Multi-degree-of-freedom clamping device for mechanical welding

A clamping device and mechanical welding technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of reducing the overall efficiency of welding operations, unable to adjust the position of the workpiece, troublesome operation, etc., to achieve stable clamping and simple structure , The effect of facilitating welding construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

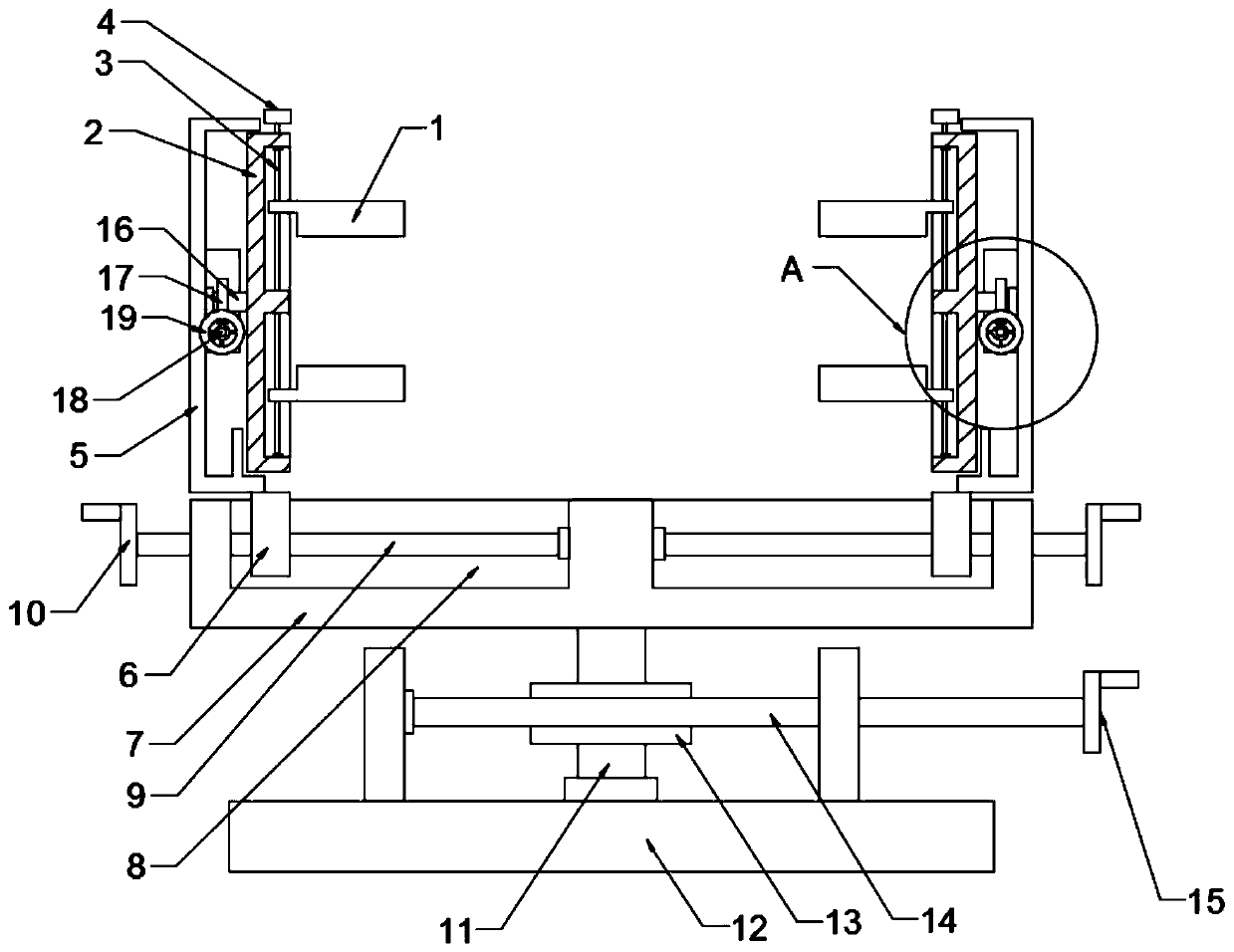

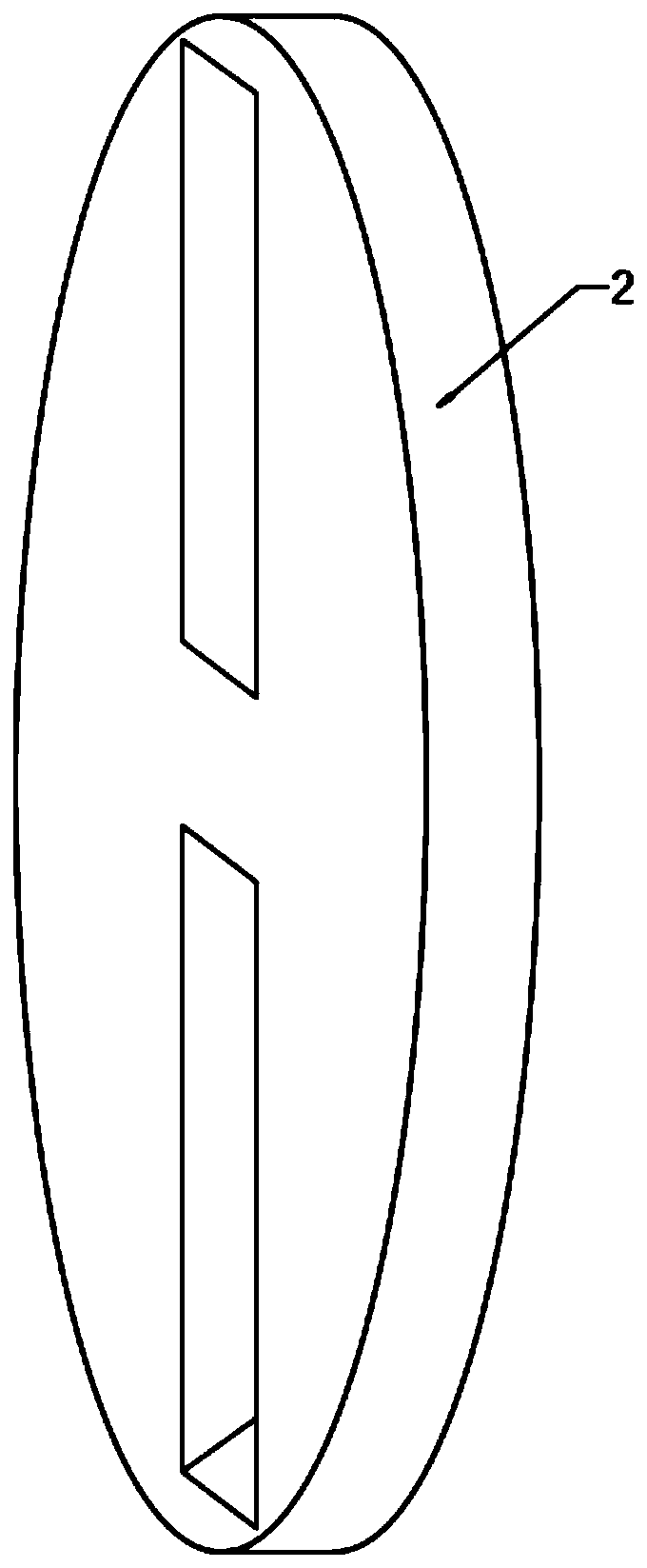

[0019] see Figure 1-3 , in an embodiment of the present invention, a clamping device for multi-degree-of-freedom mechanical welding includes a clamping device body; The holding plate 1 is nested with a turntable 2 on the outside of the holding plate 1. The turntable 2 is provided with a vertical rectangular chute. The turntable 2 is nested with a two-way screw rod 3. The two-way screw rod 3 runs through the clamping plate 3 and connects with the clamping plate. The holding plate 3 is threadedly connected; the two-way screw rod 3 extends to the outside of the turntable 2 and is fixedly connected with the first adjustment wheel 4. When the adjustment wheel 4 is rotated, the two-way screw rod 3 drives a group of clamping plates 3 distributed up and down to make opposite or back To move, and then clamp and release the workpiece to be welded.

[0020] The outer side of the turntable 2 is provided with a moving frame 5, the lower end of the moving frame 5 is fixedly connected with...

Embodiment 2

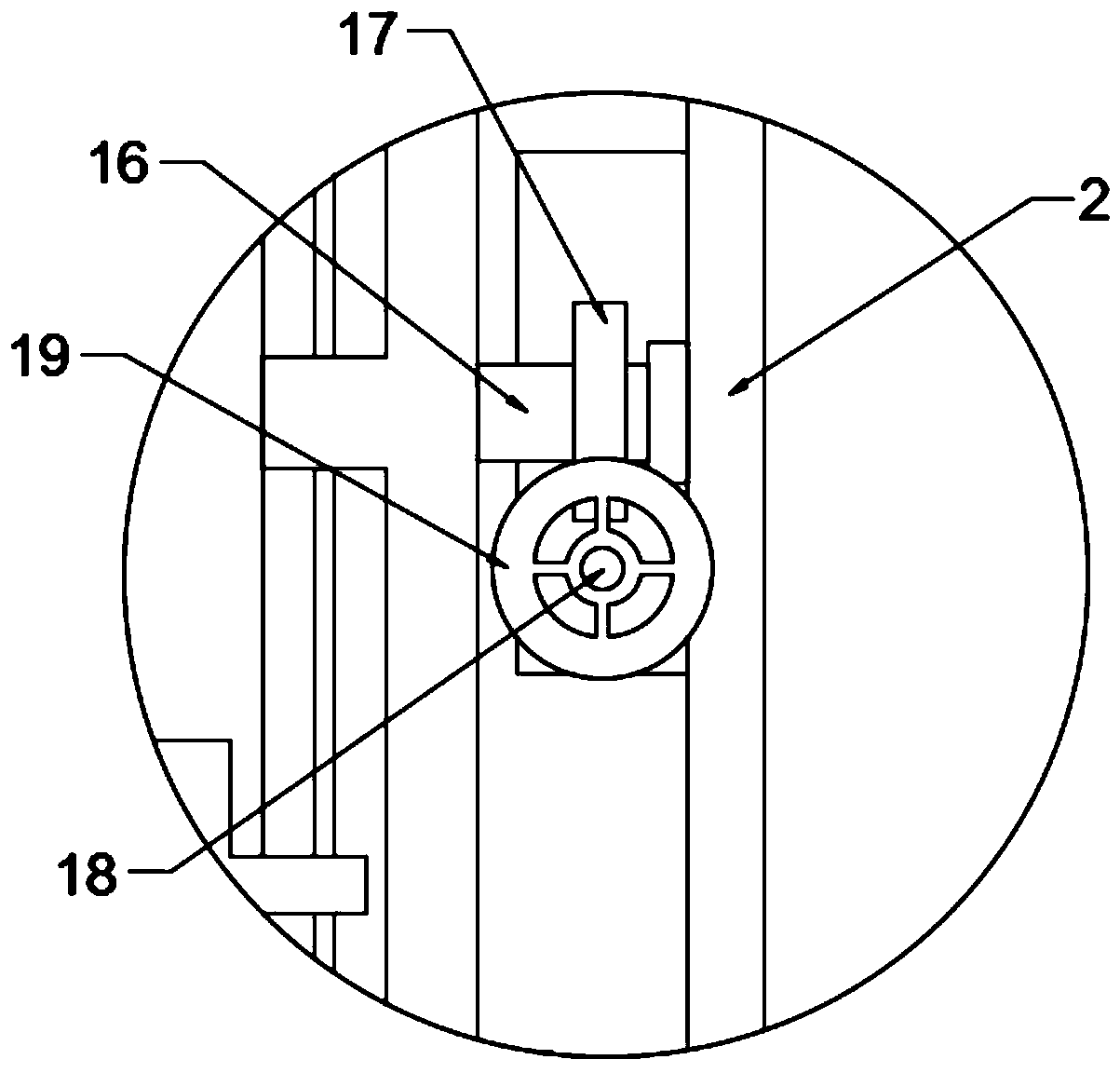

[0023] The difference between this embodiment and Embodiment 1 is: the outer side of the turntable 2 is vertically and fixedly connected with a horizontal shaft 16, and the horizontal shaft 16 is rotatably connected with the moving frame 5 through a bearing seat; the second worm wheel 17 is sleeved and fixed on the horizontal shaft 16 , the second worm gear 17 is toothed with a second worm 18, the second worm 18 is rotatably connected with the inner wall of the moving frame 5, the front end of the second worm 18 is fixedly connected with a fourth adjustment wheel 19, and the fourth adjustment wheel 19 is rotated to drive the turntable 2 to rotate , and then rotate the workpiece to adjust the welding angle, which is convenient for workers to weld.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com