Patents

Literature

41results about How to "Convenient welding construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

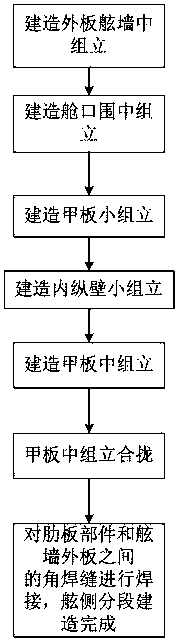

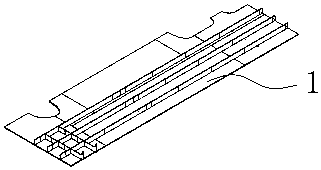

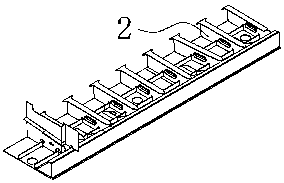

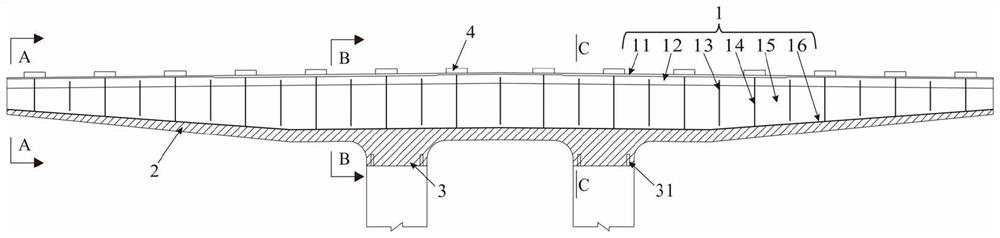

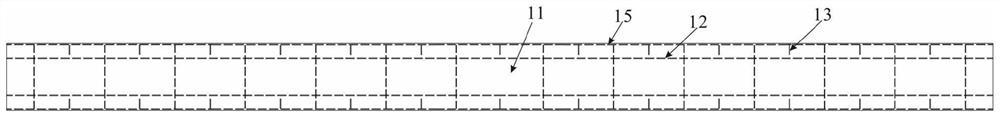

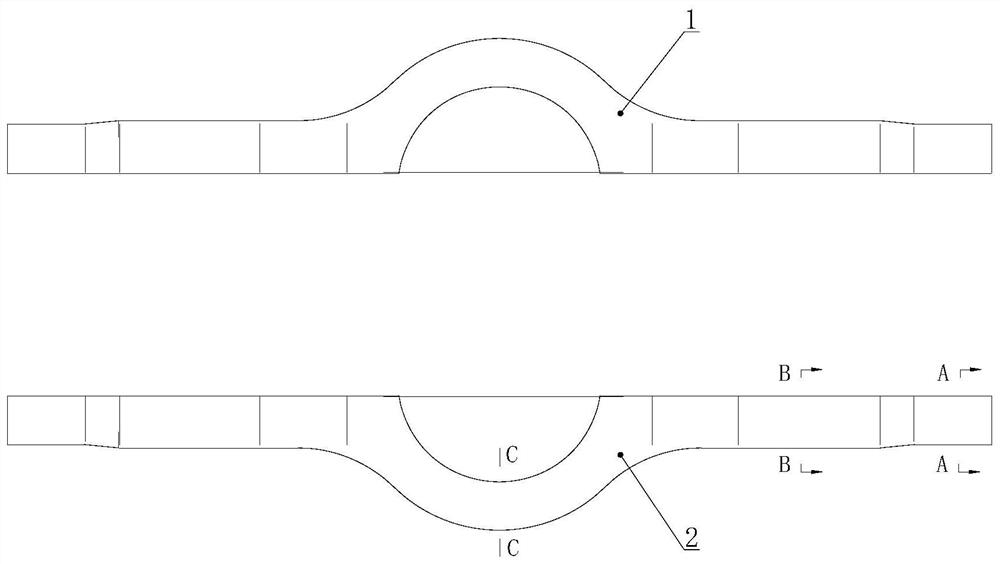

Broadside subsection integrated construction method

InactiveCN108177730AControl positioning welding accuracyAvoid wastingVessel partsEngineeringIntermediate product

The invention discloses a broadside subsection integrated construction method, and belongs to the technical field of ship construction. The broadside subsection integrated construction method comprises the following steps that 1, a planking bulwark middle assembly is constructed by taking a planking as a base face; 2, a hatch coaming middle assembly is constructed by taking a midship longitudinalwall as a base face; 3, a deck small assembly is constructed by taking the upper surface of a deck as a base face; 4, taking a longitudinal wall splicing plate as a base face, a rib plate part is mounted on an inner longitudinal wall splicing plate to form an inner longitudinal wall small assembly; 5, the deck small assembly is overturned by 90 degrees to be folded with the inner longitudinal wallsmall assembly so as to form a deck middle assembly; 6, the planking is overturned by 180 degrees and then hoisted to the top of the deck middle assembly to be folded, and the hatch coaming middle assembly is transversally moved and folded to the side face of the deck middle assembly, so that a broadside subsection is formed; and 7, the broadside subsection is overturned by 180 degrees, and welding is completed. A planking bulwark and a hatch coaming are integrally constructed, the integrity of the ship section intermediate product is expanded, the precision of ship construction is improved,and the efficiency of ship construction is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

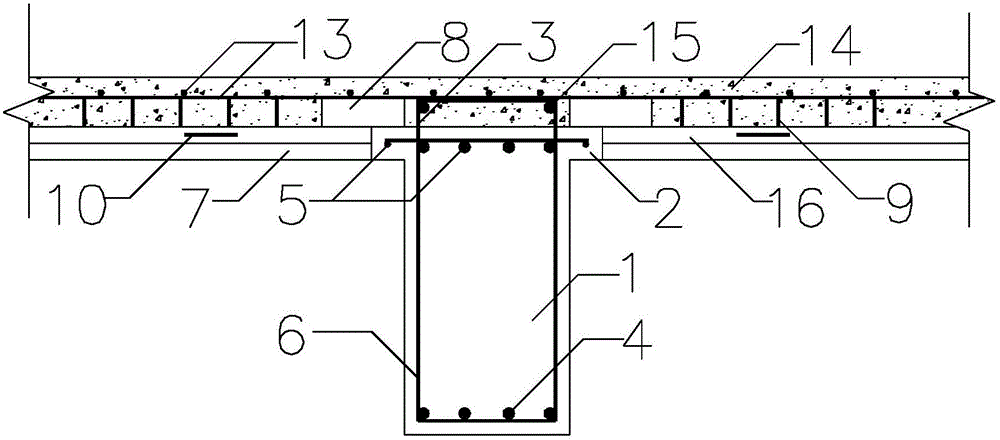

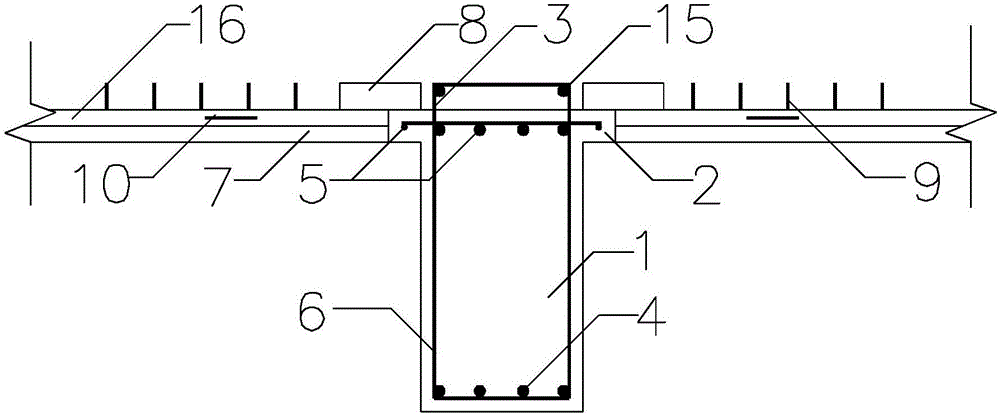

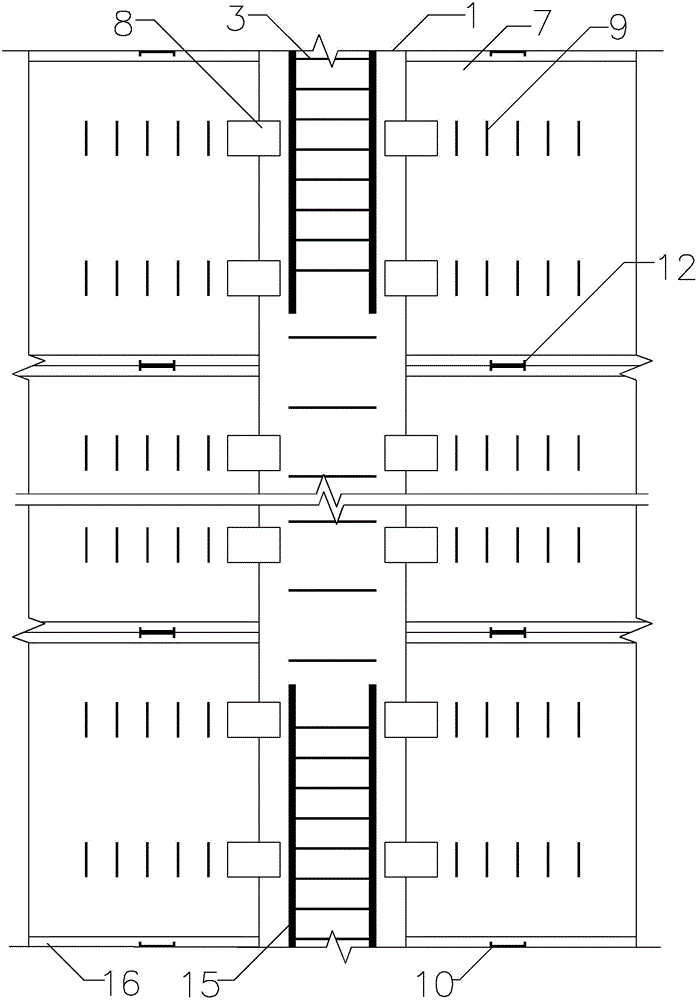

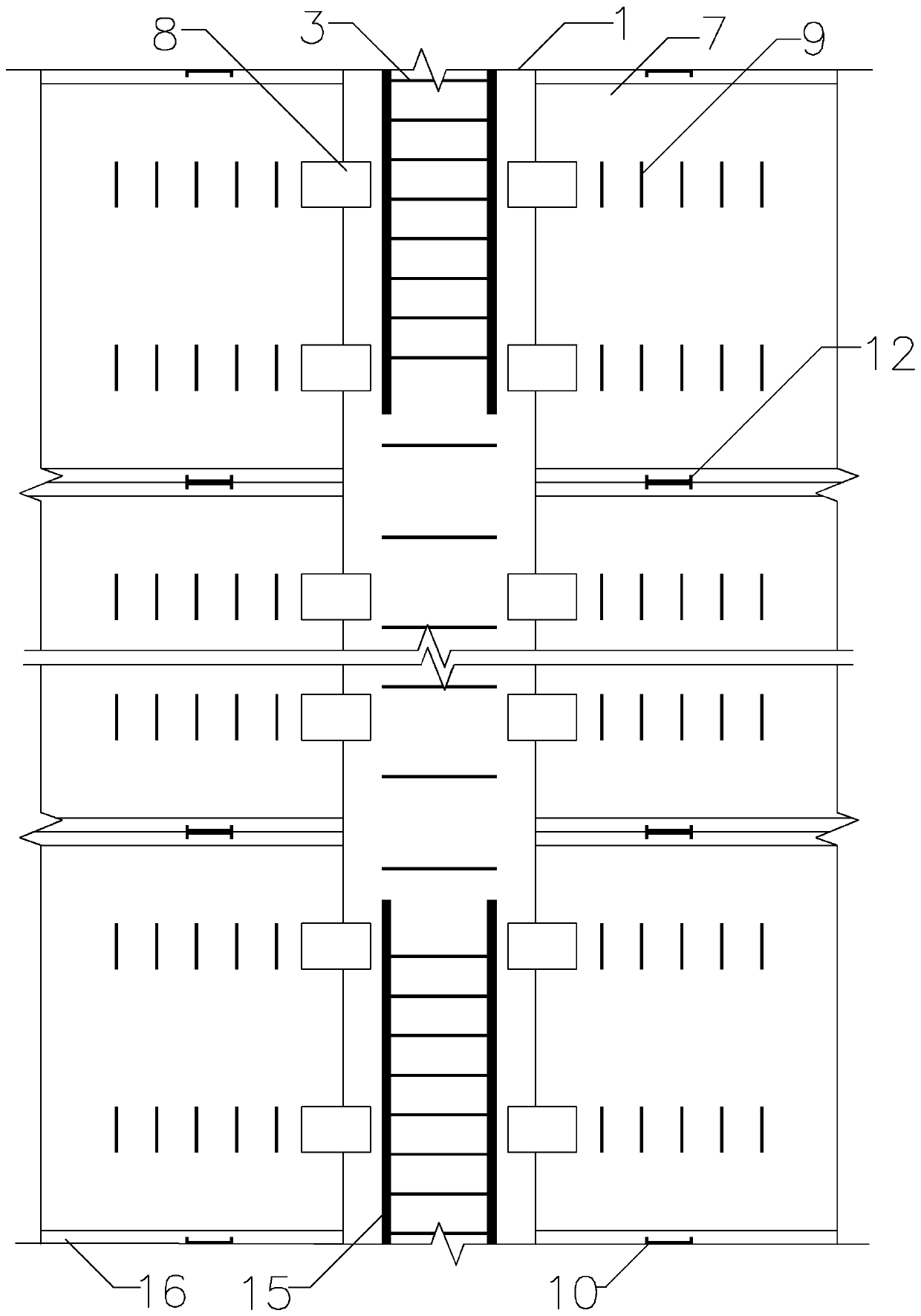

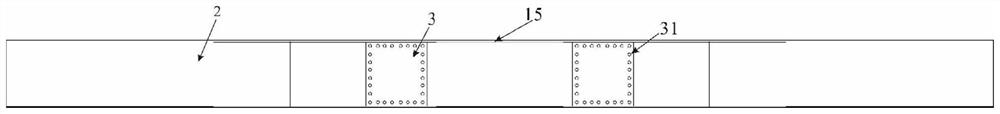

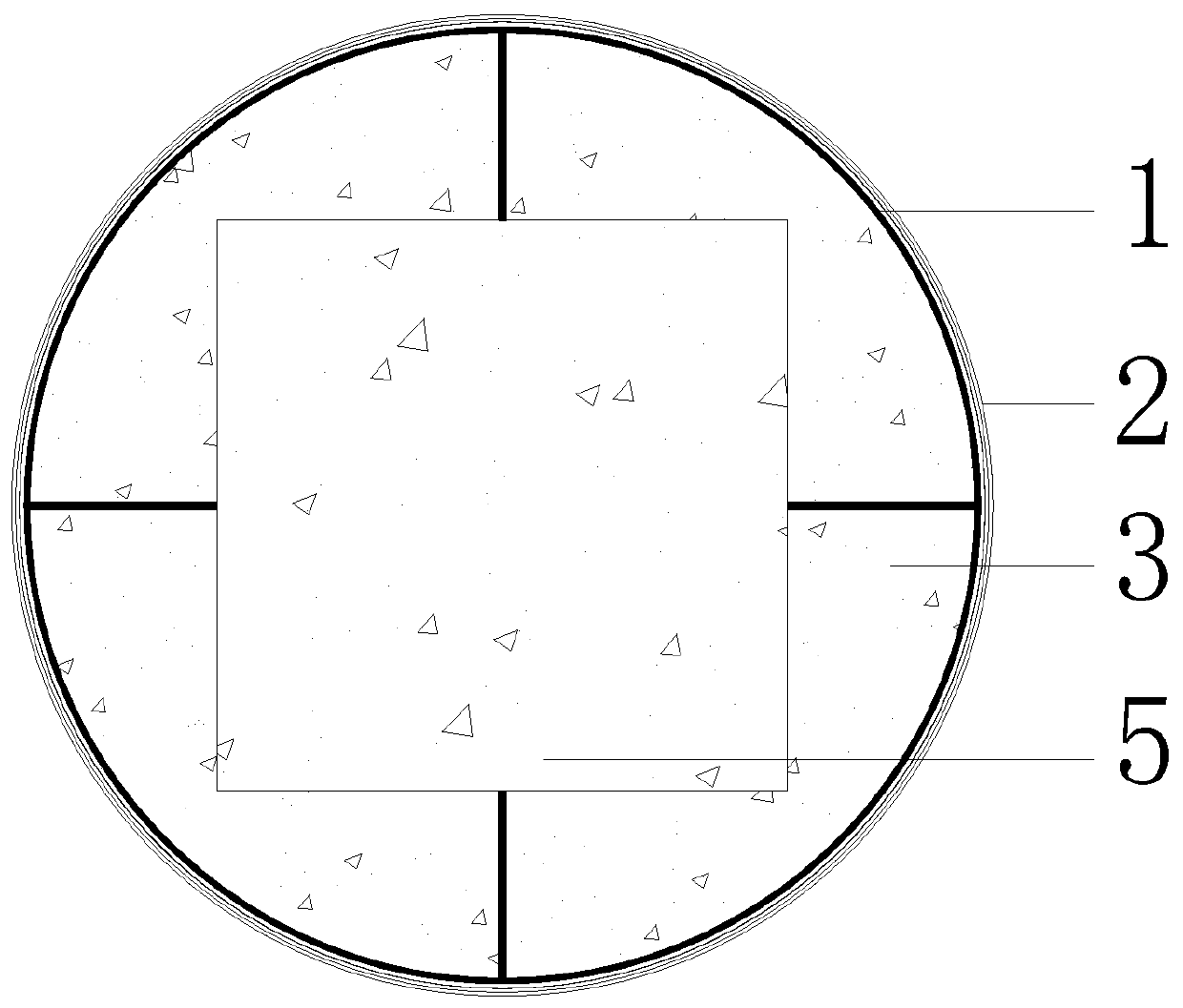

Assembled reinforced concrete beam-slab structural system with cast-in-situ layer in building structure

ActiveCN106065663AReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteEngineering

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

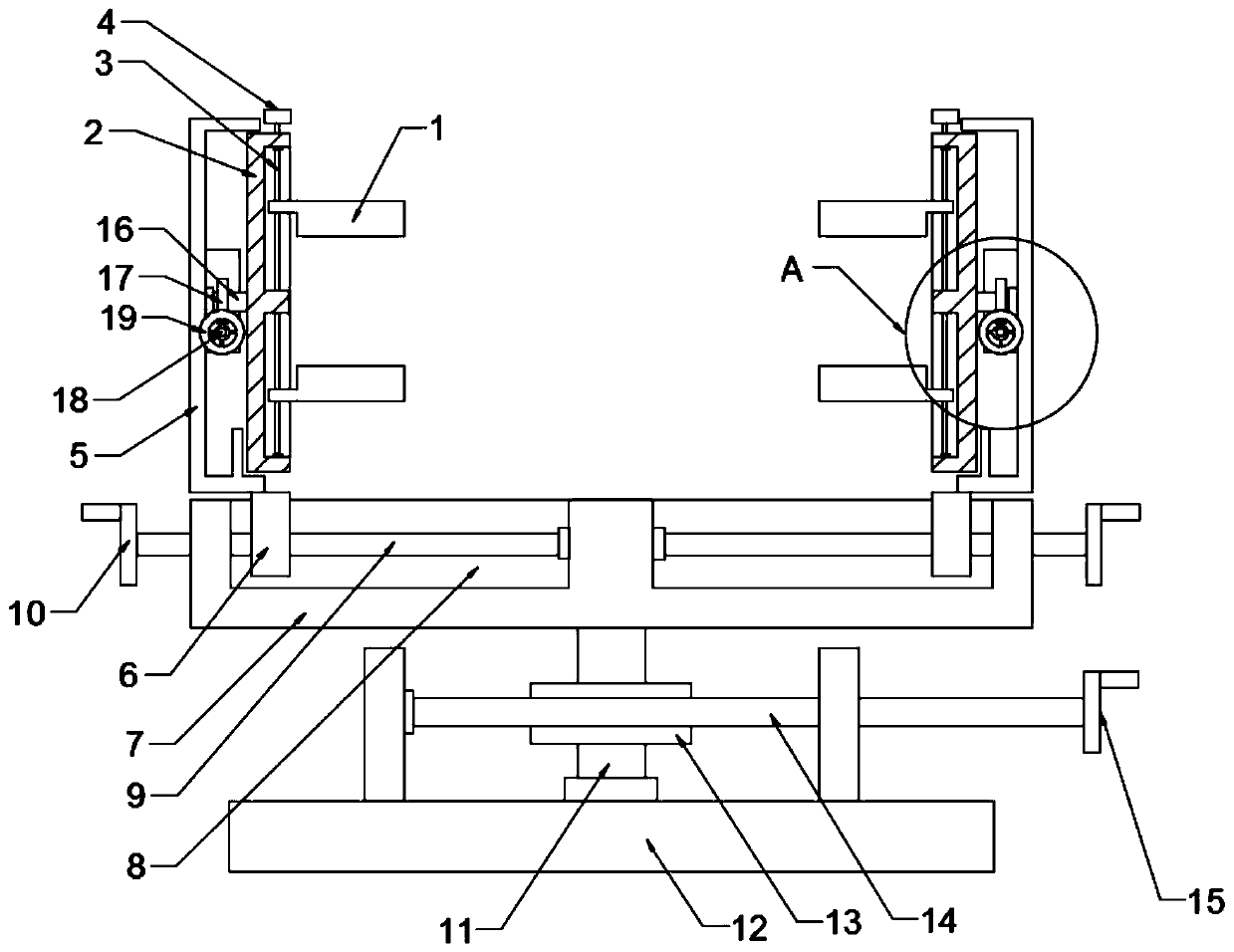

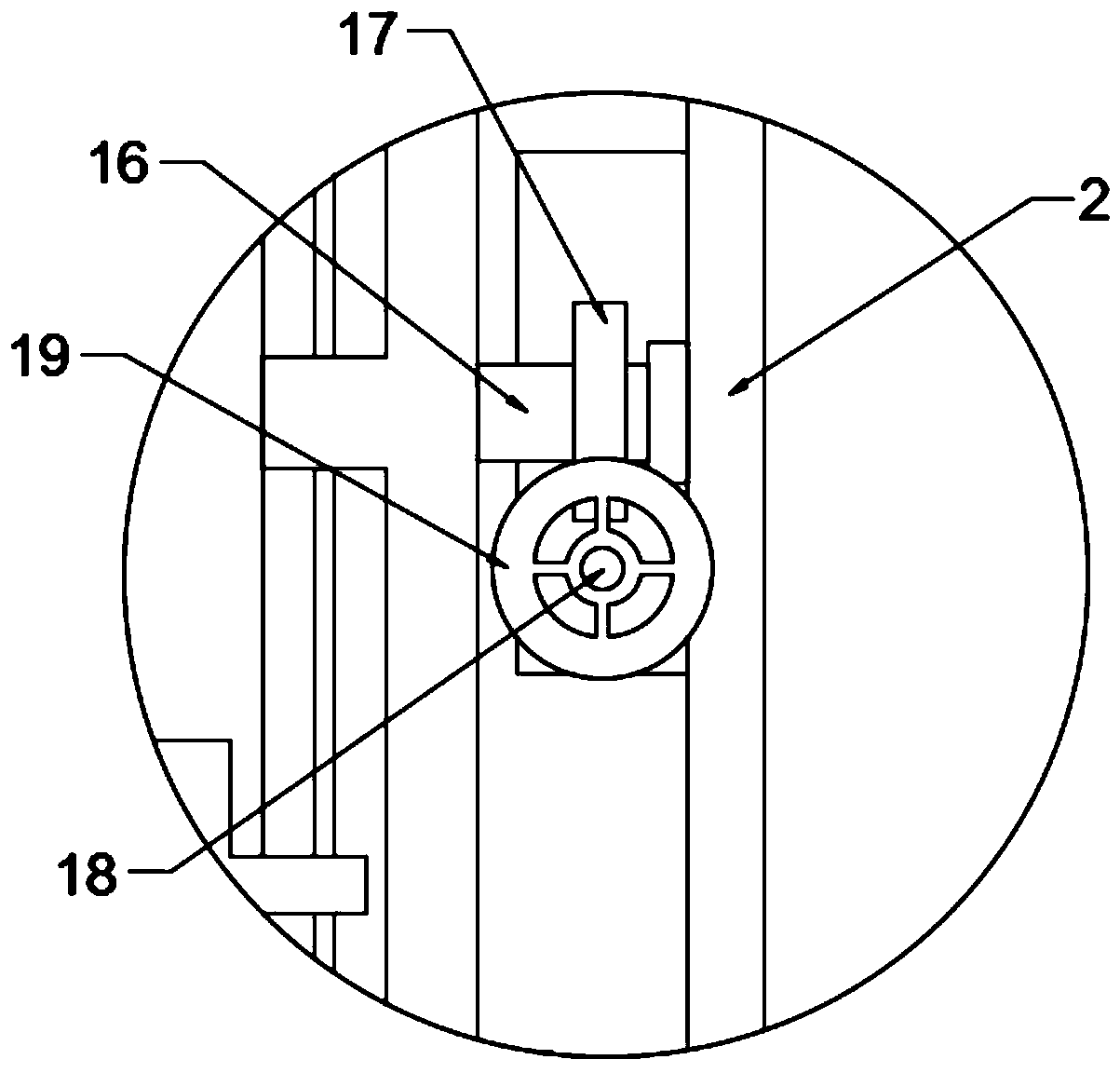

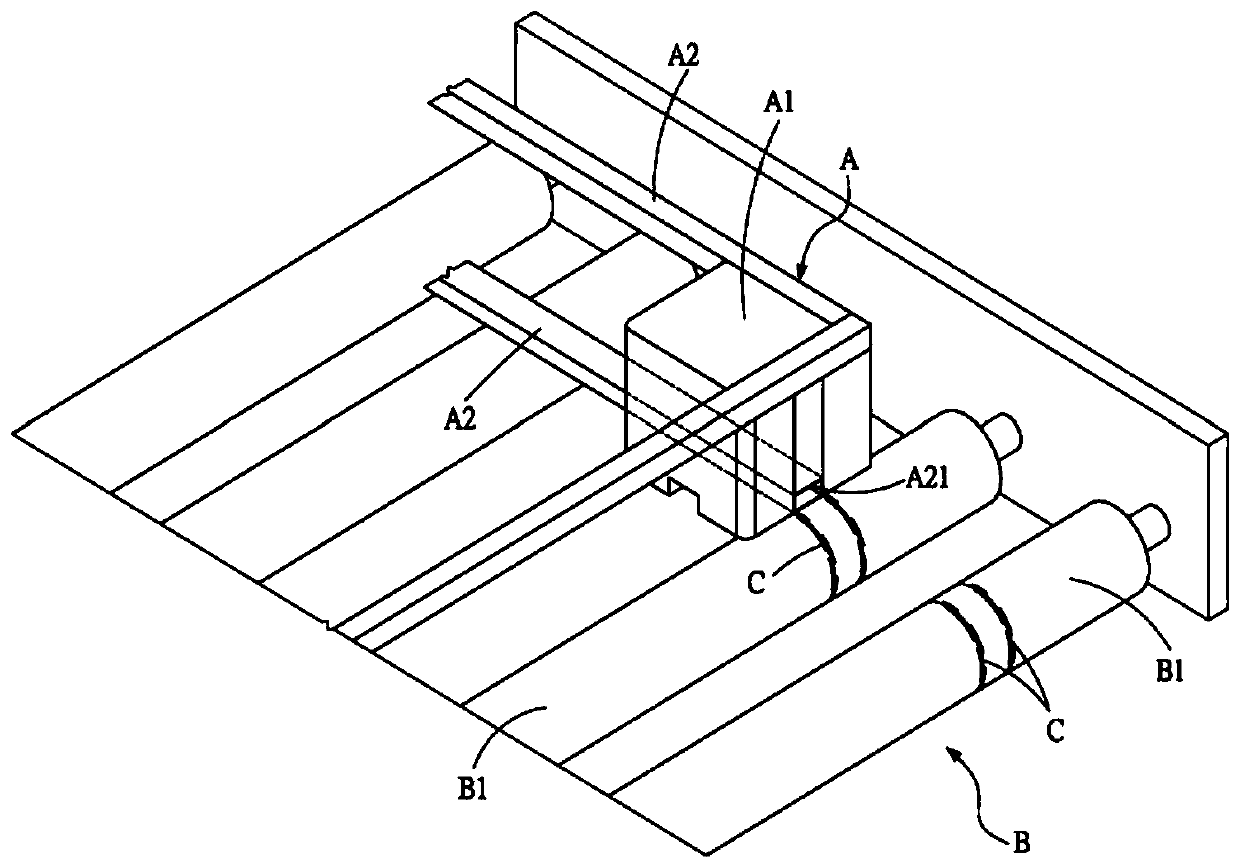

Multi-degree-of-freedom clamping device for mechanical welding

InactiveCN110497140AEasy to findEasy to flip in placeWelding/cutting auxillary devicesAuxillary welding devicesDegrees of freedomMulti degree of freedom

The invention discloses a multi-degree-of-freedom clamping device for mechanical welding. The clamping device comprises a clamping device body, wherein the clamping device body comprises two sets of clamping plate sets which are oppositely arranged, and rotating tables are nested on the outer sides of the clamping plates; and moving frames are arranged on the outer sides of the rotating tables ina sleeving mode, moving blocks are fixedly connected to the lower ends of the moving frames, and rotating seats are nested in the moving blocks. According to the multi-degree-of-freedom clamping device for the mechanical welding, the moving frames, the moving blocks and screw rods are arranged, so that the distance between two sets of clamping plates can be changed conveniently to be suitable forfixation before welding of workpieces with different sizes and specifications; according to the clamping device, rotating seats, supporting shafts, first worm gears and first worms are arranged, so that the overall orientation of a workpieces can be conveniently adjusted, and welding points can be conveniently found; the rotating tables, horizontal shafts, second worm gears and second worms are arranged, so that the workpiece can be conveniently overturned in situ to find appropriate welding construction angle welding construction is facilitated, and the construction quality is improved; and the clamping device is simple in structure, stable in clamping and large in adjustment degree of freedom.

Owner:凌军

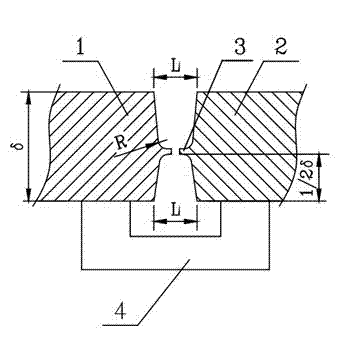

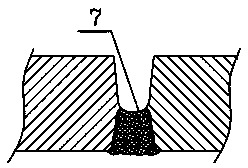

Welding torch used for composite welding of laser beams and plasma arc

A multifunctional laser beam and plasma arc composite welding torch is provided with a laser-penetrating cavity. A compression nozzle is arranged at the lower end of the welding torch cavity. A slit is formed through a plasma electrode on the compression nozzle of the welding torch. Parts of laser beams are incident on the slit edge of the electrode, and parts of the laser beams penetrate through the slit to focus on a workpiece. The electrode heated by the laser beams causes gas ionization to form a plasma arc between the electrode and the compression nozzle firstly. After compressed by the compression nozzle, the plasma arc is built between the nozzle and the workpiece. The laser beams penetrating through the nozzle focus and interact with the plasma arc to form plasma-laser discharging, accordingly the plasma arc is further contracted, and under the combined action with the laser beams, a welding point with the high energy density is formed on the workpiece. The multifunctional laser beam-plasma arc composite welding torch removes the defects of laser welding and plasma welding and has the composite heat source coupling efficiency higher than that of conventional laser beam-electric arc composite welding.

Owner:王长春

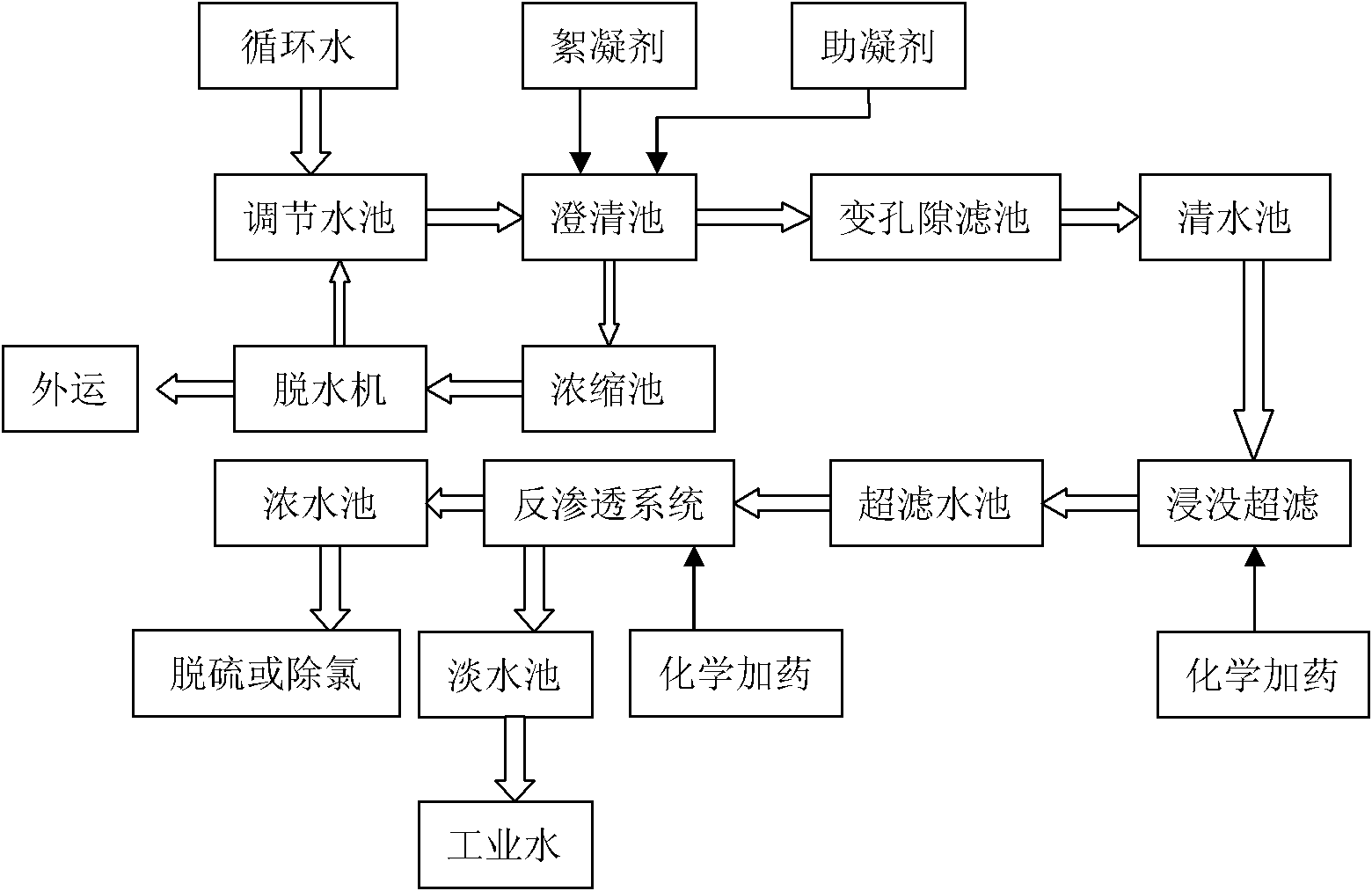

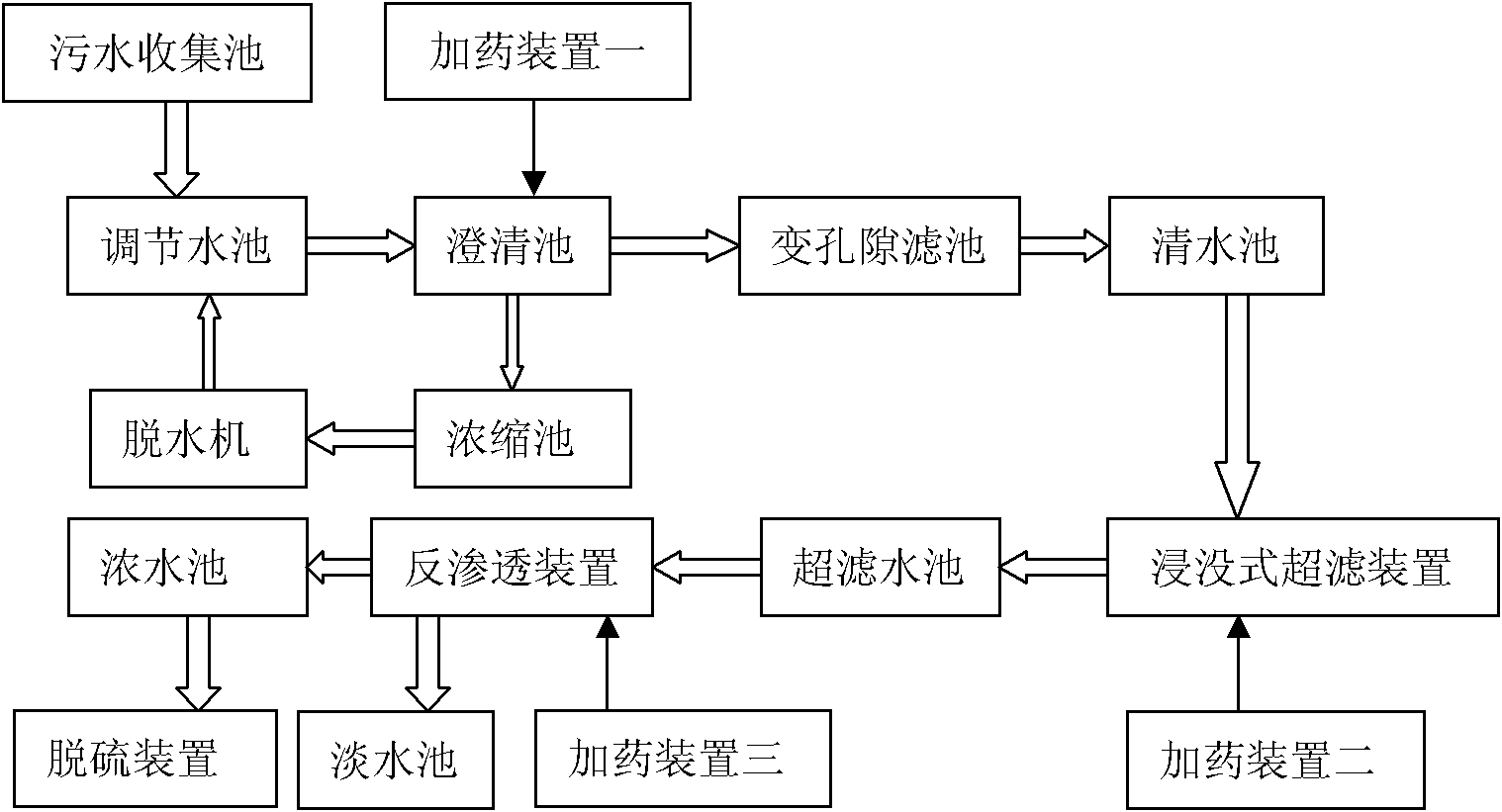

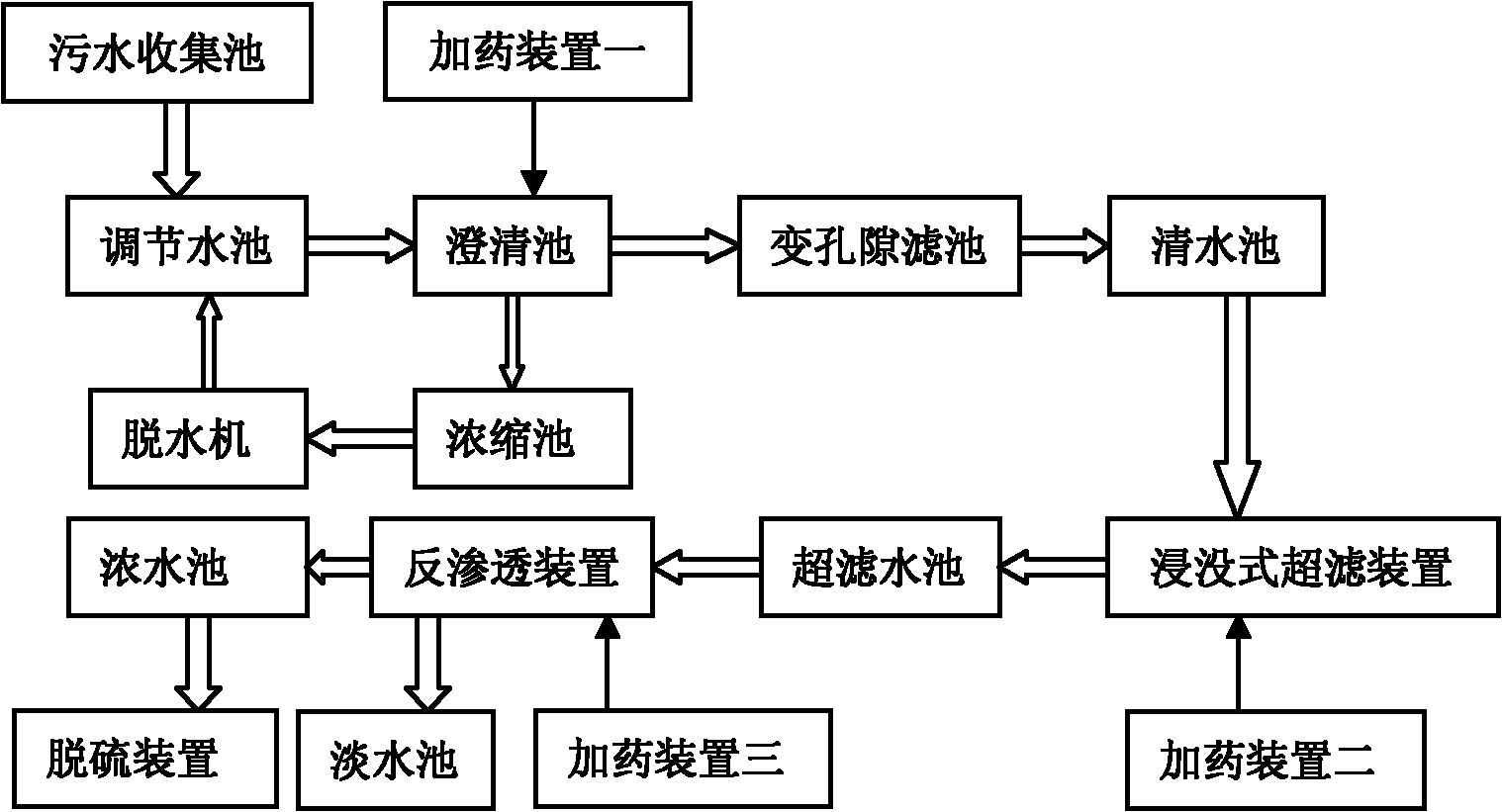

Recycling treatment process and apparatus system of power plant circulating water

InactiveCN102464412AGuaranteed uptimeEasy to installMultistage water/sewage treatmentLoad resistanceWater source

The invention discloses a recycling treatment process and a recycling treatment apparatus system of power plant circulating water. According to the invention, power plant circulating water is sequentially subject to mechanical accelerated clarification, variable void filtration, submerged ultrafiltration and reverse osmosis membrane treatments. Clear water obtained after the treatments is adopted as an industrial water source for the power plant. Compared to existing technologies, mechanical accelerated clarification, variable void filtration, submerged ultrafiltration and reverse osmosis membrane treatment technologies and an apparatus system employing the technologies are adopted. The technology and the system are advantaged in impact load resistance, low operation pressure, simple and feasible technical operation and maintenance, convenient pipeline installation, and the like. With the method and the system, recycling of power plant circulating water can be promoted. The technology and the system satisfy a development trend of energy saving and consumption reducing. With the technology and the system, recycling of water resource is effectively promoted.

Owner:董金奎

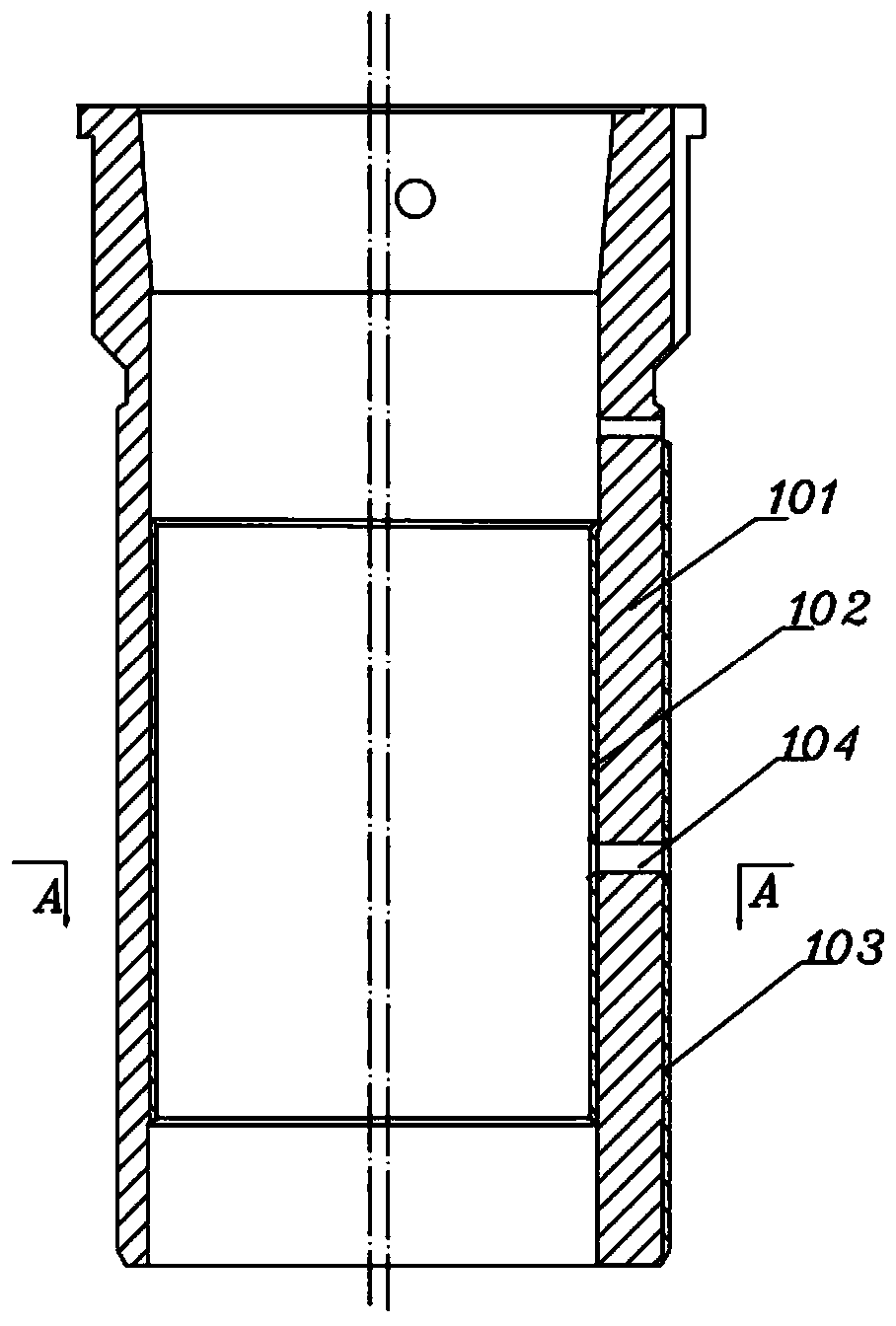

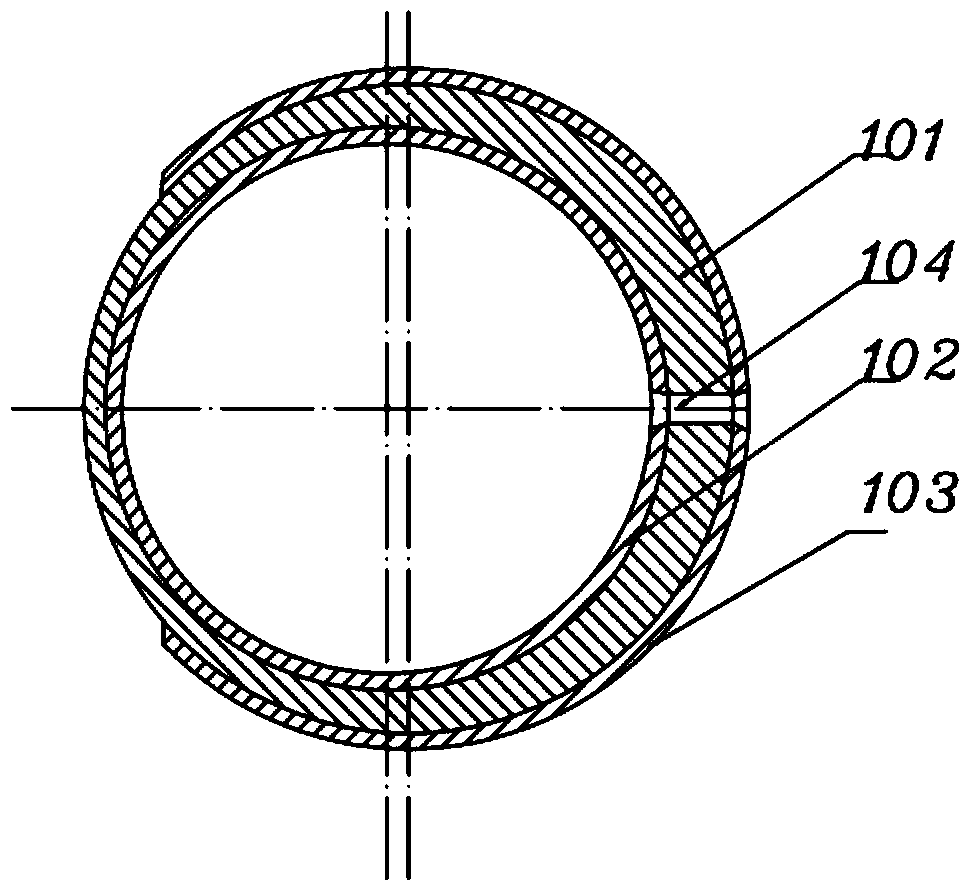

Restoring method of eccentric bushing and eccentric bushing

ActiveCN103418887AExtended service lifeImprove the mutual bonding strengthArc welding apparatusGrain treatmentsBronzeBond strength

The invention relates to a restoring method of an eccentric bushing, which comprises a cast steel matrix on which Babbitt alloy composite layers are poured and comprises the following steps of A, preparing, cleaning and washing a to-be-restored eccentric bushing and manufacturing a restoring tool; B, removing the original Babbitt alloy composite layers; C, performing flaw detection on the cast steel matrix subjected to the treatment in the step B; D, protecting a non-welding position; E, blocking slots and holes on the cast steel matrix by welding; F, overlaying the cast steel matrix by aluminum bronze to prepare a semi-finished product of the eccentric bushing; and G, machining. The method has the beneficial effects that the operation is simple, and field operation is facilitated; the restoring period is short, and the cost is low; the restored eccentric bushing is good in bonding strength; local or overall repeated restoration utilization is realized. The invention also discloses the eccentric bushing, which comprises the cylindrical cast steel matrix, and the inner wall and the outer wall of the cast steel matrix are overlaid with the Babbitt alloy composite layer respectively. The eccentric bushing has the benefit that the service life is prolonged by more than one time that of the original product.

Owner:烟台开发区蓝鲸金属修复有限公司

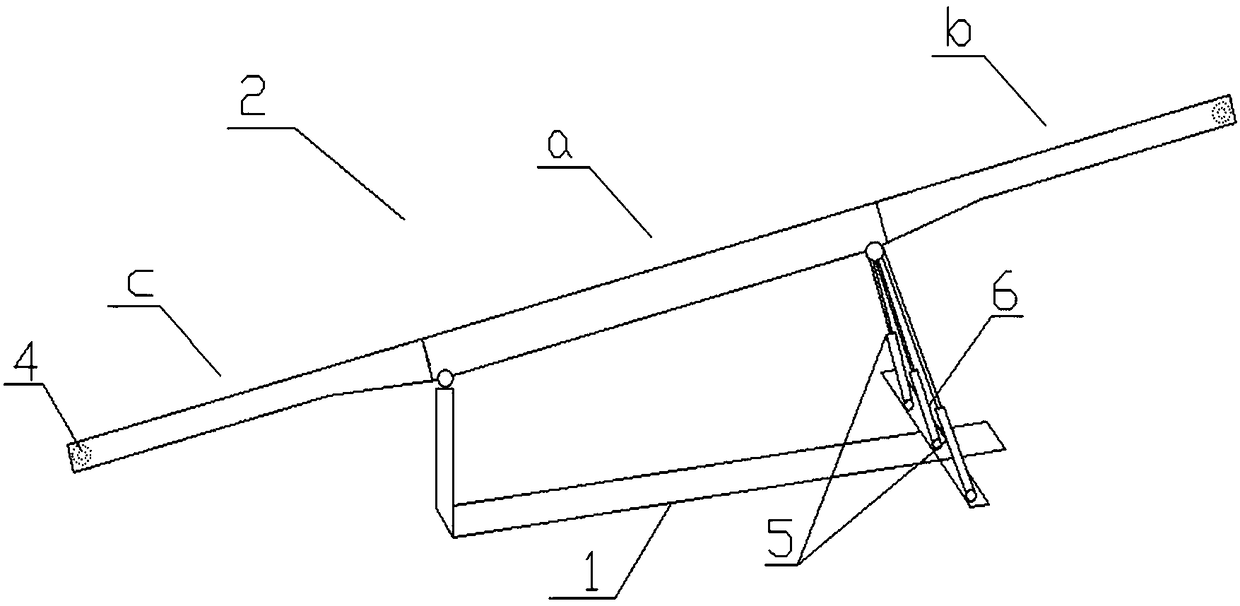

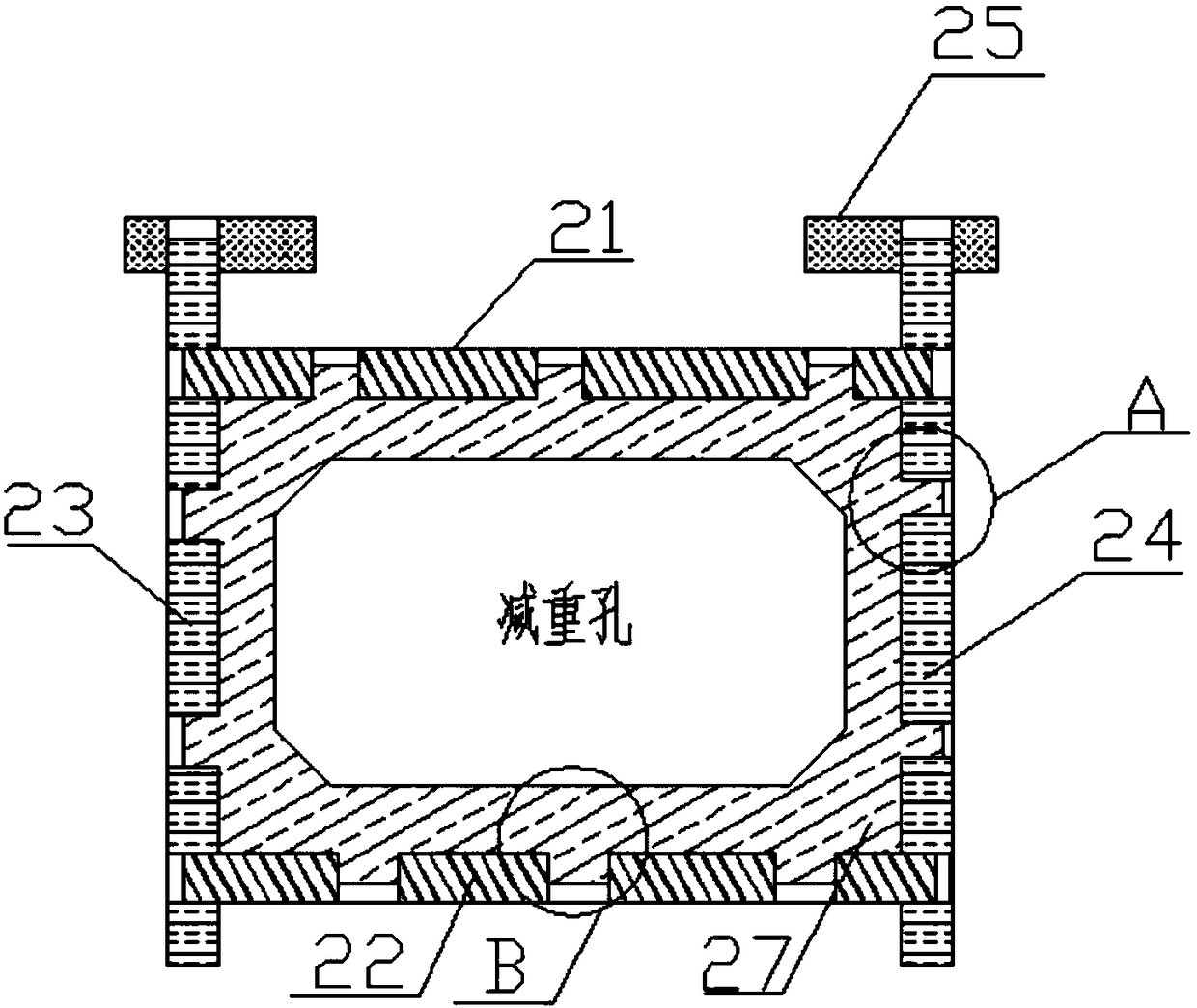

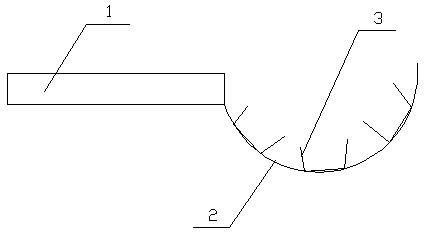

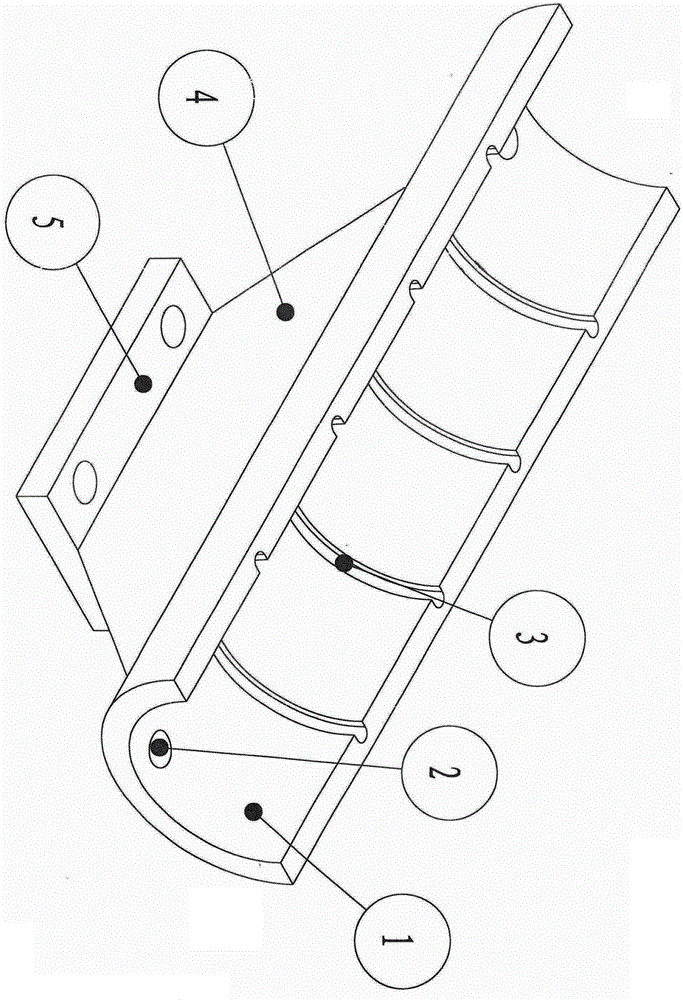

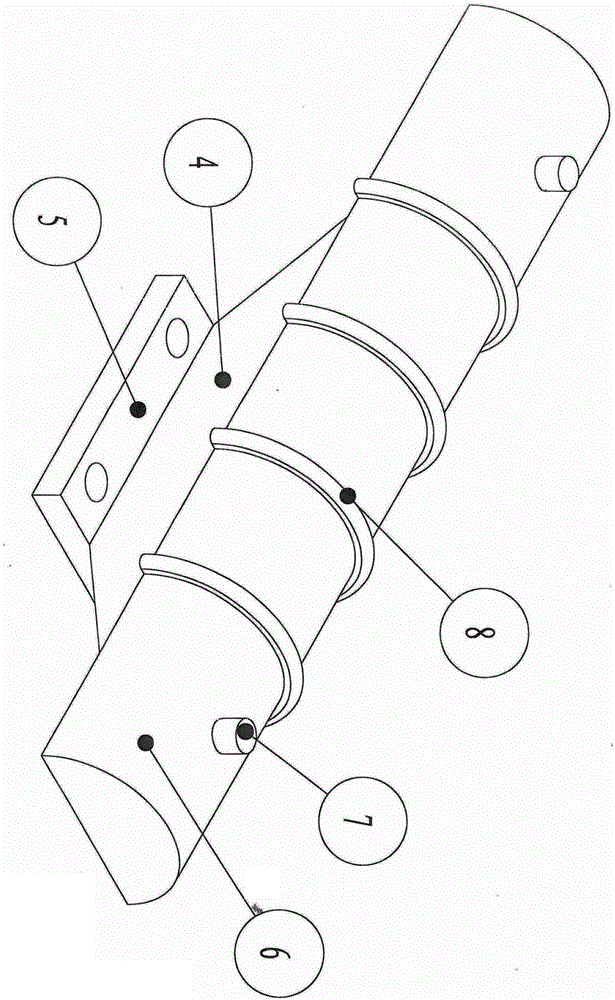

An ejection trajectory device of a launcher

PendingCN109018418AGuaranteed shape and position accuracyRapid Mass Production ManufacturingRocket launchersLaunching/towing gearHydraulic cylinderEngineering

The invention relates to the launching field of an unmanned aerial vehicle, which is an ejection trajectory device of a launcher. The device Comprises a base and a track located on the base, wherein the track can be assembled into one track or several tracks, and the tracks are folded and retracted laterally or vertically in a hinged manner in the track plane. The above-mentioned rails are mainlyinserted and welded by the alignment of the upper, lower, left and right panels and the rib panels between them. The rear part of the rail is hinged on the base, the two sides of the front part of therail are coaxially hinged with a pair of balancing hydraulic cylinders, and the other ends of the pair of balancing hydraulic cylinders are also coaxially hinged on the two sides of the base. The lifting hydraulic cylinder is hinged on the rail and the base, and the hinge axis of the lifting hydraulic cylinder can be coaxial with or parallel to the hinge axis of the balancing hydraulic cylinder.The invention has the advantages of scientific and reasonable design, assembly, high manufacturing accuracy, light weight, high strength, good stability, low construction cost and easy mass production, and is a technical revolution in the field.

Owner:QIHANG LAUNCHING TECH CO LTD

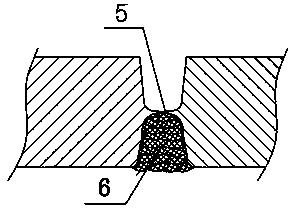

Method for detecting temperature of high-strength Cr-Mo steel double-side welding back gouging groove belt

ActiveCN102756227ASolve the technical problem of slow welding speedSolve technical problems that adversely affect welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterials science

The invention discloses a method for detecting the temperature of a high-strength Cr-Mo steel double-welding back gouging groove belt, and belongs to the technical field of the welding and detection. According to the invention, whether a groove meets the requirements after back gouging when the temperature of Cr-Mo steal back gouging is larger than 200 DEG C or not can be judged, which artfully solves the problem that cooling detection is needed in the prior art. The introduced process effectively eliminates negative influence of repeated heating and cooling on welding quality during welding, improves the first-pass yield of welding, and further solves the manufacturing problem of slow welding speed of high-strength Cr-Mo steel.

Owner:SICHUAN KEXIN MECHANICAL & ELECTRICAL EQUIPCO

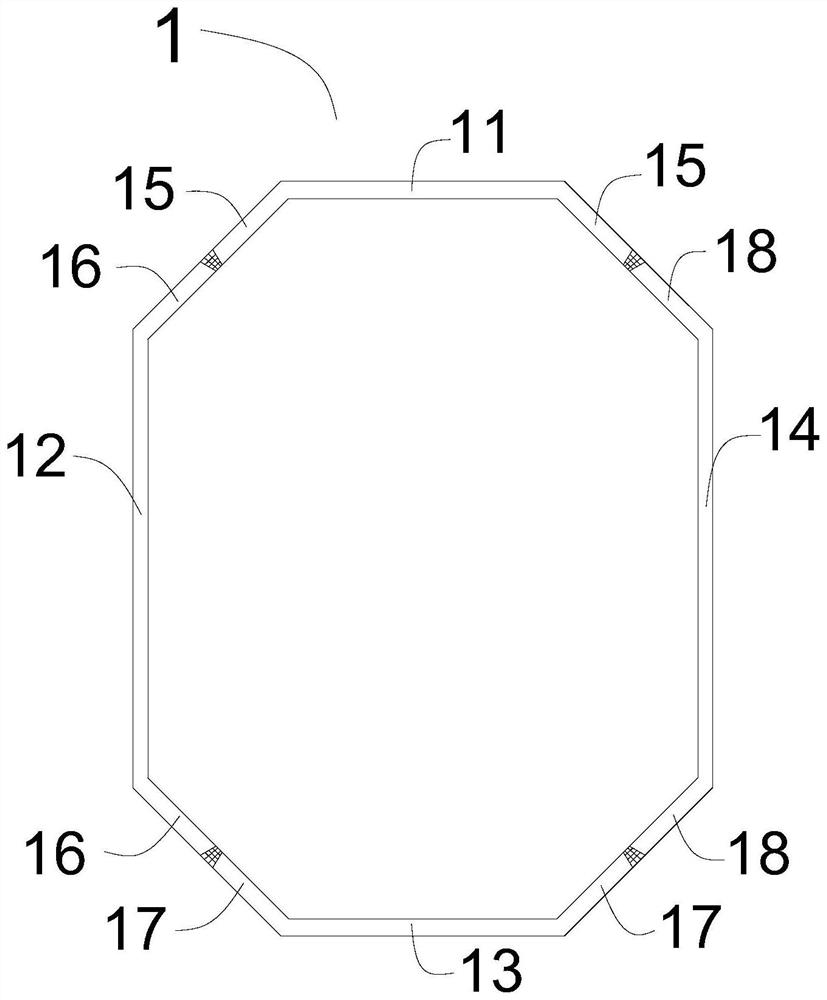

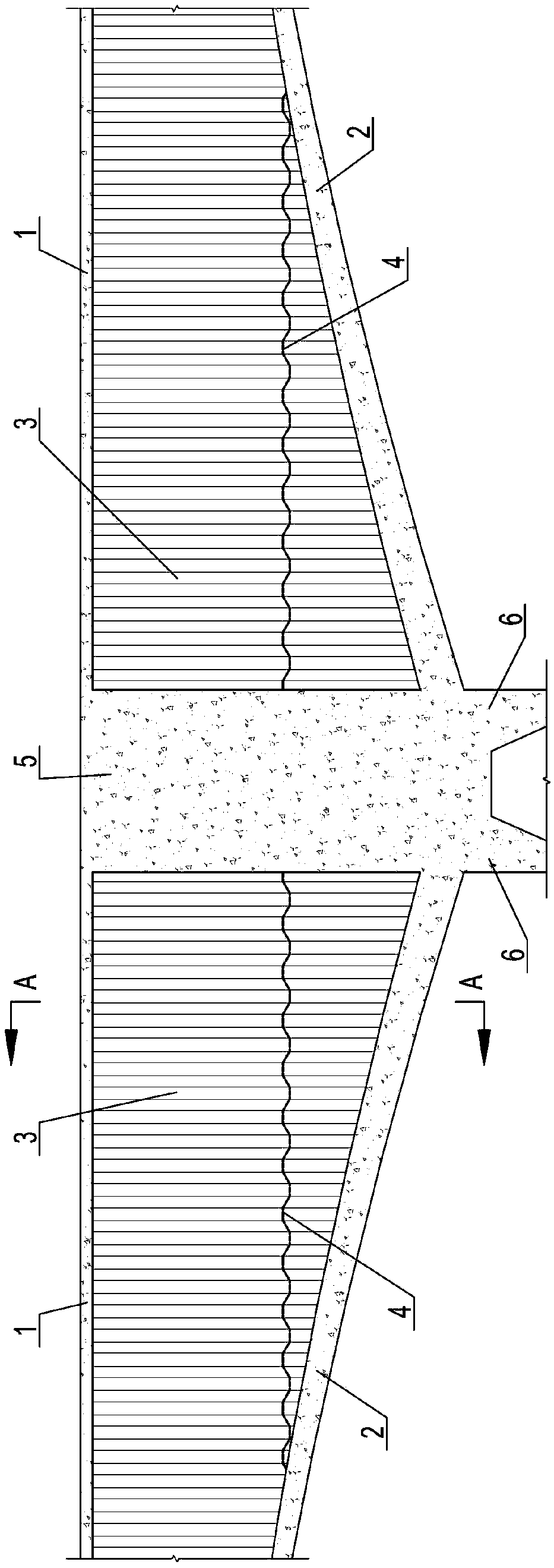

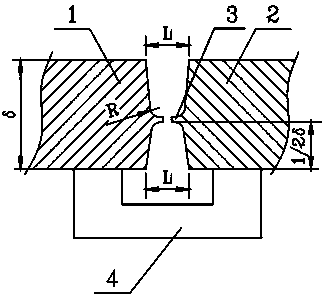

Orifice flood discharge structure in concrete dam

PendingCN111809572AConsistent thicknessGood for vibrating and compactingDamsBarrages/weirsFillet weldStress concentration

The invention relates to the technical field of concrete dams, in particular to an orifice flood discharge structure in a concrete dam. The structure comprises an orifice steel liner arranged along awater flow direction, wherein a concrete structure is poured around the orifice steel liner, the orifice steel liner comprises a plurality of steel liner sections which are sequentially connected andarranged, and the steel liner sections each comprise a top plate, a left side plate, a bottom plate, a right side plate, a first connecting folded plate, a second connecting folded plate, a third connecting folded plate and a fourth connecting folded plate. Welding seams formed by welding of the components are butt welding seams, the butt welding seams are more convenient for groove cutting and welding construction compared with fillet welding seams formed by welding in the prior art, the thickness of the periphery of the butt welding seams is consistent, the welding quality and reliability are improved, a detection operation surface is a plane, and the detection of the welding quality is also convenient. Moreover, the four corner edges of the steel liner sections are not right angles, sothat the problem of stress concentration at the four right-angle corner edges is avoided, the concrete structure is more favorable for vibrating and compacting, and the construction quality is improved.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

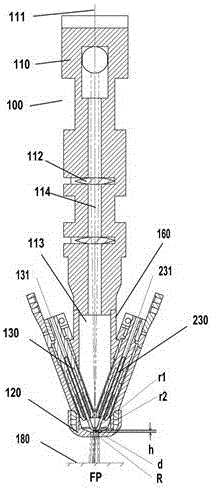

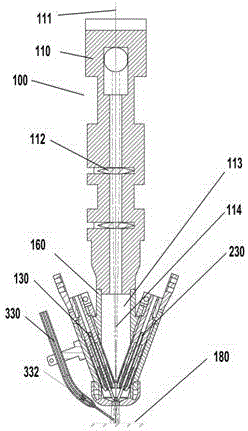

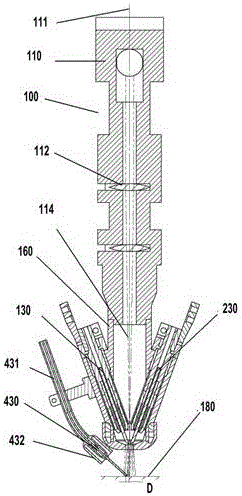

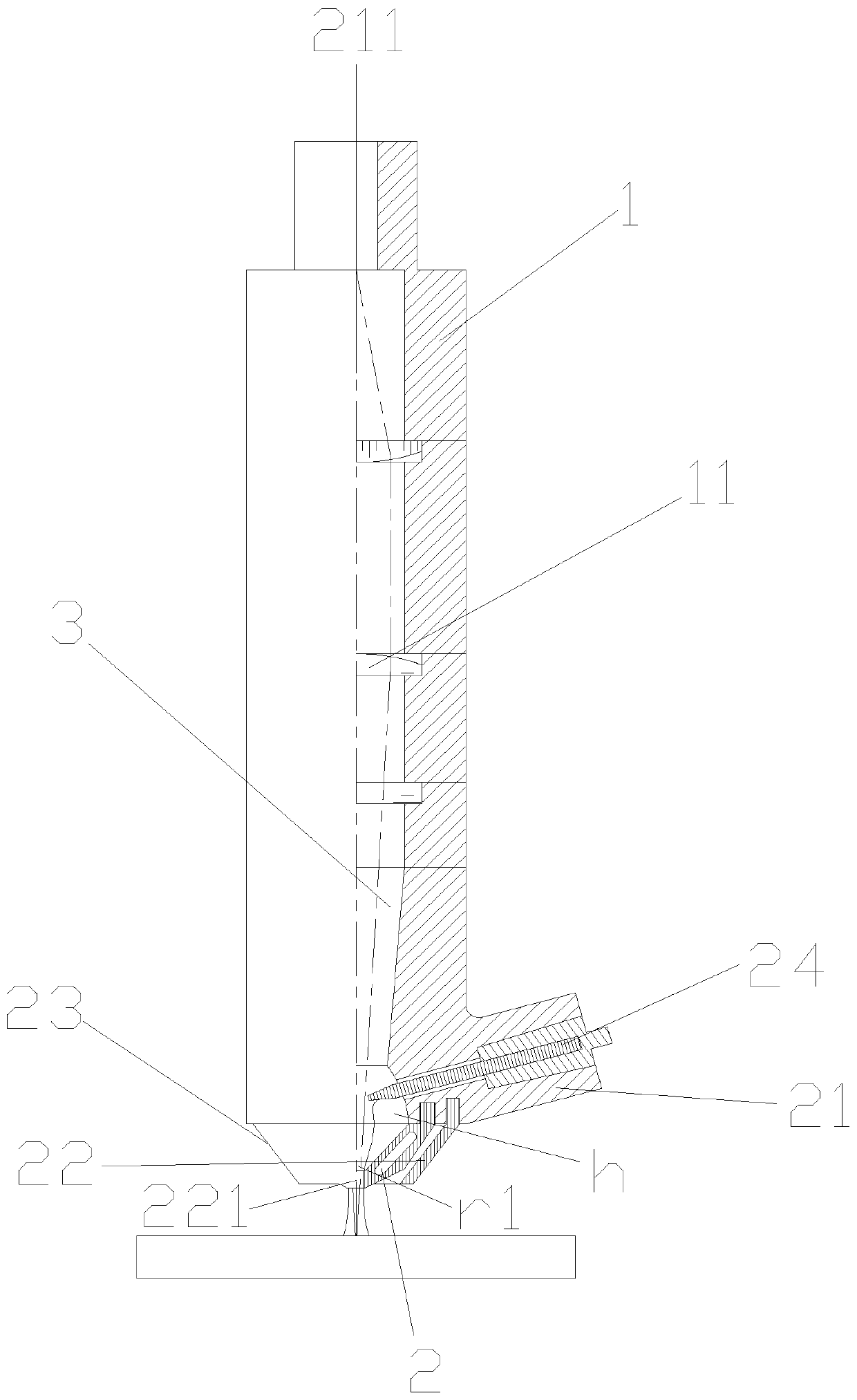

Laser and photoelectric arc compound welding welding torch

PendingCN111375896AIncrease energy densityImprove coupling efficiencyLaser beam welding apparatusEngineeringMechanical engineering

The invention provides a laser and photoelectric arc compound welding welding torch which comprises a welding torch body. The welding torch body is provided with an input end, an output end and a hollow inner cavity located between the input end and the output end. The welding torch body is provided with a center axis having a laser beam penetrating direction. The input end is provided with an incident ray lens used for focusing laser beams. The output end comprises an insulation lining, a compression nozzle, a protection nozzle and first non-melting electrodes. The insulation lining surroundsthe lower end of the hollow inner cavity. The compression nozzle is located at the output end of the insulation lining. The first non-melting electrodes are inlaid in the insulation lining and are arranged with the central axis with an oblique angle, the bottom ends of the first non-melting electrodes are located above a through hole of the compression nozzle, the distance between the bottom endsof the first non-melting electrodes and the upper surface of the through hole of the compression nozzle is h, and the distance between the bottom ends of the first non-melting electrodes is d; and the radius at of the laser beam passing through the position of the through hole of the compression nozzle is r1, and the radius of the through hole is larger than r1.

Owner:CHENGDU LASER HYBRID TECH CO LTD

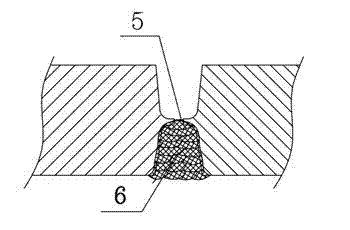

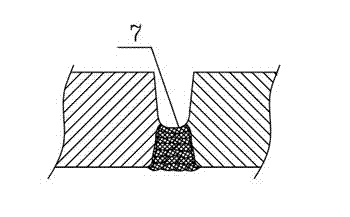

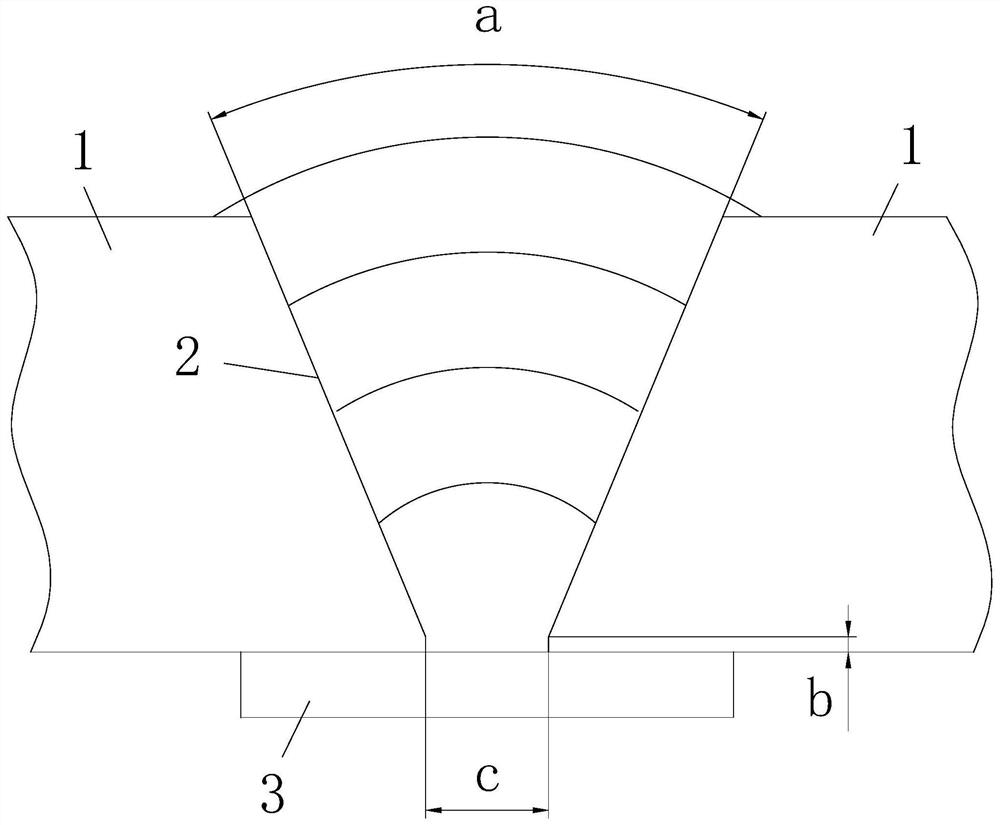

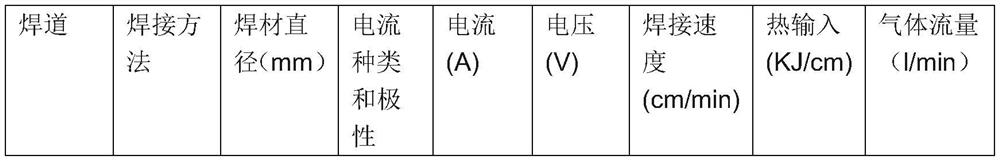

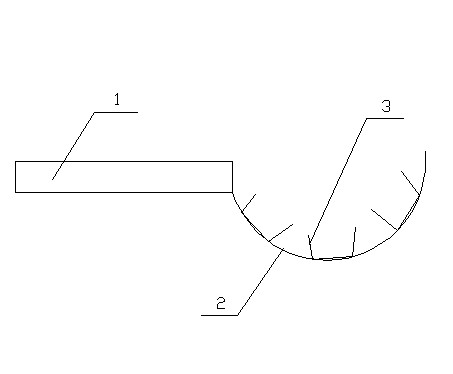

Welding method for marine low-temperature steel

InactiveCN113843482ACoarse grainReduce welding heat inputWorkpiece edge portionsWelding accessoriesButt weldingWeld seam

The invention relates to a welding method for marine low-temperature steel. The welding method comprises the following steps of: step 1, manufacturing two welding base materials made of the marine low-temperature steel, wherein a joint is in a butt welding form, and a groove is a V-shaped groove with an angle of 40-50 degrees; step 2, removing oil stains, rust and pollutants on the surface of the V-shaped groove and in a range, which is at least 20mm away from the edge of the V-shaped groove, of the upper surface and the lower surface of the welding base materials, and polishing to expose metal luster; step 3, fixing a horse plate at the lower end of the V-shaped groove, and arranging an end tab at each of the two ends of the V-shaped groove; step 4, adopting multi-layer and multi-pass welding, wherein the thickness of each layer of welding pass is 3-5mm, and the width of single-pass welding does not exceed 25mm; step 5, adopting a carbon dioxide gas shielded welding method, setting welding parameters, then welding by using the welding base materials, wherein the interlayer temperature difference is smaller than 150 DEG C, and the single-pass welding is not stopped in the midway; step 6, checking the surface quality of a welding seam, wherein the surface of the welding seam cannot have welding defects; and step 7, carrying out internal quality flaw detection on the welding seam 48 hours after the welding is ended.

Owner:PAXOCEAN ENG ZHOUSHAN CO LTD

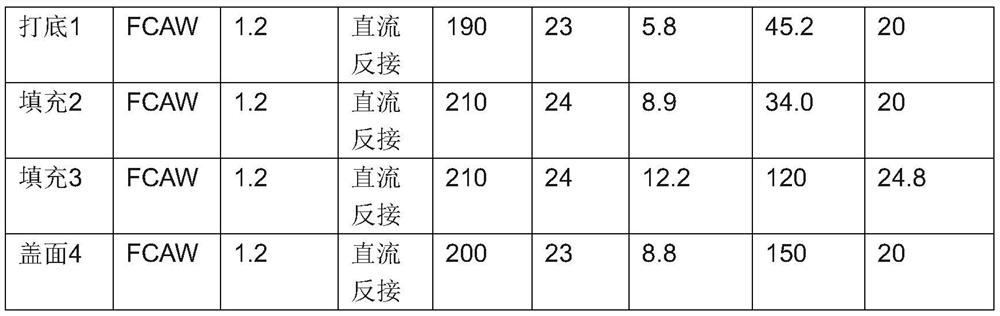

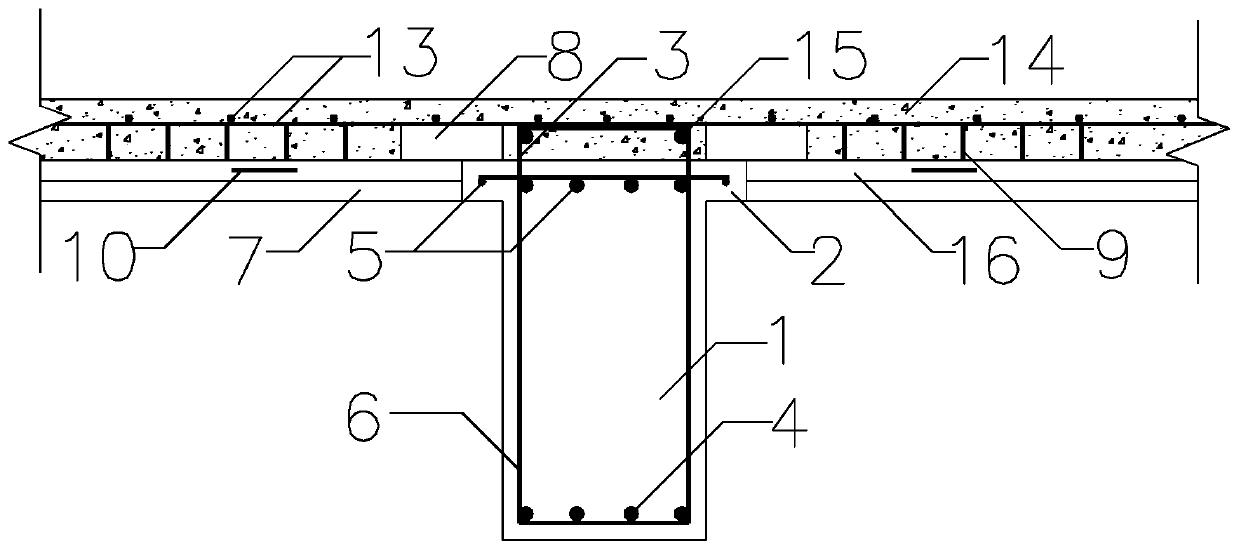

Prefabricated reinforced concrete beam-slab structure system with cast-in-place floors in building structures

ActiveCN106065663BReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteTongue and groove

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

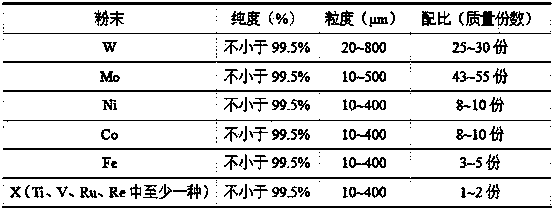

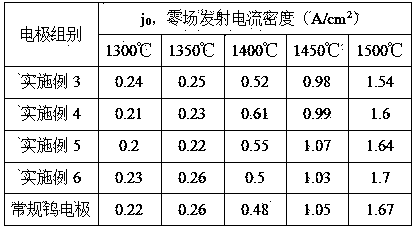

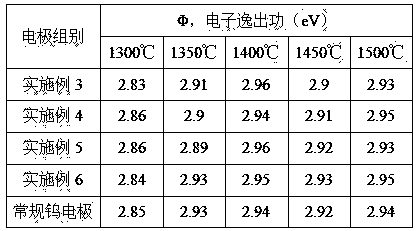

Method for manufacturing low-cost tungsten electrode

InactiveCN104259611AGuaranteed welding effectReduce construction costsWelding/cutting media/materialsCleaning using liquidsMetallurgyAlloy steel

The invention discloses a method for manufacturing a low-cost tungsten electrode. According to the method for manufacturing the low-cost tungsten electrode, a tungsten electrode rod and a Cr-W-Mo-V alloy steel rod are connected to form the low-cost tungsten electrode through a specific connecting method. The welding performance of the end of the tungsten electrode is ensured, conventional tungsten electrodes can be replaced under various stations, and the standard length of a tungsten electrode product can be obtained under the condition of saving the tungsten materials. Welding construction and use are facilitated, and the production cost and argon arc welding construction cost are saved.

Owner:建德市横山钨业有限公司

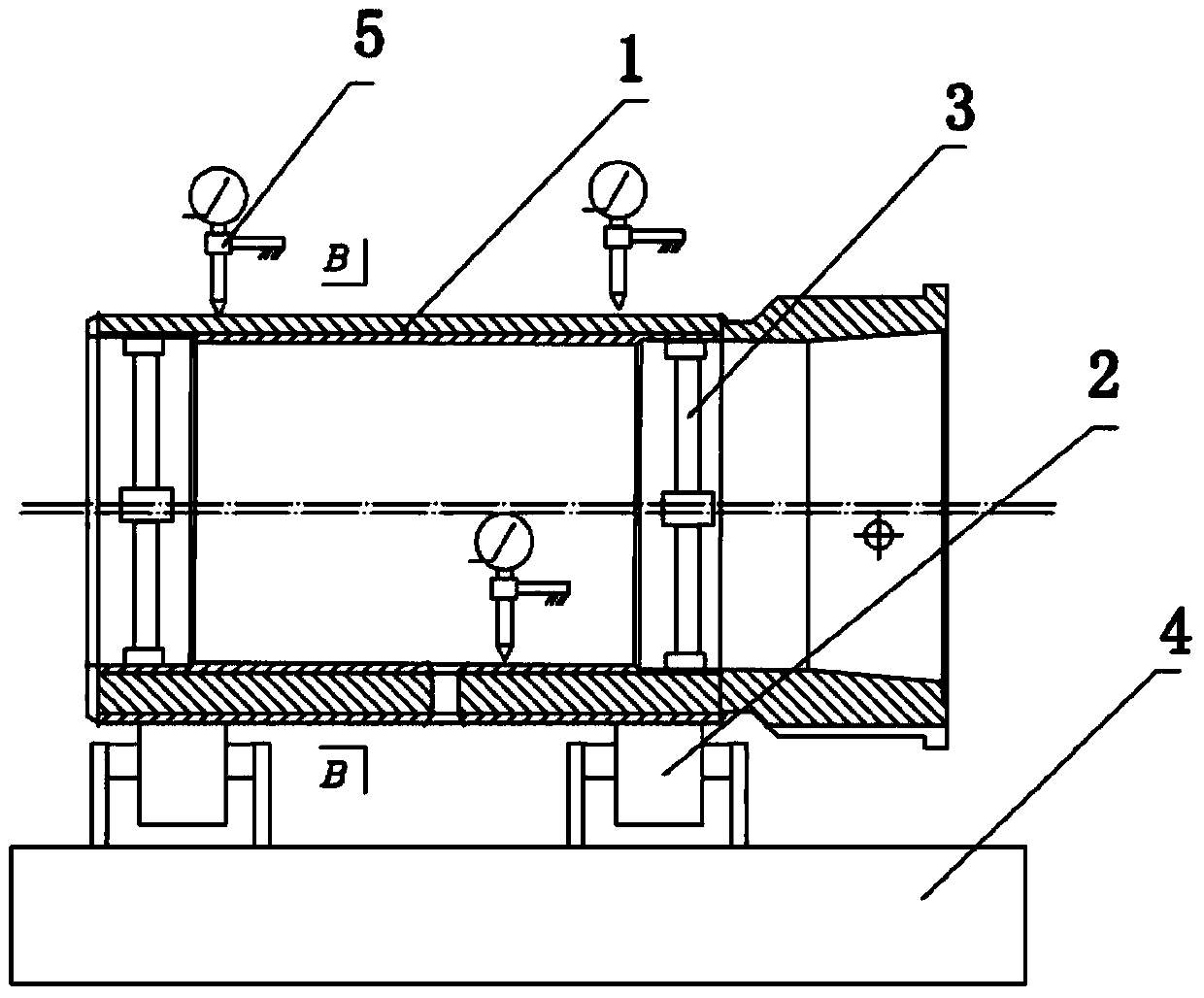

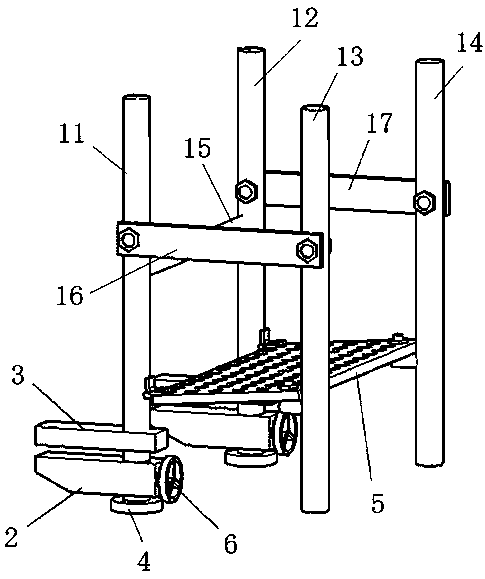

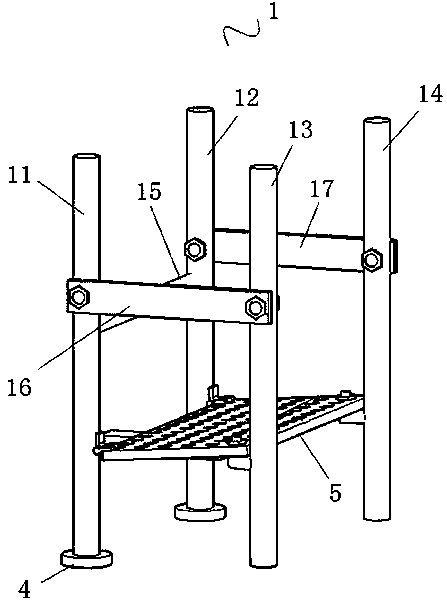

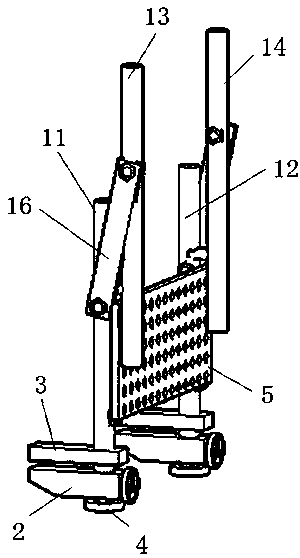

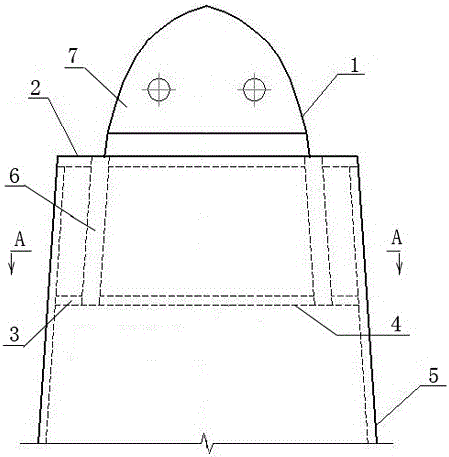

Auxiliary tool for ship body structure welding construction and application method thereof

InactiveCN109366060AReduce construction hoursIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to an auxiliary tool for ship body structure welding construction. The tool comprises an adjusting block, adjusting bolts and a foldable bracket; the adjusting block can freely slide on a bracket; the adjusting bolts clamp the bracket and the adjusting block at the same time; and the foldable bracket is used for a transverse rib plate of a ship body structure, so that constructors conveniently stand to weld components in higher places. The auxiliary tool is used for construction on a plate frame with transverse structure welding; and the bracket is supported on the transverse rib plate of the plate frame through the adjusting block and the bolts to achieve the purpose of convenience to construct in higher places. The tool is convenient for welding construction of theship body structure, and achieves the feasibility of reaching the higher positions to provide convenience and safety for welding of structures in the higher places.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

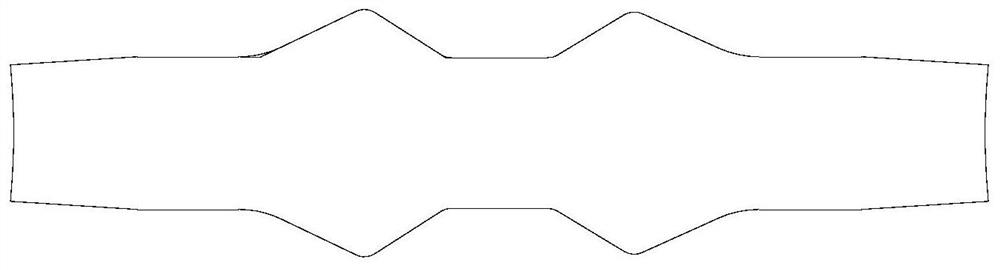

Upper-lower double-layer cellular composite folded web box girder

PendingCN109137712ASimple structureEasy constructionBridge structural detailsBridge materialsBridge engineeringSpandrel

The invention discloses an upper-lower double-layer cellular composite folded web box girder and relates to the technical field of bridge engineering. The upper-lower double-layer cellular composite folded web box girder includes a pier, a center beam, a box beam roof, a bottom plate of box girder, folded steel webs and horizontal braces. The center beam is fixedly arrange at that top of the pier,the top of the center beam is fixedly supported in the middle of the top plate of the box girder, two box girder bottom plates are symmetrically arranged on both sides of one end of the center beam near the pier, and the bottom plate of the box girder inclines and extends to the top plate of the box girder. One end of each box girder bottom plate is fixedly connected with two opposite folded steel webs, the other end of the folded steel webs is fixedly connected with the top plate of the box girder, one side of the folded steel webs is fixedly connected with the center beam, and two ends of the horizontal braces in transverse direction are fixedly connected with two folded steel webs on both sides of the horizontal braces respectively. The upper-lower double-layer cellular composite folded web box girder can better solve the problem of buckling stability of the long-span folded steel web, improve the span of the combined folded web box girder bridge, and enable the combined folded webbox girder bridge to give full play to its advantages.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Preparation method of rear axle housing of heavy-duty car

ActiveCN111037237AConvenient welding constructionImprove processing efficiencyPositioning apparatusMetal working apparatusSteel platesSeam welding

A preparation method of a rear axle housing of a heavy-duty car comprises the following steps: 1) blanking a steel plate; 2) performing cold and hot press molding to obtain an upper half shell and a lower half shell; 3) milling the joint surface of the upper half shell and the lower half shell; 4) arranging an oil drain hole at the bottom of the lower half shell corresponding to a bulge; 5) closing the upper half shell and the lower half shell, and performing spot welding at intervals along the length direction of a joint seam; (6) positioning a rear axle housing blank, using a milling machinefor machining welding grooves along the joint seam between the upper half shell and the lower half shell, and the cross sections of the welding grooves are V-shaped; (7) carrying out straight joint seam welding along the welding grooves, and obtaining a rear axle housing crude product; (8) calibrating the two ends of the rear axle housing crude product to be round, and forming stepping holes in inner holes at the two ends the rear axle housing crude product respectively; (9) carrying out machining, and setting accessories; and (10) obtaining the rear axle housing of the heavy-duty car after polishing and cleaning. The preparation method is simple in process, high in production efficiency, capable of effectively reducing the machining cost of the product and guaranteeing the quality of theproduct.

Owner:重庆康桥工业有限公司

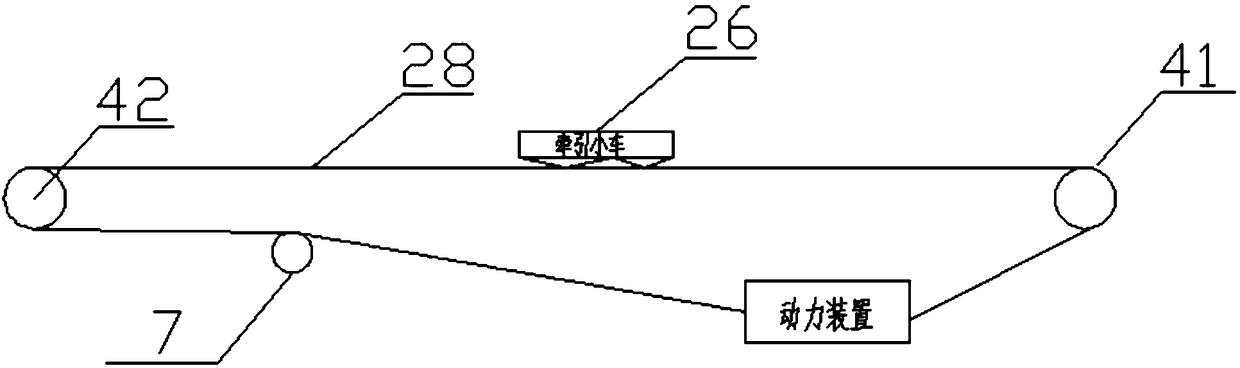

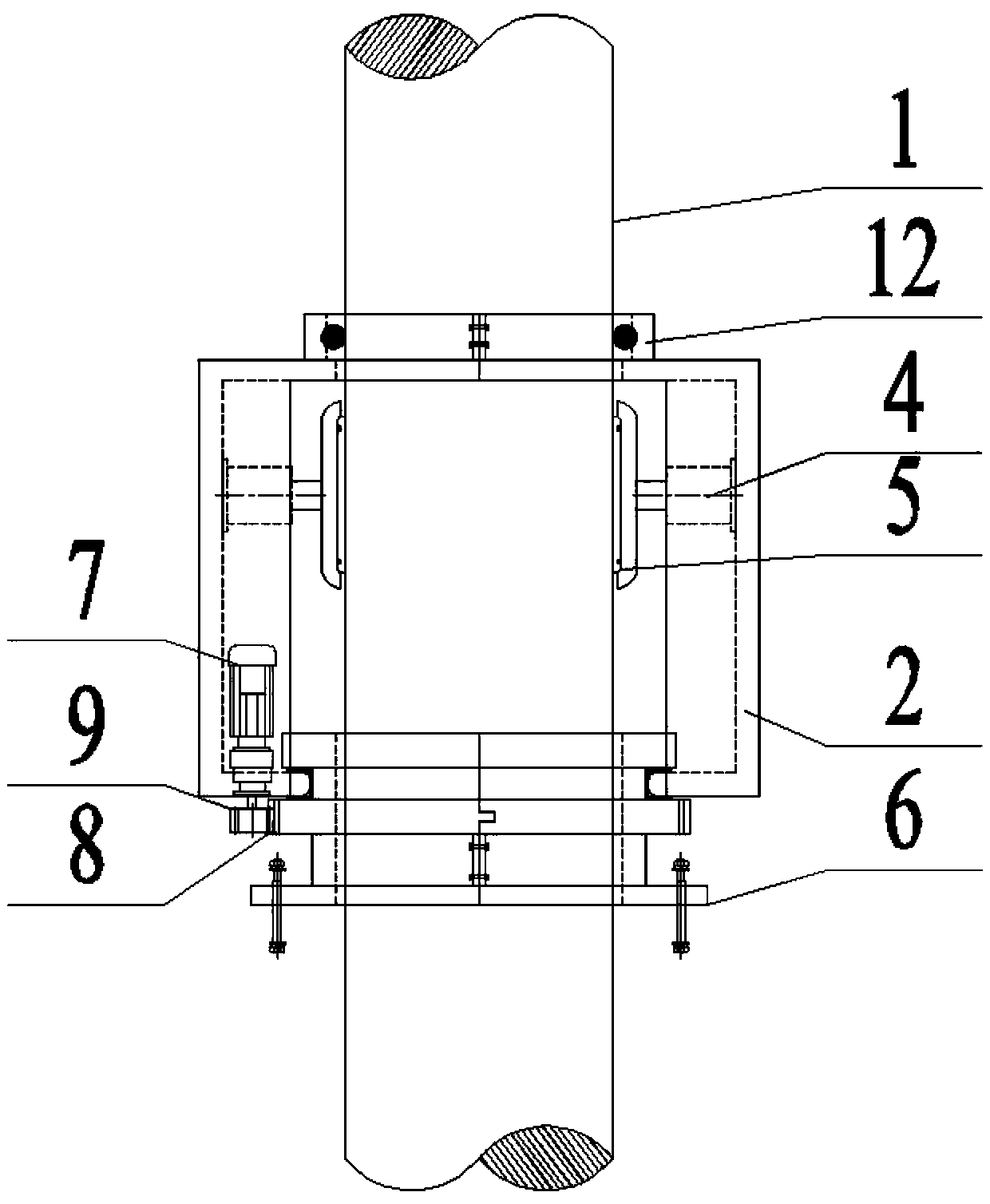

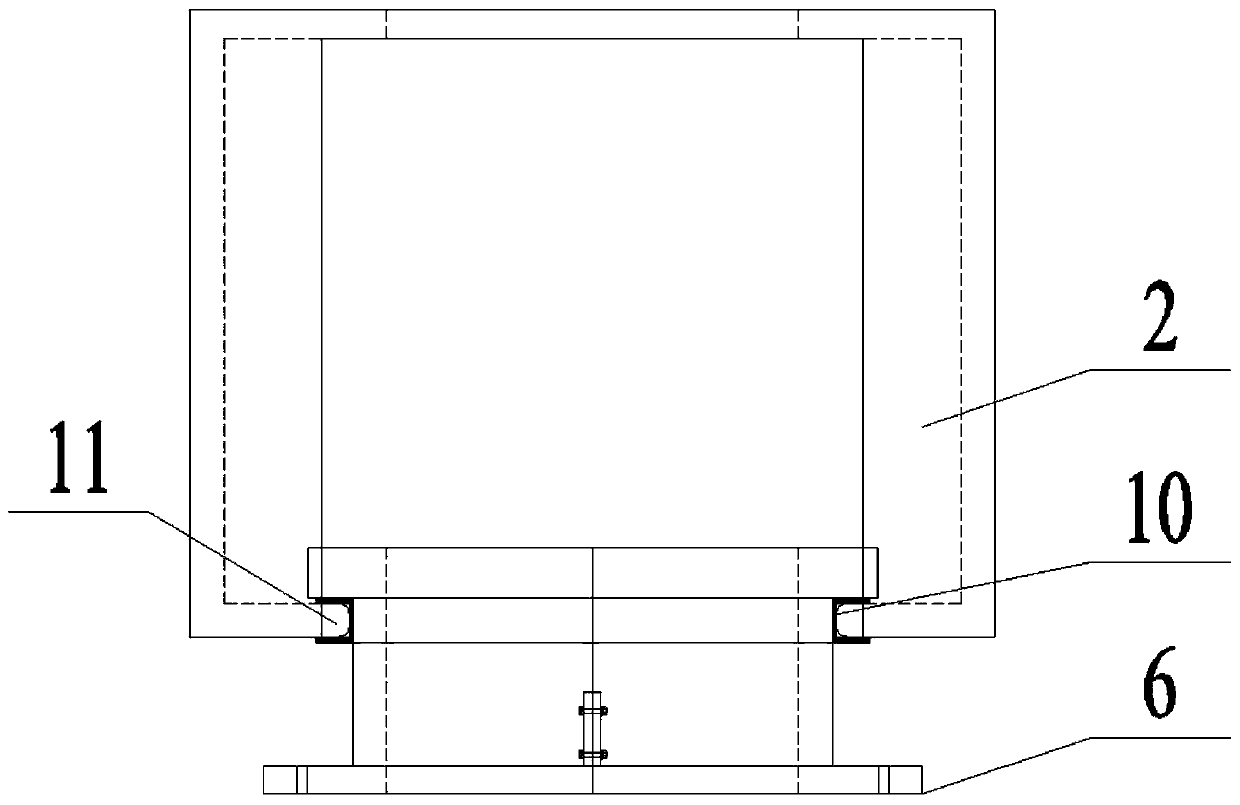

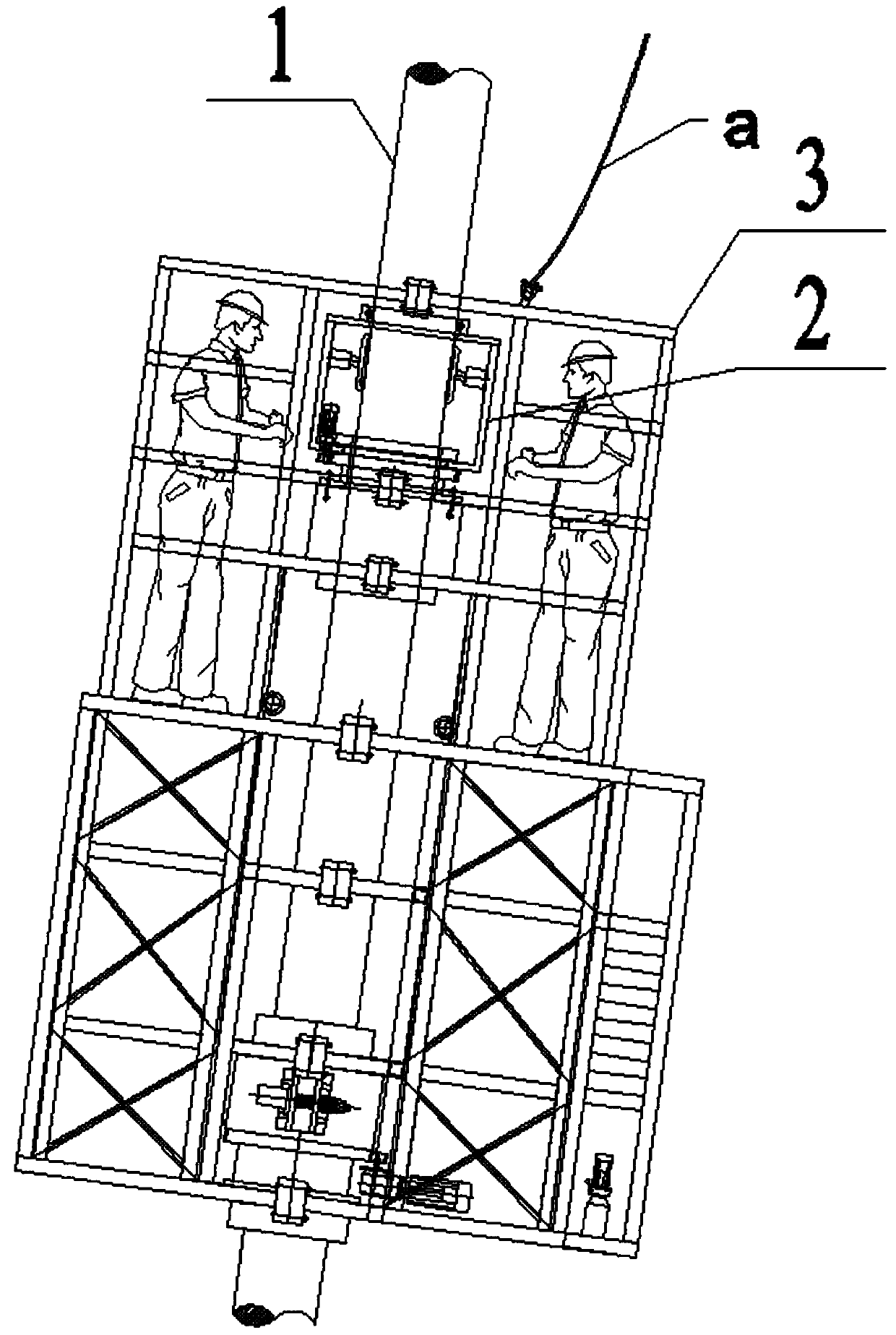

Mounting structure and method for guide bar of stay cable

PendingCN110607748AEasy to installPrecise positioningBridge structural detailsBridge erection/assemblyMaterial resourcesLow input

The invention relates to the technical field of the mounting of stay cables, in particular to a mounting structure and method for a guide bar of a stay cable. The mounting structure comprises a guideframe and a construction platform, wherein the guide frame sleeves the stay cable; the construction platform can be driven by a traction device to move in the axial direction of the stay cable; the guide frame is hinged to the construction platform in a manner that the guide frame can be rotated around the axis of the stay cable; a welding device for welding the guide bar to the outside of the stay cable is arranged on the guide frame; and a circumferential adjusting device for driving the guide frame to rotate around the axis of the stay cable is arranged between the construction platform andthe guide frame. The mounting structure for the guide bar, provided by the invention, has the advantages of simplicity, high efficiencies and precisions of welding and mounting, simple welding and mounting processes and low input costs of human and material resources, greatly facilitates the operation of constructors, and has great promotion value.

Owner:CCCC SECOND HARBOR ENG +1

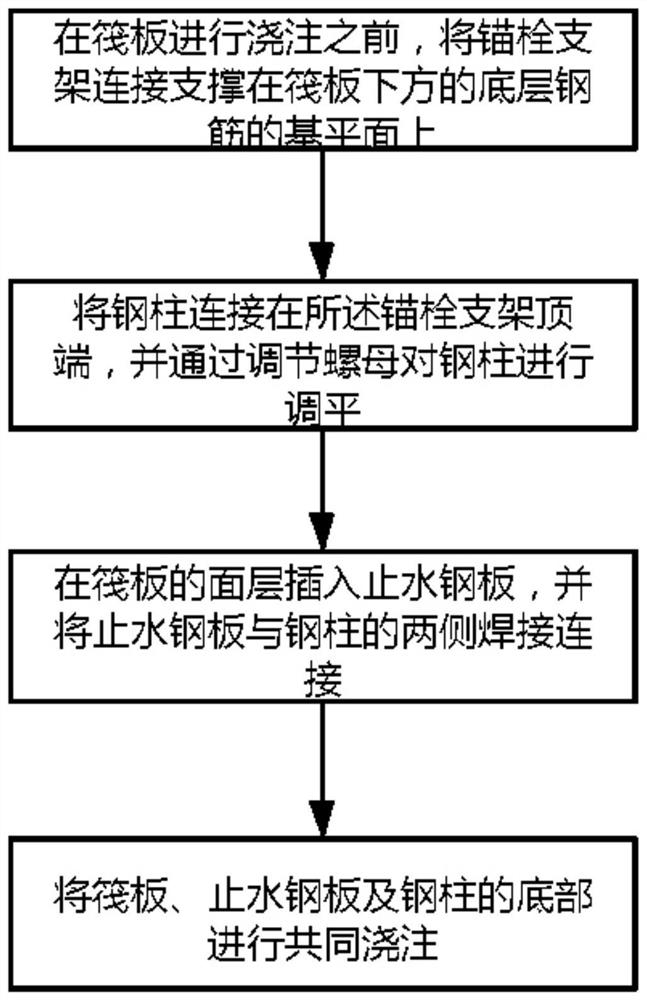

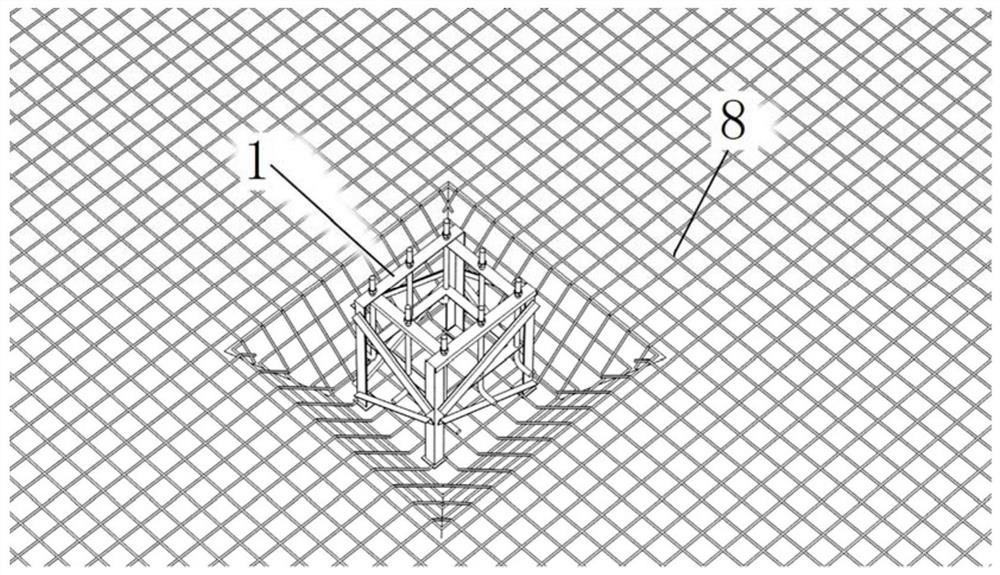

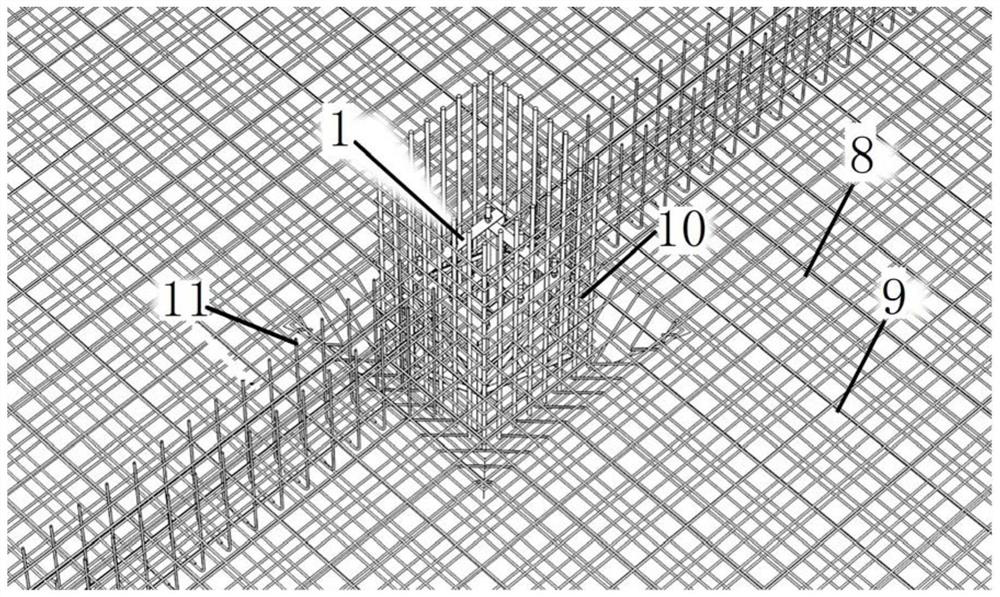

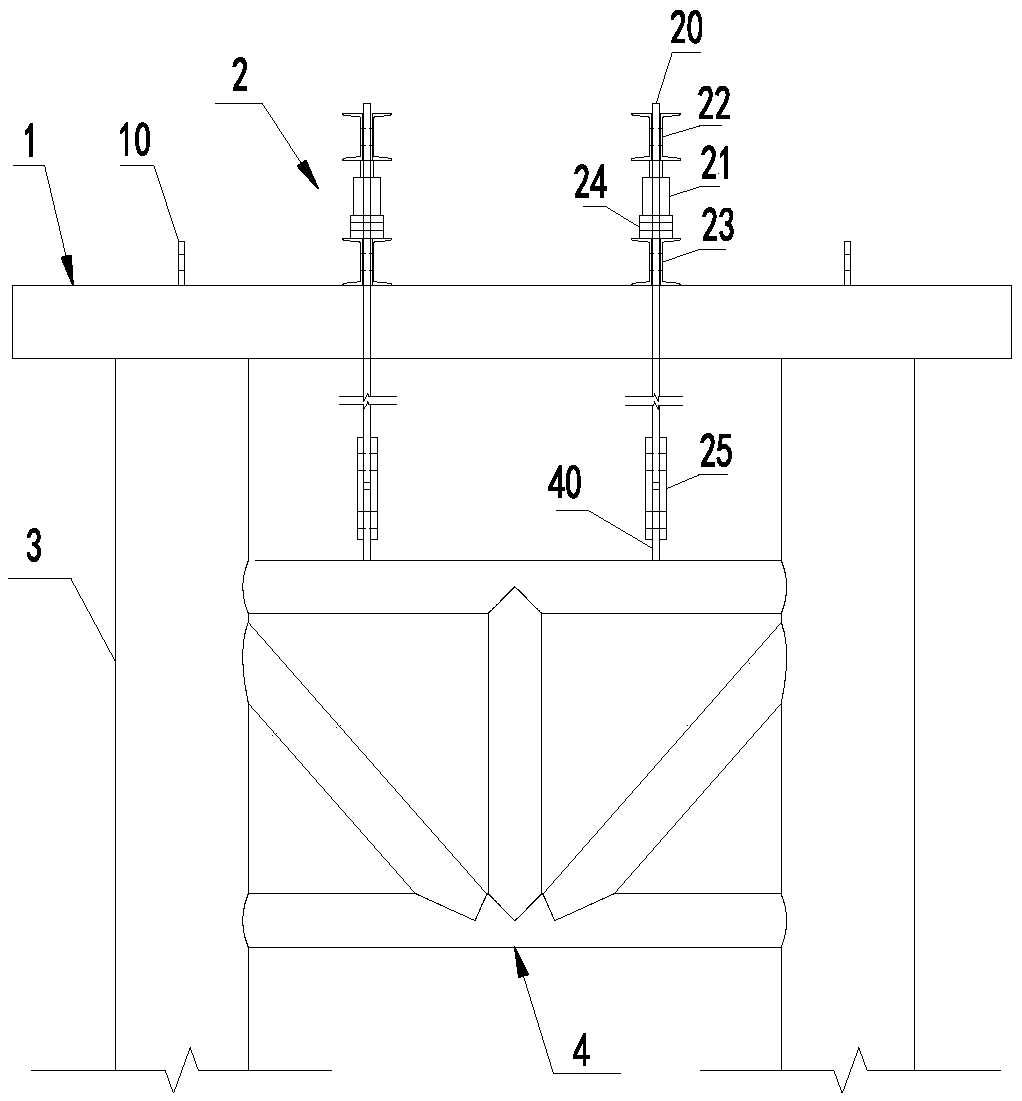

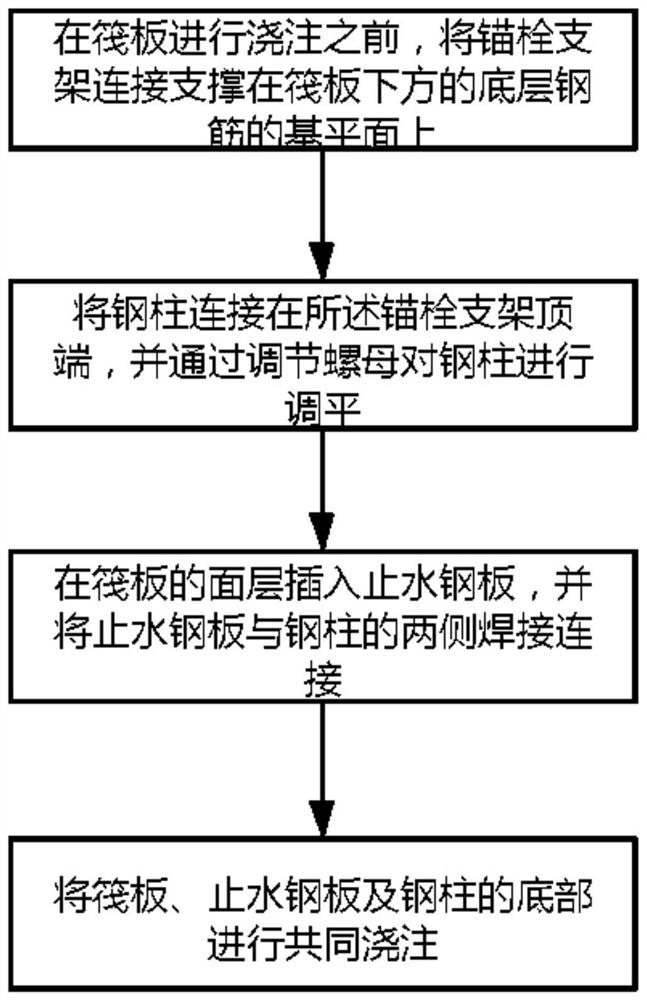

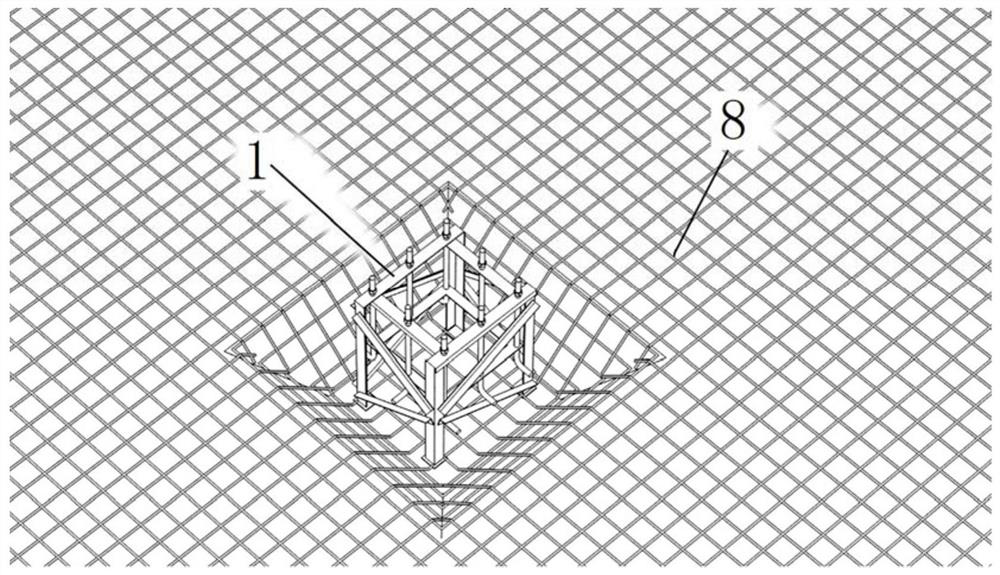

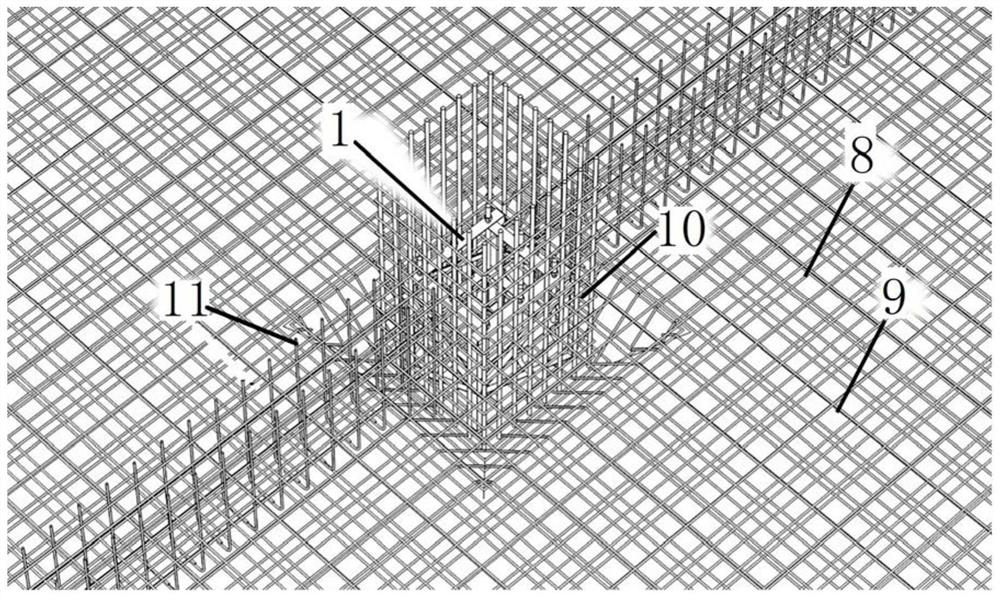

Basement steel column water stop treatment method

ActiveCN111926860AAvoid water leakage and seepageImprove structural integrityArtificial islandsProtective foundationWater stopWater leak

The invention provides a basement steel column water stop treatment method, and belongs to the technical field of basement water stop construction. The method comprises the following steps that beforea raft plate is poured, an anchor bolt support is supported on a base plane below the raft plate; a steel column is connected to the top end of the anchor bolt support, and the steel column is leveled through an adjusting nut; a water stop steel plate is inserted into the surface layer of the raft plate, and the water stop steel plate is connected with the two sides of the steel column in a welded mode; and the bottoms of the raft plate, the water stop steel plate and the steel column are poured together. According to the method, the bottom of the steel column, the bottom of the water stop steel plate and the raft plate are poured into an integrated structure, the structural integrity is good, no construction joint exists between the bottom of the steel column and the raft plate, and thewater leakage and seepage phenomena of a basement at the bottom of the steel column can be avoided.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

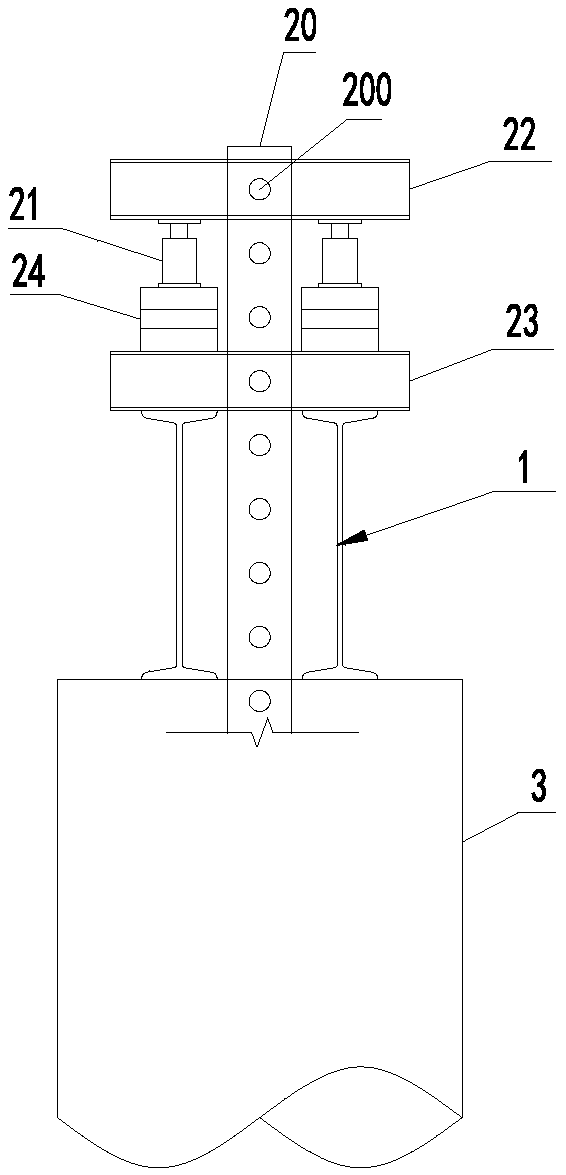

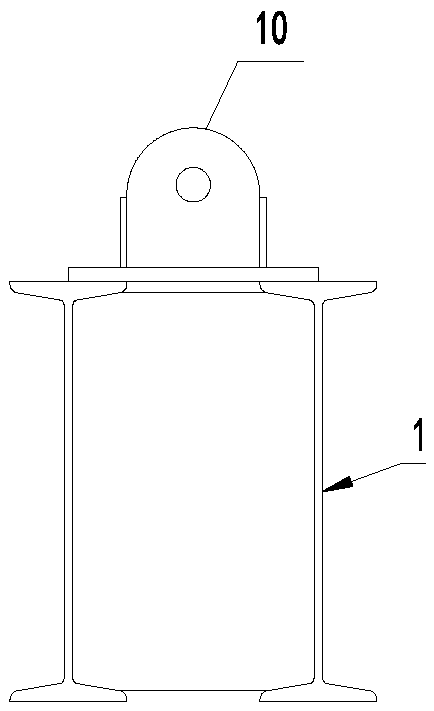

Device and a method for installing a connection system of a construction platform

ActiveCN109267492AAffect welding constructionImprove utilization efficiencyBridge erection/assemblyCoupling systemArchitectural engineering

The invention discloses a device and a method for installing a connection system of a construction platform. The mounting device comprises a support mechanism arranged horizontally and an adjustment mechanism arranged vertically. The supporting mechanism is provided with a first lifting lug, and the supporting mechanism is used for supporting on two steel pipe piles adjacent to the construction platform. The bottom end of the adjusting mechanism is fixed on the coupling system, the top end passes through the supporting mechanism, and the top end of the adjusting mechanism can move up and downto adjust the position of the coupling system in the vertical direction. The installation device provided by the invention can improve the utilization efficiency of the floating crane and is beneficial to the welding construction of the coupling system.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Steel beam-ultra-high performance concrete slab combined bent cap and construction method thereof

PendingCN114775404AGuaranteed stabilityReduce lifting weightBridge structural detailsBridge erection/assemblyClassical mechanicsAssembly (construction)

The invention discloses a steel beam-ultra-high performance concrete plate combined capping beam, which comprises a steel beam and an ultra-high performance concrete (UHPC) plate, the steel beam comprises a bottom plate and webs, the webs are arranged on two sides of the longitudinal bridge direction of the bottom plate, the bottoms of the webs extend downwards to be provided with downward extending sections, and the UHPC plate is clamped in a cavity defined by the downward extending sections and the bottom plate. The invention further provides a construction method of the steel beam-ultra-high performance concrete slab combined cover beam. The steel beam-ultra-high performance concrete slab combined bent cap has the advantages that the hoisting weight is light, the economical efficiency is good, the beam height is easy to control, the bearing capacity is guaranteed, the rigidity meets the requirement, and assembly construction is rapid and reliable.

Owner:HUNAN UNIV

A water-stop treatment method for basement steel columns

ActiveCN111926860BAvoid water leakage and seepageImprove structural integrityArtificial islandsProtective foundationWater stopWater leak

The invention provides a basement steel column water-stop treatment method, which belongs to the technical field of basement water-stop construction, and includes the following steps: before the raft slab is poured, the anchor bolt support is supported on the base plane below the raft slab; Connect to the top of the anchor bolt bracket, and level the steel column through the adjusting nut; insert the water-stop steel plate on the surface of the raft, and weld the water-stop steel plate to both sides of the steel column; connect the raft, stop The water steel plate and the bottom of the steel column are co-cast. In the present invention, the bottom of the steel column, the bottom of the water-stop steel plate and the raft are poured into an integrated structure, the structural integrity is good, there is no construction joint between the bottom of the steel column and the raft, and water leakage and seepage of the basement at the bottom of the steel column can be avoided Phenomenon.

Owner:CHINA CONSTR SCI & IND CORP LTD

Method for detecting temperature of high-strength Cr-Mo steel double-side welding back gouging groove belt

ActiveCN102756227BSolve the technical problem of slow welding speedSolve technical problems that adversely affect welding qualityWelding/cutting auxillary devicesAuxillary welding devicesFirst passTemperature drop

The invention discloses a method for detecting the temperature of the root-clearing groove of high-strength Cr-Mo steel double-sided welding, which belongs to the technical field of welding and detection. The invention can judge whether the groove meets the requirements after root cleaning when the root cleaning temperature of Cr-Mo steel is greater than 200°C, and cleverly solves the problem of temperature drop detection in the existing technology, and the process improvement brought by it is effectively It solves the adverse effects of multiple temperature rises and falls on the welding quality during welding, improves the first pass rate of welding, and also solves the manufacturing problem of slow welding speed of high-strength Cr-Mo steel.

Owner:SICHUAN KEXIN MECHANICAL & ELECTRICAL EQUIPCO

Cable fast welding tool and welding method thereof

InactiveCN102500857AConvenient welding constructionAdapt to the needs of welding heatSolder feeding devicesTinBuilding construction

The invention discloses a cable fast welding tool which comprises a handle and a heating spoon connected with the handle, wherein a plurality of tin-taking positions are arranged in the heating spoon. The invention further discloses a welding method of the cable fast welding tool. The welding method comprises the following steps that: tin wires are melted in the tin-taking positions in the heating spoon; cable heads needing to be welded are inserted into the tin-placing positions with the melted tin wires; and the cable heads are taken out of the tin-taking positions after absorbing enough tin. For the cable fast welding tool, the plurality of tin-taking positions are arranged in the heating spoon, therefore, the plurality of cable heads can be welded at the same time, the construction efficiency is greatly improved, the welding speed is high, the welding quality is good, the requirement of hot welding on the plurality of cable heads can be quickly met, the efficiency is very high, the adaptability is strong, and the cable fast welding tool is very convenient for welding construction of the cable heads.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

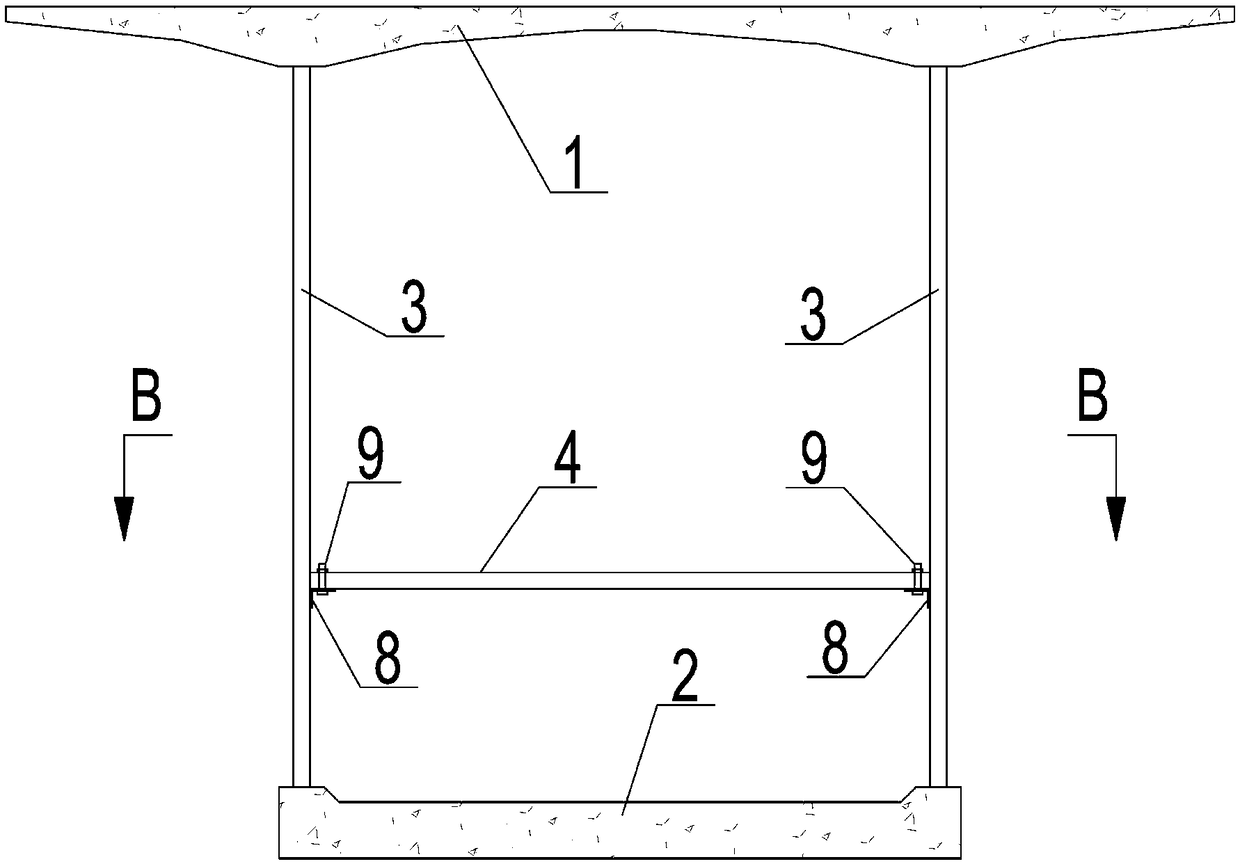

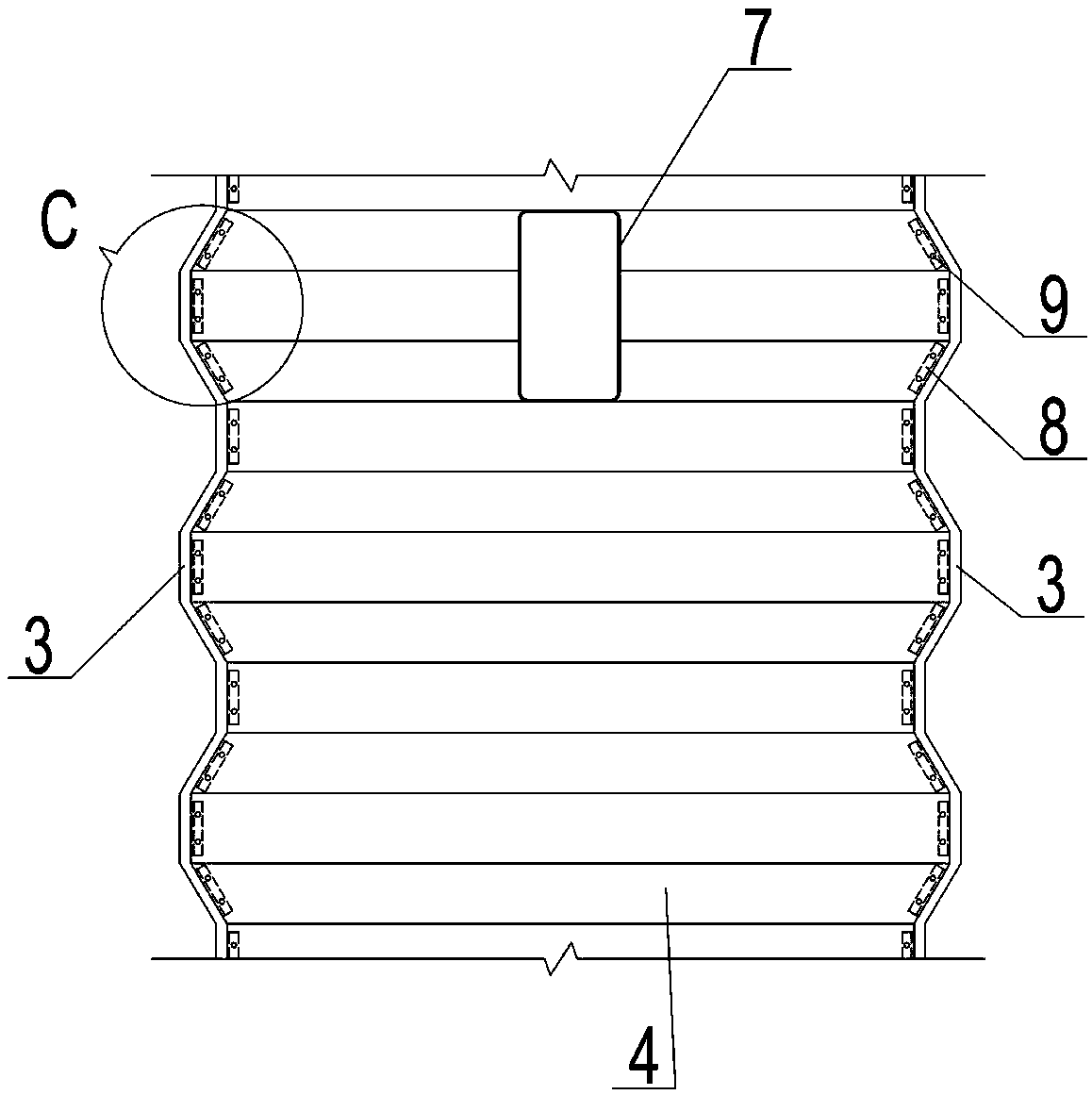

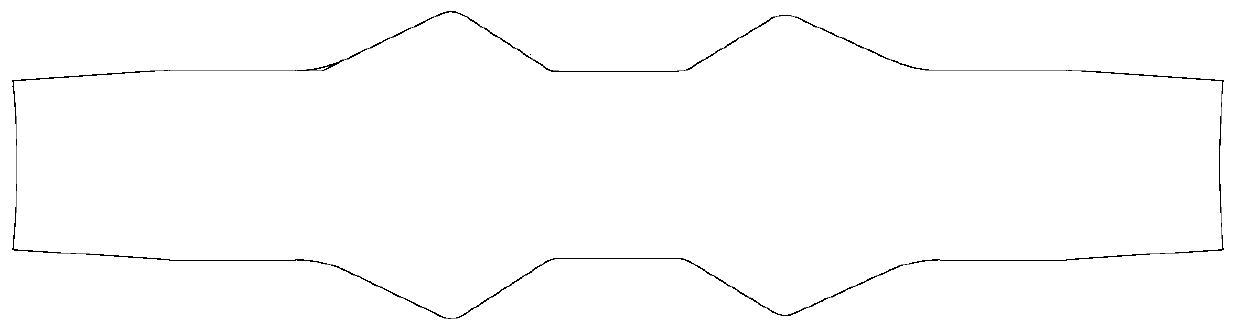

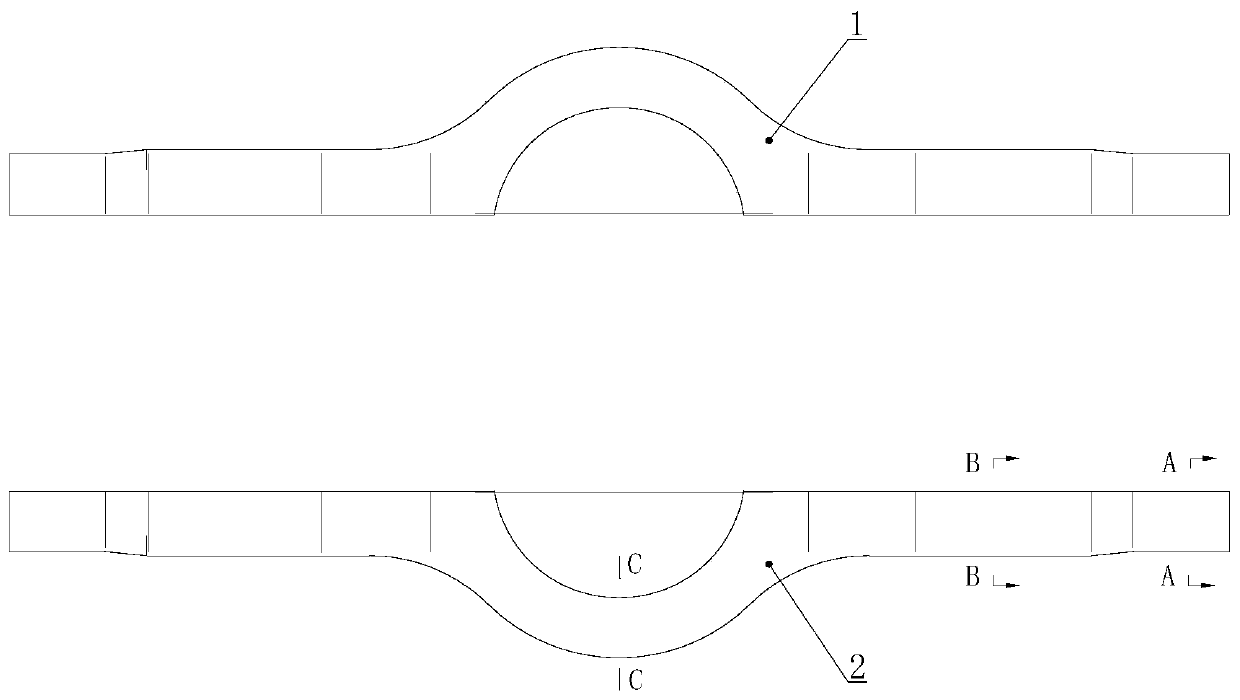

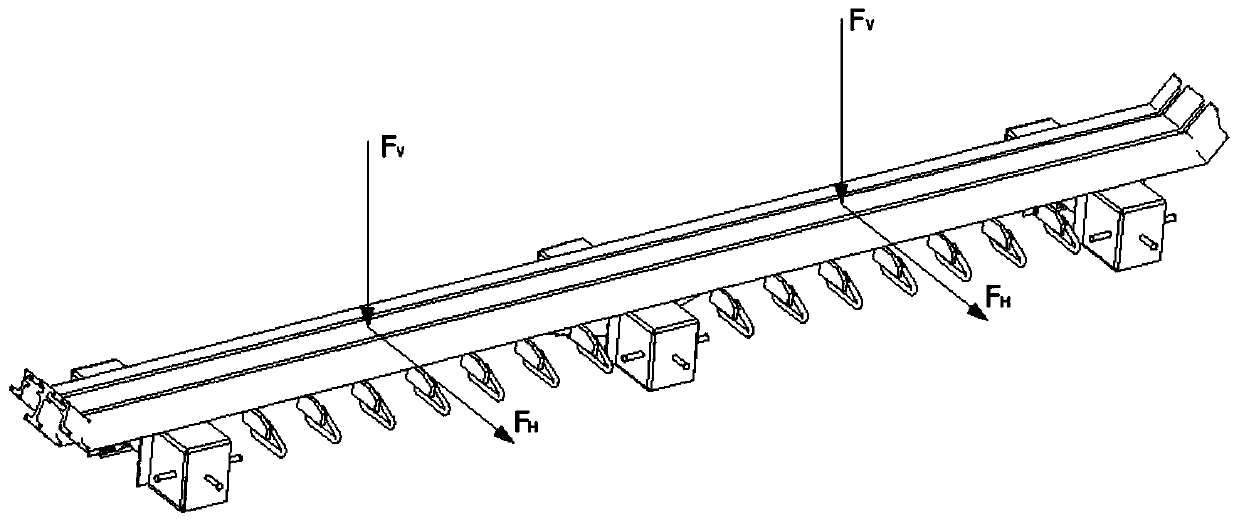

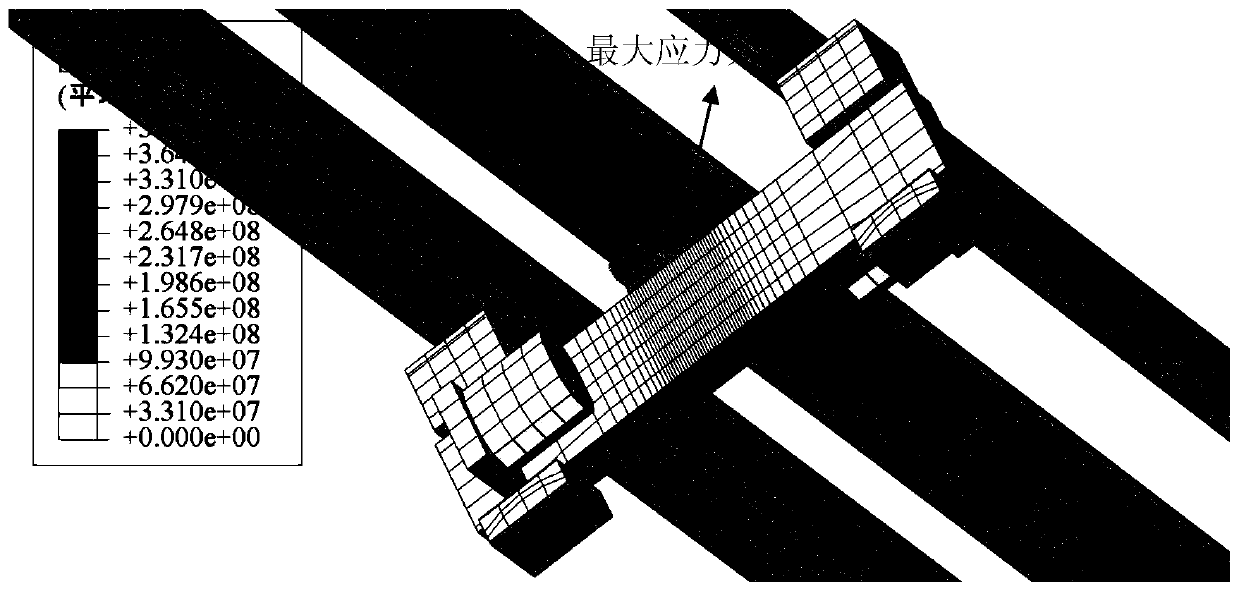

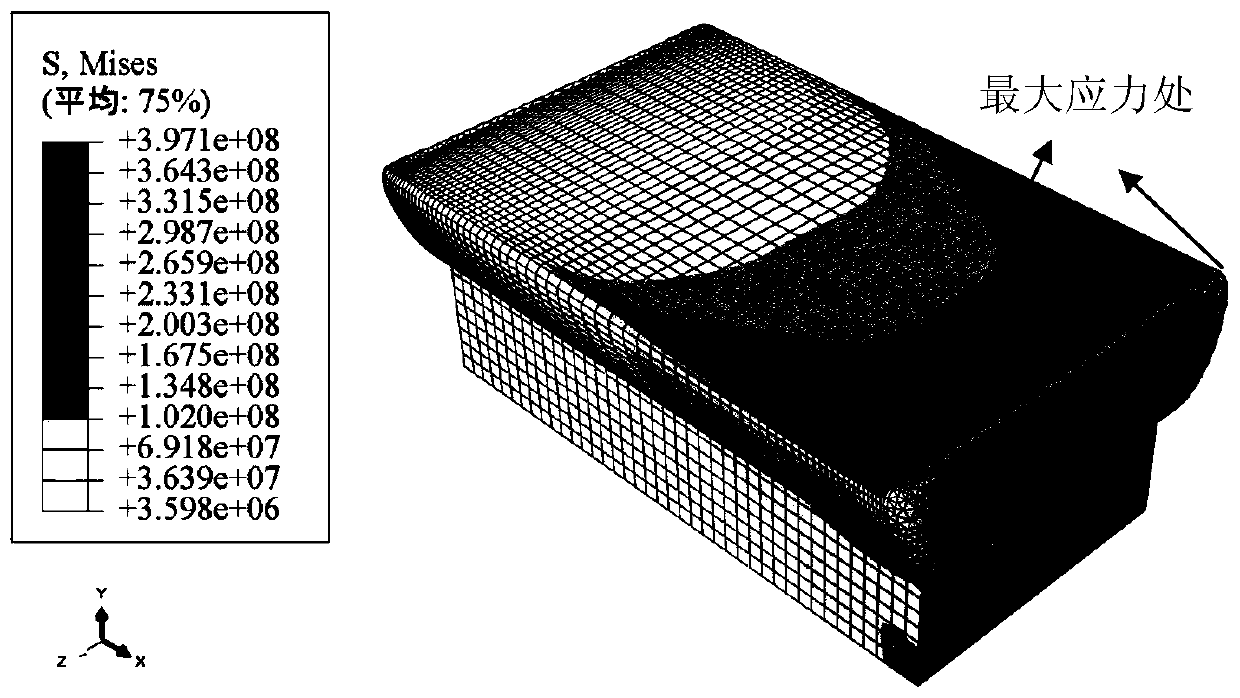

High-strength anti-fatigue modular bridge expansion device and construction method

ActiveCN110080098AConvenient welding constructionImprove welding qualityBridge structural detailsEngineeringHigh intensity

The invention discloses a high-strength anti-fatigue modular bridge expansion device and a construction method. The high-strength anti-fatigue modular bridge expansion device comprises a roadway displacement box; boundary beams are correspondingly arranged on the two sides of the roadway displacement box; a plurality of anchor plate welding pieces are uniformly distributed on the external side walls of the boundary beams; one or multiple center sills are arranged between the two boundary beams; cross beams perpendicular to the center sills horizontally penetrate into the roadway displacement box; the high-strength anti-fatigue modular bridge expansion device is characterized in that upper expanded special supporting cushion blocks are welded and connected between the center sills and the cross beams; at least one center sill supporting rib plate is fixedly arranged on the two sides, in the length directions of the center sills, of the upper expanded special supporting cushion blocks; the top edges of the center sill supporting rib plates are welded to the center sills; and the side edges of the center sill supporting rib plates are welded and connected to the cross beams. In the construction process, the upper surfaces of the upper expanded special supporting cushion blocks are connected with the center sills in a full-length welding manner. The high-strength anti-fatigue modular bridge expansion device has the advantage that strength and anti-fatigue requirements of national regulations on the bridge expansion device can be satisfied through calculation.

Owner:NINGBO UNIV

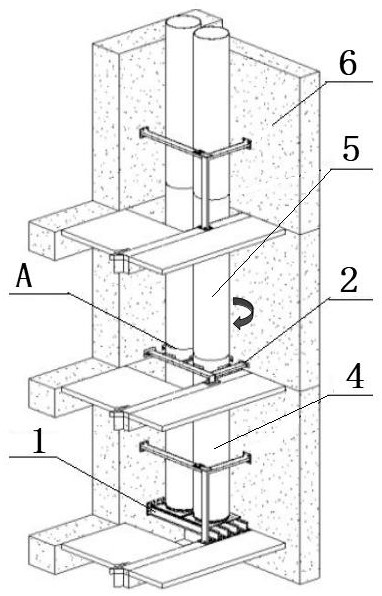

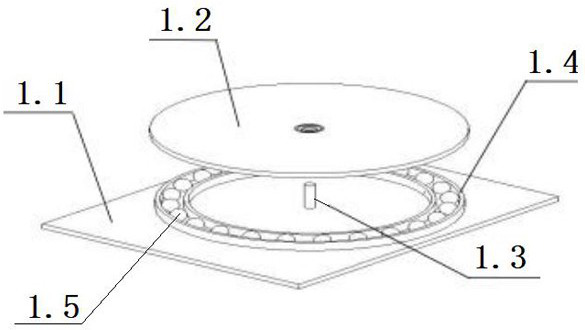

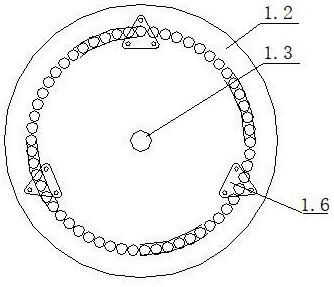

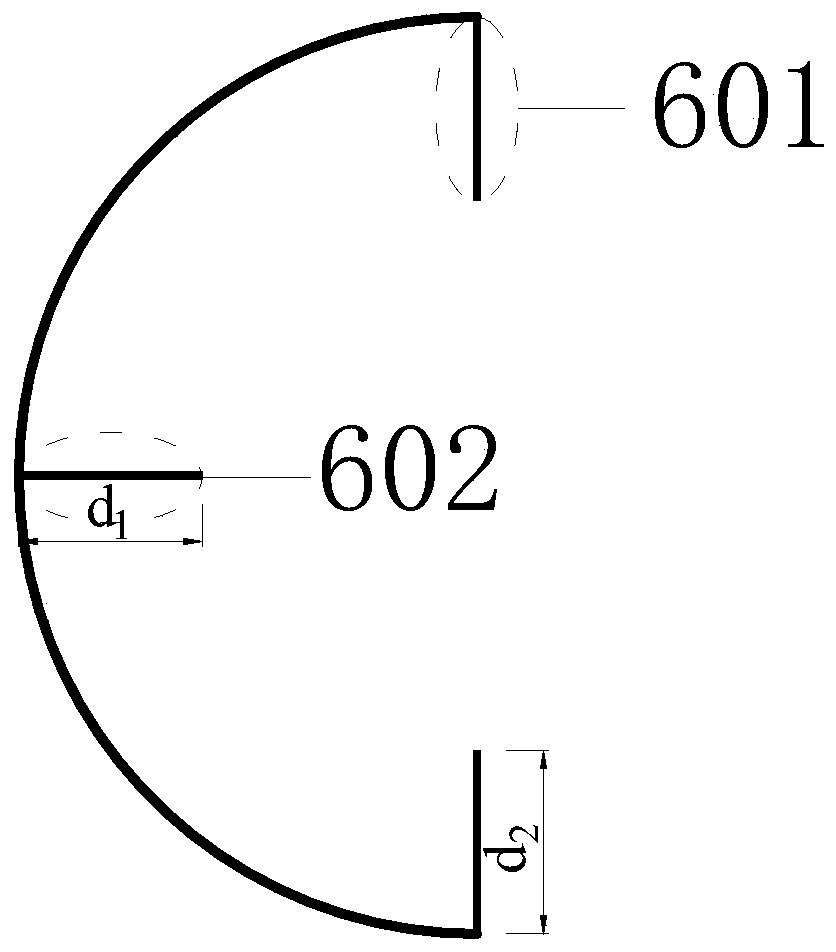

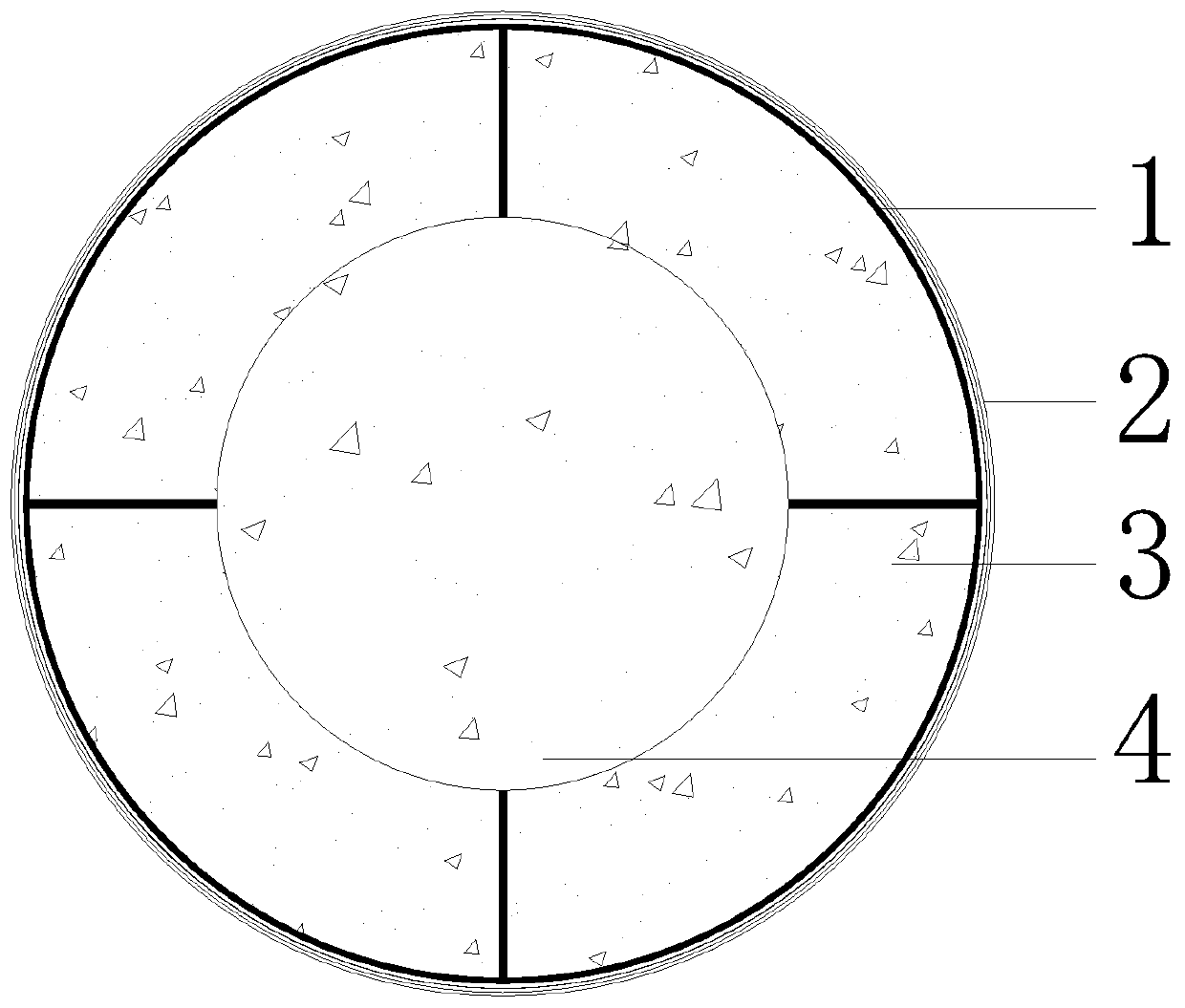

A pipe cage pipe welding construction method

ActiveCN113245784BConvenient welding constructionReduce construction areaWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe

The invention provides a pipe cage pipe welding construction method, which adopts a welding construction device, the welding construction device includes a rotating base, the rotating base is arranged at the bottom of the pipe cage, and is used to support and rotate the pipe, the rotating base The base includes a plurality of supporting seats; a rotating force component is installed on the outer circumference of the first section of the pipeline, and the first section of pipeline is rotated by the rotating force component; the unfinished welding part of the first section of the pipeline and the adjacent section of the pipeline is exposed to the outside , Continuously weld the part that has not been welded. The technical solution provided by the invention not only solves the problem of inconvenient welding of pipelines in a narrow space, but also ensures the stability of the pipeline during the welding process and the convenience of disassembling the welding device after the welding is completed.

Owner:中建五局安装工程有限公司

A kind of preparation method of heavy-duty automobile rear axle housing

ActiveCN111037237BQuality assuranceConvenient welding constructionPositioning apparatusMetal working apparatusStructural engineeringWeld seam

A preparation method of a rear axle housing of a heavy-duty car comprises the following steps: 1) blanking a steel plate; 2) performing cold and hot press molding to obtain an upper half shell and a lower half shell; 3) milling the joint surface of the upper half shell and the lower half shell; 4) arranging an oil drain hole at the bottom of the lower half shell corresponding to a bulge; 5) closing the upper half shell and the lower half shell, and performing spot welding at intervals along the length direction of a joint seam; (6) positioning a rear axle housing blank, using a milling machinefor machining welding grooves along the joint seam between the upper half shell and the lower half shell, and the cross sections of the welding grooves are V-shaped; (7) carrying out straight joint seam welding along the welding grooves, and obtaining a rear axle housing crude product; (8) calibrating the two ends of the rear axle housing crude product to be round, and forming stepping holes in inner holes at the two ends the rear axle housing crude product respectively; (9) carrying out machining, and setting accessories; and (10) obtaining the rear axle housing of the heavy-duty car after polishing and cleaning. The preparation method is simple in process, high in production efficiency, capable of effectively reducing the machining cost of the product and guaranteeing the quality of theproduct.

Owner:重庆康桥工业有限公司

Method for reinforcing reinforced concrete column by enlarging section of self-compacting concrete sleeved with FRP-steel composite pipe

ActiveCN110565976APrevents concave bucklingReduce rust rateBuilding repairsReinforced concrete columnRebar

The invention provides a method for reinforcing a reinforced concrete column by enlarging the section of self-compacting concrete sleeved with an FRP-steel composite pipe, and relates to a structure reinforcing technology in the field of civil and architectural engineering. The method comprises the following steps: (1) construction preparation; (2) treatment of the surface of the existing reinforced concrete column; (3) sleeving of the steel pipe; (4) pasting of an FRP cloth; and (5) concrete pouring. According to the method, the bearing capacity and the rigidity of the reinforced concrete column which is reinforced can be improved remarkably, the ductility of the reinforced concrete column is improved, the plasticity and toughness of the concrete column are improved, operation is easy, construction is rapid, the engineering cost is low, and the method has wide application prospects.

Owner:WUHAN UNIV

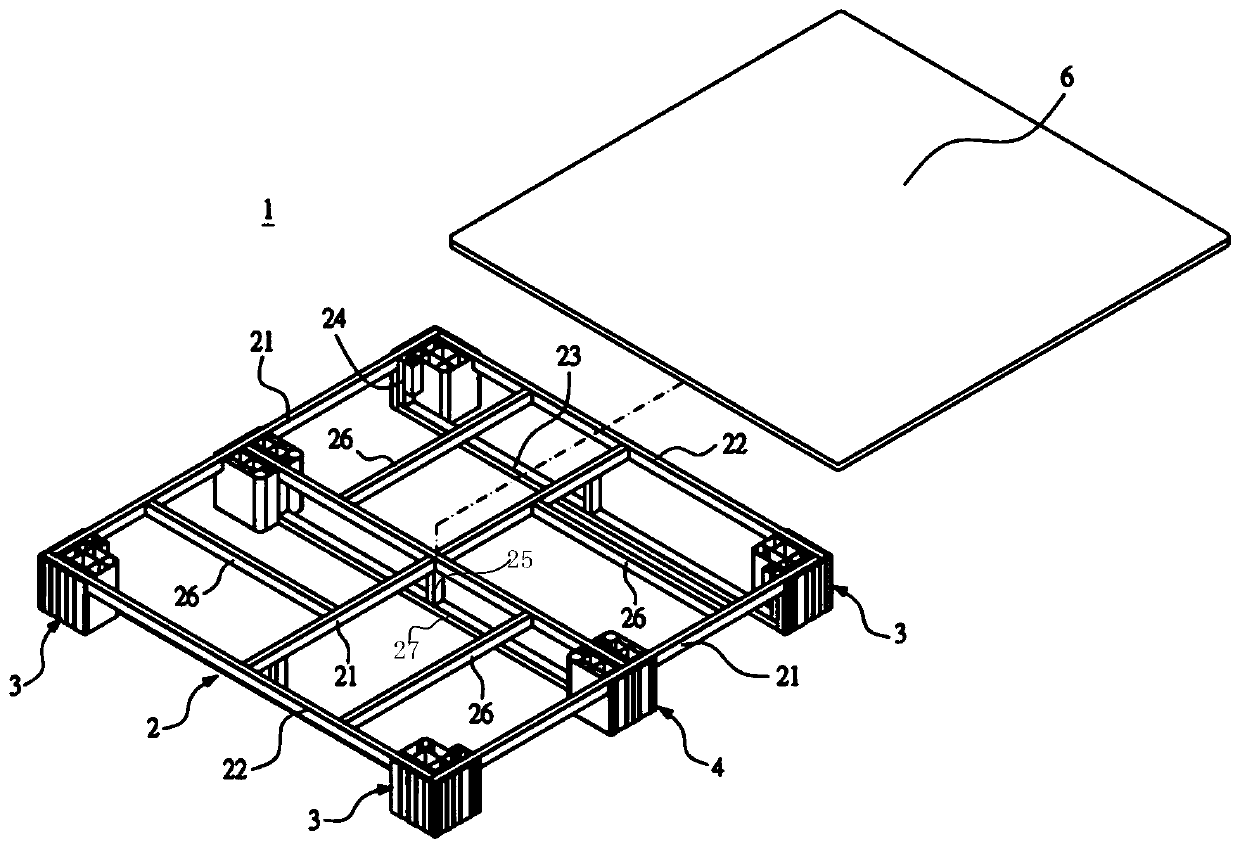

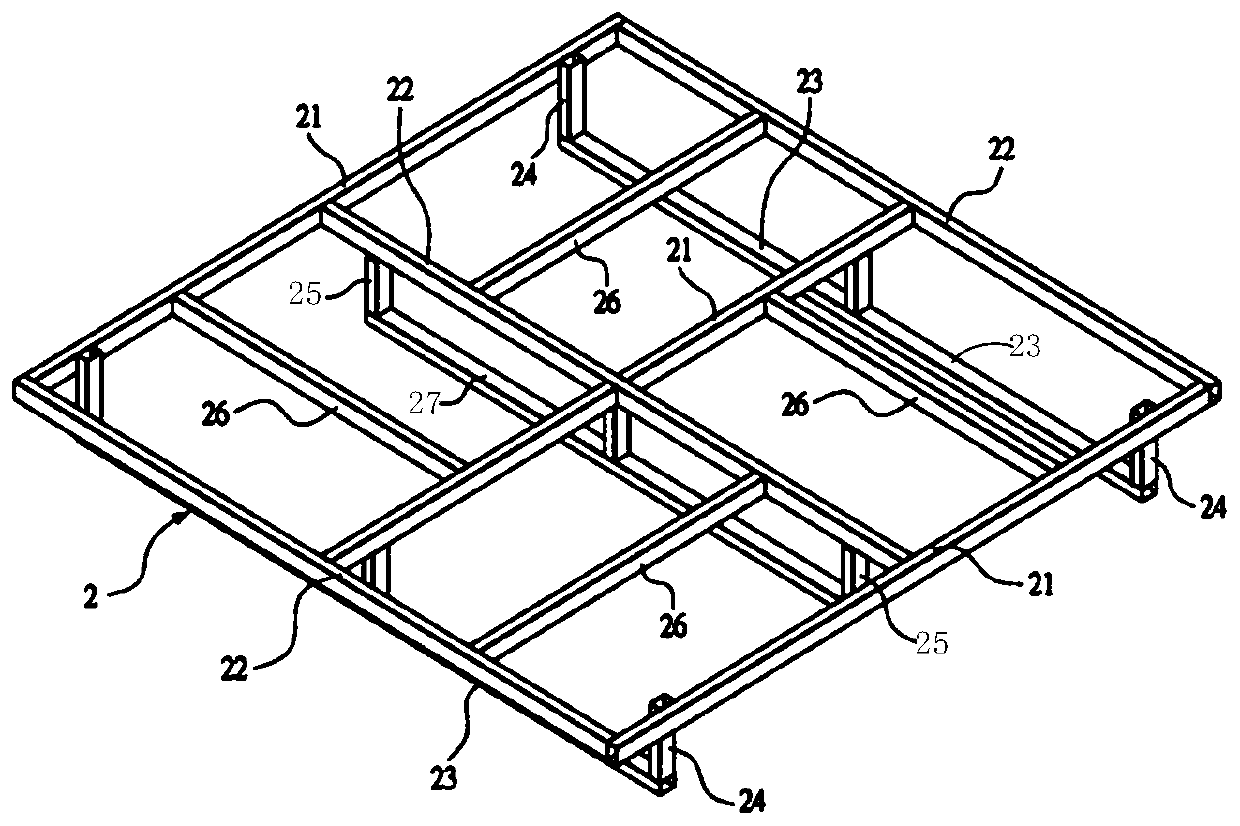

Combined pallet

Owner:KUNSHAN AIRBAG PACKING CORP

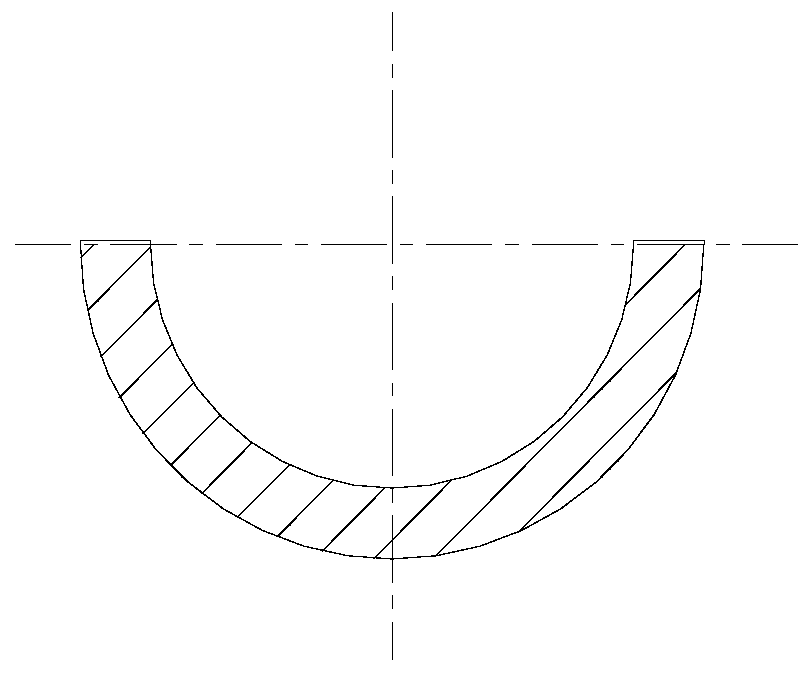

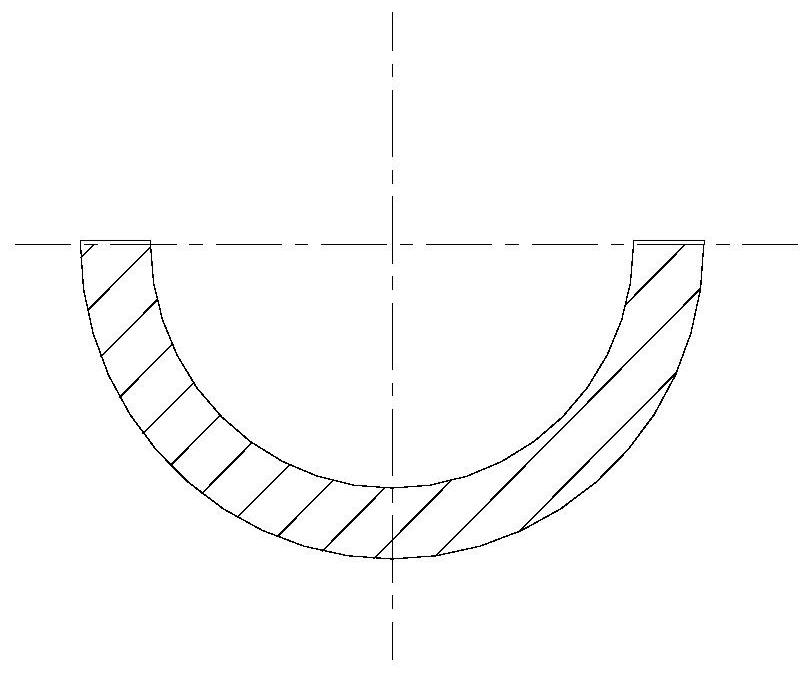

A kind of anti-piercing pipe pressing mold

ActiveCN103302219BResolve inhibitionAddress stressForging/hammering/pressing machinesEngine componentsLine tubingEngineering

The invention discloses a compacting tool set for a penetration-proof tube. The compact tool set comprises a male die body and a female die body; the female die body and the male die body are designed to be semi-circular; the radius of the female die body is greater than that of the male die body; circular arc grooves for eliminating elastic stress are uniformly formed in the inner arc-shaped surface of the female die body; two mutually symmetrical positioning pin holes are formed in two ends of the inner arc-shaped surface respectively; a support is axially arranged at the middle part of the outer arc-shaped surface of the female die body; a flat plate-type connecting seat is welded on the support, and bolt holes are arranged at the four angles of the connecting seat; arc-shaped cogs matched with the circular arc grooves formed in the inner arc-shaped surface of the female die body are uniformly arranged on the outer arc-shaped surface of the male die body; cylindrical positioning pins matched with the positioning pin holes in the inner arc-shaped surface of the female die body are arranged at the two ends of the outer arc-shaped surface of the male die body; a support is axially arranged at the middle part of the section of the male die body; a flat plate-type connecting seat is welded on the support and bolt holes are arranged at the four angles of the connecting seat; the connecting seat of the female die body is connected with the piston of a mould press; and the connecting seat of the male die body is connected with the workpiece platform of the mould press. The compacting tool set, provided by the invention, solves the problem of penetration-proof tube pressing and elastic stress eliminating; and the two parts of the penetration-proof tube pressed can be buckled in an anastomotic manner, so that the penetration-proof tube can be tightly fit with the pipeline which is protected by the penetration-proof tube, the welding procedure is convenient, and the construction efficiency is significantly improved.

Owner:山东宇明月石油工程有限公司

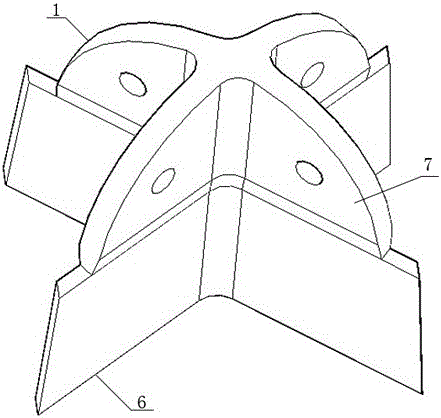

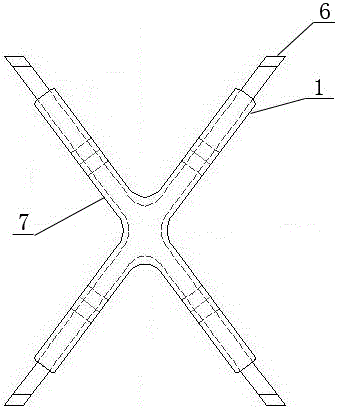

A steel pipe column column top x-shaped pin shaft support node

ActiveCN104452971BChange directionHigh strengthBuilding constructionsPull forceUltimate tensile strength

The invention relates to an X-type pin support joint for the top of a steel pipe column. The X-type pin support joint comprises the steel pipe column and an X-type casting. The X-type casting is arranged at the top of the steel pipe column and comprises an upper X-type-casting portion and a lower X-type-casting portion. The upper X-type-casting portion is positioned on the upper side of the top end of the steel pipe column. The lower X-type-casting portion is positioned in the steel pipe column, extends radially to the inner wall of the steel pipe column and is welded to the inner wall of the steel pipe column. The improved X-type pin support joint has the advantages that directions and positions of welding joints are changed, and strength, particularly strength of bearing pulling force and horizontal thrust, of the X-type pin support joint for the top of the steel pipe column is improved.

Owner:中南建筑设计院股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com