Method for detecting temperature of high-strength Cr-Mo steel double-side welding back gouging groove belt

A detection method and high-strength technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor welding quality and poor magnetic particle detection effect, avoid adverse effects, facilitate fine processing, The effect of welding and root cleaning quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

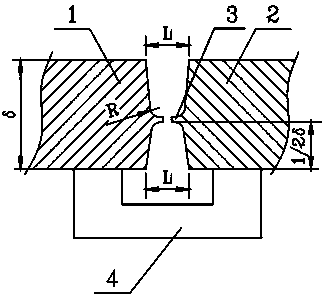

[0049] Embodiment 1, high-strength Cr-Mo steel double-sided welding root cleaning groove temperature detection method, such as figure 1 As shown, the Cr-Mo steel plate Ⅰ1 and steel plate Ⅱ2 with a thickness of 80mm are processed, so that the blunt edge 3 of the groove of the steel plate Ⅰ1 and the steel plate Ⅱ2 are butted together to form a double U-shaped groove symmetrical to the blunt edge 3 of the groove. The thickness of the blunt edge 3 of the groove is 5 mm, and it is located at the 1 / 2 thickness (40 mm) of the Cr-Mo steel. The circular curvature R of the U-shaped groove is 8 mm. The gap between the blunt edge 3 of the steel plate groove is 0mm; the width L of the U-shaped groove should at least be able to satisfy the welding head of the submerged arc welding machine to freely extend into the groove for welding to ensure the quality of automatic welding; the double U formed after the butt joint Preheat the U-shaped groove to 200°C, and then use a single-sided multi-lay...

Embodiment 2

[0050] Embodiment 2, high-strength Cr-Mo steel double-sided welding root cleaning groove temperature detection method, such as figure 1 As shown, the Cr-Mo steel plate Ⅰ1 and steel plate Ⅱ2 with a thickness of 100 mm are processed, so that the blunt groove edge 3 of the steel plate Ⅰ1 and steel plate II 2 is butted together to form a double U-shaped groove symmetrical to the blunt edge 3 of the groove. The thickness of the blunt edge 3 of the groove is 5.5mm, and it is located at the 1 / 2 thickness (50mm) of the Cr-Mo steel. The circular curvature R of the U-shaped groove is 10mm, and the two steel plates are assembled by using the assembly tool 4, The gap between the blunt sides 3 of the two steel plate grooves is 0.5mm; the U-shaped slope width L should at least be able to satisfy the welding head of the submerged arc welding machine to freely extend into the groove for welding to ensure the quality of automatic welding; Preheat the U-shaped groove to 220°C, and then use a si...

Embodiment 3

[0051] Embodiment 3, high-strength Cr-Mo steel double-sided welding root cleaning groove temperature detection method, such as figure 1 As shown, the Cr-Mo steel plate Ⅰ1 and steel plate Ⅱ2 with a thickness of 120 mm are processed, so that the blunt edge 3 of the groove of the steel plate Ⅰ1 and the steel plate Ⅱ2 are butted together to form a double U-shaped groove symmetrical to the blunt edge 3 of the groove. The thickness of the blunt edge 3 of the groove is 6mm, and it is located at the 1 / 2 thickness (60mm) of the Cr-Mo steel. The circular curvature R of the U-shaped groove is 12mm. The gap between the blunt edge 3 of the steel plate groove is 1 mm; the width L of the U-shaped slope should at least be able to satisfy the welding head of the submerged arc welding machine to freely extend into the groove to ensure the quality of automatic welding; the double U-shape formed after the butt joint The groove is preheated to 250°C, and then one side of the U-shaped groove is wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com