Sawing machine dynamic adjustment clamping guide structure

A technology of guiding structure and dynamic adjustment, applied in the field of sawing machines, can solve the problems of sawing efficiency, sawing quality, impact of saw blade life, sawing skew, and low efficiency, so as to reduce abnormal consumption and realize dynamic sawing. , The effect of improving sawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

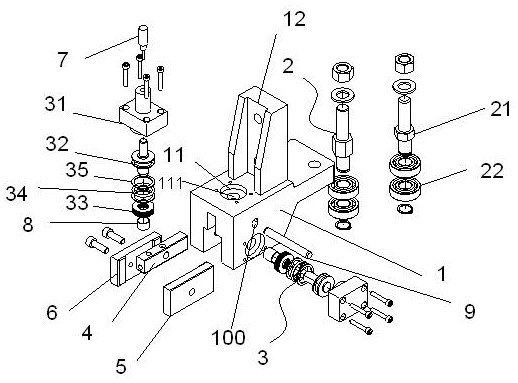

[0020] A sawing machine dynamic adjustment clamping guide structure, such as figure 1 As shown, it includes a guide seat 1 and a locking adjustment structure 3 arranged on the upper side and the right side of the front end of the guide seat 1 .

[0021] At the action end, the locking adjustment structure 3 is respectively connected with the tungsten steel 4 and the right tungsten steel 5 on the upper side and the right side inside the front end of the guide seat 1. Tungsten steel 6, the left and right tungsten steel are used to clamp the saw blade to prevent it from lateral deviation, and the upper tungsten steel can press the saw blade.

[0022] Specifically, the upper tungsten steel 4 has a vertical degree of freedom in the guide seat 1, and the realization of this degree of freedom is that the guide seat 1 is provided with a vertical strip-shaped connecting groove 100 for the parallel pin 9, and the parallel pin 9 The upper tungsten steel 4 is connected in the guide seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com