Welding torch used for composite welding of laser beams and plasma arc

A hybrid welding and plasma arc technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of laser beam welding application limitations, low energy conversion efficiency, unsuitable for laser welding, etc., and achieve high-efficiency plasma welding methods , Fast solidification of the weld bead, and the effect of eliminating laser welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

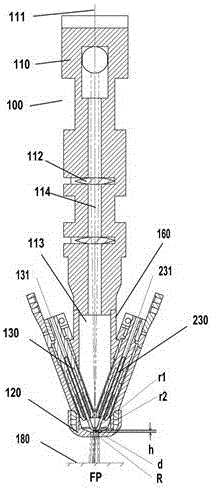

[0074] The torch 100 of the present invention includes a torch body 110 having a central axis 111 and a cavity 113 . On one end of the torch body 110 there is an optical system including a lens 112 . The lens 112 is used to focus the incident laser beam 114 such that the beam 114 is collinear with the central axis 111 of the torch body 110 and is focused to a focal point FP located outside the torch 100 .

[0075] exist figure 1 Among them, the welding torch main body 110 includes 2 (or 1, or 4 electrodes and arranged in pairs) electrodes 130 and 230, a compression nozzle 120, and a conical protective shield arranged concentrically with the compression nozzle 120 outside the compression nozzle Nozzles, both inside and outside of the compression nozzle 120 (between the compression nozzle 120 and the protection nozzle) pass through protective gas. The laser beam 114 has a certain radius r1 at the slit formed by the two electrodes, and has a certain radius r2 at the opening of ...

Embodiment 2

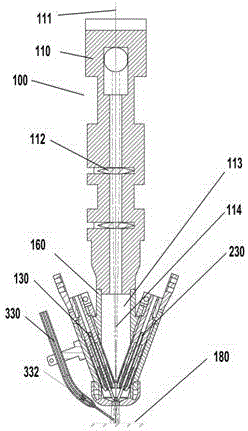

[0090] Such as figure 2 As shown, on the basis of Embodiment 1, the welding torch 100 also includes a wire feeding tube 330 for laser beam plasma wire filling welding, and the wire feeding tube 330 is arranged at an acute angle with the central axis 111 of the welding torch body 100, and Arranged on the opposite side of the welding torch 100 along the welding direction, the range of the acute angle between the wire feeding tube 330 and the central axis 111 of the welding torch body 100 is most preferably between 20° and 80°, and the best effect is to ensure that the welding wire and The plasma arc intersects the upper surface of the workpiece 180 without making the torch unwieldy in size. The longitudinal axis 332 of the wire liner 330 intersects the centerline 111 of the torch body at the upper surface of the workpiece 180 .

Embodiment 3

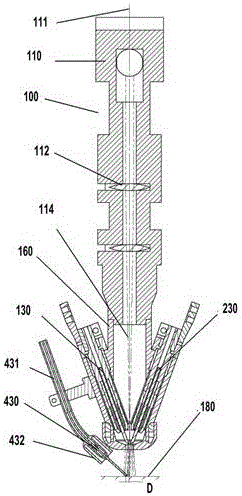

[0092] Such as image 3 As shown, on the basis of Embodiment 1, the welding torch 100 also includes a melting electrode contact tip 430 for laser beam plasma MIG welding, a wire feeding tube 431 and a protective gas jacket 432, and the conductive tip 430 is located in the protective gas jacket. 432 inside and concentric with 432; the contact tip 430 is arranged at an acute angle with the central axis 111 of the welding torch body 100, and the acute angle is in the range of 0 to 60 degrees, and is arranged on the opposite side of the welding torch 100 along the welding direction. The longitudinal axis 432 intersects the centerline 111 of the torch body 110 below the upper surface of the workpiece 180, and is at a distance D from the intersection point of the centerline 111 of the torch on the upper surface of the workpiece 180; D is defined as the melting electrode arc on the workpiece 180 The distance D between the arc impact point on the surface and the plasma arc impact poin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com