Steel beam-ultra-high performance concrete slab combined bent cap and construction method thereof

An ultra-high performance, concrete slab technology, used in bridges, bridge materials, bridge construction, etc., can solve the problems of low utilization of space under bridges, high cost of steel structures, and disparity in stiffness, and improve welding quality and economy. performance and use effects, the effect of reducing beam height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

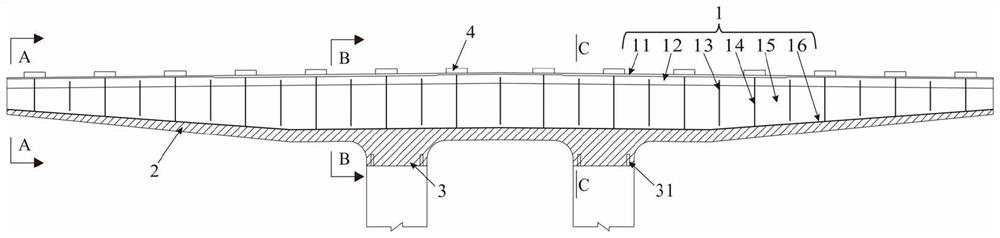

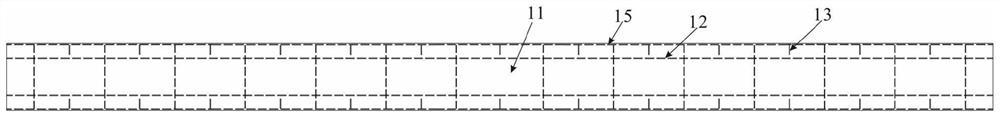

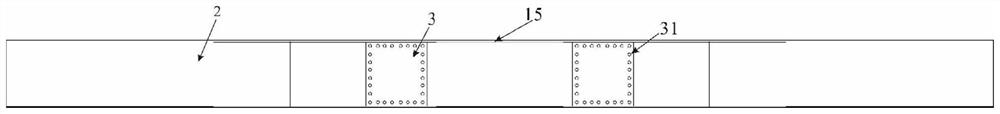

[0050] like Figure 1-Figure 6 As shown, the steel girder-UHPC slab composite cover girder of this embodiment includes a steel girder 1 and a UHPC slab 2, the steel girder 1 includes a base plate 16 and a web 15, and the web 15 is arranged in the longitudinal bridge direction of the base plate 16. There are lower extension sections 151 extending downward on both sides and the bottom of the web 15 , and the UHPC board 2 is sandwiched in the cavity enclosed by the lower extension section 151 and the bottom plate 16 . The above-mentioned webs 15 are seamlessly fixed on both sides of the longitudinal bridge of the bottom plate 16, so that the bottom surface of the cavity and the two sides of the longitudinal bridge are in a closed state for the later pouring of the UHPC board 2, and the UHPC board 2 obtained by pouring is solid. The plate is fixed into a whole with the steel beam 1.

[0051] In this embodiment, the thickness of the UHPC board 2 does not exceed 1 / 5 of the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com