Broadside subsection integrated construction method

A construction method and side-side technology, which is applied in ship construction, ship parts, ships, etc., can solve the problems of low installation accuracy and low efficiency of side-side segmented construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

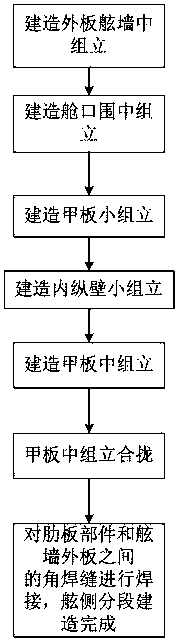

[0027] Example: such as Figure 1 to Figure 6 As shown, a side-side segmented integrated construction method, the method includes the following steps:

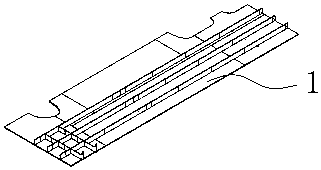

[0028] Step 1. Assembling in the construction of the outer plate bulwark 1, place the outer plate panels on the construction platform and weld them to form the outer plate of the bulwark, hoist the outer plate of the bulwark to the tire frame of the first plane, the structure of the outer plate of the bulwark The non-structural side of the bulwark is facing downwards, correct the straightness of the longitudinals of the outer plating of the bulwark, install and position the longitudinals of the outer plating on the upper surface of the outer plating of the bulwark, and weld the longitudinals of the outer plating and the outer plating of the bulwark to form an outer Assembled in the plate bulwark 2;

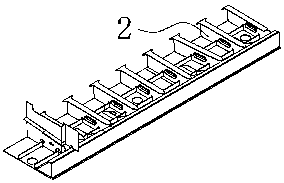

[0029] Step 2: Construct the hatch enclosure assembly 3, hoist the first inner longitudinal wall panel to the second flat tire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com