Angle steel

A technology of angle steel and body, applied in the direction of slender components, building components, etc., can solve the problems of angle steel corrosion resistance, troublesome disassembly and assembly, time-consuming and laborious, etc., and achieve the effects of prolonging service life, strong practicability, and simplifying installation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

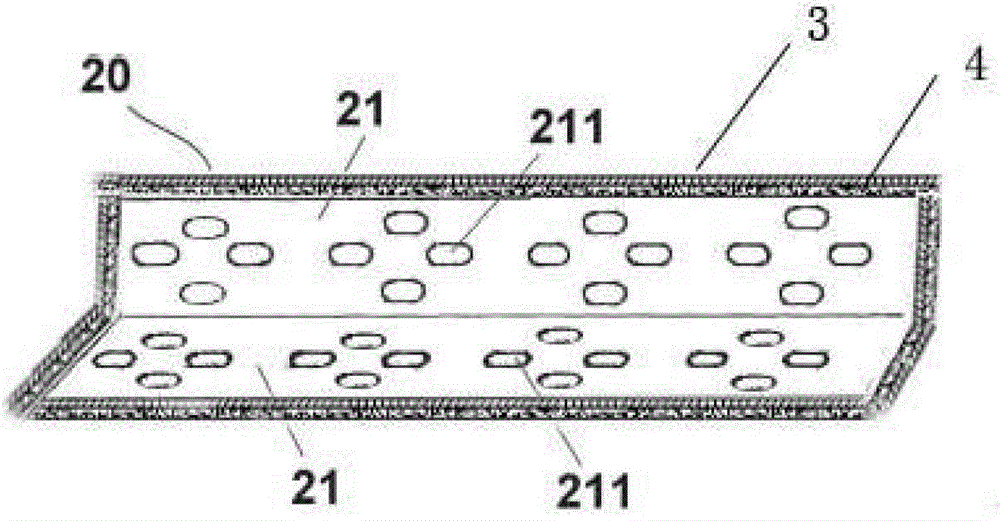

[0014] Such as figure 1 As shown, an angle steel includes an angle steel body 20, and the angle steel body 20 is composed of two mutually perpendicular angle steel feet 21, and a plurality of elliptical holes are arranged in the angle steel feet 21. There is a layer of copper plating 4 on the outer surface of the angle steel body 20 , and a layer of zinc plating 3 is provided on the outer surface of the copper plating 4 layer.

[0015] The thickness of the layer of copper plating 4 is 0.01 mm, and the thickness of the layer of zinc plating 3 is 0.03 to 0.2 mm.

[0016] The shape of the fixing hole 211 can be ellipse, square, pentagon, triangle and so on.

[0017] In the process of using, two angle steel feet 21 perpendicular to each other form 90 degrees, the angle steel feet 21 on the first face are equidistantly provided with a row, four longitudinal fixing holes, and the fixing holes on the angle steel frame on the second face 211 is symmetrical about the intersecting lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com