Method for reinforcing reinforced concrete column by enlarging section of self-compacting concrete sleeved with FRP-steel composite pipe

A reinforced concrete column and self-compacting concrete technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of low utilization rate of outsourcing steel materials, inability to work as a whole, poor durability and fire resistance of reinforced columns, etc. , to achieve the effect of convenient splicing and welding construction, prolonging the service life and delaying the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

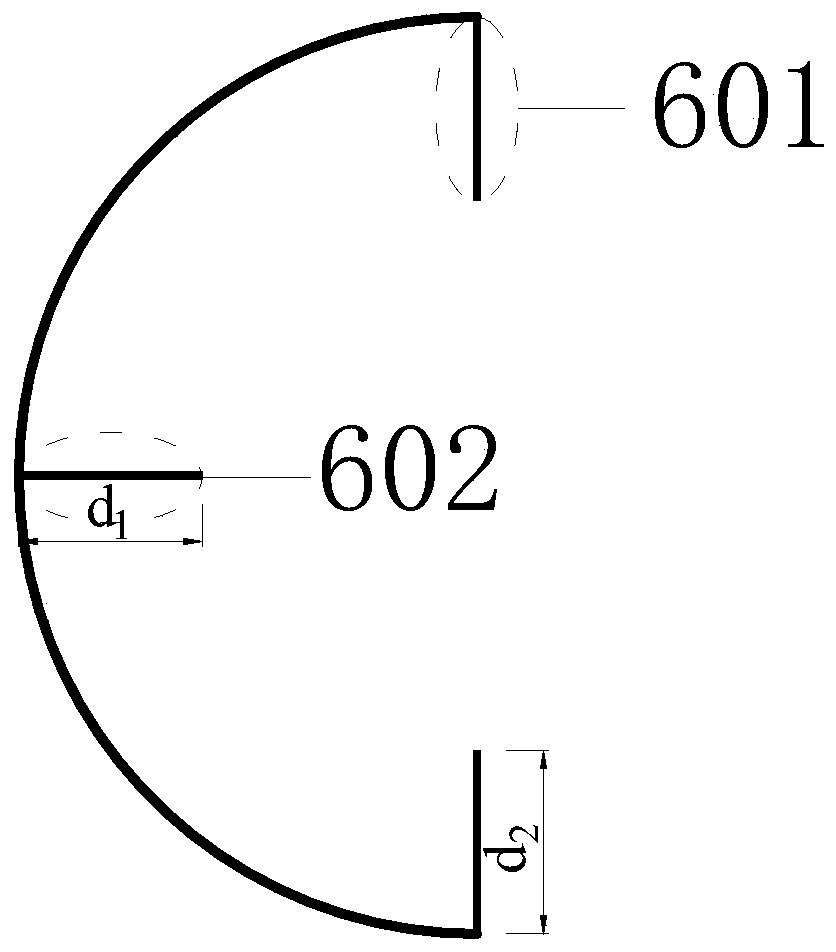

[0029] (1) Construction preparation: as attached figure 1 As shown, the rectangular steel rib plate 602 is vertically placed in the middle of the rolled semicircular steel plate and fully welded, so that it forms a whole of the ribbed semicircular steel plate, and the end of the ribbed semicircular steel plate is at right angles to the inside Bending to form the bent portion 601 at the end of the rolled semicircular steel plate.

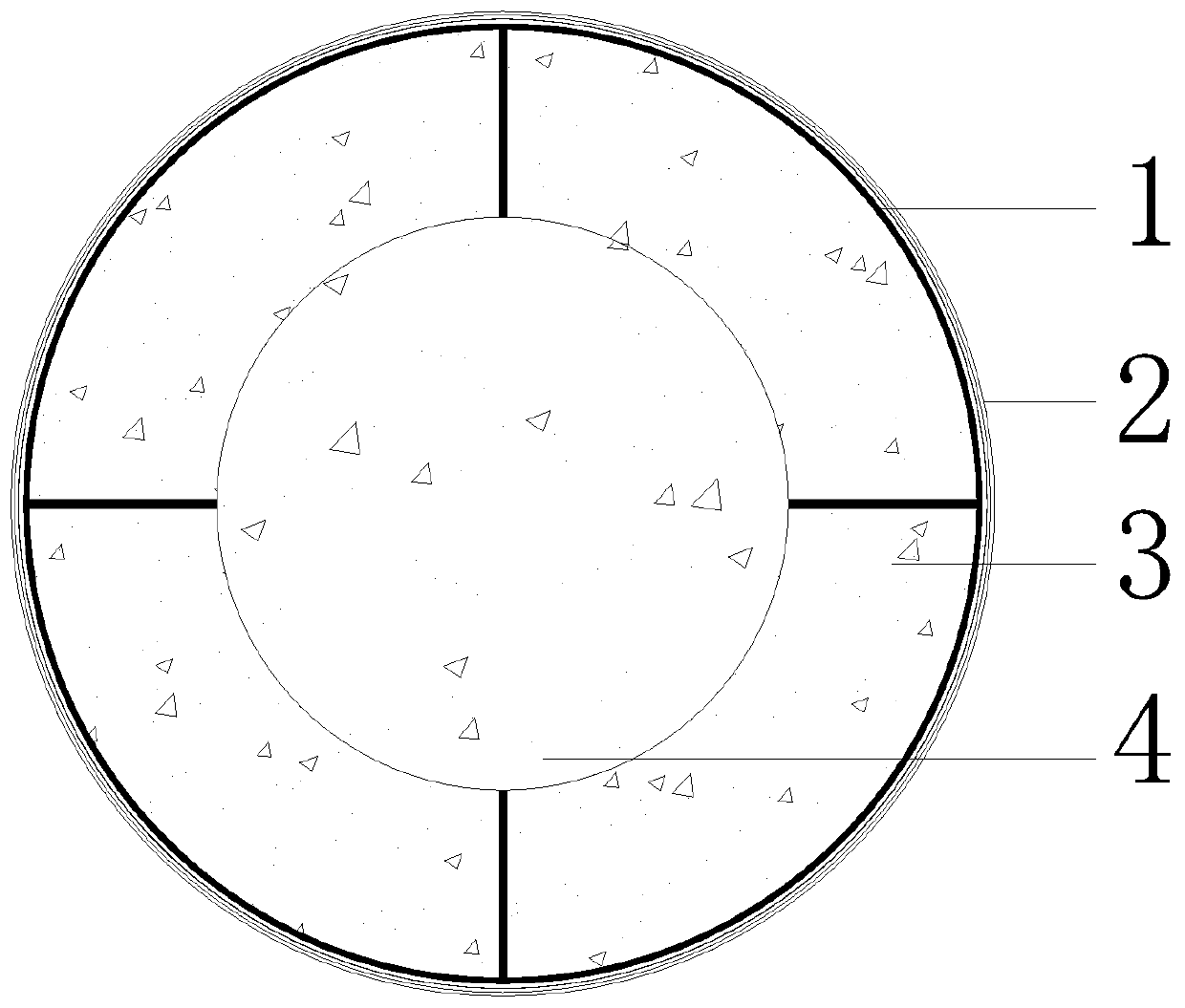

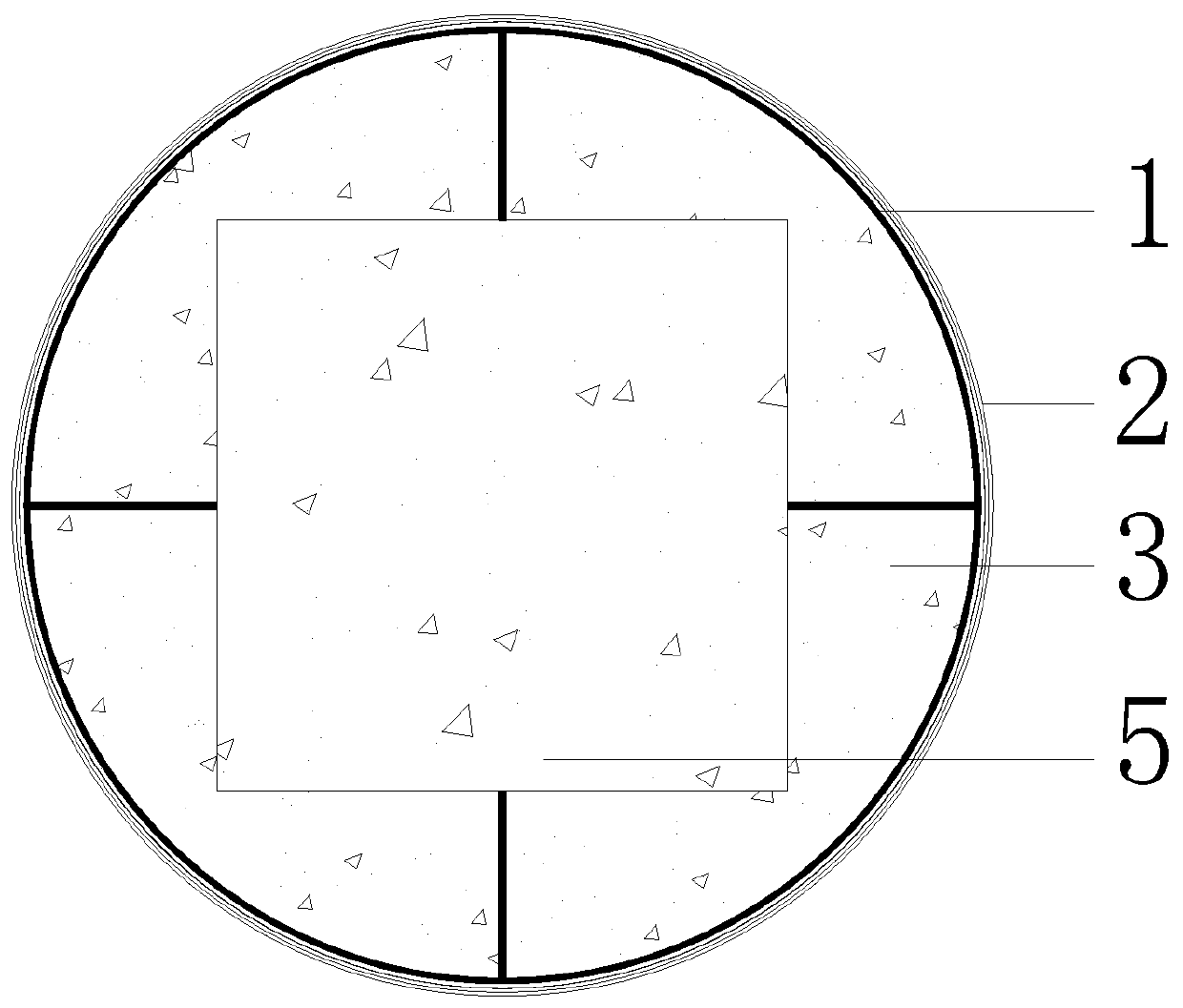

[0030] (2) Treat the surface of the existing reinforced concrete column 4 (or reinforced concrete square column 5 ): chisel off the original protective layer, chisel the surface, and moisten it with water.

[0031] (3) Outer steel pipe: put two ribbed semicircular steel plates on the outside of the reinforced concrete column 4 (or reinforced concrete square column 5), so that the long side of the rectangular steel rib pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com