Method for manufacturing low-cost tungsten electrode

A tungsten electrode, a low-cost technology, is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of convenient welding construction and use, increasing homogeneity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Using traditional powder metallurgy, swaging, drawing, and cutting to prepare tungsten electrodes, the length of the tungsten electrode rod is only 3 / 4 to 4 / 5 of the current standard length of tungsten electrodes of various specifications;

[0044] 2) Take the Cr-W-Mo-V alloy steel rod with the same diameter as the tungsten electrode rod;

[0045] 3) Put the above-mentioned tungsten electrode rod and alloy steel rod into an ultrasonic cleaning device equipped with an environmentally friendly water-based cleaning agent for ultrasonic cleaning. ~1000W, vibration washing time is 10~60min;

[0046] 4) Put the cleaned tungsten electrode and alloy steel rod into an ultrasonic cleaning device equipped with deionized water for ultrasonic cleaning. 300~600W, vibration washing time is 5~10min; then take out the tungsten electrode and alloy steel rod, put them into the ultrasonic cleaning device with deionized water again and repeat cleaning 2~5 times;

[0047] 5) Put the abo...

Embodiment 2

[0059] Steps 1) to 7) are the same as described in Example 1;

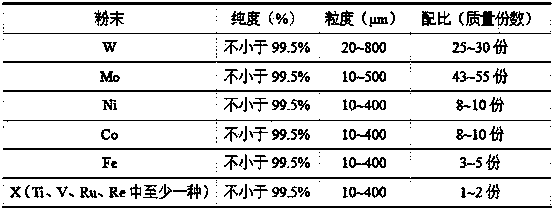

[0060] 8) Preparation of flux: Weigh 250g of each raw material powder according to the ratio in Table 2, mix them evenly, put them into a stainless steel ball mill tank, then add 100~300ml of ethanol and 0.25~2.5kg of hard alloy balls; set planetary The speed of the ball mill is 100~300r / min, argon gas is introduced into the ball mill tank, and the grinding time is 30~50h; the obtained composite powder is dried under a power of 100~500W infrared lamp for 5~10min for later use;

[0061] Table 2 The raw material formula of flux

[0062]

[0063] 9) Add 3.13~31.3g of polyethylene glycol PEG400 and 30~240g of ethanol to the composite powder obtained above, perform ball milling at a speed of 50~100r / min for 15~30 min, and add 2.5~25g of Foaming agent (one selected from emulsified silicone oil, high-carbon alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene pentaerythritol ether, polyoxyethylene polyo...

Embodiment 3

[0068] 1) A tungsten electrode rod with a diameter of 2.4mm and a length of 140mm is prepared by traditional powder metallurgy, swaging, drawing, and cutting processes for preparing tungsten electrodes;

[0069] 2) Take a Cr-W-Mo-V alloy steel rod with a diameter of 2.4mm and a length of 35mm;

[0070] 3) Put the above-mentioned tungsten electrode rod and alloy steel rod into an ultrasonic cleaning device equipped with an environmentally friendly water-based cleaning agent for ultrasonic cleaning. Washing time is 30min;

[0071] 4) Put the cleaned tungsten electrode and alloy steel rod into an ultrasonic cleaning device equipped with deionized water for ultrasonic cleaning. The ultrasonic cleaning frequency is 80kHz, the solvent temperature is controlled at 20~50°C, and the ultrasonic power is 400W. The vibration washing time is 5 minutes; then take out the tungsten electrode and alloy steel rod, put them into the ultrasonic cleaning device with deionized water again and repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com