Prestressed fabricated concrete joint curved surface connecting structure

A connection structure and assembly technology, applied in the direction of building structure, construction, etc., can solve the problems of reducing structural stability and service life, and achieve the effects of improving shear force transmission capacity, delaying crushing, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

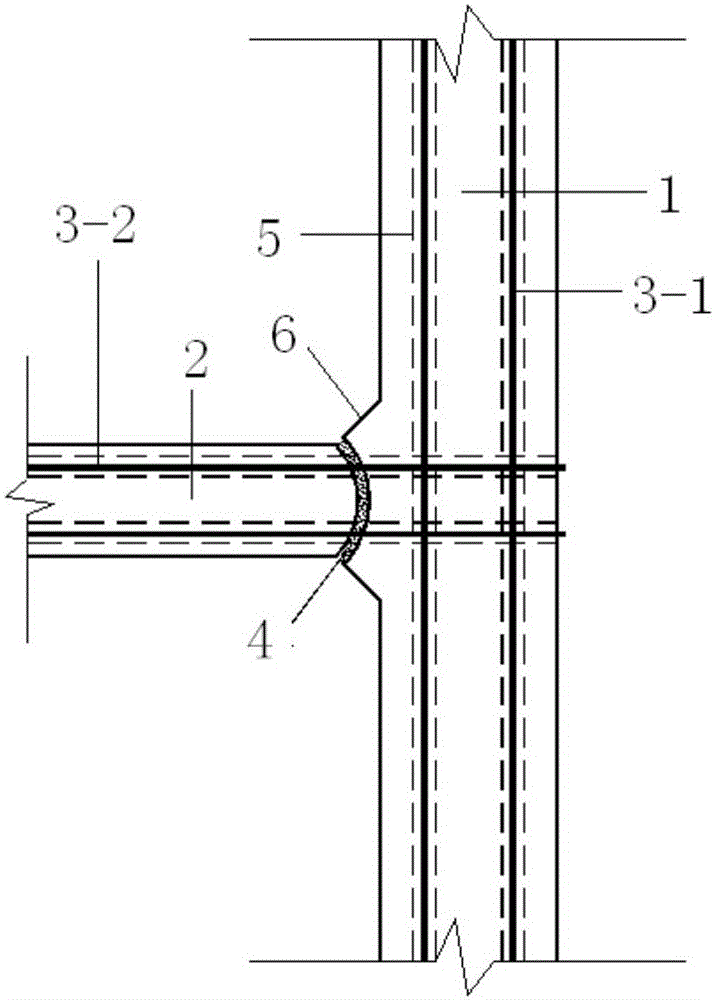

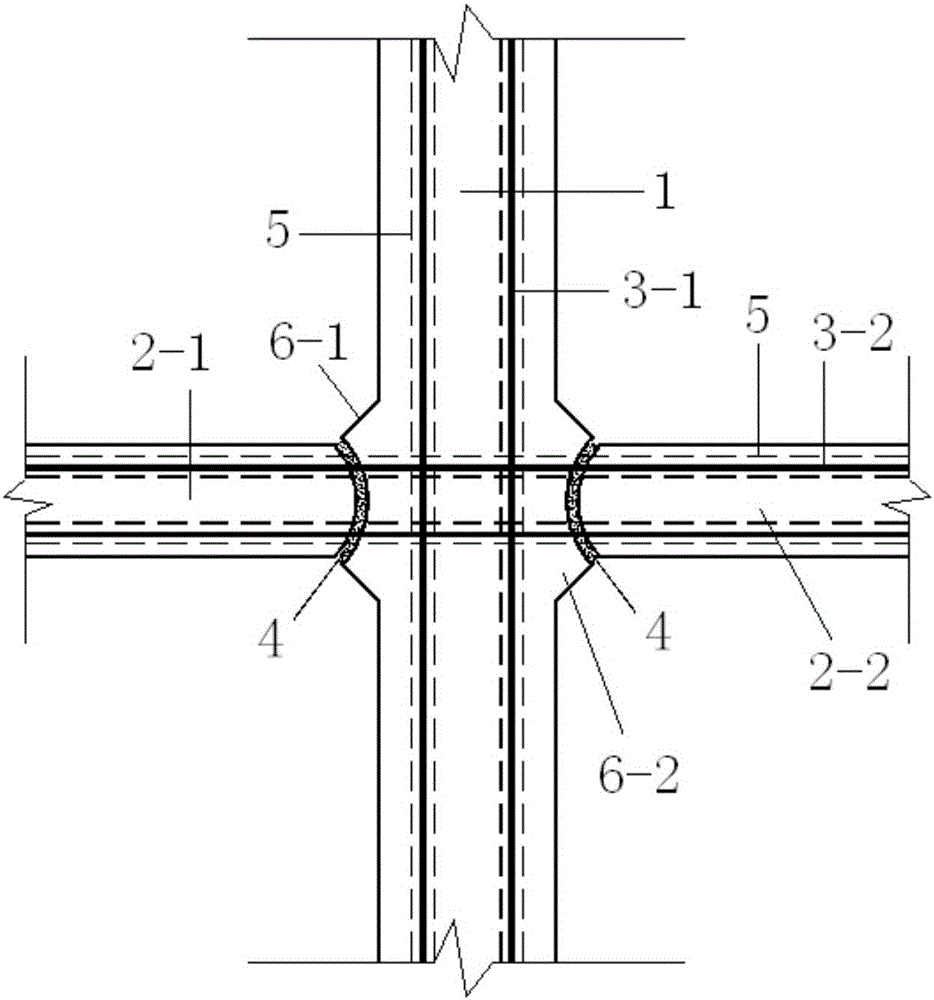

Embodiment 1

[0039] see figure 2 , a prestressed prefabricated concrete node curved surface connection structure, including a prefabricated column 1, a left prefabricated beam 2-1, a right prefabricated beam 2-2, a left node outrigger 6-1, and a right node outrigger 6-2; The left node outrigger 6-1 and the right node outrigger 6-2 are symmetrically arranged on the left and right sides of the prefabricated column 1, and the left node outrigger 6-1, the right node outrigger 6-2 and the precast column 1 Integral molding structure; the left node outrigger 6-1 is connected with the left prefabricated beam 2-1, and the right node outrigger 6-2 is connected with the right prefabricated beam 2-2;

[0040] The outrigger 6-1 at the left node and the outrigger 6-2 at the right node are variable-section structures. The end face of the beam connection is concave;

[0041] The connecting end surface of the left prefabricated beam 2-1 and the left node outrigger 6-1 is a convex surface, which is equal...

Embodiment 2

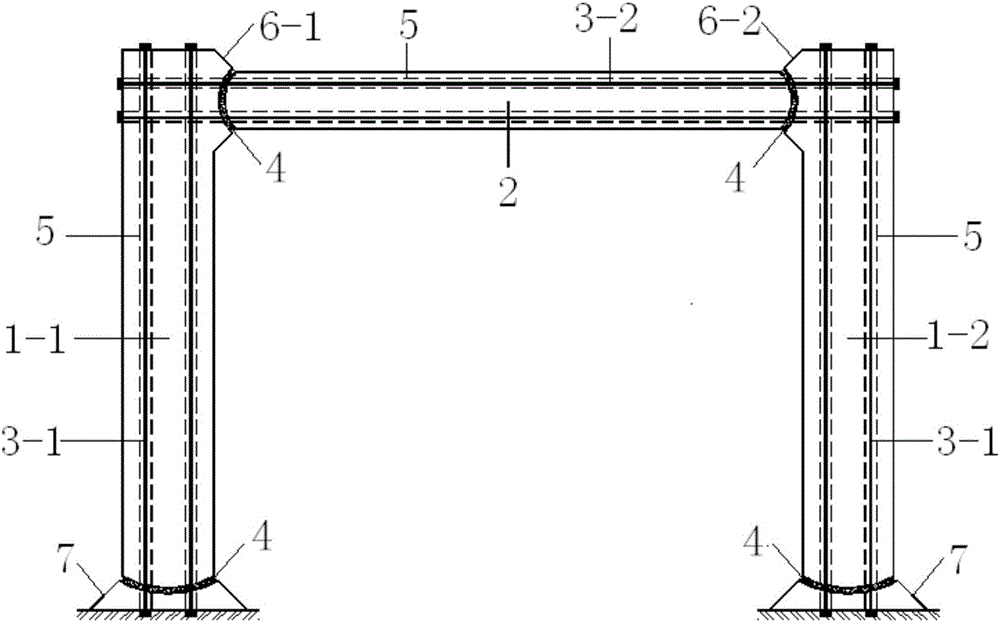

[0046] see image 3 , taking a single-story single-span planar frame structure as an example. A prestressed prefabricated concrete node curved surface connection structure, including a left prefabricated column 1-1, a right prefabricated column 1-2, a left node outrigger 6-1, a right node outrigger 6-2 and a prefabricated beam 2, left The precast column 1-1 is connected to one end of the precast beam 2 through the left node outrigger 6-1, and the right precast column 1-2 is connected to the other end of the precast beam 2 through the right node outrigger 6-2; the left precast column 1 -1 is integrally formed with the left node outrigger 6-1, and the right prefabricated column 1-2 is integrally formed with the right node outrigger 6-2;

[0047] The outriggers at the left and right nodes are of variable cross-section structure, the cross-section at the connection with the left and right prefabricated columns is large, the cross-section at the connection with the prefabricated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com