Recycling treatment process and apparatus system of power plant circulating water

A technology of treatment process and treatment device, which is applied in the field of water treatment, can solve the problems of carbon steel material that cannot meet the needs of use and increase in salt content, and achieve simple and easy process operation and maintenance, promote recycling, and facilitate recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

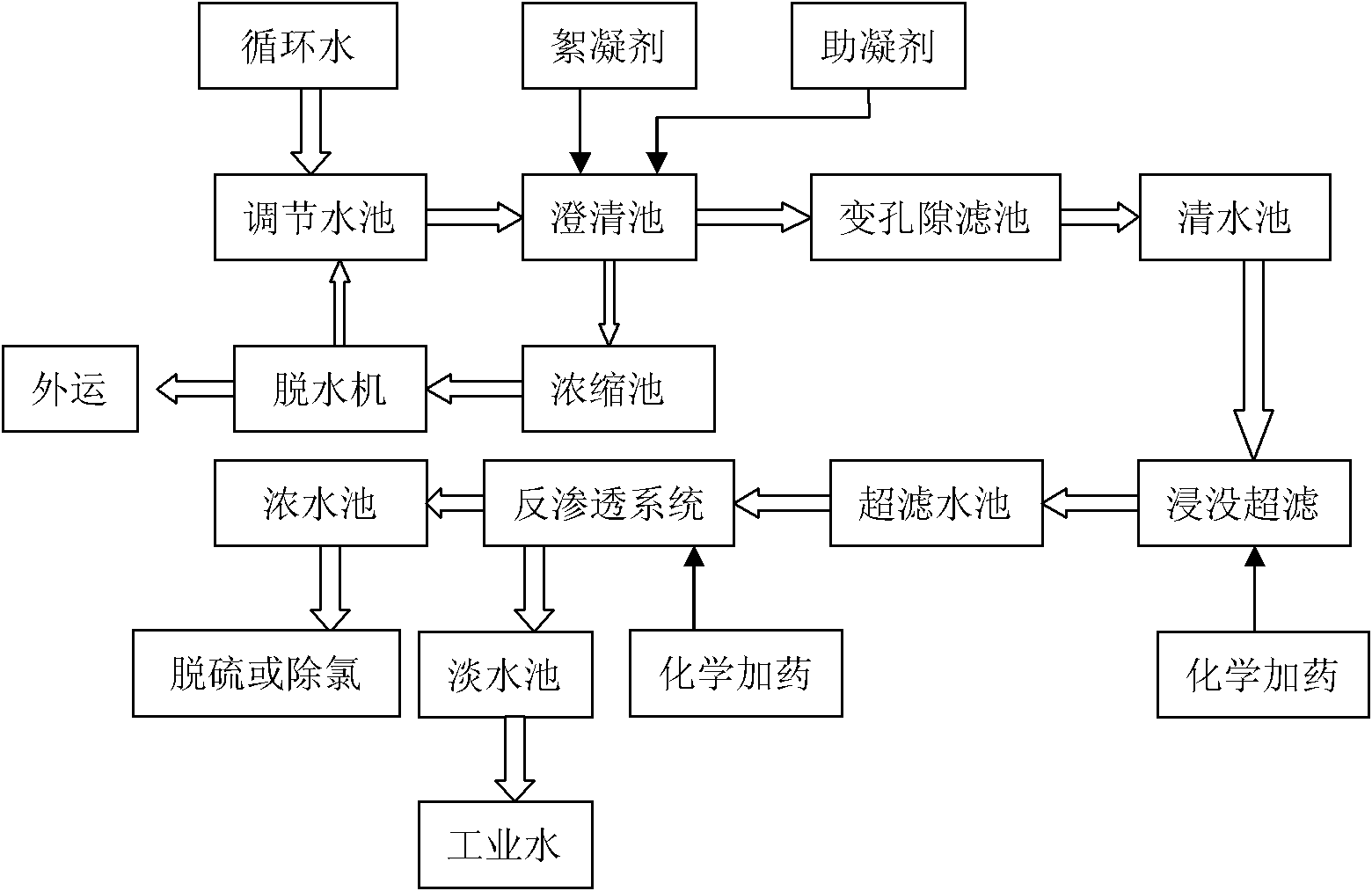

[0034] Embodiment 1 of the present invention: the reuse treatment process (such as figure 1 shown): the circulating water of the power plant is first collected into the regulating pool, then enters the clarification tank, adds flocculant, coagulant and bactericide for mechanically accelerated clarification, and then is transported to the variable pore filter for filtration, and the filtered water is submerged ultra-thin Filtration (using ZeeWeed1000 ultrafiltration membrane, made of PVDF), and then transported to the reverse osmosis system through the ultrafiltration pool, adding sodium sulfite for reverse osmosis treatment (using spiral-wound anti-pollution membrane, the material is aromatic polyamide), the treated water It can be used as industrial water for power plants; the sludge in the clarification tank is concentrated in the thickening tank, dehydrated by the dehydrator, and then transported outside, and the effluent of the dehydrator is returned to the regulating pool;...

Embodiment 2

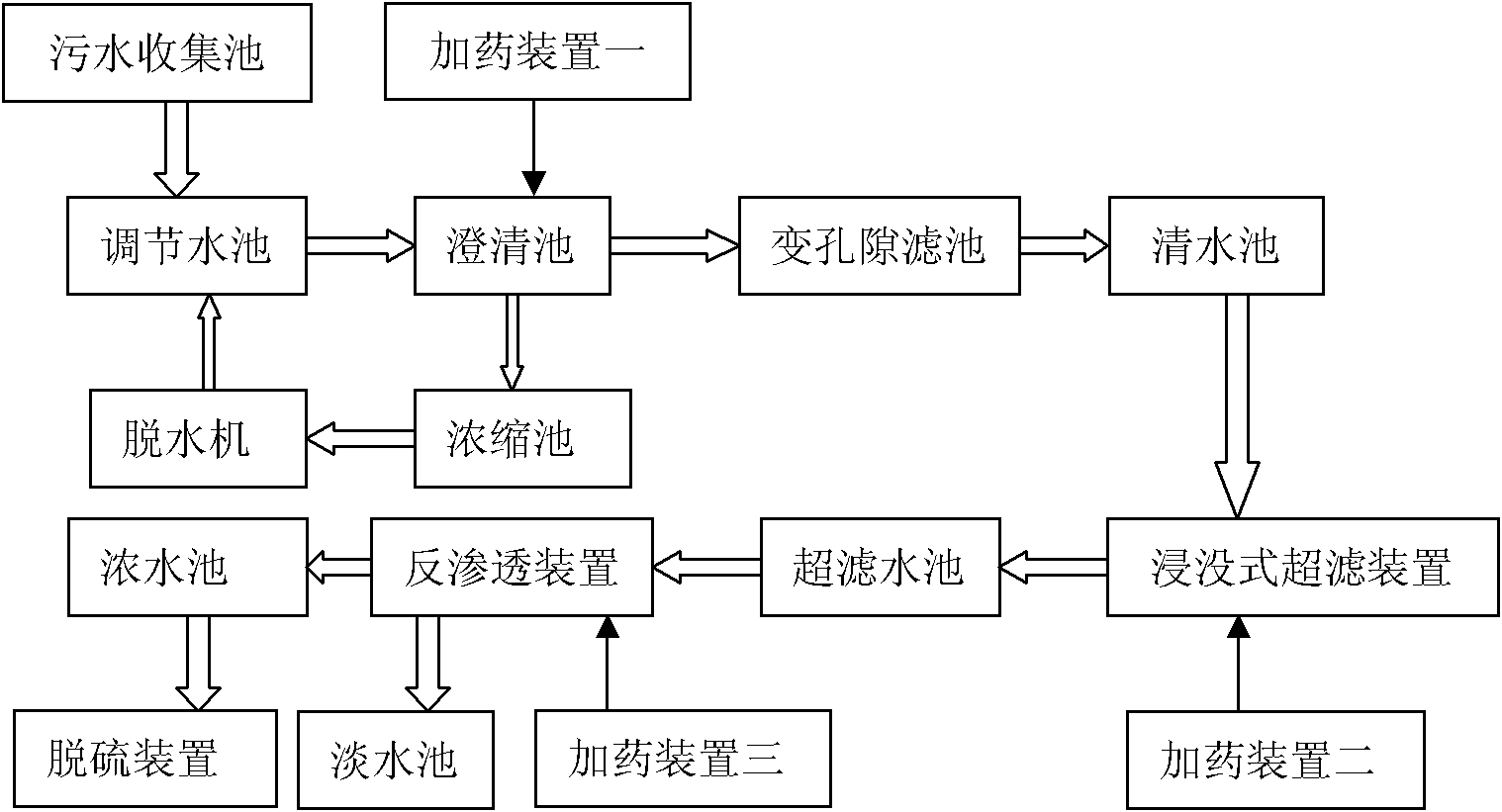

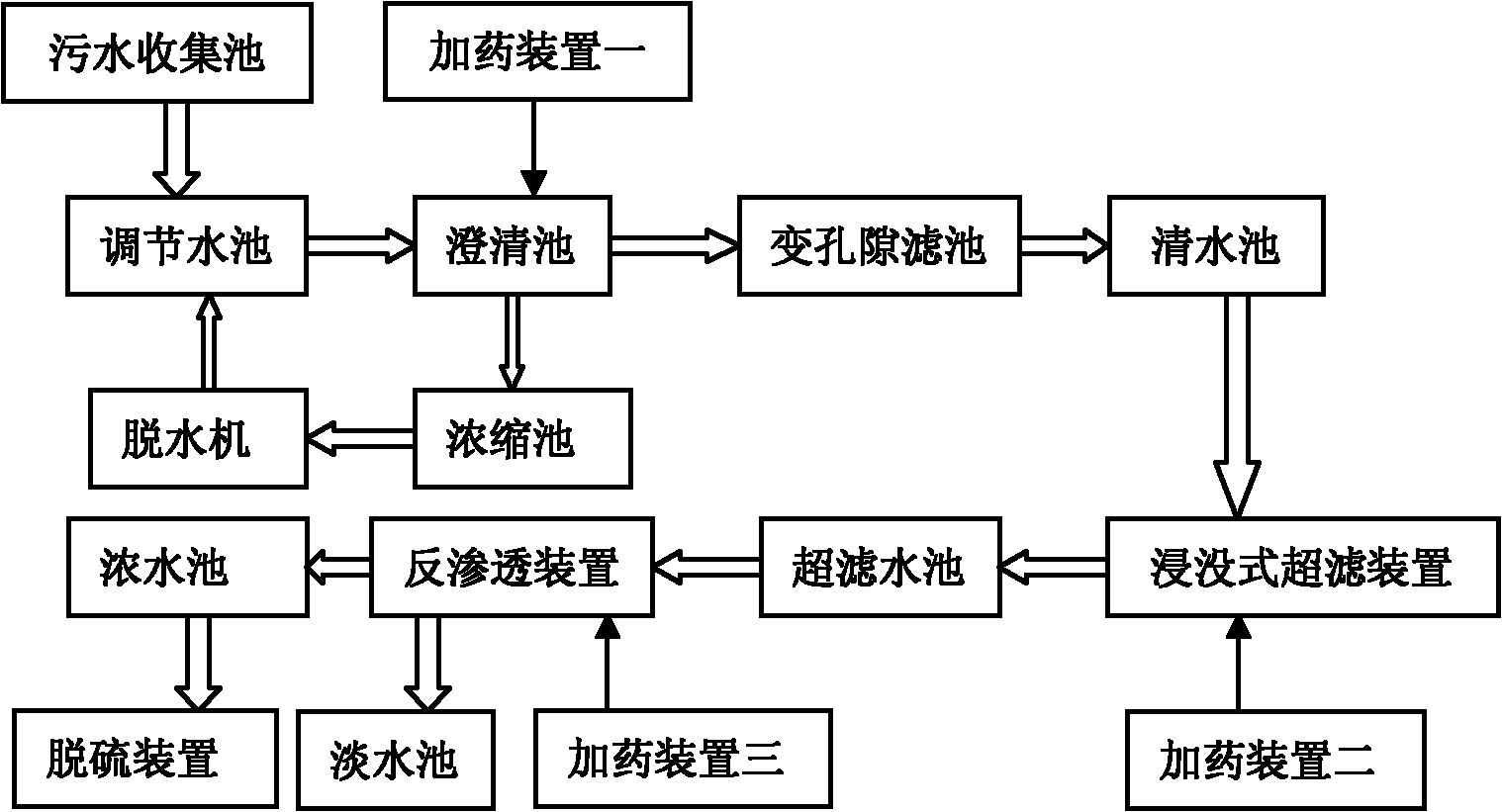

[0036] Embodiment 2 of the present invention: Reuse treatment process of circulating water in power plants: the circulating water in power plants is first collected into the regulating pool, then enters the clarification tank, adds flocculants, coagulants and bactericides for mechanically accelerated clarification, and then transports to the variable pore filter The filtered water is subjected to immersion ultrafiltration, and then transported to the reverse osmosis system through the ultrafiltration pool, and sodium sulfite is added for reverse osmosis treatment. The treated clean water can be used as industrial water for power plants; the sludge in the clarification tank is passed through Concentrated in the concentration tank, dehydrated by the dehydrator and transported outside, the effluent from the dehydrator is returned to the regulating pool; the concentrated water from the reverse osmosis system is collected into the concentrated water tank, and reused in the ash and sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com