Restoring method of eccentric bushing and eccentric bushing

A repair method and eccentric sleeve technology, applied in arc welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of increasing the production cost of equipment using enterprises, complex stress state, harsh working environment, etc., so as to facilitate repeated on-site local repairs , Improve the mutual bonding strength, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

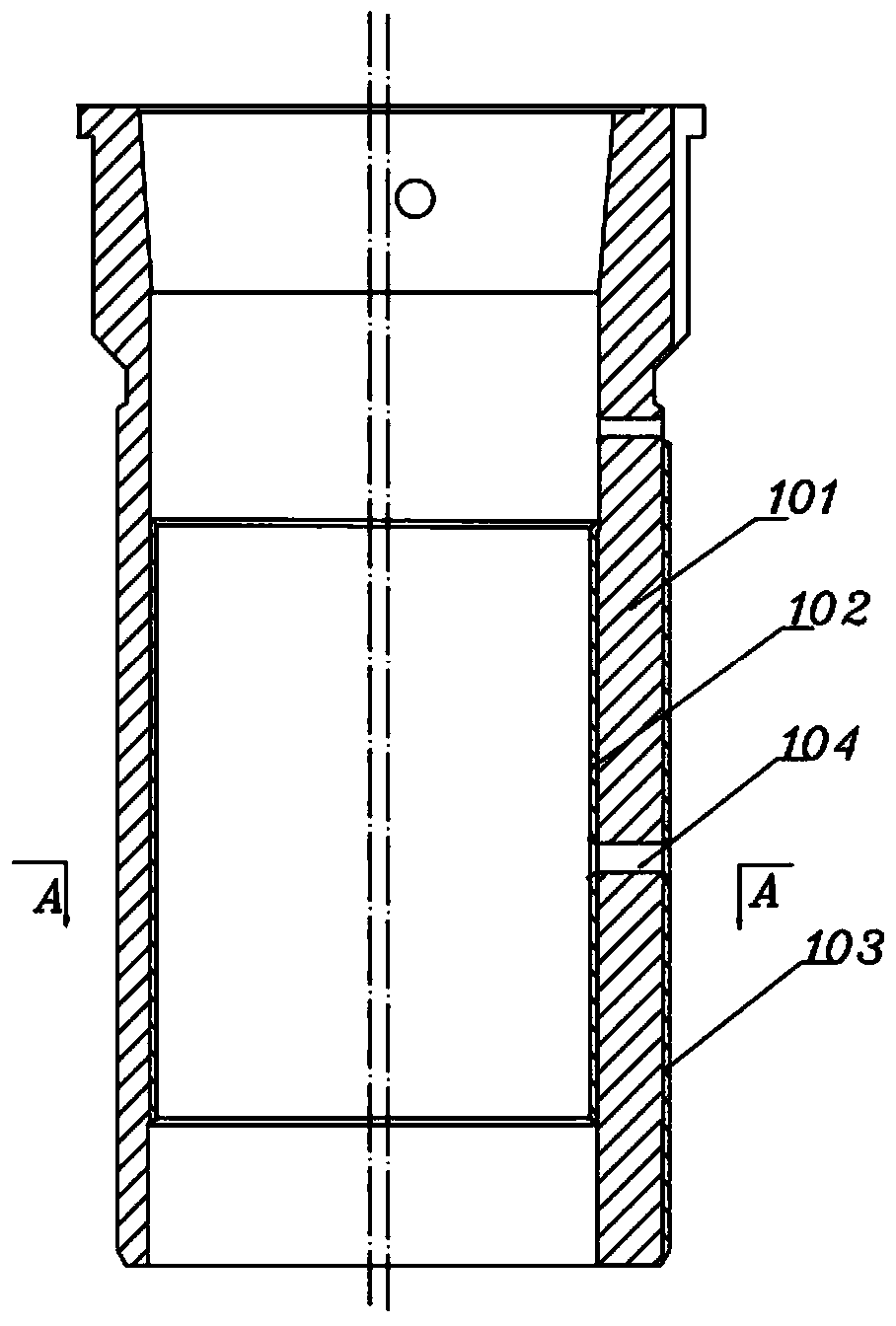

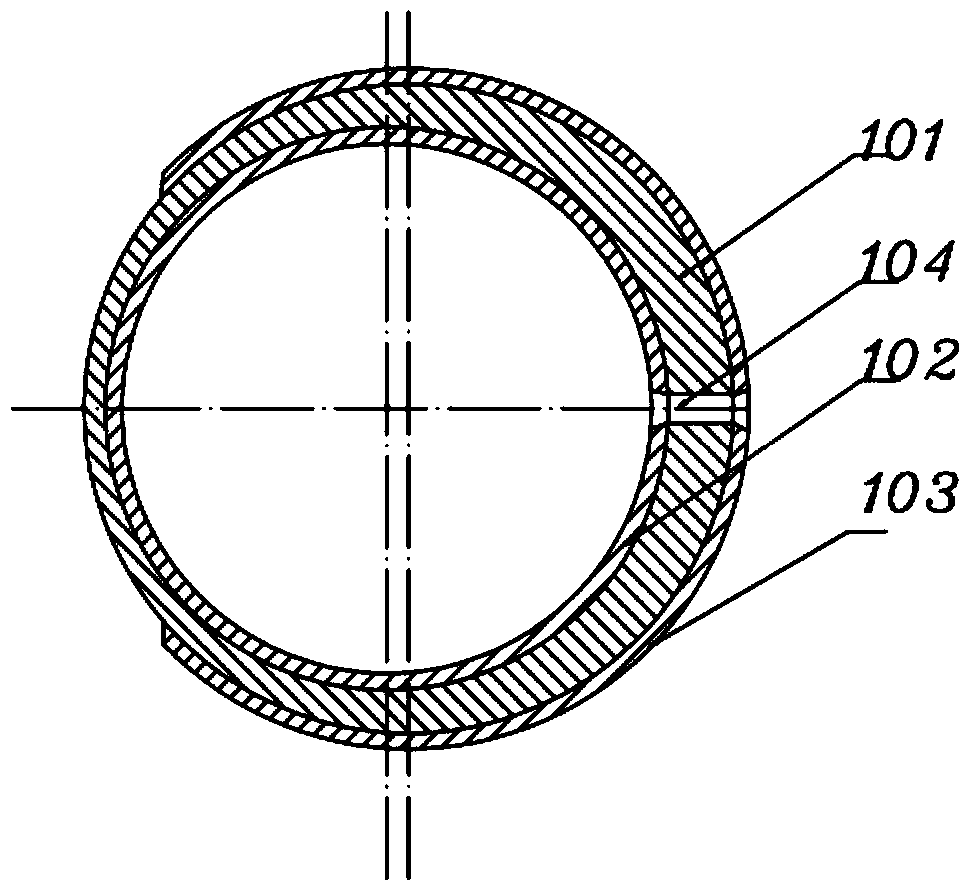

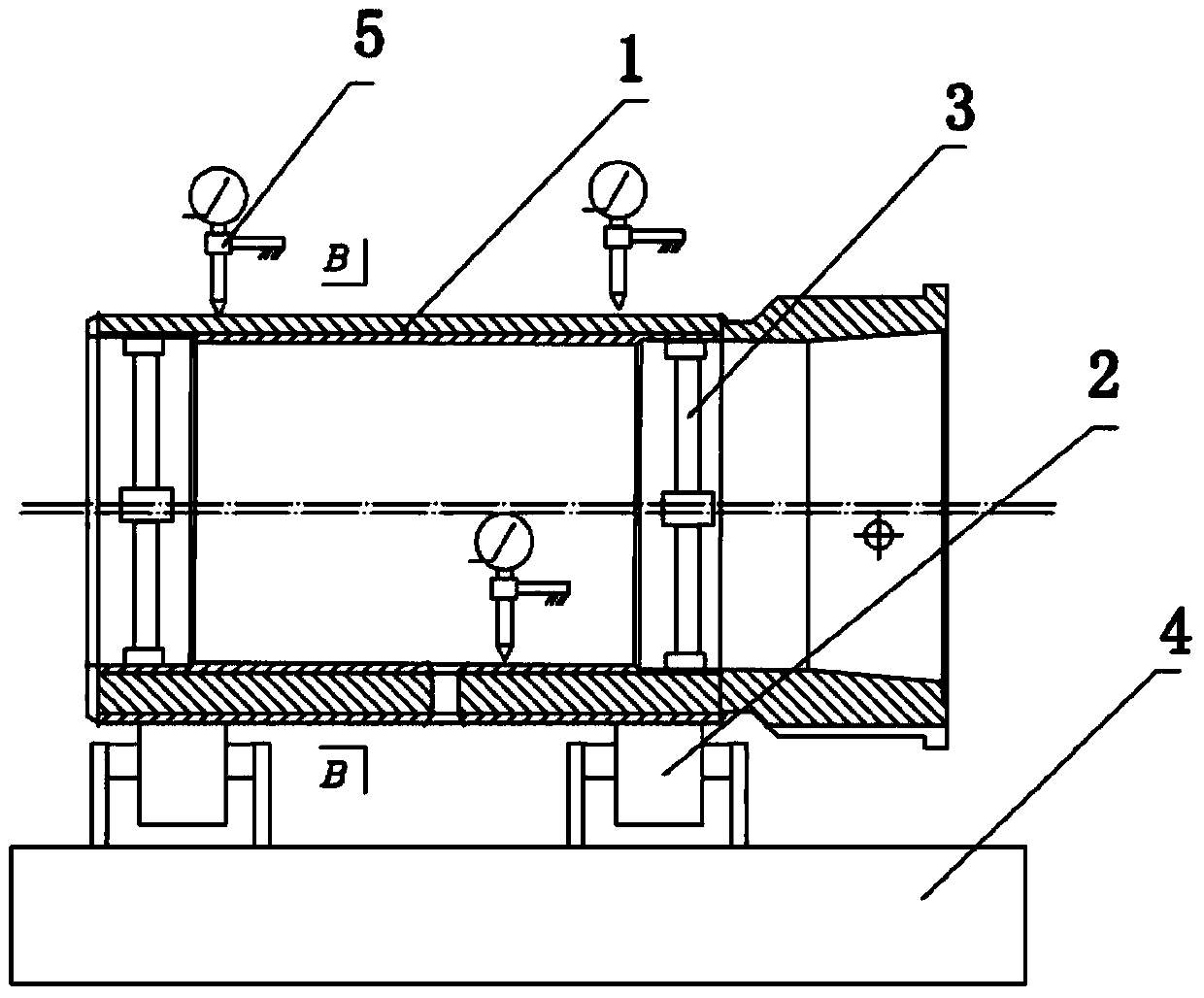

[0038] Such as Figure 1 to Figure 4 As shown, a method for repairing an eccentric sleeve includes a cast steel base 101, and the cast steel base 101 is cast with a Babbitt alloy composite layer, which is characterized in that it includes the following steps:

[0039] A. Prepare:

[0040] (1) Clean and clean the eccentric sleeve to be repaired;

[0041] (2) Make repair tooling;

[0042] B. Removing the Babbitt alloy composite layer poured on the cast steel substrate 101; clearing the waste materials in the groove body and the through hole of the cast steel substrate.

[0043] C. Place the cast steel substrate treated in step B on the repair tool, and perform flaw detection on the cast steel substrate 101 . If th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com