Prestressed unbonded anchor rod reinforcing steel bar, anchor rod and construction method

A prestressed, non-bonded technology, used in the installation of anchor rods, infrastructure engineering, sheet pile walls, etc., to save construction time, improve project quality and efficiency, and reduce creep deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

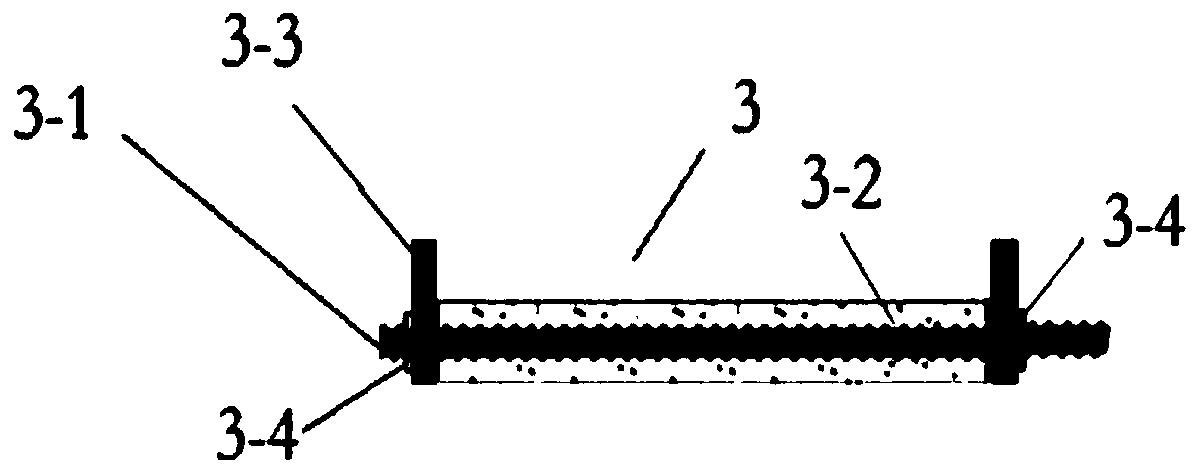

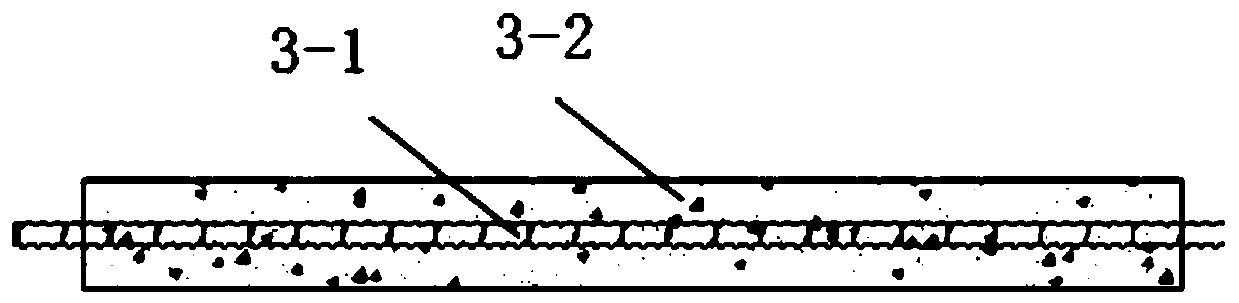

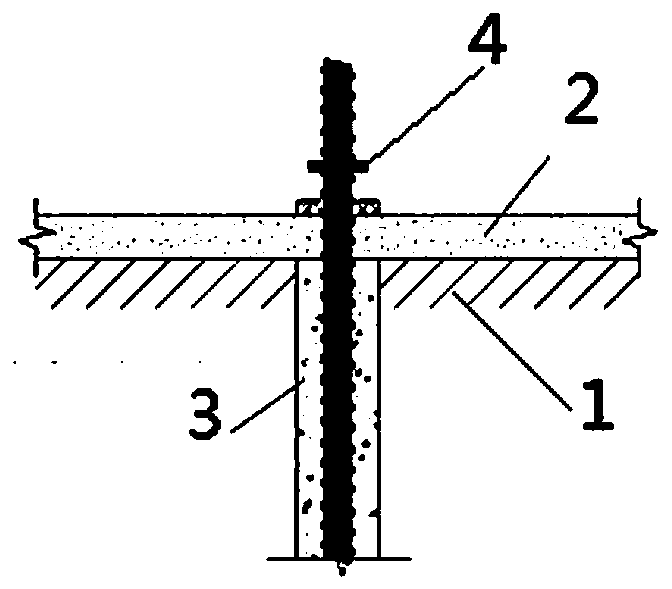

[0071] As shown in the figure, the example of parts in the figure: base 1, concrete cushion 2, anchor rod after pouring or called anchor rod 3, the main reinforcement prepared by concrete or mortar pouring or the pipe column of the outer layer of the finished thick steel bar, that is, the anchor rod Concrete or mortar for the outer layer of steel bars 3-2, fixed plate or bearing plate 3-4, nuts for applying prestress 3-3, anti-corrosion grease layer 3-6, plastic film sleeve 3-5, limiter 11, flange The nut assembly 16-1 is used to fix the anchor rod steel bar (main reinforcement or finish-rolled thick steel bar) 3-1 on the base plate. Prestressing of rolled steel bars. Waterstop rubber strip 4, flange nut 16, concrete bottom plate 8, concrete bottom plate reinforcement 8-1, bottom plate cushion 8-2, and steel cage 10 can be straight-through or enlarged head structure, and the figure is variable diameter The enlarged diameter steel cage structure. Grouting body 12, nut connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com