A kind of anti-piercing pipe pressing mold

A technology for pressing molds and anti-piercing pipes, which is applied in the direction of manufacturing tools, forging/pressing/hammering machines, forging/pressing/hammer devices, etc. It can solve the problem of loose fitting of pipelines, irregular anti-piercing pipes, and influence on popularization and use and other problems, to achieve the effect of convenient welding construction, improved construction efficiency, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

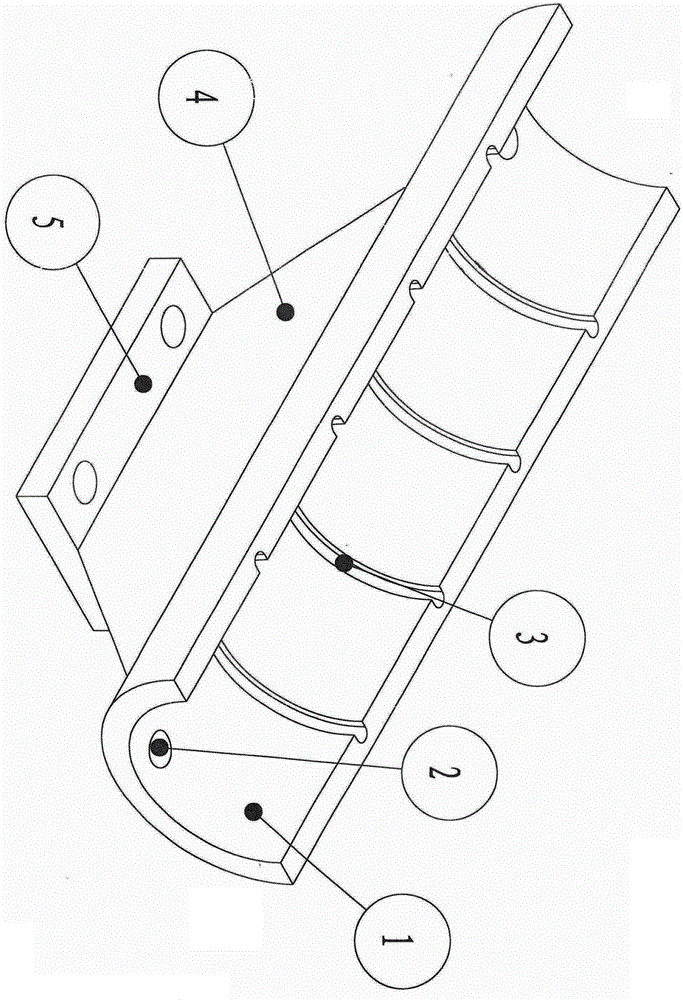

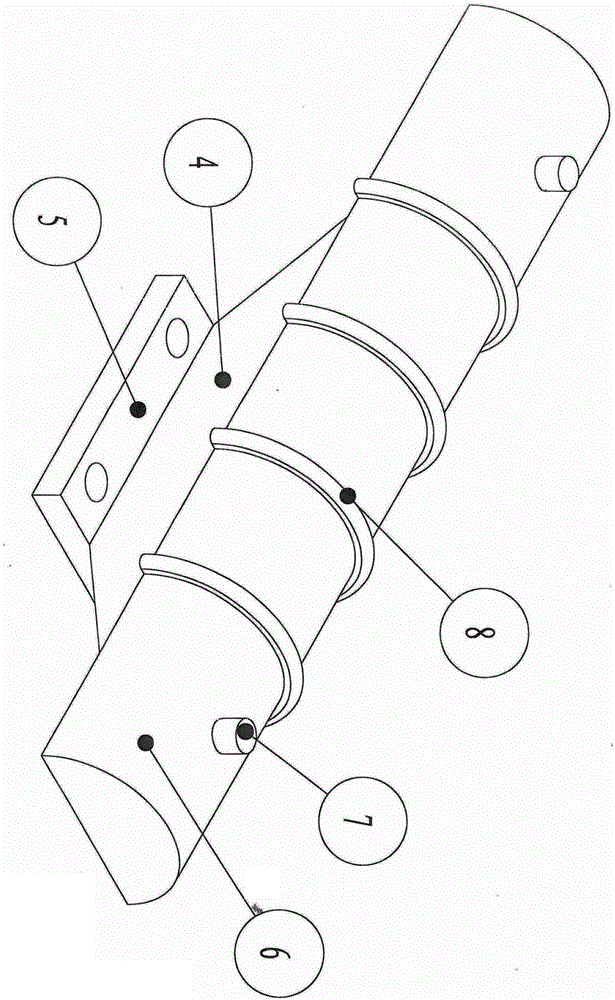

[0010] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0011] When applying the present invention, the female mold body 1 is connected on the piston rod of the molding machine, the male mold body 6 is installed on the molding workpiece platform, so that the two mold bodies correspond up and down, the positioning pin holes 2 correspond to the positioning pins 7, and the anti- Put the special steel plate through the pipe, and the special steel plate that conforms to the outer area of the buckle pipeline is placed horizontally on the surface of the male mold body, start the molding machine, the female mold body 1 goes down, buckles on the special steel plate, and cooperates with the male mold body 6, A circular arc-shaped anti-piercing pipe with an arc-shaped rib can be pressed out. During the construction, the two arc-shaped anti-piercing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com