Drum-shaped combined steel box joint, arch frame joint structure and construction method thereof

A node and steel box technology, applied in the field of support node installation and connection, can solve problems such as difficult construction, difficulty in pulling through steel bars, overlapping welds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

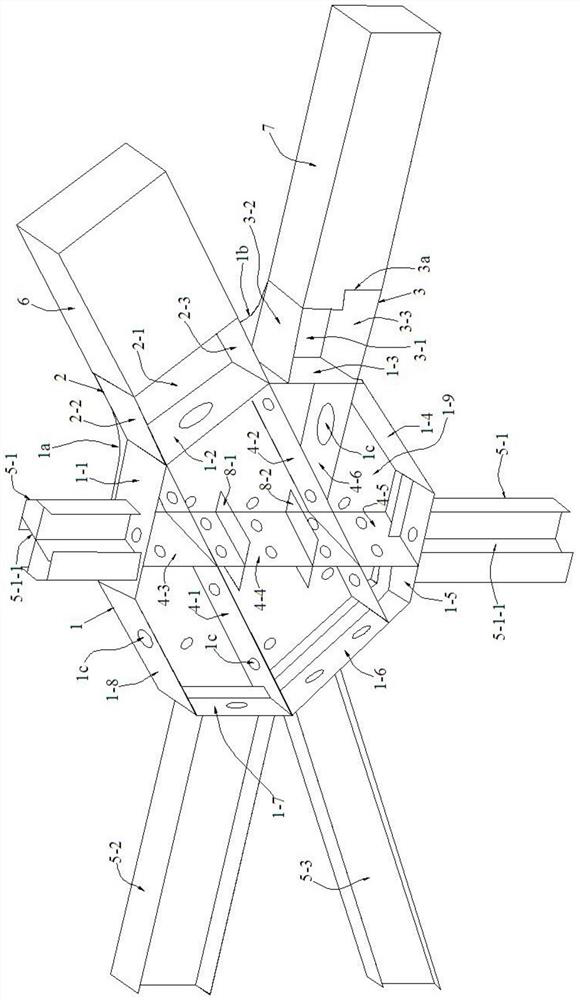

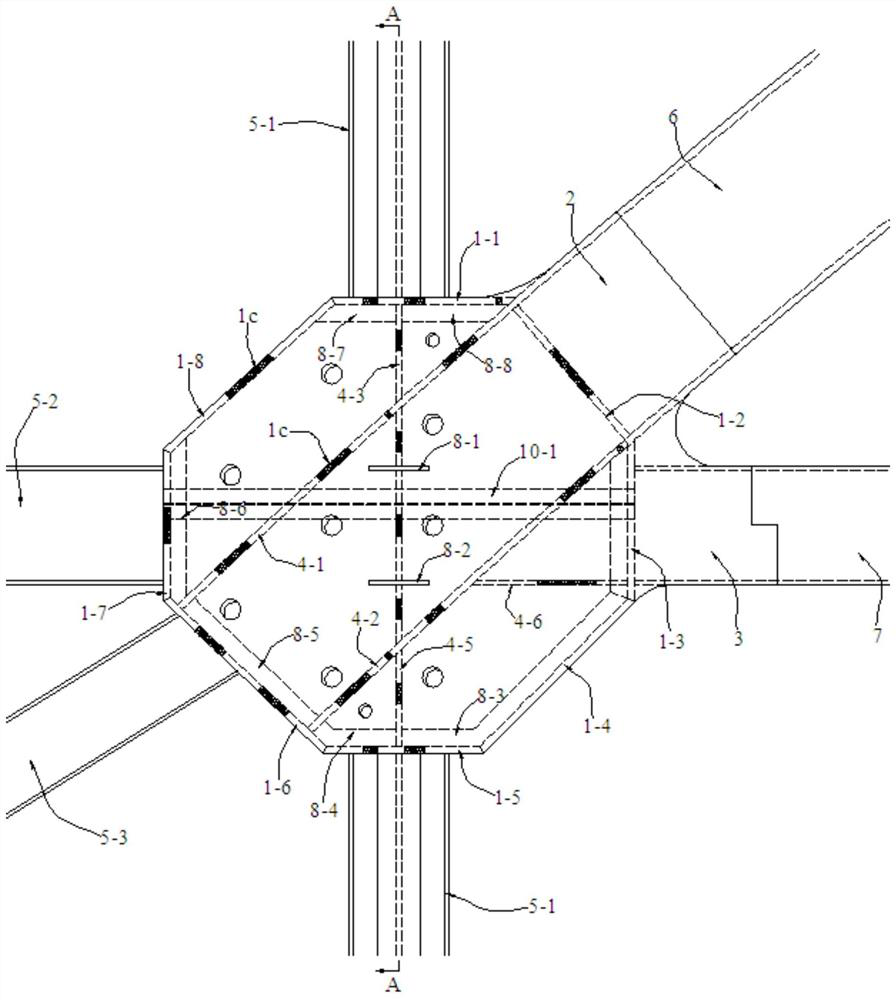

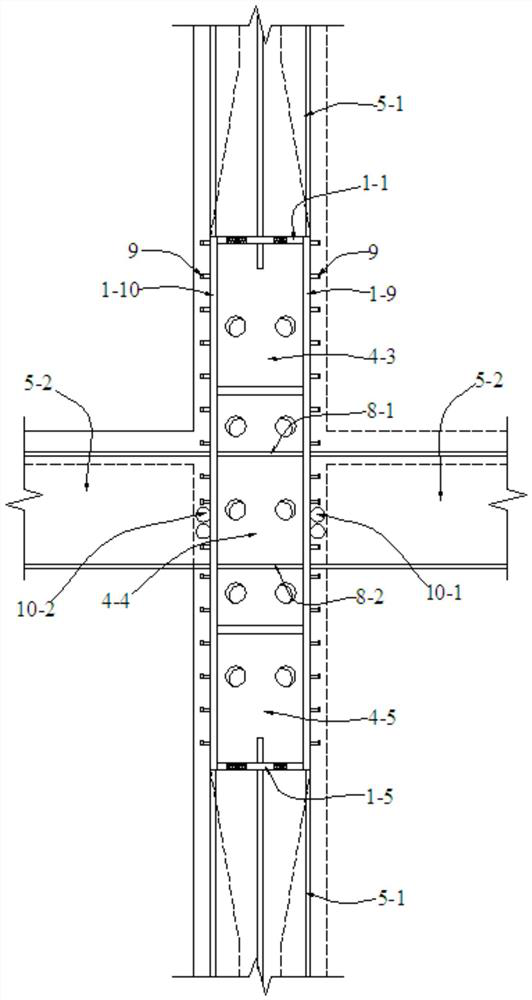

[0051] Such as Figure 1 to Figure 3 As shown, the present invention discloses a drum-shaped combined steel box node, which is characterized in that it includes: a node box 1, the node box 1 is composed of a box front panel 1-10, a box rear panel 1-9 and Composed of eight side panels, the eight side panels are connected end to end in turn and are welded vertically between the front panel 1-10 of the box and the rear panel 1-9 of the box, and the eight side panels are clockwise The directions are sequentially recorded as the first side plate 1-1 to the eighth side plate 1-8;

[0052] Moreover, the outside of the node box 1 is provided with a first corbel 2 whose internal port is connected to the second side plate 1-2 and a second corbel 3 whose internal port is connected to the third side plate 1-3. The outer port 3a of the second corbel 3 is a tongue and groove, to increase the length of the weld and stagger the connection port, and improve the welding reliability with the ar...

Embodiment 3

[0070] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

Embodiment 4

[0074] On the basis of any one of the above-mentioned Embodiments 1 to 3, this Embodiment 4 also adopts the following preferred implementation modes:

[0075] The inside of the node box is also provided with a sixth inner partition 4-6 vertically connected between the box front panel 1-10 and the box rear panel 1-9, and the sixth inner partition 4 -6 is connected between the second inner partition 4-2 and the third side panel 1-3 and is coplanar with the lower side panel 3-3 of the second corbel 3, and the sixth inner partition Plates 4-6 are provided with pouring communication holes 1c. Therefore, it is possible to increase the structural strength of the drum-shaped combined steel box joint margin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com