High-energy consumption viscoelastic silicone oil cabin vibration damper

A high-energy-consuming viscoelasticity and shock absorber technology, which is applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve the problems of increased maintenance work, poor shock isolation effect, and reduced service life. To achieve the effect of reducing the inconvenience of later maintenance, increasing the effect of shock absorption and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

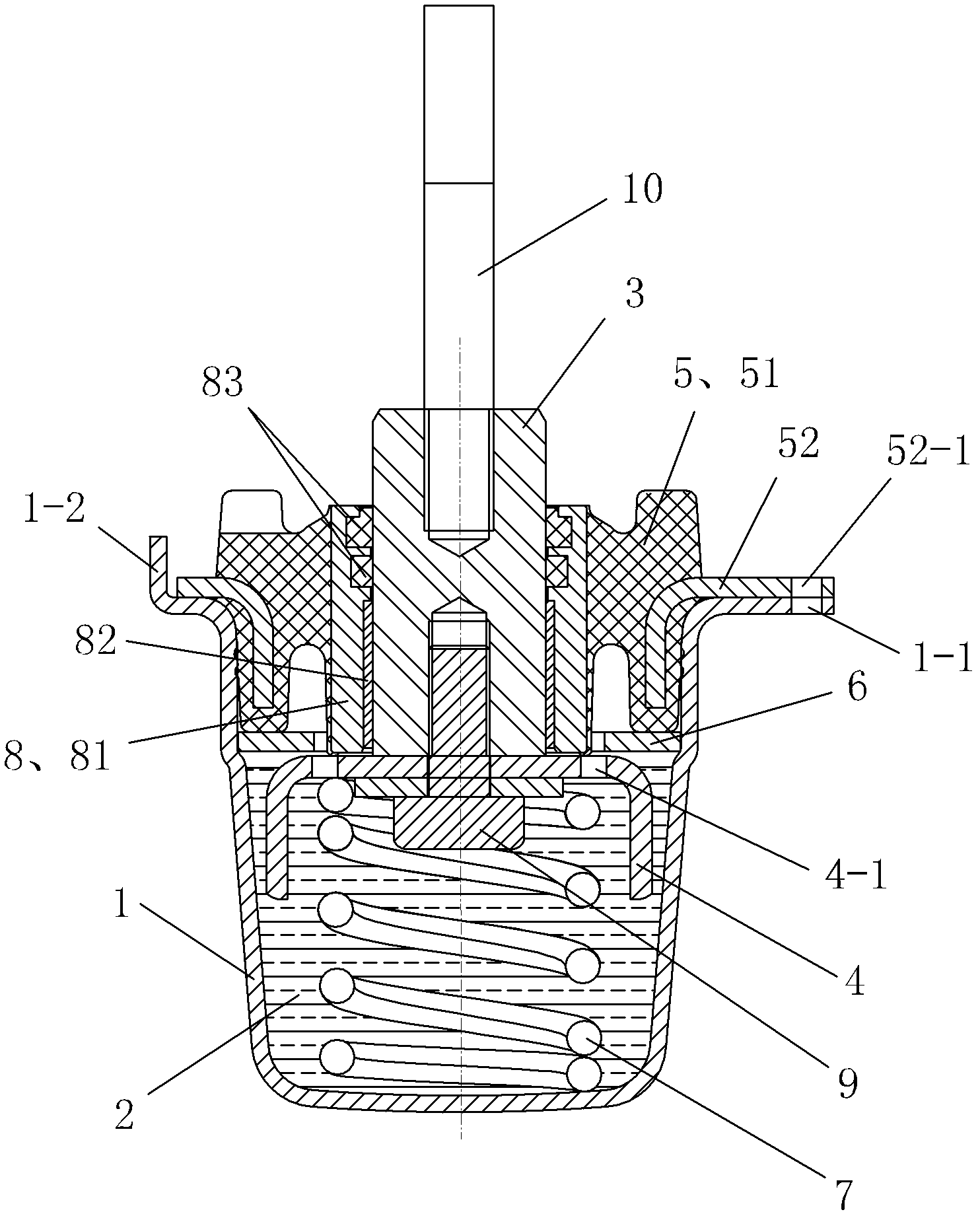

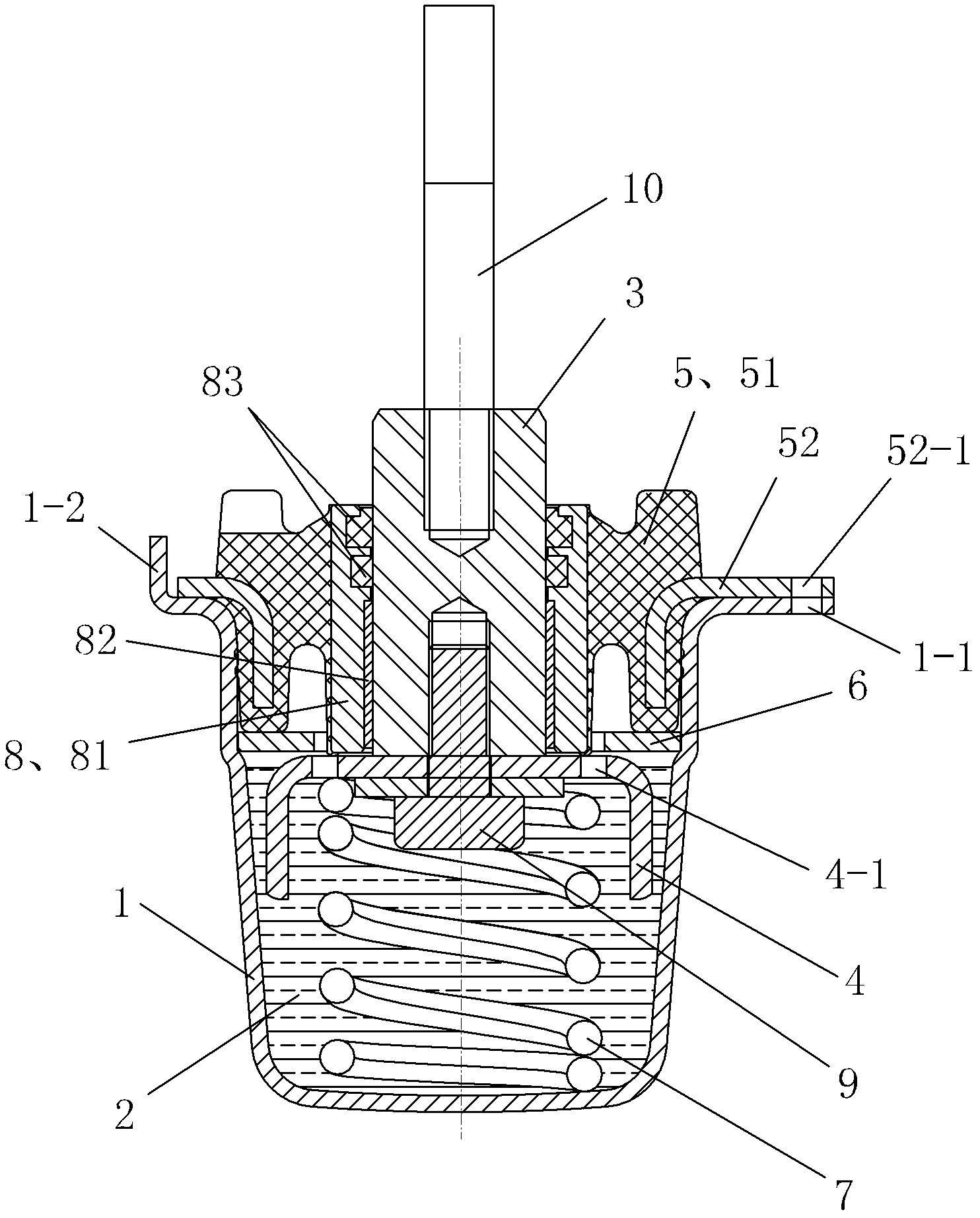

[0018] The high-energy-consuming viscoelastic silicone oil cockpit shock absorber of this embodiment includes an oil cylinder 1 , silicone oil 2 , a central shaft 3 , a damping cup 4 , a damping element 5 , a support piece 6 , a spring 7 , and an axle seat assembly 8 .

[0019] The oil cylinder 1 is provided with a mounting hole 1-1 and a flange 1-2. There is no oil injection hole on the oil cylinder 1, and the silicone oil 2 is injected into the oil cylinder 1 at one time when leaving the factory.

[0020] The damping cup 4 is fixedly connected with the central shaft 3 through bolts 9, and the bottom of the damping cup 4 is provided with a damping cup oil port 4-1.

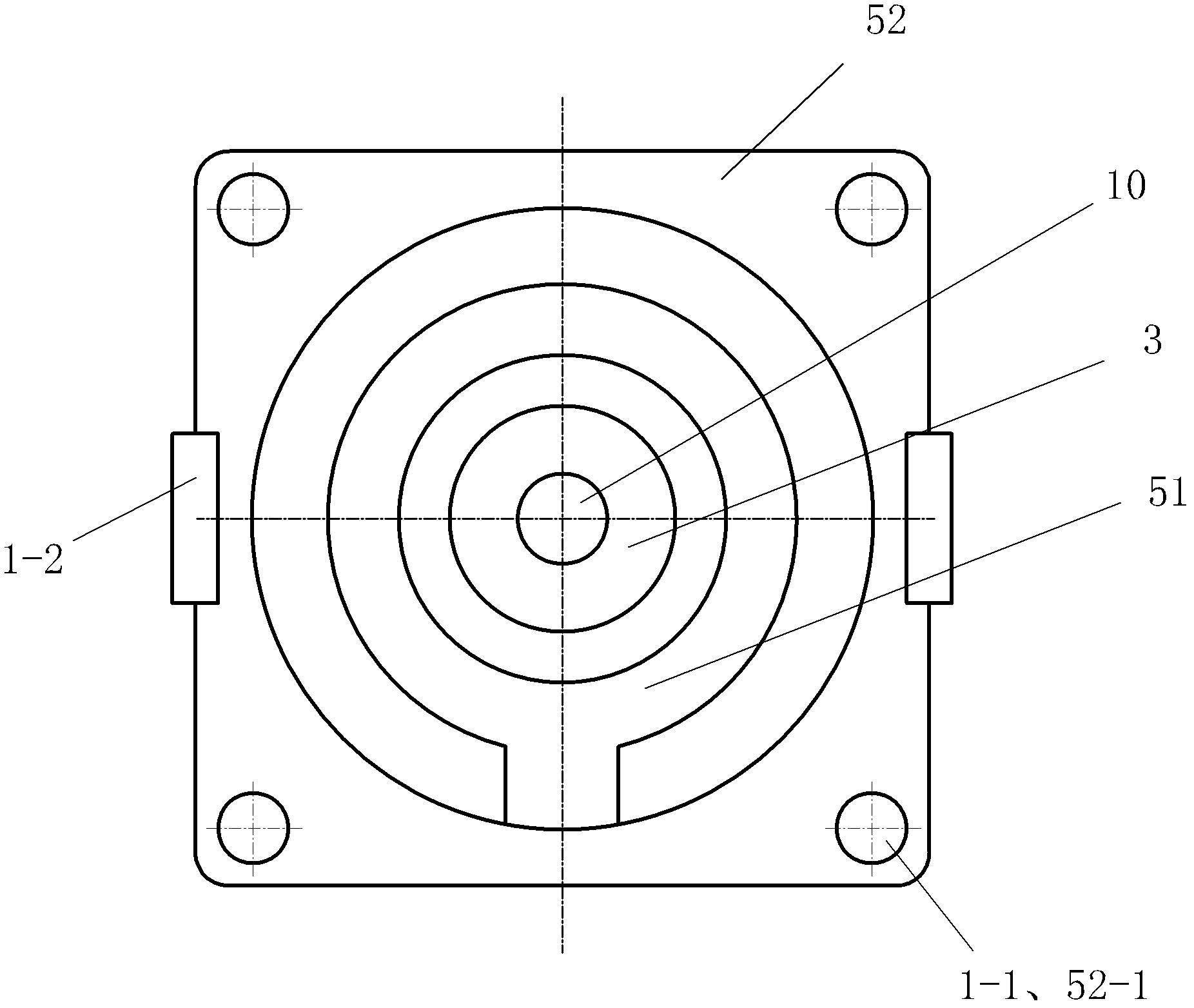

[0021] The damping material in the damping element 5 is a high energy consumption viscoelastic damping material 51; and a tubular reinforcement 52 is embedded in the high energy consumption viscoelastic damping material 51 to support and protect the high energy consumption viscoelastic damping material 51 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com