Orthotropic deck plate bolt welding joint and external wide splice plate

A technology of splicing plates and webs, which is used in bridges, bridge parts, bridge construction and other directions to achieve smooth and reliable force transmission, improved fatigue performance, and convenient production and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

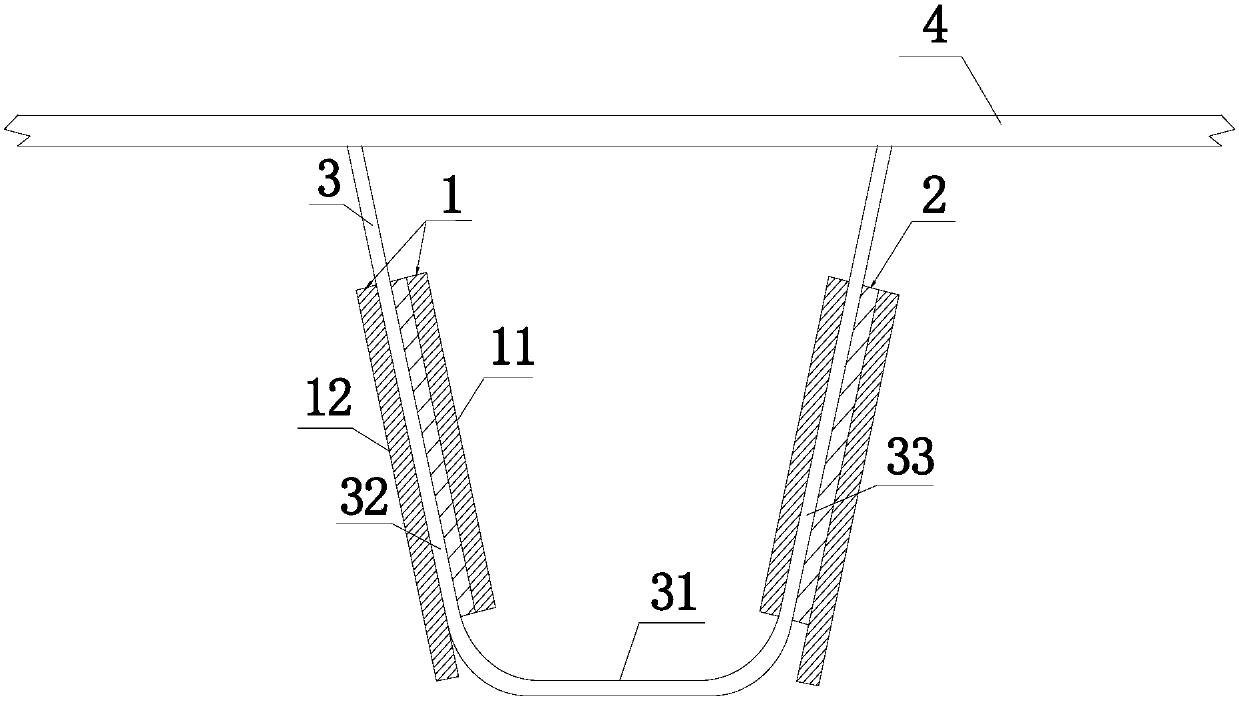

Embodiment 1

[0038] Example 1: The impact of the U-rib butt joint deviation of the roof on the unfavorable stress of the bolted welded joints of the orthotropic bridge deck It is Q345qc steel. The height of the standard section is 3.58m, the width is 40.54m, the thickness of the top plate is 16mm, the thickness of the bottom plate is 14mm, the thickness of the transverse diaphragm is 12mm, the thickness of the reinforced transverse diaphragm is 16mm, the thickness of the middle longitudinal web is 14mm, the thickness of the side longitudinal web is 14mm, and the distance between the transverse diaphragms is 3m. The longitudinal U-rib section is 300×280×8mm, and the center distance is 600mm. The steel box girder sections are connected by bolt welding, except that the U-rib of the top plate is connected by splicing plate bolts, and the rest of the beam sections are welded. U-rib butt joint spacing is 16mm. The design size of the splicing board is 536mm (length) × 180mm (width) × 12mm (thi...

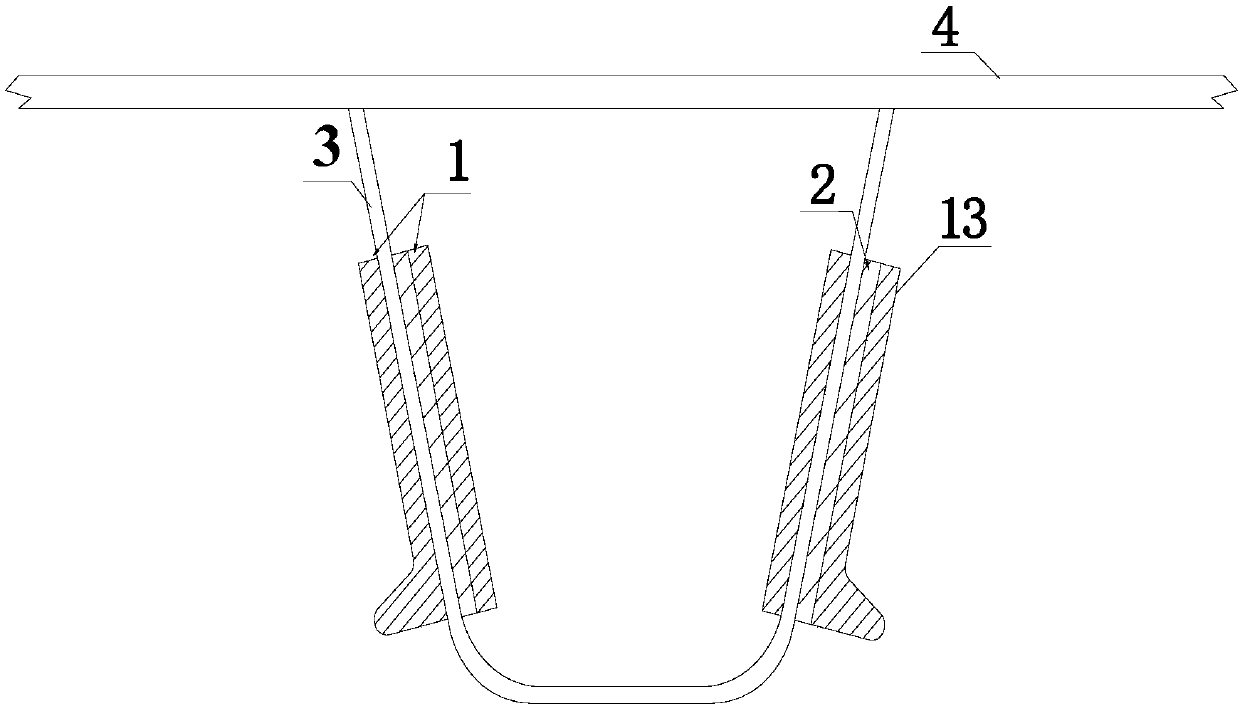

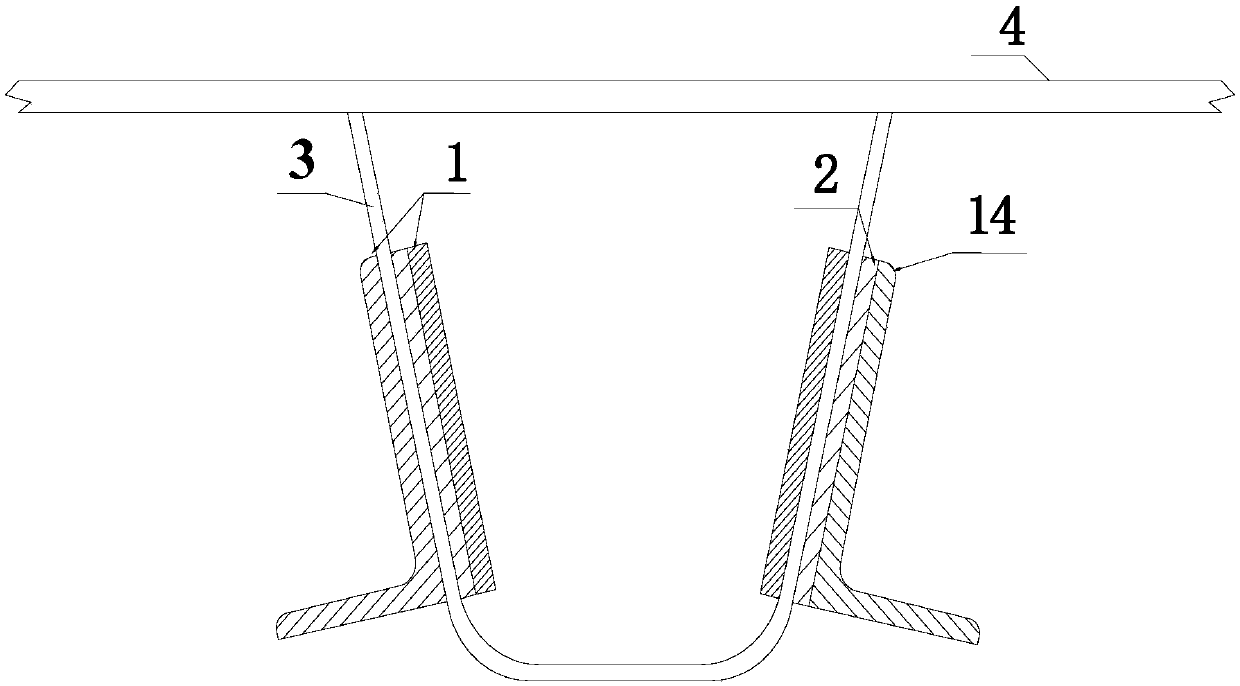

Embodiment 2

[0046] Embodiment 2: Improvement of the unfavorable stress of the bolted welded joint after the outer spliced plate adopts the present invention (to ensure that the number of materials used remains unchanged)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com