High-strength anti-fatigue modular bridge expansion device and construction method

A telescopic device, anti-fatigue technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of only touching its surroundings, affecting the overall strength of the structure, easy to fatigue damage, etc., achieving small residual stress and residual deformation, The effect of increasing the effective cross-sectional area of the weld and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

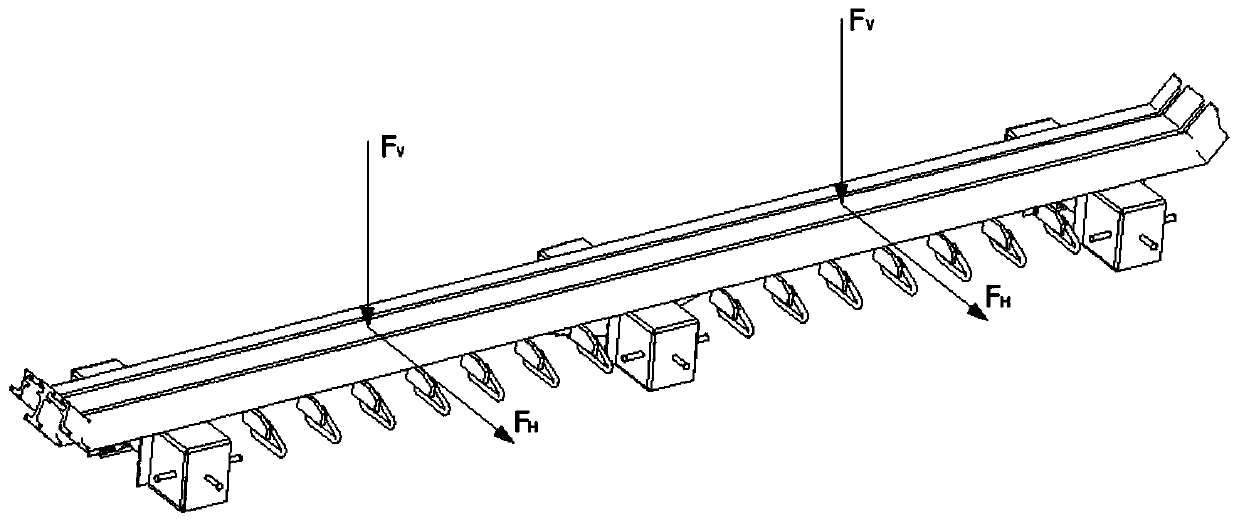

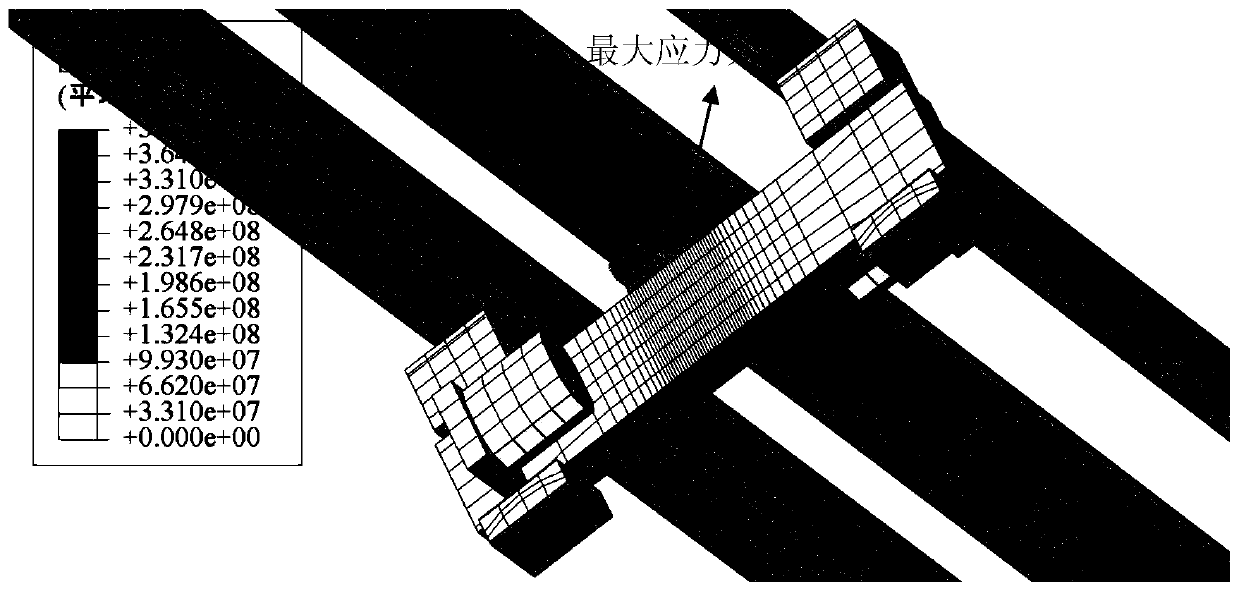

[0043] A high-strength anti-fatigue modulus bridge expansion device, such as Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, including the roadway displacement box 1, side beams 2 are respectively arranged on both sides of the roadway displacement box 1, and several anchor plate weldments 3 are evenly distributed on the outer side wall of the side beam 2, and the two side beams 2 A single or multiple middle beams 4 are arranged in the middle, and a crossbeam 5 perpendicular to the middle beam 4 is horizontally pierced in the roadway displacement box 1, and the upper part of the externally expanded special-shaped support pad is welded and connected between the middle beam 4 and the crossbeam 5 6. The upper part of the externally expanded special-shaped support pad 6 is fixed with a center beam support rib 7 on both sides along the length direction of the center beam 4. The top edge of the center beam support rib 7 is welded to the center beam 4, an...

specific Embodiment 2

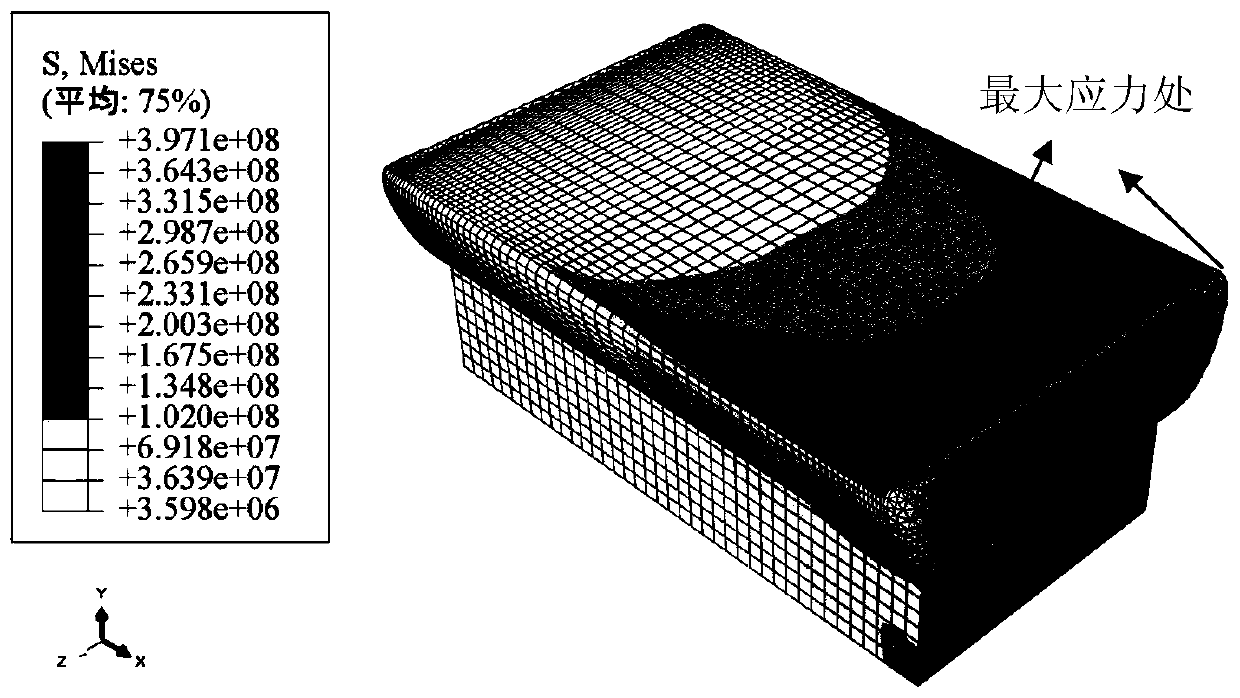

[0050] If the construction space for the welding operation is sufficient, two middle beam support ribs 7 with a thickness of 16mm can be respectively set on both sides of the upper externally expanded special-shaped support pad 6, such as Figure 15 , Figure 16 , Figure 17 and Figure 18 Shown, all the other are with above-mentioned concrete example one. like Figure 8 and Figure 9 As shown, after the finite element analysis, it is found that the new maximum stress position of the weld is at the bottom of the junction between the diagonal brace and the weld, which reflects the force transmission effect of the diagonal brace. At this time, the maximum stress is 175MPa, which can meet the two indicators of yield strength and pulsation strength better than Example 1, and the structural strength and fatigue resistance performance are further improved. The process is also more complicated.

[0051] The present invention is not limited to the center sill support ribs 7 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com