Relay

A relay, electromagnetic technology, applied in the direction of relay, electromagnetic relay, electromagnetic relay detailed information, etc., can solve the problem of increasing the installation space of the yoke-armature device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

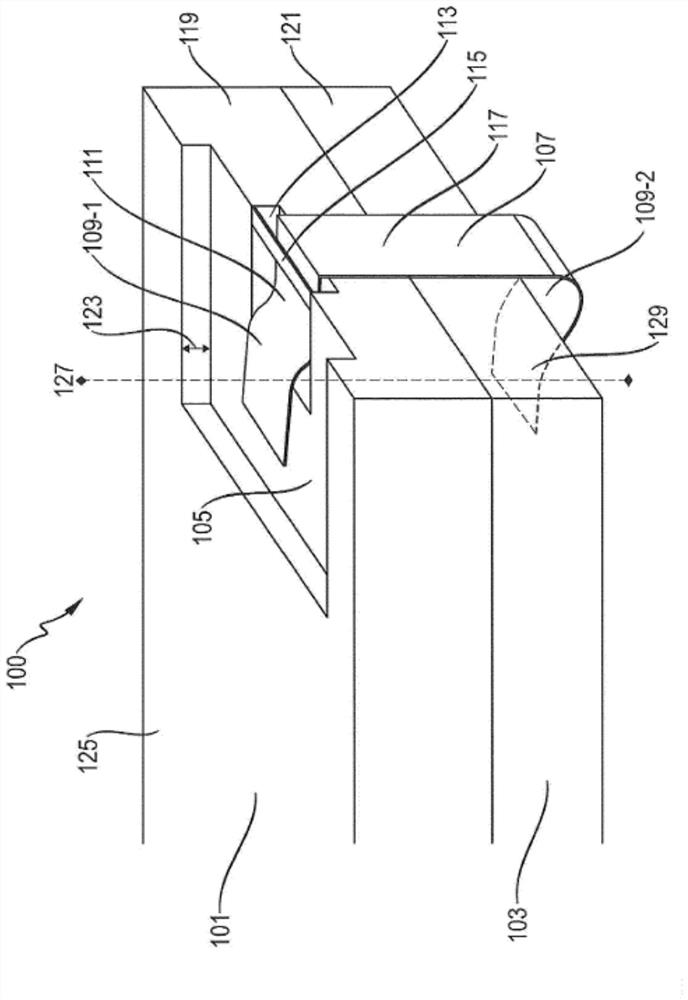

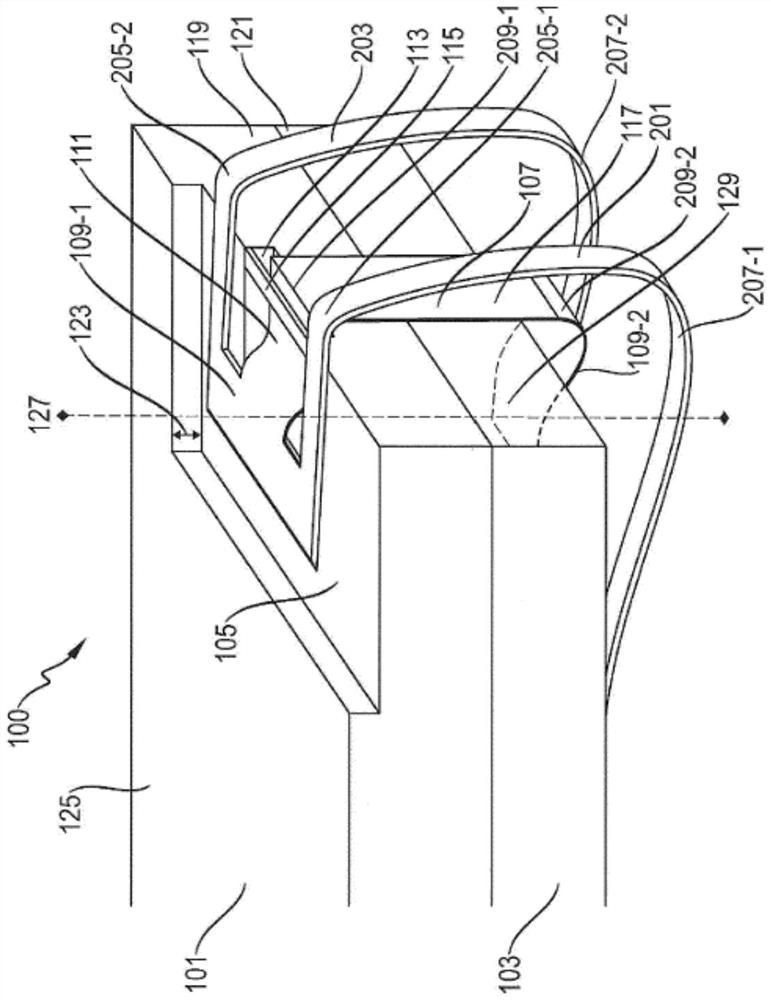

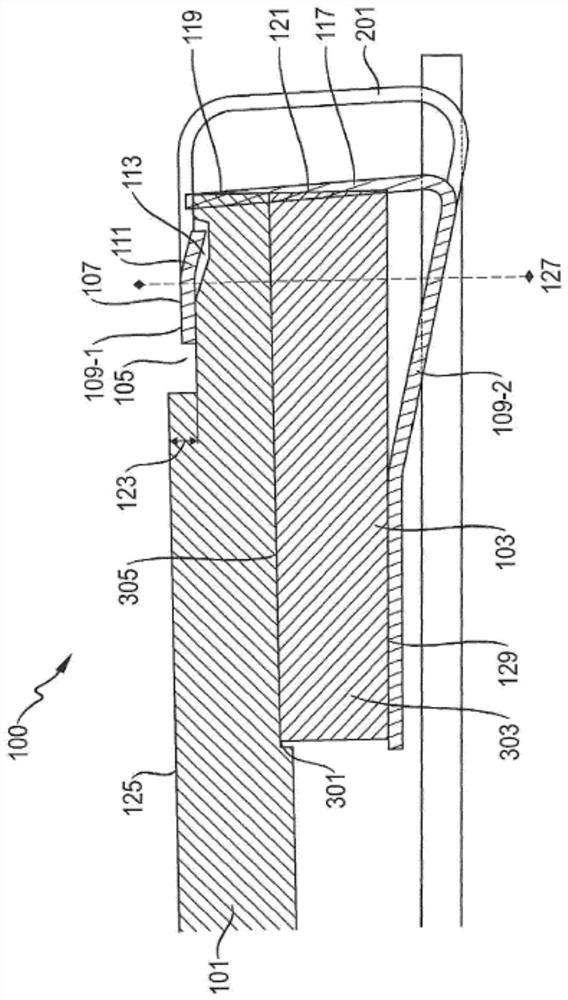

[0098] figure 1 A schematic diagram of the relay 100 , the relay includes an armature 101 and a yoke 103 that can be electromagnetically connected to the armature 101 . The armature 101 is at least partially flat on the yoke 103 , and the receiving groove 105 is partially formed in the armature 101 . The relay 100 also includes an arched clamping spring 107 , which is enclosed at the end faces of the armature 101 and the magnetic yoke 103 to fix the armature 101 on the magnetic yoke 103 . The arched clamping spring 107 has a first clamping arm 109 - 1 disposed in the receiving groove 105 and a second clamping arm 109 - 2 placed on the magnetic yoke 103 . Furthermore, the first clamp arm 109 - 1 has a curved tongue 111 which elastically engages in a recess 113 formed in the receiving groove 105 of the armature 101 .

[0099] The armature 101 has a web 115 which at least partially bridges the recess 113 and / or ends flush with the receiving groove 105 . The web 115 forms a clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com