Method for pillar adjacency single side partial filling of ascending re-mining hollow coal seam

A side part and column side single technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve threats to safe and efficient production, instability and damage, and affect the integrity and stability of the overlying hollow coal seam and its floor rock And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are intended to illustrate and explain the present invention, but not to limit the scope of the present invention.

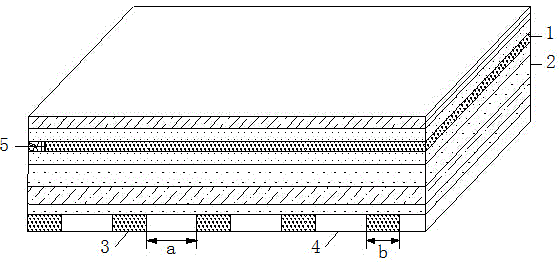

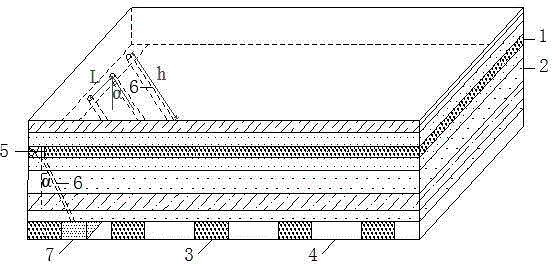

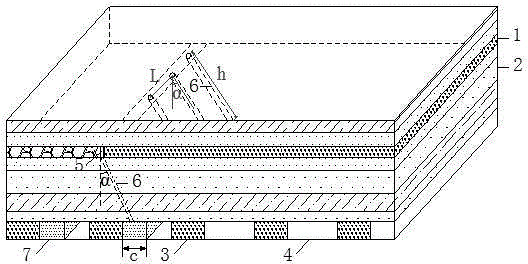

[0032] In order to have a clearer understanding of the technical objectives, features and effects of the present invention, the method for filling up the double-side part of the column side partly filling the upward re-mining of the empty coal seam will be further described in detail in conjunction with the accompanying drawings.

[0033] In the 1990s, the Baijiazhuang Coal Mine of Xishan Coal and Electricity Group surpassed the No. 6 coal seam and gave priority to mining the lower No. 8 coal seam. At present, the ground position of the No. 6 coal seam 36703 working face of Baijiazhuang Coal Mine is located in the mountainous area southwest of Yeyu Fengshaft. The right part is the unmined area of the 36701 working face, and the lower part is the 38502 knife-pillar goaf, which belongs to the typical knife-pillar residual mining are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com