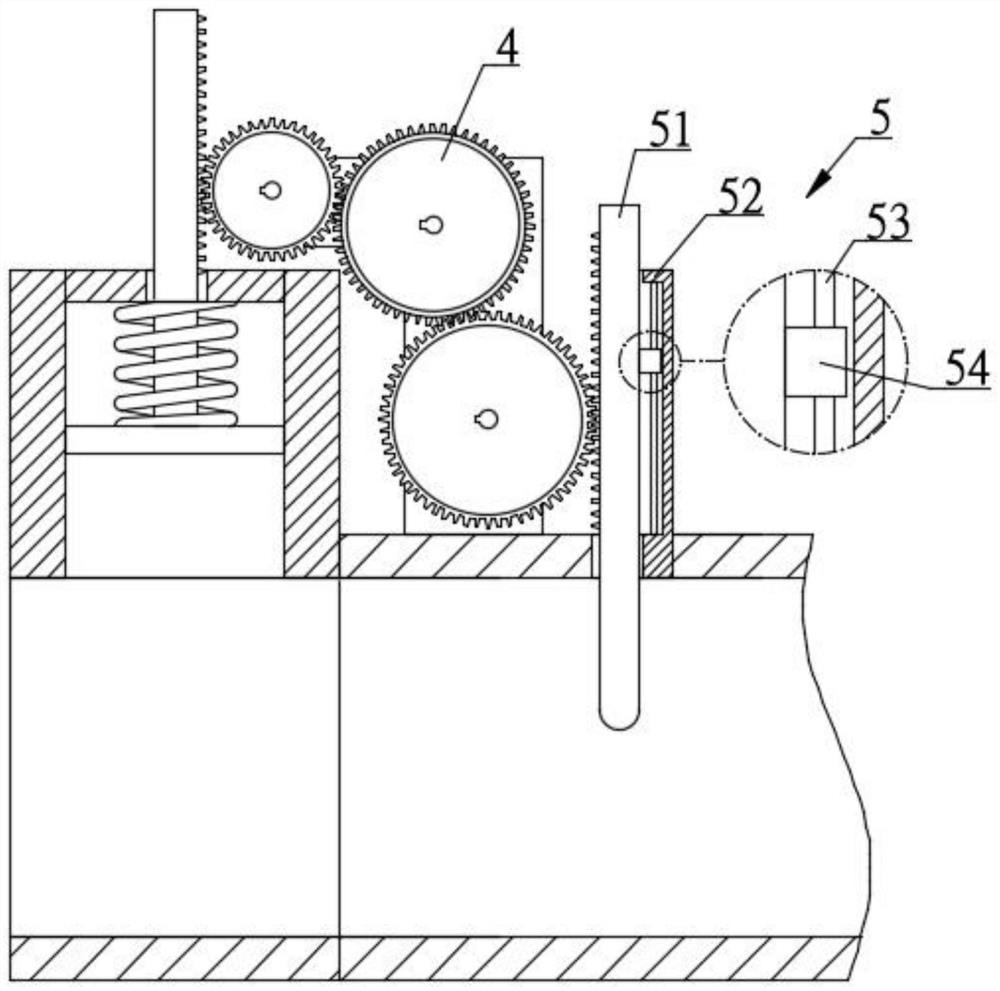

[0030] refer to Figure 1-4 , a flow control structure of a nitrogen-oxygen separation device, including a pipeline 1, a casing 2, a flow monitoring component 3, a transmission component 4 and a flow control component 5.

[0031] refer to figure 1 , the pipeline 1 is composed of three parts: the conical section 1a, the monitoring section 1b and the control section 1c, and the three parts of the conical section 1a, the monitoring section 1b and the control section 1c are integrally formed, and the setting of the conical section 1a plays a role The effect of reducing the diameter of the pipe reduces the diameter of the pipes at the monitoring section 1b and the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com