A kind of preparation method of heavy-duty automobile rear axle housing

A technology for heavy-duty vehicles and rear axles, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems affecting the market competitiveness of products, uneven welding grooves, low processing efficiency, etc., to reduce processing costs. , The effect of convenient welding construction and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In the present invention, the components without specific structure and connection mode are generally conventional components or connection modes, and those without specific process and method are generally conventional process or method.

[0051] The preparation method of heavy-duty automobile rear axle housing comprises the following steps:

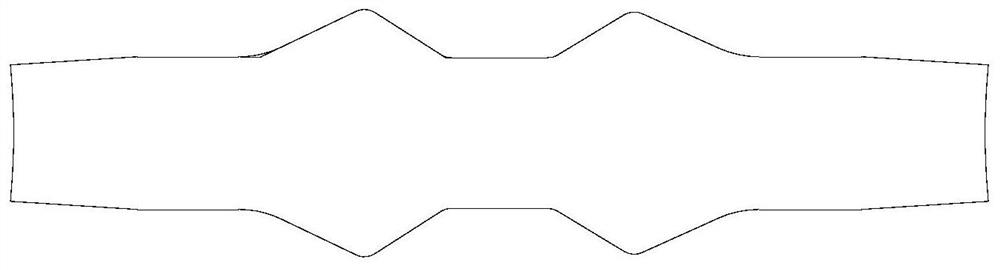

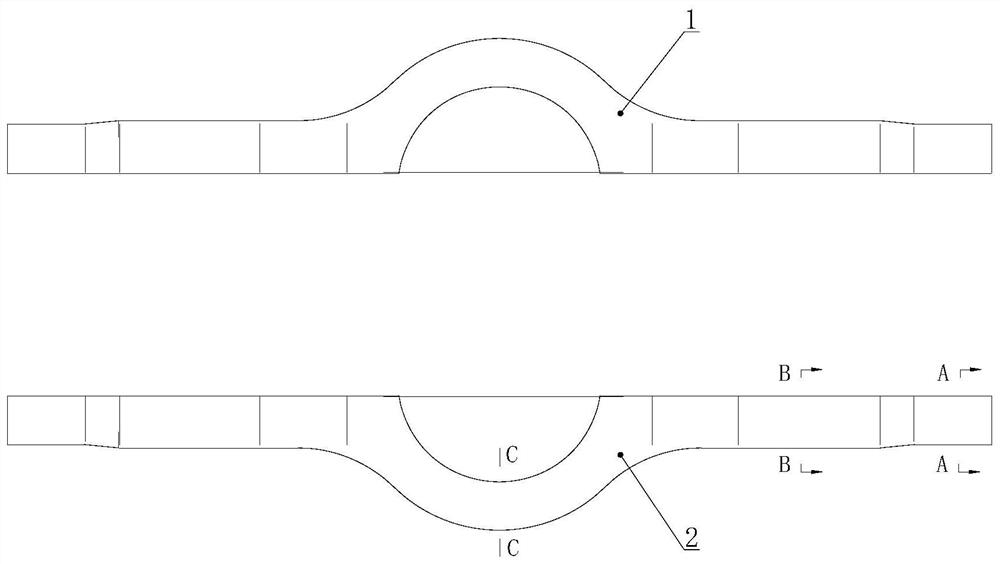

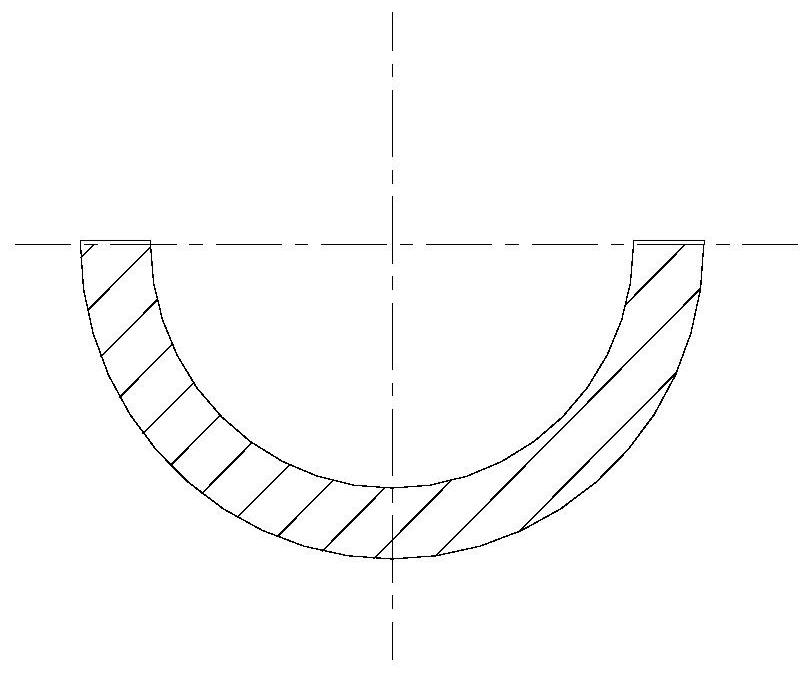

[0052]1. Take the steel plate 510L-16, cut the blanks with flame, and get two blanks. The length of the blank is 1510±2mm, and the width at both ends is 213±2mm. Specifically, the short side of the blank is an arc segment that bends inward, and the radius of the circle is 1134.8mm. The long side of the blank is formed by the The first straight side, the second straight side on both sides of the first straight side, the first hypotenuse connecting the short side and the second straight side, the second hypotenuse connecting the second straight line and the first straight side, and the third hypotenuse The side constitutes, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com