Dobby loom and loom mounted with said dobby loom

A technology for dobby machines and looms, applied in the field of dobby machines, can solve the problems of high force, bending or breaking of large-diameter rods, expensive materials, etc., to achieve effective force transmission, loose manufacturing tolerances, and cheap materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

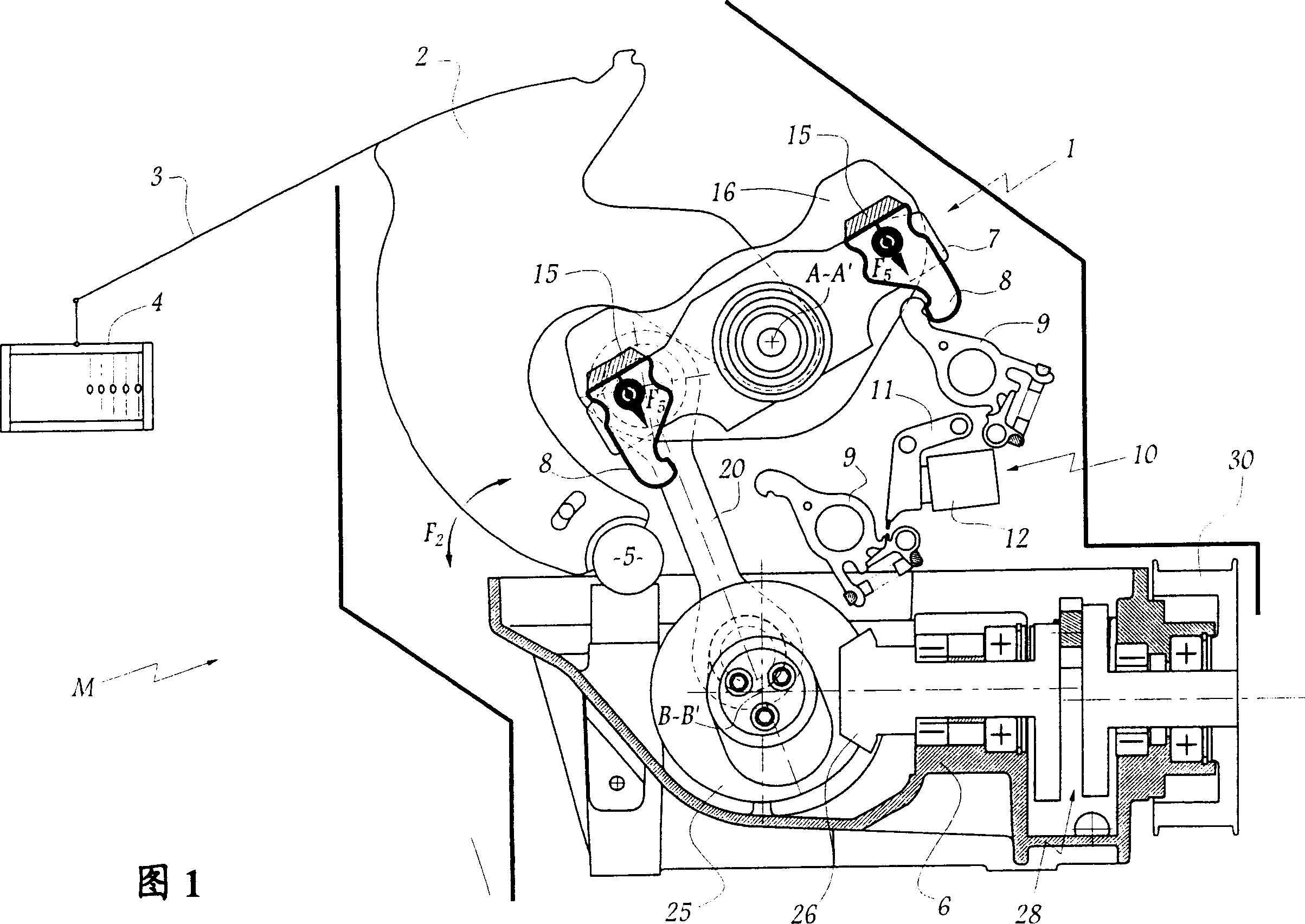

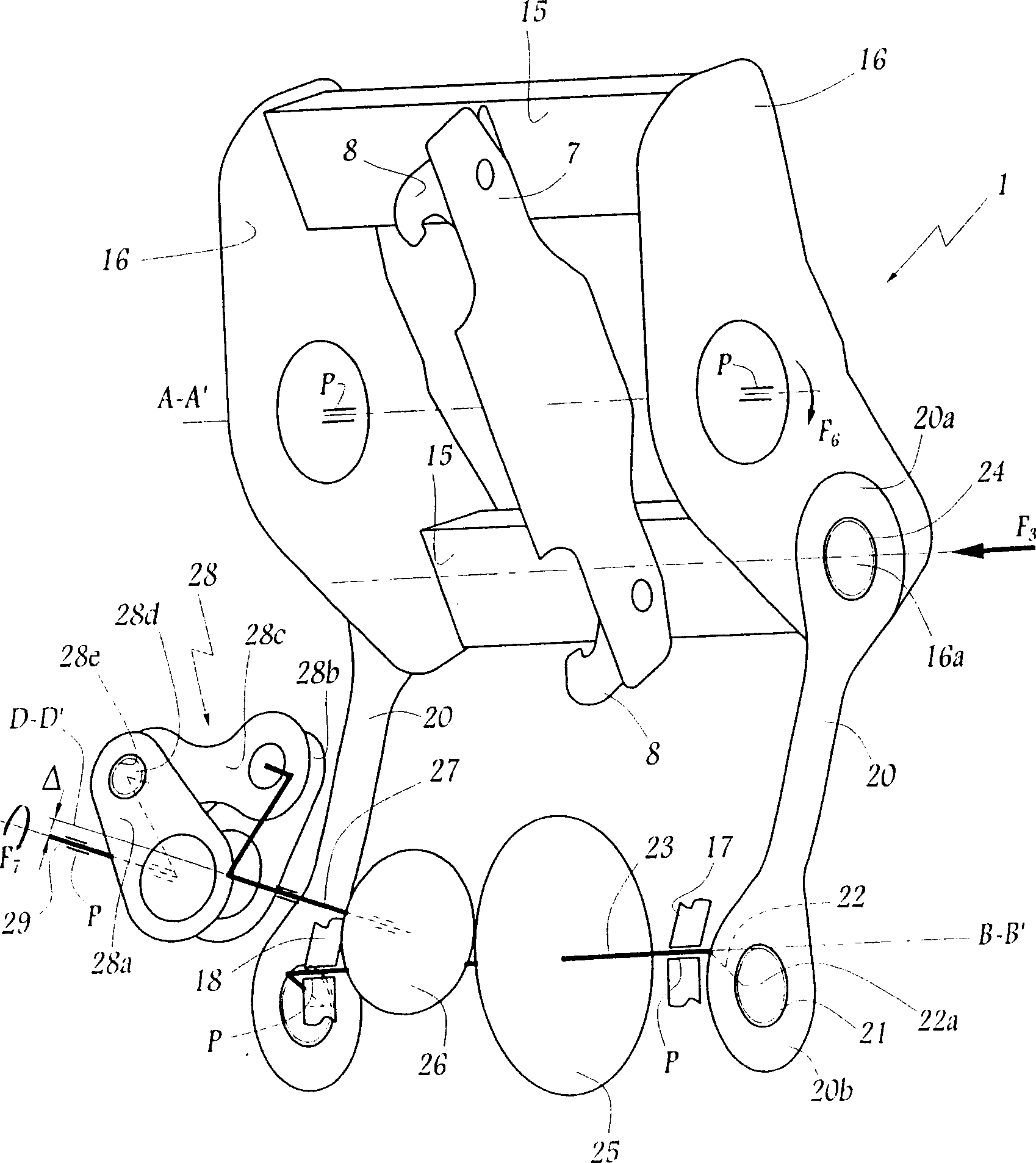

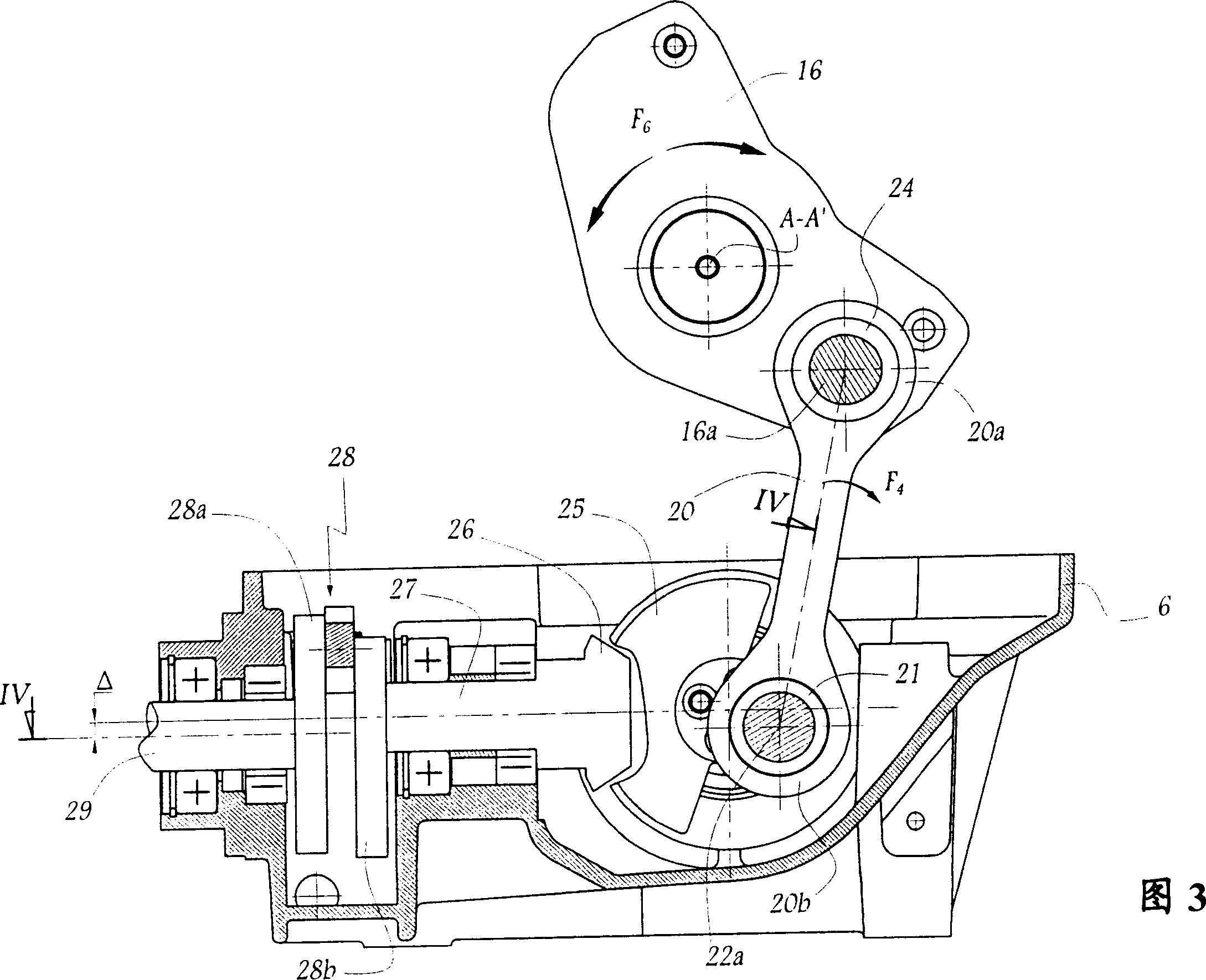

[0019] Referring now to the drawings, the dobby 1 shown in FIGS. The swing bar 2 is connected to a heald frame 4 of a loom M via a drawing cable 3 . The lever 2 is mounted to pivot about an axis 5 fixed relative to the frame 6 of the dobby 1 . arrow F 2 Indicates the rocking motion of rod 2.

[0020] The rod 2 is equipped with a double rocking rod 7 on which are articulated for selective control with a rocking rod 11 (rocking rod) belonging to a threading device 10 and interacting with an electromagnet 12. Keep hook 8 engaged with hook 9.

[0021] In order to pivot the double rocker 7 interacting with the rods 2 about an axis A-A' fixed relative to the frame 6, between the two drives 16 there is supported a pusher element 15 extending therebetween.

[0022] In this way, following the pivotal movement of the lever 7, one or the other of the movable hooks 8 can be held by one of the hooks 9, while the lever 2 is held in position near the dead center of its stroke. In the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com