Cable fast welding tool and welding method thereof

A technology of rapid welding and welding method, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of not being able to weld cable joints at the same time, welding quality is not too hard, electric construction is inconvenient, etc., to achieve fast welding speed, welding The effect of good quality and easy welding construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below by specific embodiment, further illustrate advantage of the present invention:

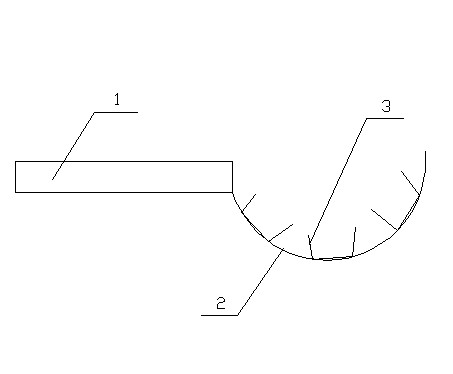

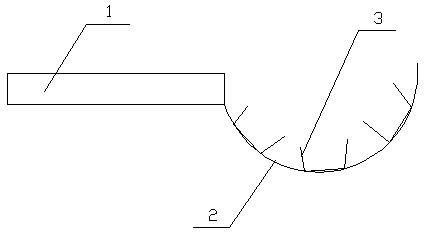

[0016] like figure 1 Shown: a fast cable welding tool, including a handle 1 and a heating spoon 2 connected to the handle 1, and a plurality of tin picking positions 3 are arranged in the heating spoon 2. The tin taking position can be set as a two-wire position, a three-wire position or a four-wire position.

[0017] The welding method of the fast cable welding tool includes the following steps: first melt the solder wire in each tin-taking position 3 in the heating spoon 2; then insert the wire to be welded into the tin-taking position 3 where the solder has been melted ; Wait for the thread to get through the tin and then take it out.

[0018] In the present invention, multiple tin-taking positions 3 are set in the heating spoon 2 of the fast cable welding tool, so that multiple cable ends can be welded at the same time, so that the construction efficiency is greatly increased, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com