Central rotating equipment support

A technology for rotating equipment and supports, applied in mechanical equipment, non-rotating vibration suppression, supporting machines, etc., can solve problems such as increasing motor power, wasting electric energy, increasing friction between fixed supports and rotating central axis, and reducing screw The rate of corrosion, the reduction of the possibility of screw rusting, the effect of smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

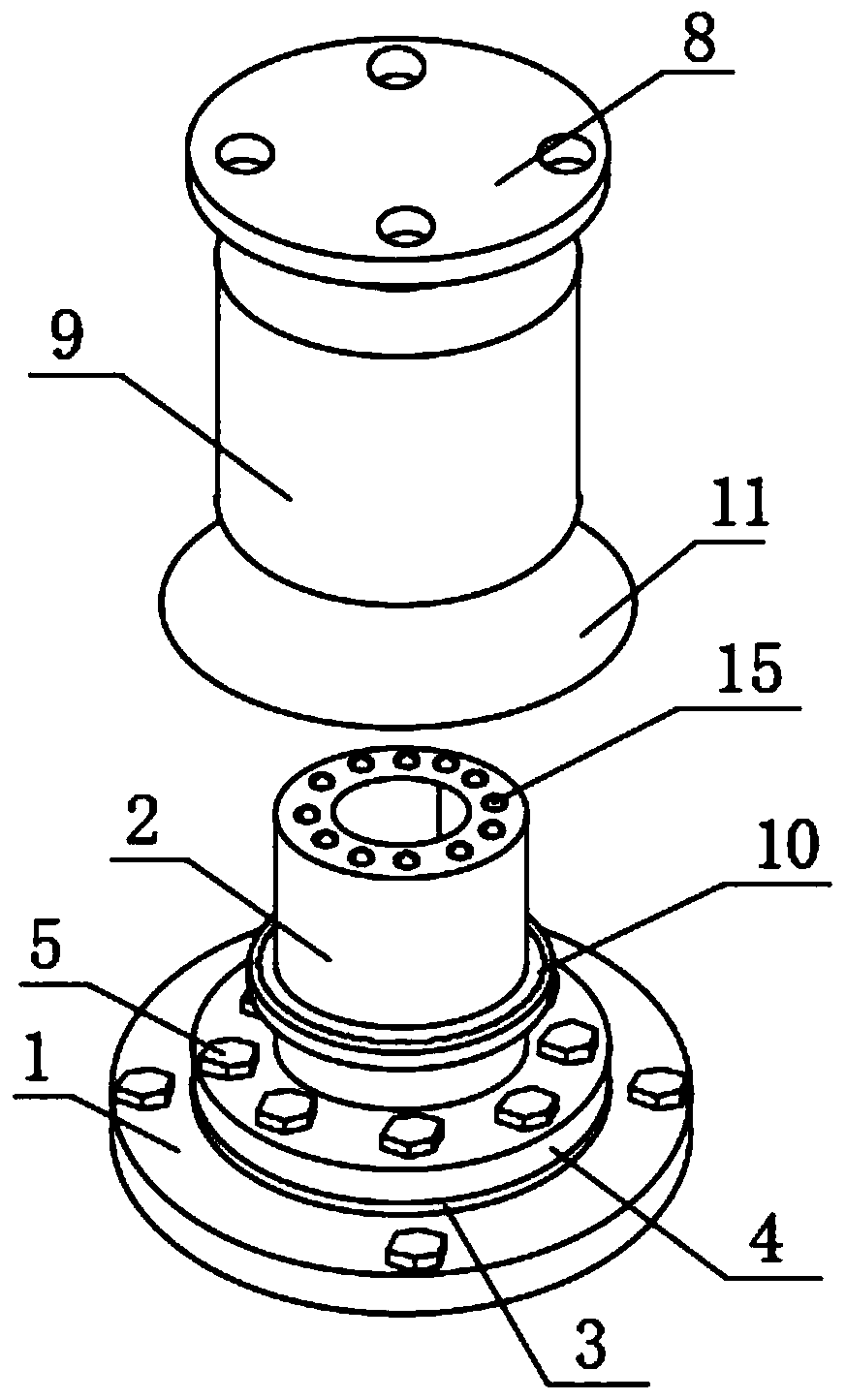

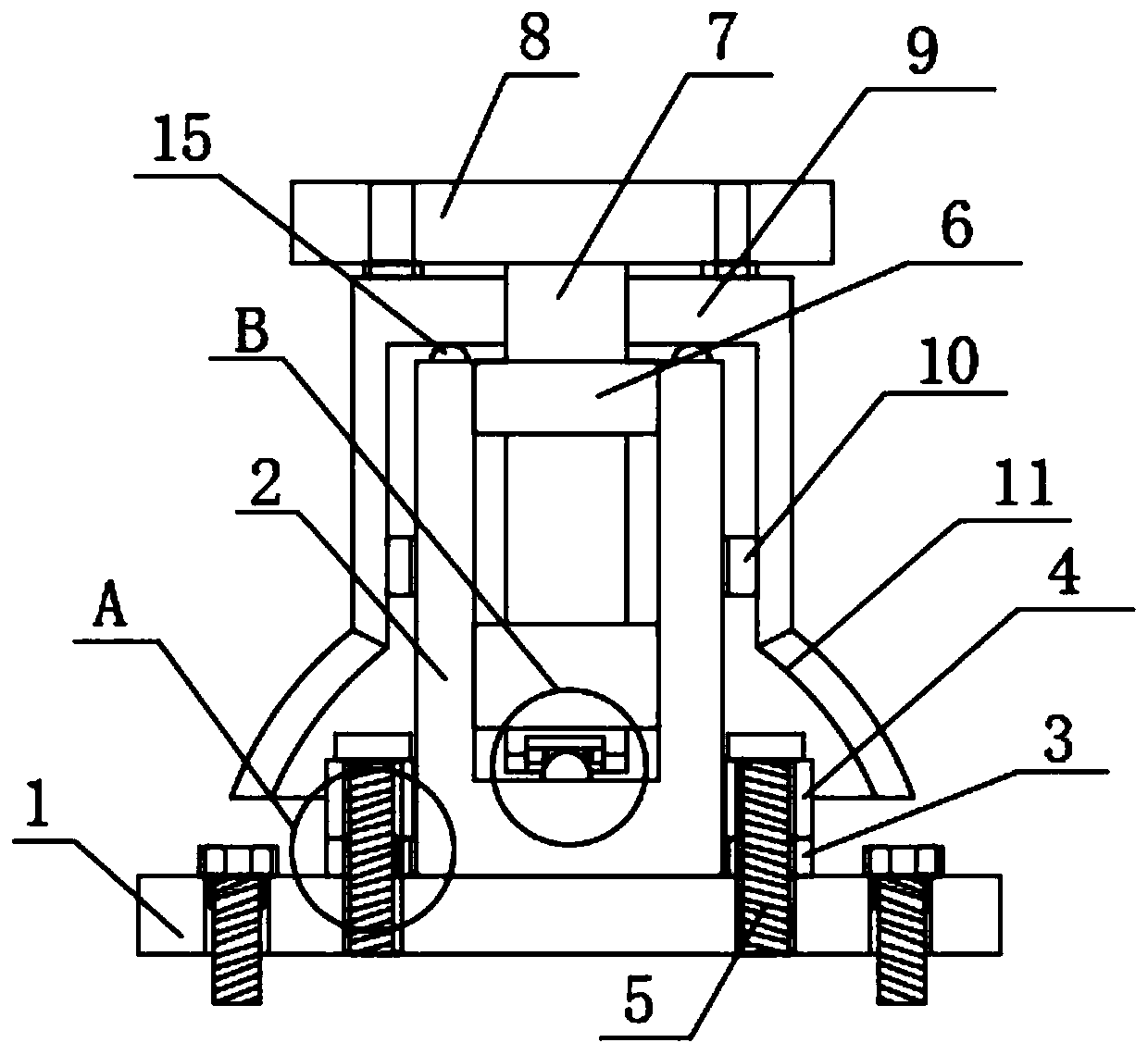

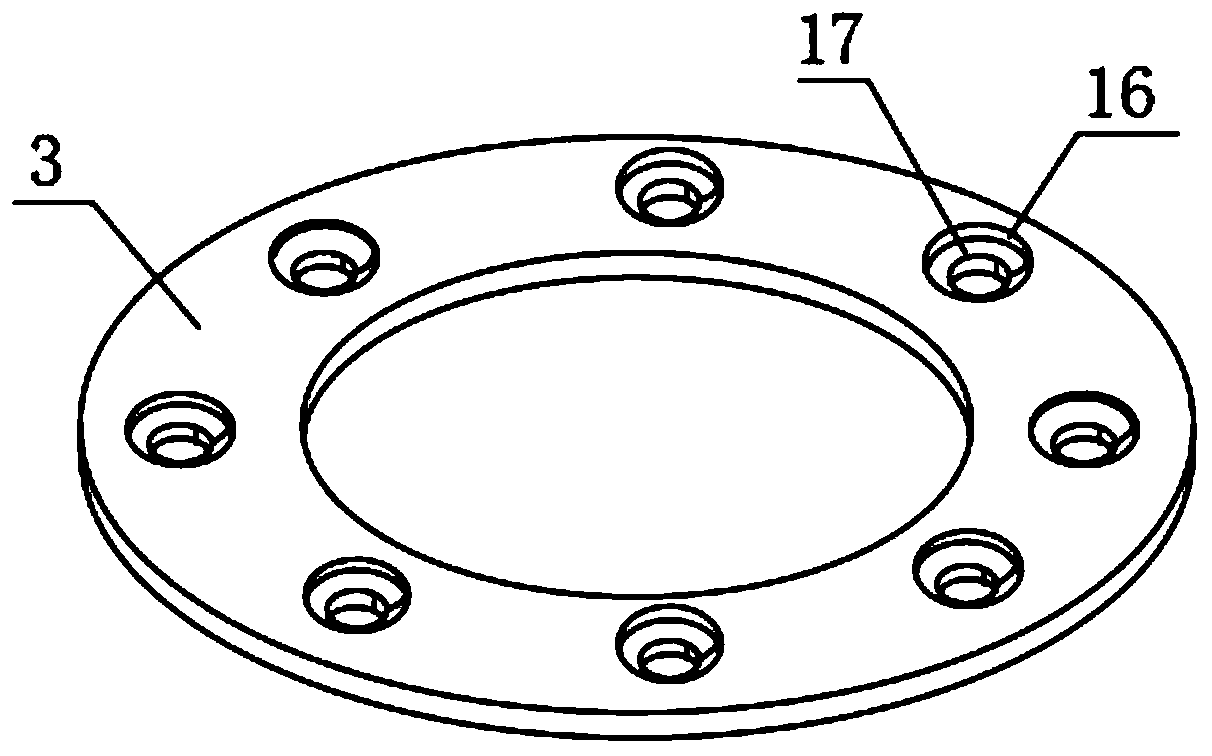

[0021] see Figure 1~5 , in an embodiment of the present invention, a central rotating equipment support includes a base 1, a sleeve 2 is fixedly connected to the top of the base 1, the surface of the sleeve 2 is sleeved with a rubber pad 3, and the surface of the sleeve 2 is sleeved with The flange 4 located above the rubber pad 3, the top of the rubber pad 3 is provided with a water blocking hole 16, the top of the flange 4 is threaded with a screw 5, the screw 5 penetrates the water blocking hole 16 and is threaded with the base 1, the water blocking hole The middle part of the inner wall of 16 is provided with a protruding block 17, and the protruding block 17 makes the screw 5 interfere with the water blocking hole 16. The inner wall of the base 1 is fixedly connected with two first bearings 6, and the inner wall of the first bearing 6 A rotating shaft 7 is sleeved on the edge of the rotating shaft 7, and the top of the rotating shaft 7 is fixedly connected with a rotatin...

Embodiment 2

[0024] see Figure 1~5 , on the basis of Embodiment 1, a further improvement is made: the bottom of the inner wall of the sleeve 2 is provided with a steel ball 12, the bottom of the rotating shaft 7 is provided with a hollow groove 13, and the inner wall of the hollow groove 13 is fixedly connected with a third bearing 14, the third The diameter of the inner edge of the bearing 14 is smaller than the diameter of the steel ball 12, and the third bearing 14 is sleeved on the surface of the steel ball 12, which can play a good supporting effect on the rotating shaft 7 without affecting the rotation of the rotating shaft 7, and avoid the rotating shaft 7 being damaged. The pressure is all applied on the first bearing 6 and the second bearing 10, which reduces the burden on the first bearing 6 and the second bearing 10, and makes the support more stable in use.

[0025] Wherein, the top of the casing 9 is fixedly connected with a rubber ring, and the top of the rubber ring is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com